Energy-saving and effect-enhancing type rolling and kneading machine

A tumbler and consistent technology, applied in slaughtering, meat tenderization, food science, etc., can solve the problems of axial bias, difficult cleaning, complicated process, etc., achieve uniform force, save materials, and good rolling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

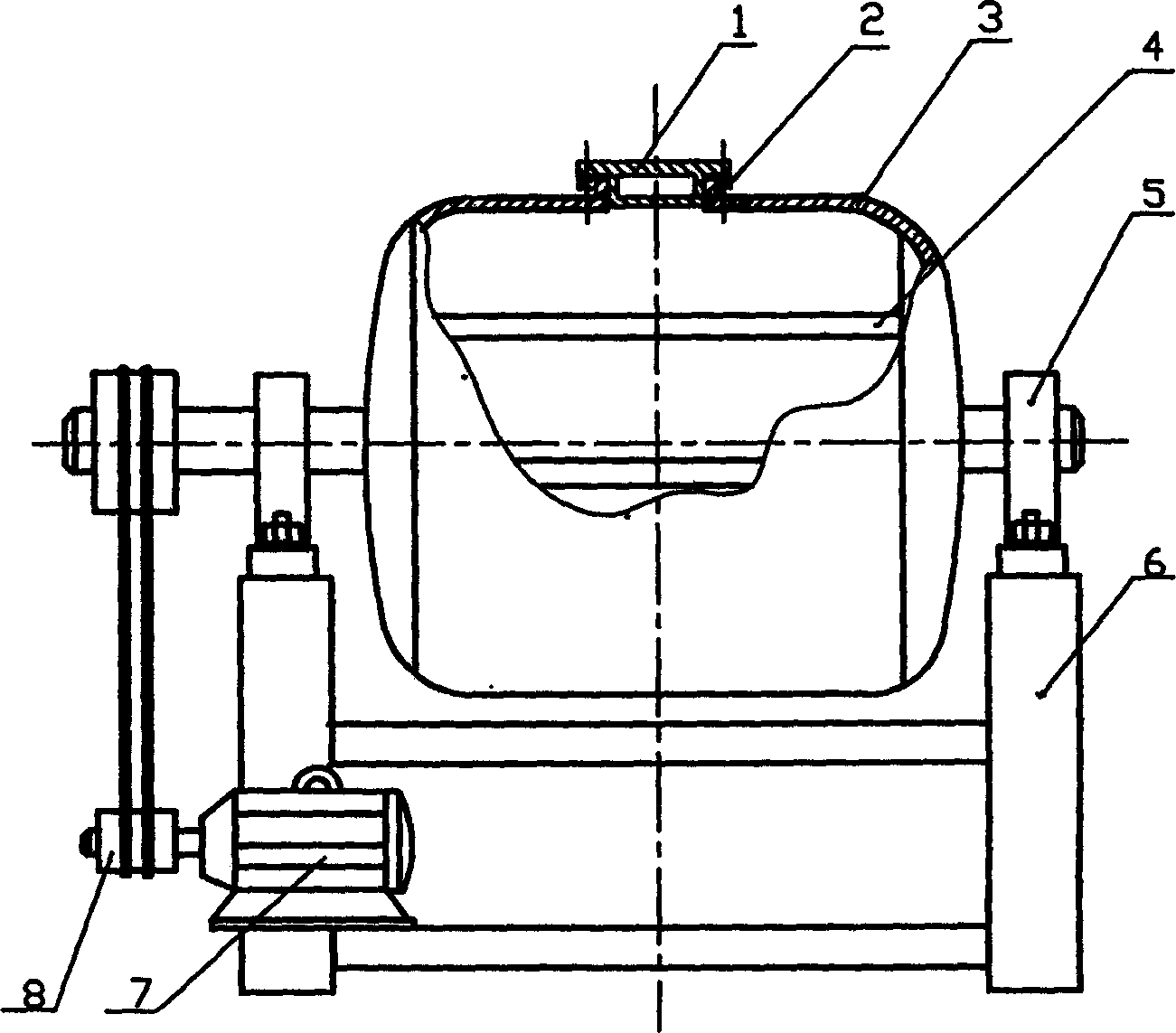

[0017] The content of the present invention is described in further detail below in conjunction with the embodiment shown in the accompanying drawings:

[0018] As shown in the figure: both ends of the tank body (3) are spherical, and the radial center of the tank body is provided with a feeding port (2). The cover is sealed with bolts, and other cover sealing structures such as handwheels can also be used to seal the feeding port tightly. The entire feeding port cover and feeding port are very short to reduce the weight, and they are all arc-shaped, and their arc is the same as that of the tank body. Also more aesthetically pleasing.

[0019] The feeding port cover is buckled into the tank so that no large pits are formed in the tank, which is beneficial to the tumbling of the tumbling meat. Because the feeding port is set in the radial direction of the tank body, in order to keep the radial rotation force of the tank body uniform and consistent, the layout position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com