The flex arm suspension device between the mill roller assembly and the plum blossom frame

The technology of a suspension device and a plum blossom stand is applied in the field of pulverizers, which can solve the problems of inability to meet production requirements, decline in equipment output, and low rolling force of the grinding roller assembly, so as to improve the rolling production efficiency, improve the service life, Strong crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

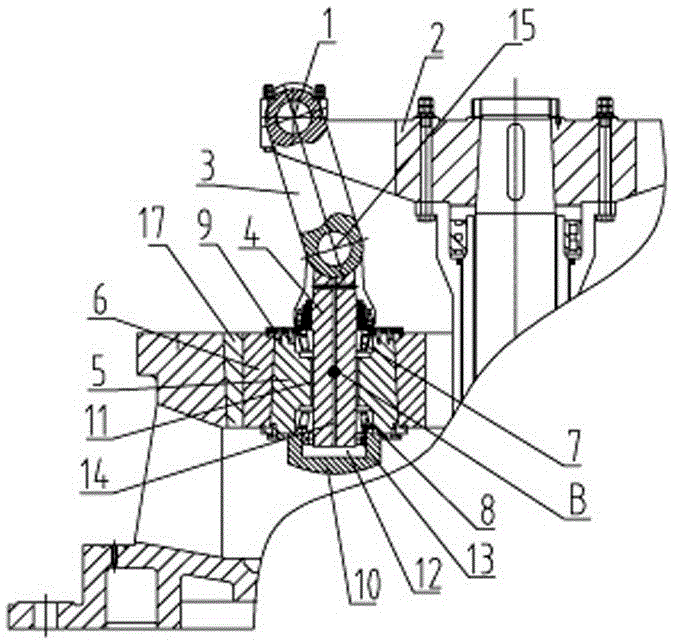

[0015] Such as figure 1 As shown, the flex arm suspension device between the mill roller assembly and the quincunx frame according to the present invention includes a quincunx frame 2 with a cross-arm shaft 1, and a grinding roller assembly is connected to the cross-arm shaft 1 , the grinding roller assembly includes the grinding roller shaft and the roller core and the grinding roller fixedly arranged at the lower part of the grinding roller shaft. The upper oblique connecting rod 3 and the vertical grinding roller shaft 4 connected to the lower end of the oblique connecting rod 3 through the swing shaft 15, on the vertical grinding roller shaft 4 are sequentially fitted with a roller core 5, a grinding roller 6, and a grinding ring 17. Set outside the grinding roller 6, the upper and lower ends of the roller core 5 are provided with upper and lower bearing holes respectively, the upper bearing 7 set on the vertical grinding roller shaft is placed in the upper bearing hole, ...

Embodiment 2

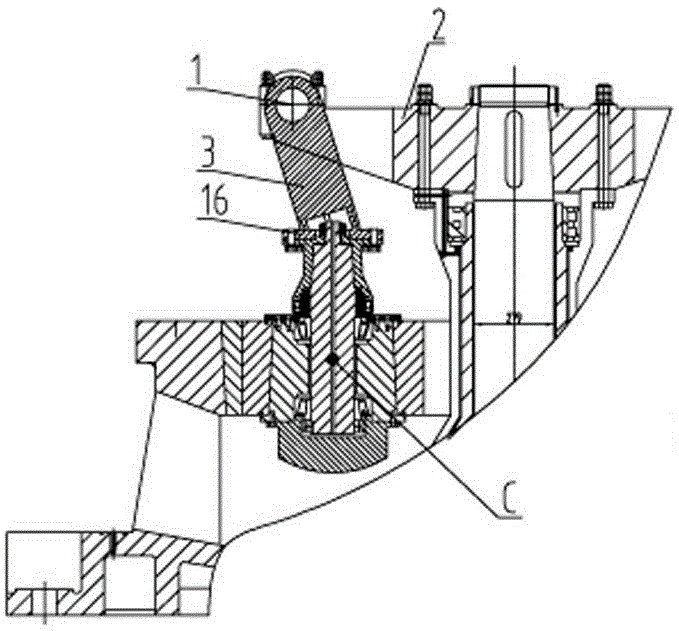

[0019] Such as figure 2 As shown, compared with Embodiment 1, this technical solution differs only in that the oblique connecting rod 3 whose upper end is sleeved on the cross-arm shaft is fixedly connected to the oblique connecting rod 3 through the connecting flange 16 (or other fixed connection methods). The lower end of rod 3. from figure 2 It can be clearly seen that the center of mass of the grinding roller assembly is located at point C. Compared with the structure of the traditional grinding roller assembly, the moment is also significantly lengthened, and the rolling force converted from the self-weight of the grinding roller assembly increases, making the rolling Work efficiency is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com