Liquid crystal polymer film and production method thereof

A technology of liquid crystal polymer and production method, applied in the field of material processing, can solve the problems of poor tear strength, delamination, and inability to meet the use requirements of flexible circuit boards, and achieve the effect of simple production process and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

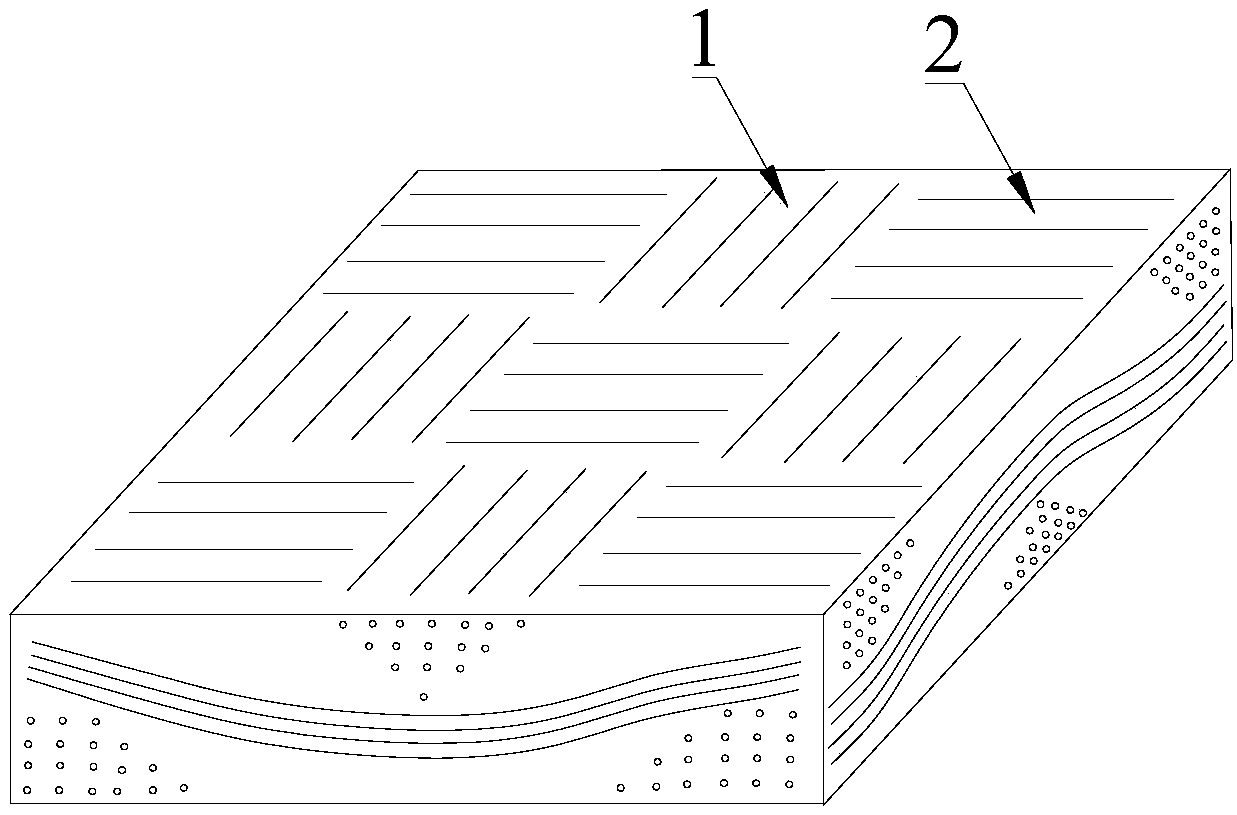

[0038] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0039] A liquid crystal polymer film, comprising at least two first alignment units 1 and at least two second alignment units 2, the alignment direction of the first alignment unit 1 intersects the alignment direction of the second alignment unit 2 , at least two of the first orientation units 1 and at least two of the second orientation units 2 are arranged in a net-like weaving structure. Preferably, at least two first alignment units 1 are arranged parallel to each other, at least two second alignment units 2 are arranged parallel to each other, and the first alignment unit 1 is perpendicular to the second alignment unit 2 set up. In this embodiment, the cross-sectional areas of the first alignment unit 1 and the second alignment unit 2 are both 10 -6 ~1mm 2 . The reticular braided structure is hot-pressed to obtain the liquid crystal polymer film, and the material of the liquid crystal polym...

Embodiment 2

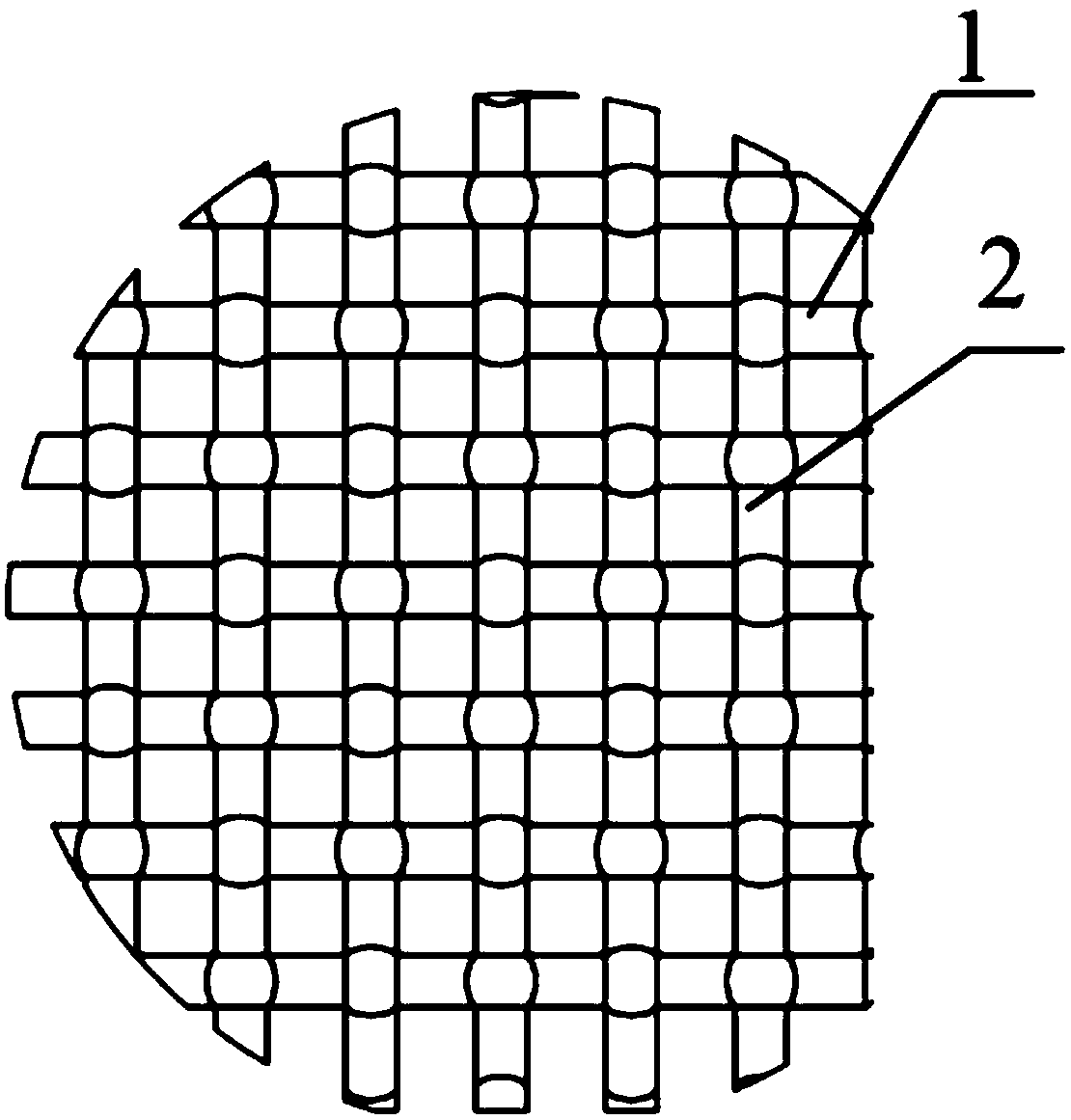

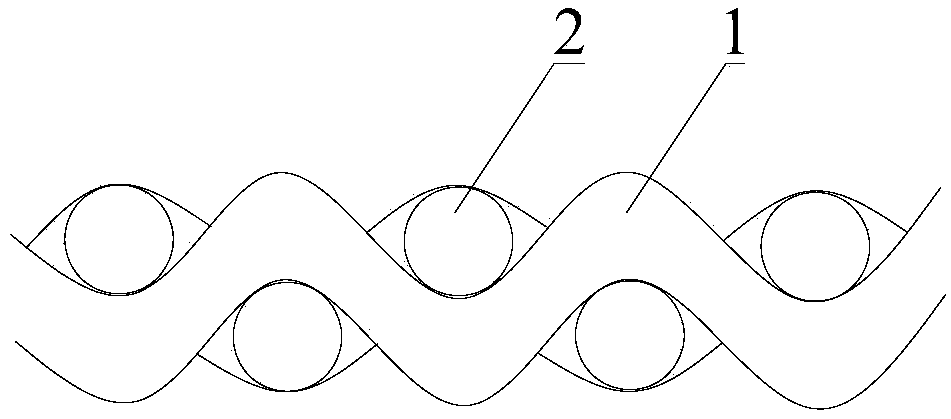

[0040] Please refer to figure 2 and image 3 , the second embodiment of the present invention is:

[0041] A method for making a liquid crystal polymer film, used to obtain the liquid crystal polymer film in Example 1, comprising the steps of:

[0042]First, melt spinning or electrospinning is performed using thermoplastic liquid crystal polymers to obtain highly oriented fibrous intermediate products, which can also be achieved by cutting anisotropic films. In this embodiment, the thermoplastic polymer is a liquid crystal polymer containing a benzene ring, a liquid crystal polymer containing a naphthalene ring, a liquid crystal polymer containing an aliphatic segment, or a liquid crystal polymer containing a cyclic polyester group. Melt spinning generally uses an extruder to plasticize the raw resin, and prepares liquid crystal polymer fibers through a spinning die. This method can easily obtain fibers with a circular cross-section, with a diameter ranging from 5 to 1000 μ...

Embodiment 3

[0046] Embodiment 3 of the present invention is a method for manufacturing a liquid crystal polymer film, and the difference from Embodiment 2 is:

[0047] A thermoplastic liquid crystal polymer resin (VECTRA A950) was spun at 310° C. using a melt spinning machine to obtain fibers with a circular cross-section and a diameter of 80 μm. Due to the shear force of the spinning die, the polymer segments inside the fiber are distributed in orientation. The spinning temperature is generally Tm~(Tm+80°C), where Tm is the melting point of the thermoplastic liquid crystal polymer. A weaving machine was used to weave the fibers in plain weave, and the distance between two adjacent orientation units was controlled to be 60 μm to obtain a net-like weave structure. Its effective thickness is 71.8 μm as measured by weighing.

[0048] A calender is used to press the intermediate products of the strips to prepare an isotropic liquid crystal polymer film. The calendering temperature is 220°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com