Microcellular foam of thermoplastic resin prepared with die having improved cooling property and method for preparing the same

A microcellular foam and foam technology, applied in the field of thermoplastic resin microcellular foam and its preparation, can solve the problems of poor mechanical properties and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the preparation method according to the present invention, the temperature at the end of the pressure drop zone can be adjusted according to the specific thermoplastic resin used, but the temperature is preferably 150-250°C. If the temperature at the end of the pressure drop zone is lower than 150°C, sufficient micropores will not be formed. On the contrary, if the temperature at the end of the pressure drop region exceeds 250°C, deterioration of the thermoplastic resin or excessive foaming will occur.

[0050] In addition, the temperature at the beginning of the cooling zone can also be adjusted according to the specific thermoplastic resin used. Preferably, the temperature is slightly higher than the melting or softening point of the thermoplastic resin, and more preferably a temperature of 40 to 150°C. If the temperature at the beginning of the cooling zone is lower than 40°C, rapid solidification may hinder a smooth manufacturing process. On the contrary, if th...

Embodiment 1

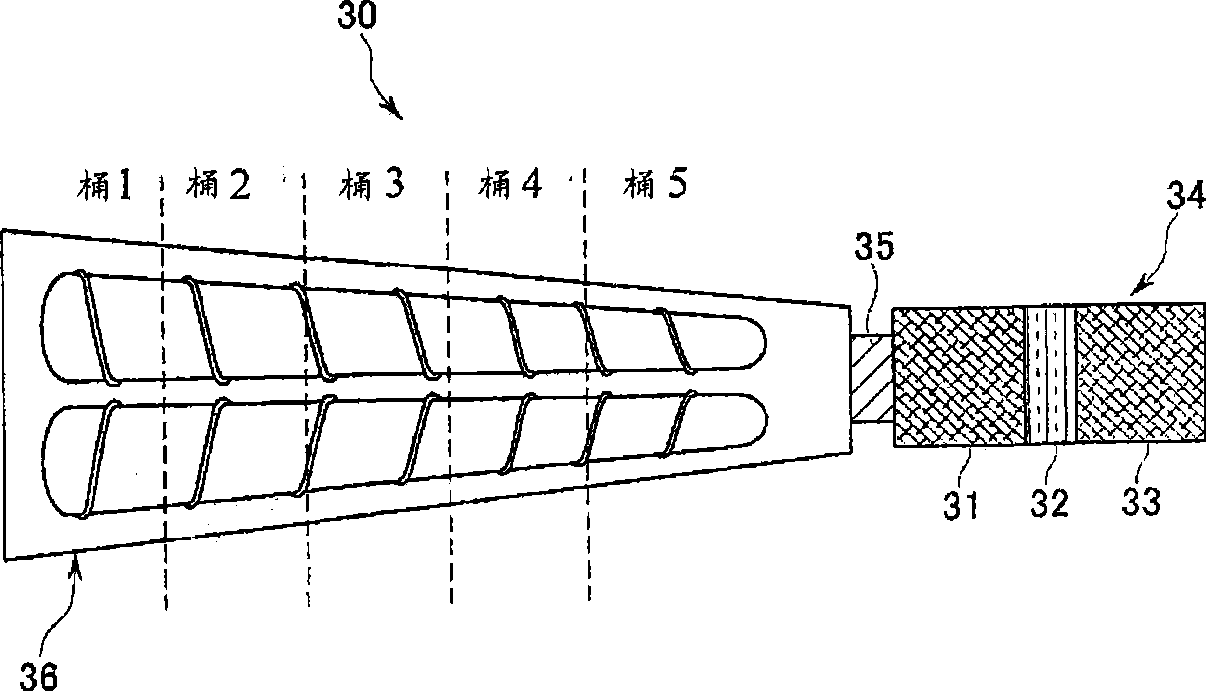

[0069] Such as image 3 As shown, a temperature-controllable extrusion die 34 (which includes a pressure drop zone 31, a temperature change zone 32, and a cooling zone 33) and a connector (adapter) 35 is connected to a twin-screw extruder 36 (G ttfert Extrusiometer 350) to prepare extrusion device 30. The lengths of the pressure drop zone 31 , the temperature change zone 32 and the cooling zone 33 of the extrusion die are 125mm, 27mm and 40mm respectively.

[0070] 98 parts by weight of a rigid polyvinyl chloride (PVC) compound (LG Chem), which can be used as indoor / outdoor and building materials, was charged into the above-mentioned extruder. After the PVC is completely plasticized, 2 parts by weight of nitrogen is added to the barrel 4 of the extruder with a high-pressure pump. The resulting single-phase mixture was foamed to obtain a microcellular foam sheet 2 mm thick and 100 mm wide.

[0071] The temperature of barrel 1 was maintained at 190°C, the temperature of barr...

Embodiment 2 and 3

[0074] A microcellular foam sheet was prepared in the same manner as in Example 1, except that the temperatures in the pressure drop zone, temperature change zone, and cooling zone were changed to the temperatures given in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com