Thin belt material single-rack continuous mill and implementation method

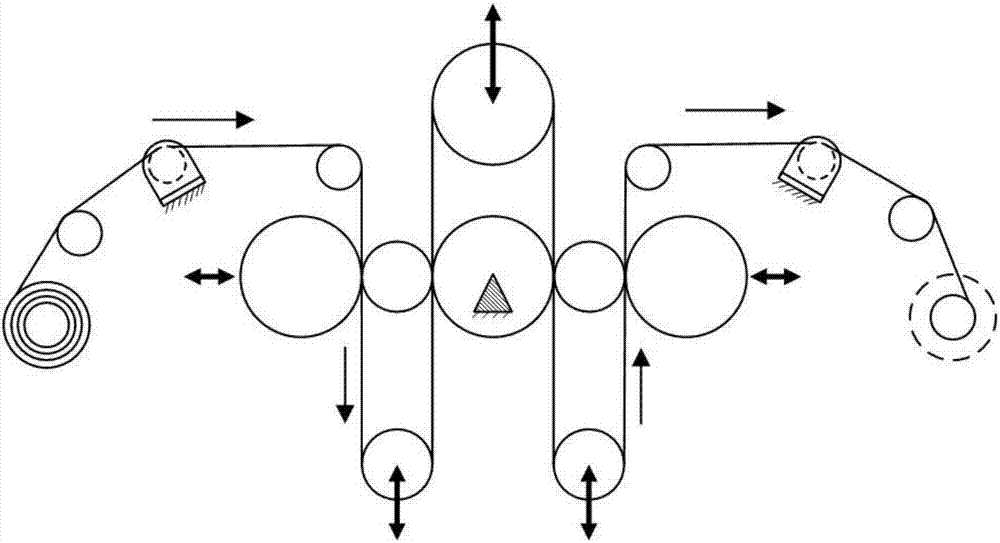

A single stand, continuous rolling mill technology, applied in the field of sheet and strip rolling, can solve the problems of high production, operation and maintenance costs, low thinning capacity of multi-roll mills, low production efficiency of ultra-thin strips, etc., to reduce equipment requirements and The effect of maintenance cost, improvement of shape quality, reduction of equipment investment and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

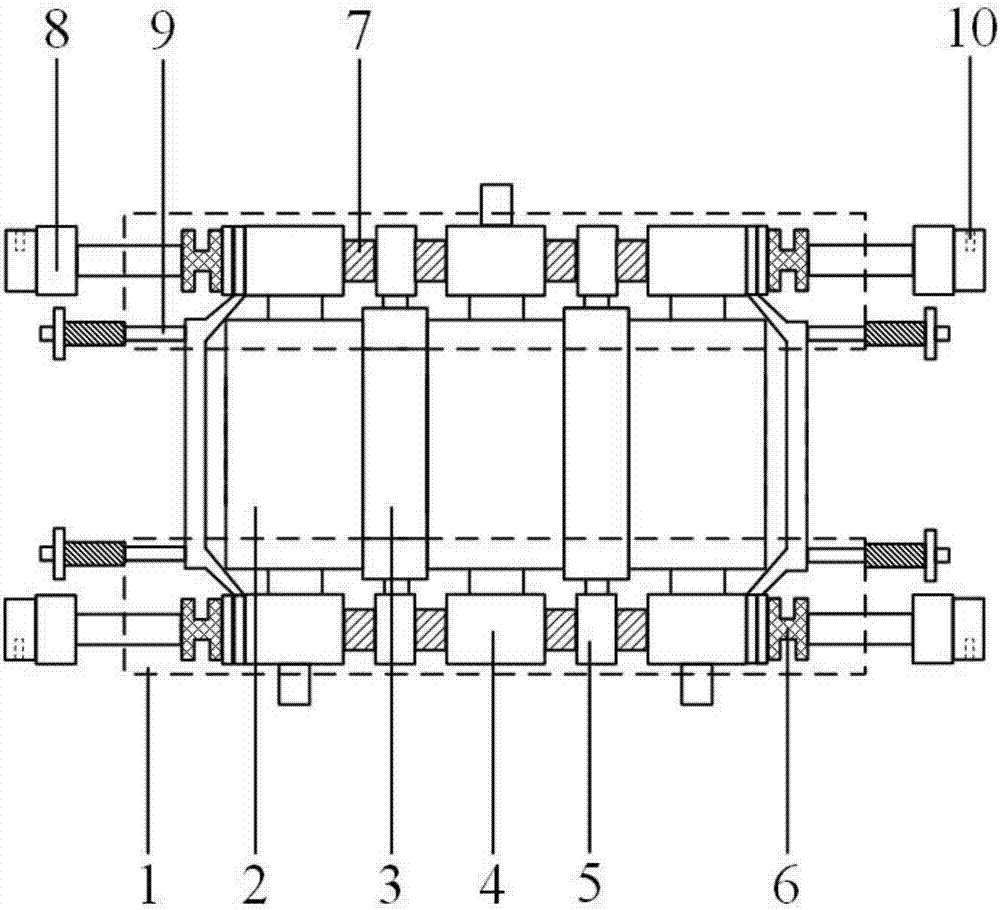

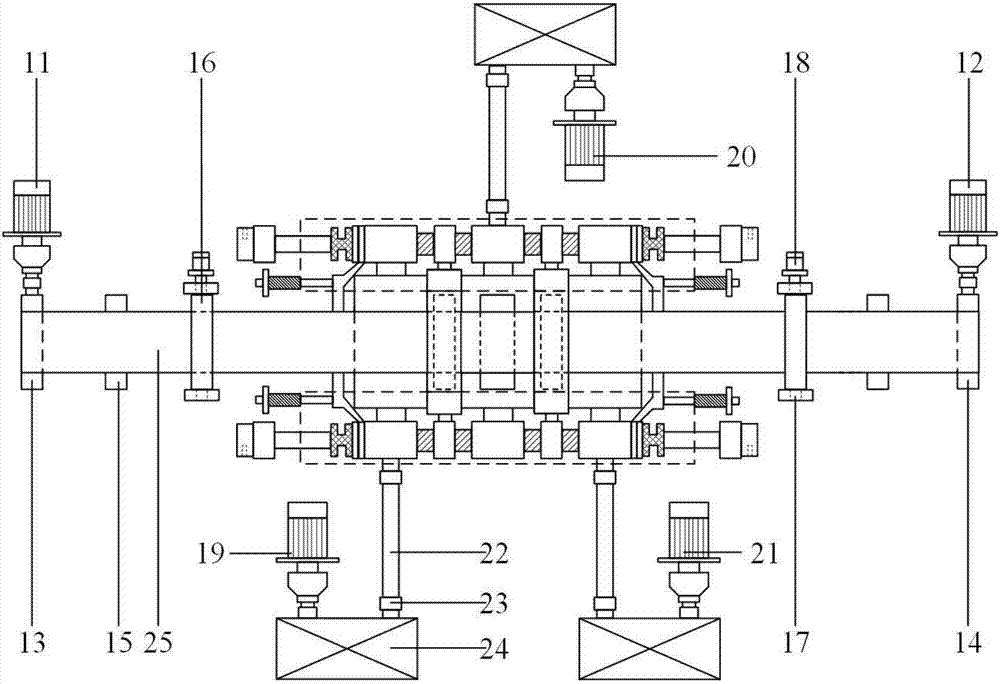

[0044] Single-stand different-diameter five-high asynchronous rolling mill, including three large-diameter rolls 2 and two small-diameter rolls 3, the large and small rolls are placed at intervals in the same plane, and the three large-diameter rolls 2 are driving rolls, respectively. Driven by a transmission motor; two small-diameter rolls 3 are driven rolls. The remaining components of the rolling mill include: pressing device 8, archway 1, first transmission motor 19, second transmission motor 20, third transmission motor 21, first tension motor 11, second tension motor 12 and first, second, and second tension motors. Three loopers.

[0045] The archway 1 adopts horizontal placement, wherein three large-diameter rolls 2 and two small-diameter rolls 3 are figure 2 Place the large-diameter roll chocks 4 and small-diameter roll cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com