A kind of rolling method of high manganese plate for lng storage tank

A high-manganese, storage tank technology, applied in metal rolling, metal processing equipment, etc., can solve the problems of ultra-low temperature impact toughness anisotropy, etc., to improve ultra-low temperature impact toughness, reduce the total number of rolling passes, and improve rolling production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The chemical composition of high manganese austenitic steel is: C: 0.45%, Si: 0.02%, Mn: 27.3%, P: 0.005%, S: 0.0044%, Cr: 3.9%, Cu: 0.52%, Yu The amount is Fe and unavoidable impurities.

[0045] A method for rolling high manganese plate for LNG storage tanks is realized through the following technical solutions, and the specific steps are as follows:

[0046] Step 1, forging:

[0047] High manganese austenitic steel ingots are forged to open billets at a forging temperature of 1070°C to obtain steel billets;

[0048] Step 2, heating:

[0049] Heat the billet or ingot to 1200°C and keep it warm for 2 hours;

[0050] Step 3, rolling:

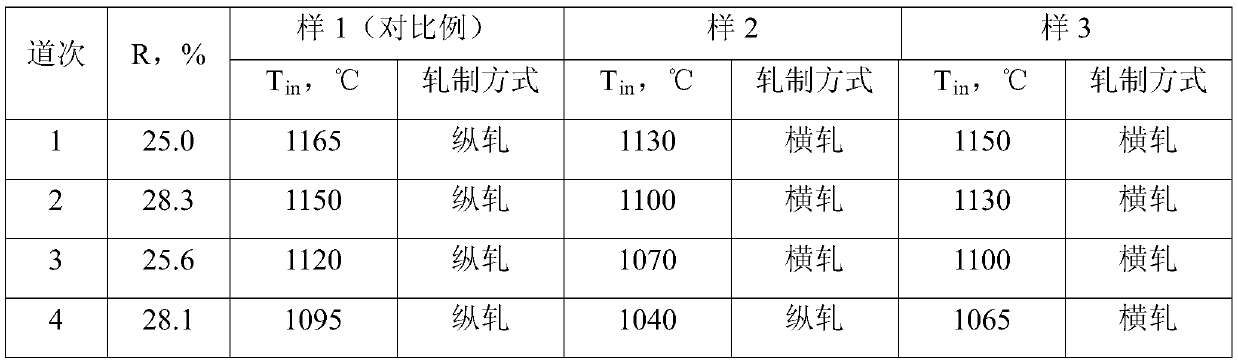

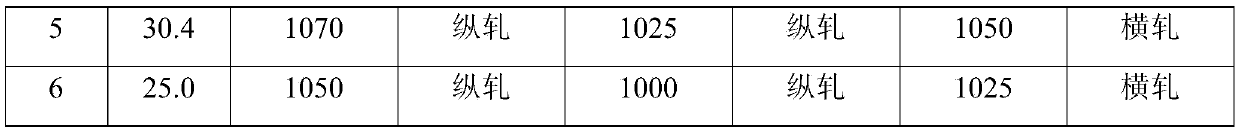

[0051] Using the narrow billet widening rolling method, the heated steel billets of sample 2 and sample 3 are subjected to 6 passes of full horizontal rolling or horizontal and vertical alternate rolling, and the rolling start temperature (T in ), single pass reduction rate (R) as shown in Table 1, obtain hot-rolled steel, and hot-ro...

Embodiment 2

[0063] The chemical composition of the high manganese austenitic steel in this example is by weight percentage: C: 0.48%, Si: 0.18%, Mn: 23.9%, P: 0.0070%, S: 0.0054%, Cr: 3.9%, Cu: 0.49 %, V: 0.025%, the balance is Fe and unavoidable impurities.

[0064] A method for rolling high manganese plate for LNG storage tanks is realized through the following technical solutions, and the specific steps are as follows:

[0065] step 1:

[0066] High manganese austenitic steel is smelted at 1650°C, and the obtained molten steel is directly poured into a square mold to obtain a thin ingot with a thickness of 70mm;

[0067] Step 2, heating:

[0068] Heat the billet or ingot to 1200°C and keep it warm for 2 hours;

[0069] Step 3, rolling:

[0070]Thin slab direct rolling method is adopted, the heated ingot is rolled through 4 passes of full longitudinal rolling, and the rolling start temperature (T in ), single pass reduction rate (R) as shown in Table 4, to obtain a hot-rolled steel...

Embodiment 3

[0078] The chemical composition of high manganese austenitic steel is by weight percentage: C: 0.58%, Si: 0.51%, Mn: 23.6%, P: 0.0080%, S: 0.0060%, V: 0.25%, Al: 1.9%, Yu The amount is Fe and unavoidable impurities.

[0079] A method for rolling high manganese plate for LNG storage tanks is realized through the following technical solutions, and the specific steps are as follows:

[0080] step 1:

[0081] High manganese austenitic steel is smelted at 1650°C, and the obtained molten steel is directly poured into a square mold to obtain a thin ingot with a thickness of 70mm;

[0082] Step 2, heating:

[0083] Heat the billet or ingot to 1200°C and keep it warm for 2 hours;

[0084] Step 3, rolling:

[0085] Using the thin slab direct rolling method, the heated ingot is rolled through 7 passes of full longitudinal rolling, and the rolling start temperature (T in ), single pass reduction rate (R) are as shown in Table 5, and the hot-rolled steel obtained, the thickness of hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com