Magnesium alloy wide plate three-roll casting-rolling mill

A casting and rolling mill, magnesium alloy technology, applied in the direction of metal rolling, etc., can solve the problems of difficult realization of structure, restriction of casting and rolling quality, and increase of the length of the roll gap process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

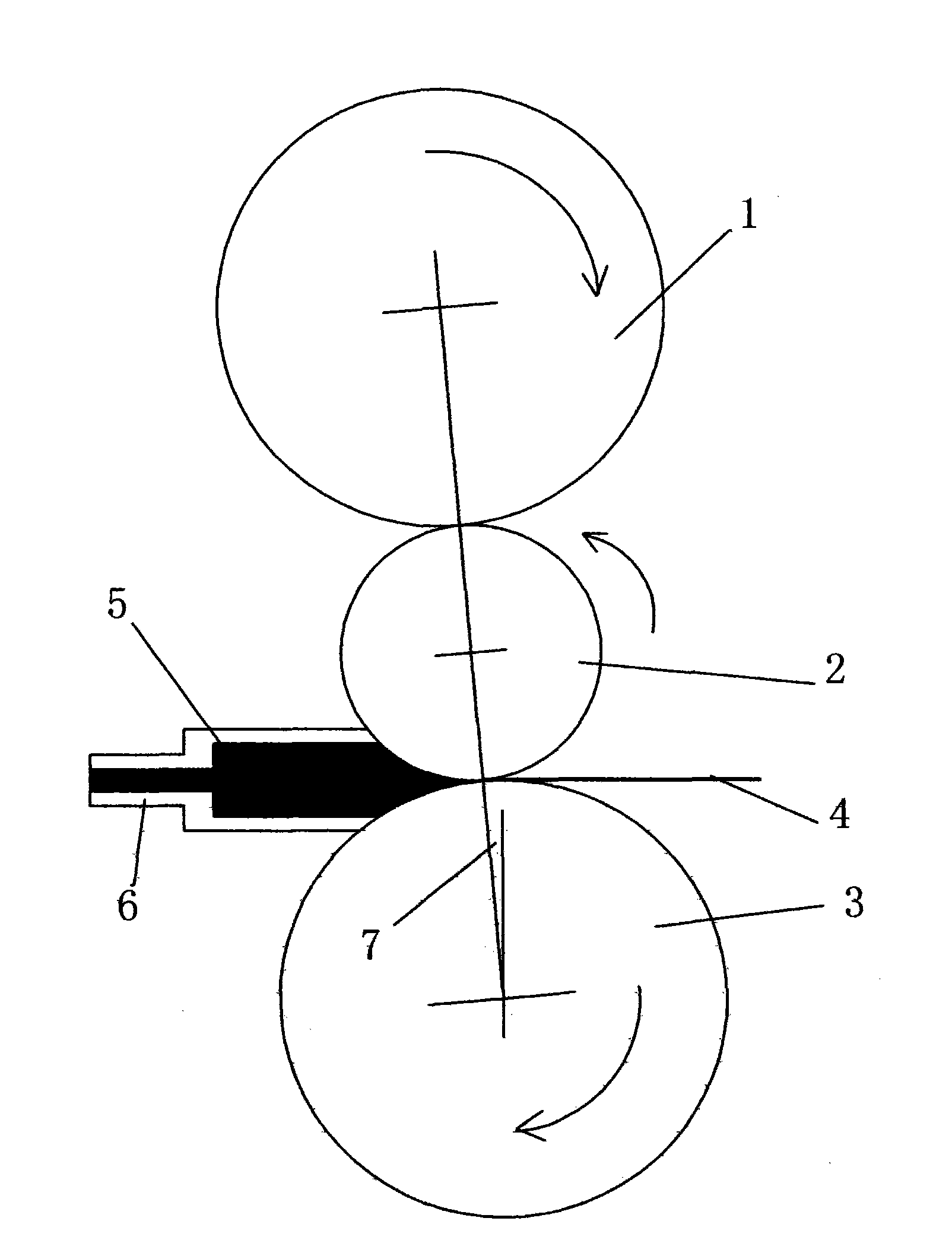

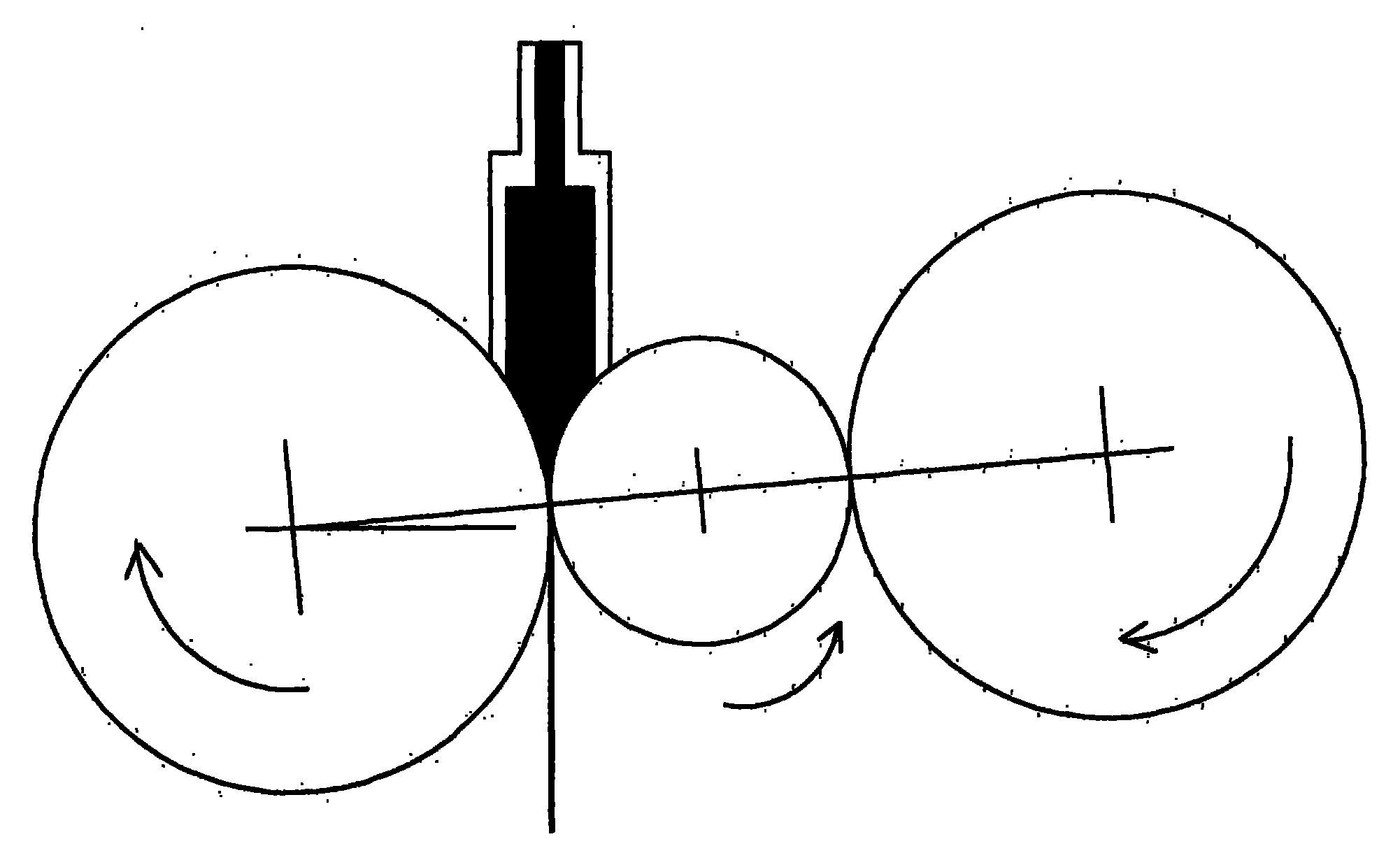

[0019] 1800mm magnesium alloy thin plate three-roll casting mill

[0020] The structure of the widest 1800mm magnesium alloy thin plate three-roll casting mill, the actual working section length of the three rolls is 2000mm. The middle roll is 350mm in diameter and the two double drive drive rolls are 960mm in diameter. The internal water cooling structure of the roll is designed according to the internal water cooling parameters of ordinary casting and rolling mills. The axial plane of the roll is inclined 10 degrees to the direction of the nozzle. Two pairs of upper and lower hydraulic cylinders are used in the archway, with a maximum rolling force of 2,000 tons, and the roll gap at the left and right ends of the roll can be adjusted separately as required. The rotation direction of the upper and lower driving rolls of the double drive is the same, and the speed can be adjusted steplessly. The design range of the surface linear speed of the casting roll is 2 m / min to 8 m / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com