Large-specification Ti2AlNb alloy ring piece and manufacturing method thereof

A manufacturing method and alloy ring technology, which are applied in the field of forging manufacturing process, can solve the problem that the AlNb alloy integral casing cannot be rolled and formed, and achieve the effects of improving the lasting performance, expanding the rolling temperature range and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] In a specific embodiment of the present invention, the Ti 2 The preparation method of AlNb alloy ring billet comprises the following steps:

[0080] Billeted Ti 2 After the AlNb alloy rod is kept at 1000~1050℃ for 1.5~2h, it is upsetting and drawn, and then upsetting and punching.

[0081] In a specific embodiment of the present invention, the strain rate of the upset and elongation is 0.01s -1 .

[0082] In actual operation, after the heat preservation treatment of the bar, it is placed on a press to perform the above operations.

[0083] In a specific embodiment of the present invention, the Ti 2 The weight of the AlNb alloy ring blank is above 350kg.

[0084] In a specific embodiment of the present invention, the Ti 2 The composition of AlNb alloy is Ti-20~22Al-24.5~26.5Nb by atomic percentage, such as Ti-22Al-25Nb. Specifically, the above atomic percentage of Ti-20~22Al-24.5~26.5Nb means that the atomic percentage of Al is 20%~22%, and the atomic percentage o...

Embodiment 1

[0088] Large size Ti 2 Manufacture of AlNb alloy rings (Ti with nominal composition Ti-22Al-25Nb 2 AlNb alloy as an example):

[0089] Fabricate large-scale Ti under the fabrication conditions listed in Table 1 2 AlNb alloy rings.

[0090] Table 1 Large size Ti 2 Manufacturing Conditions of AlNb Alloy Rings

[0091]

[0092] Note: T in the table 1 , T 2 , T 3 , T 4 respectively refer to the temperature, t 1 , t 2 , t 3 , t 4 respectively refer to time, k 1 、k 2 、k 3 、k 4 refer to the heating or cooling rate, respectively.

[0093] Large size Ti 2 The manufacture method of AlNb alloy ring, specifically comprises the following steps:

[0094] (1) Preparation of ring blank

[0095] Ti after billeting 2 AlNb alloy rods were placed in a high-temperature heat treatment furnace and heated to 1000-1050 °C for 120 min, then placed on a press for 0.01 s -1 Ti 2 AlNb alloy casing ring billet; among them, Ti 2 The weight of AlNb alloy casing ring blank is 450kg. ...

experiment example 1

[0111] The metallographic structures of the rings prepared in Example 1 and Comparative Examples 1-3 were respectively observed with a metallographic microscope.

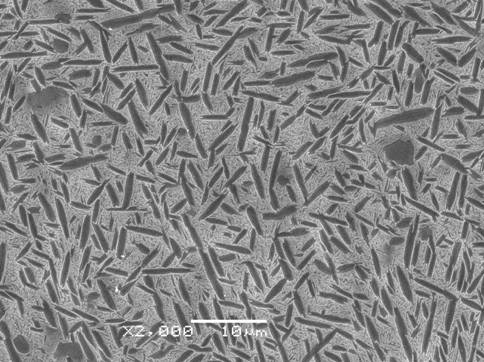

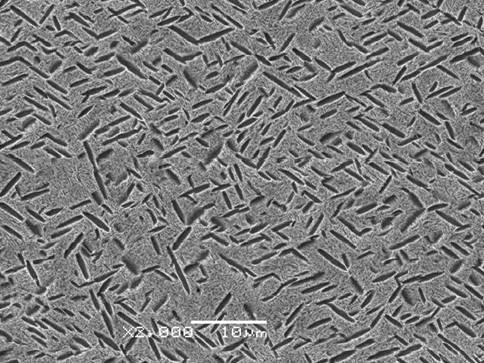

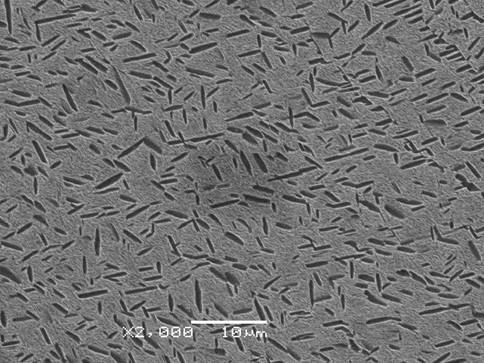

[0112] The Ti that 1#~7# of the embodiment of the present invention 1 makes 2 The metallographic structure diagrams of AlNb alloy rings are shown in Figure 1~Figure 7 . As can be seen from the figure, the Ti produced by the manufacturing method of the present invention 2 There is no obvious B2 flat grain boundary in the microstructure of the AlNb alloy ring, and there is no continuous precipitated second phase at the B2 grain boundary. The average grain size of B2 is 300~500μm, and the primary O phase lath (O phase coarse lath) The volume percentage is 15%~30%, and the volume percentage of the secondary O phase lath (O phase thin lath) is 30%~40%.

[0113] The details are as follows:

[0114] figure 1 For the 1# large-scale Ti that the embodiment of the present invention 1 makes 2 Metallographic structure dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com