Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Avoid fuzz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

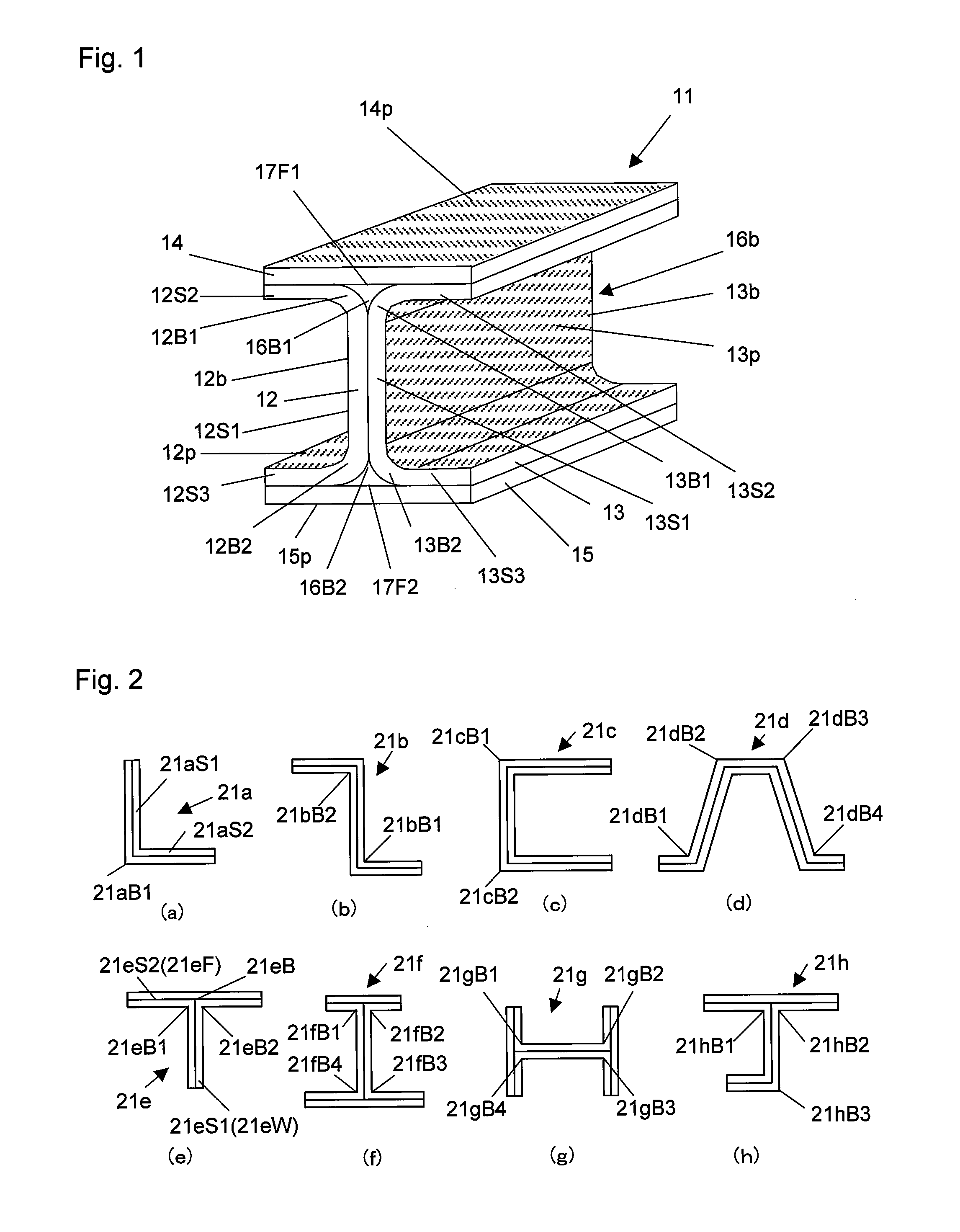

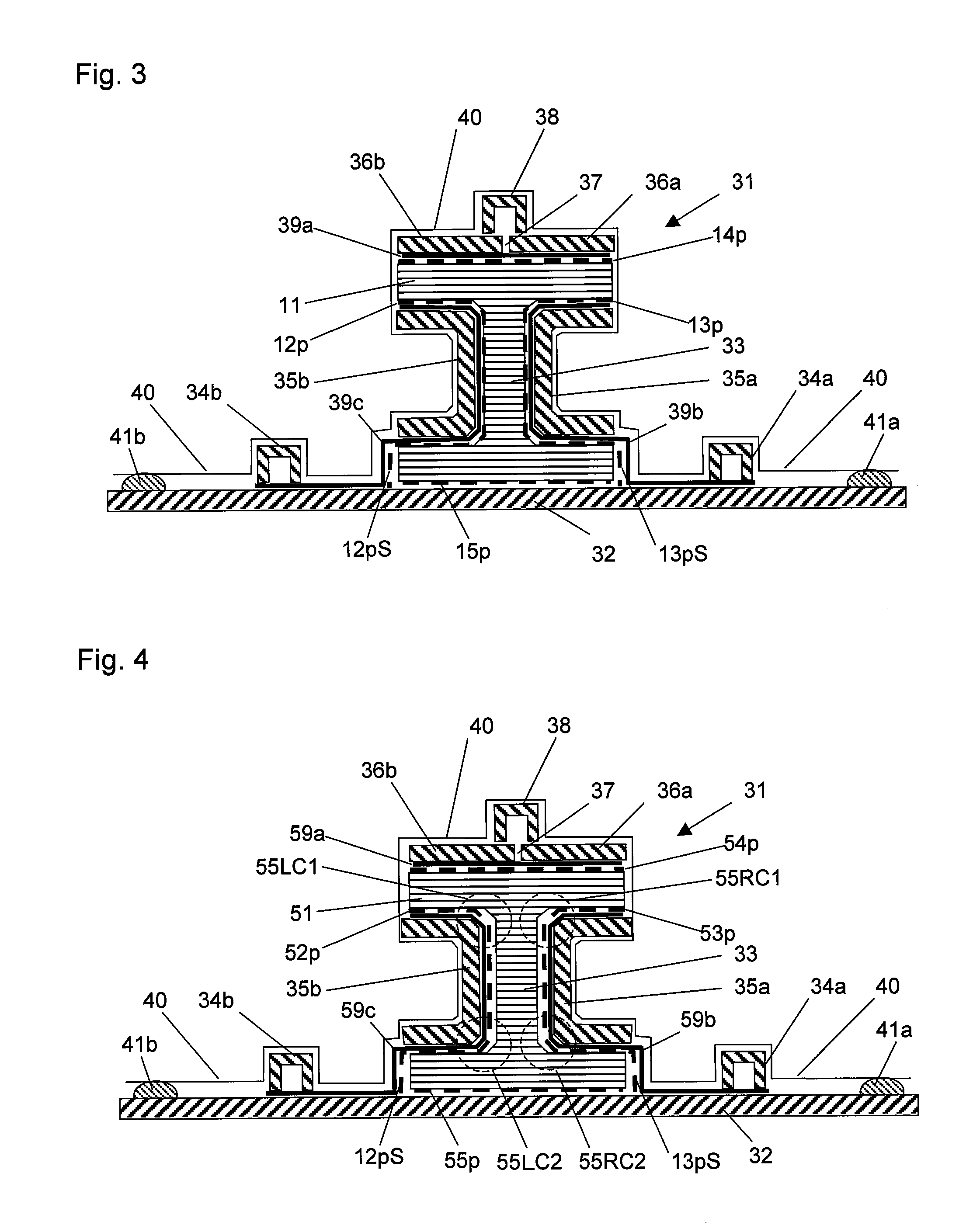

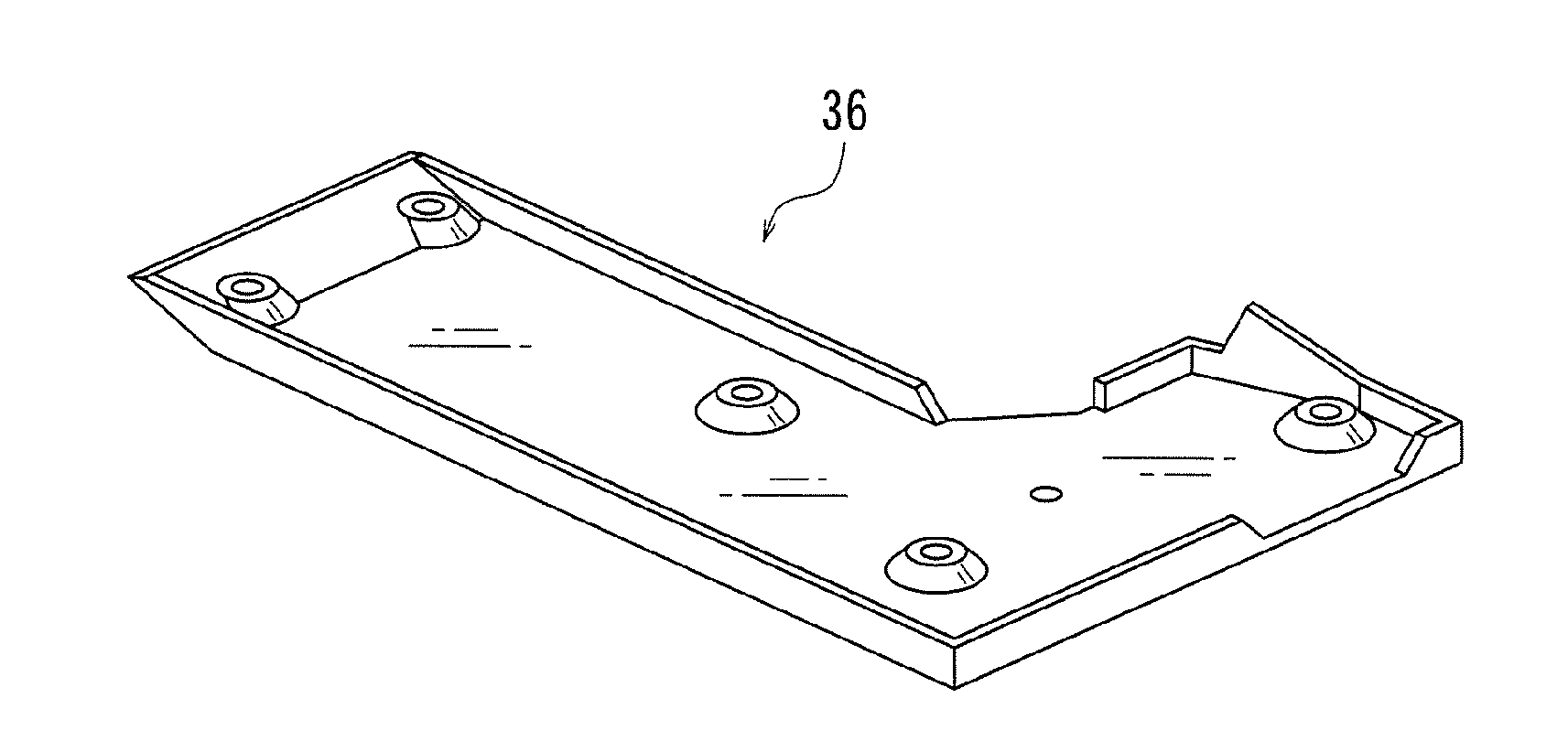

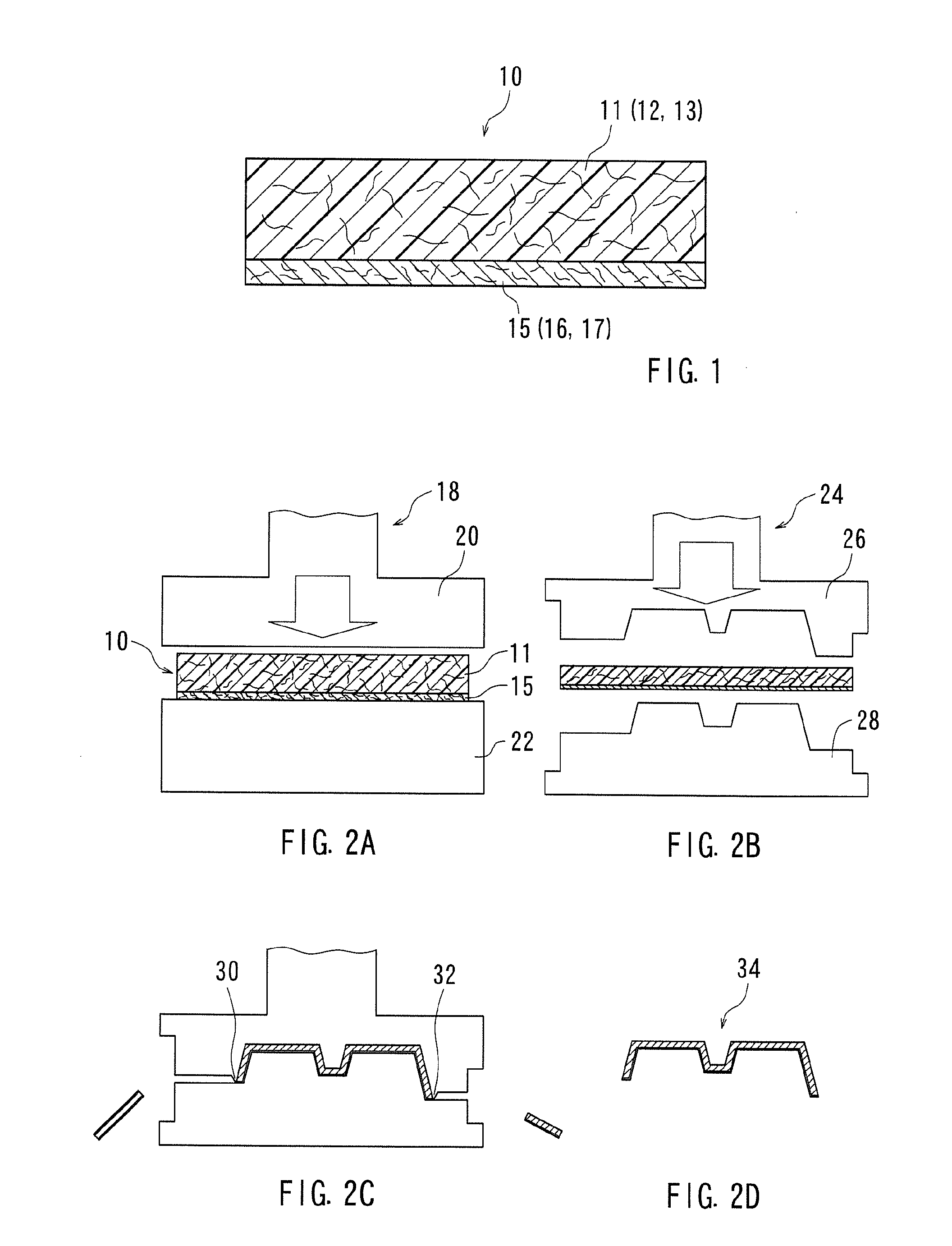

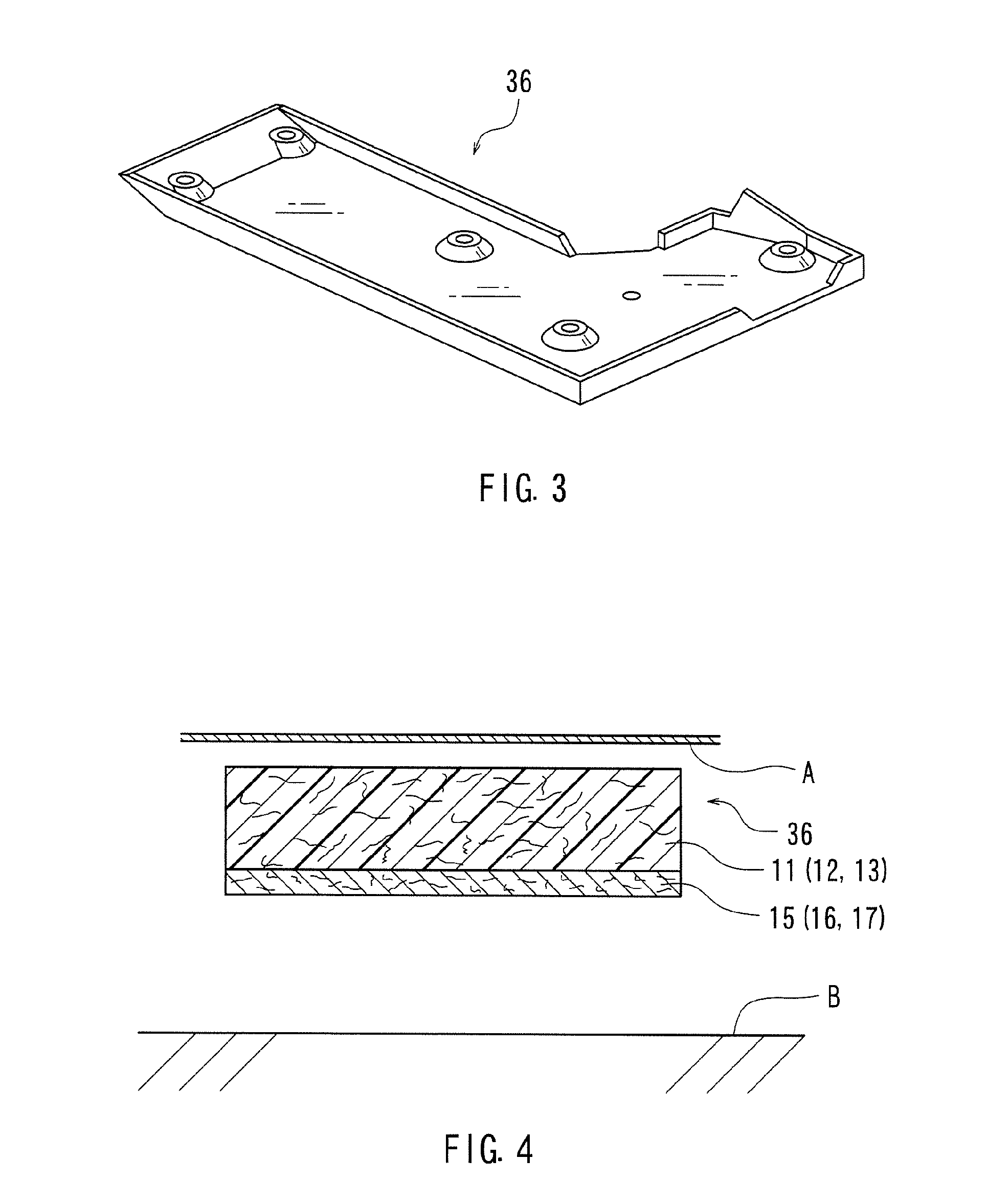

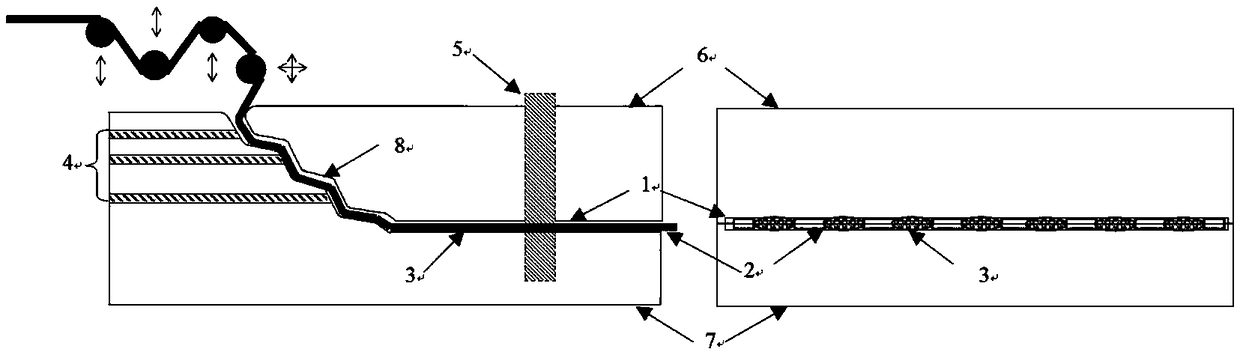

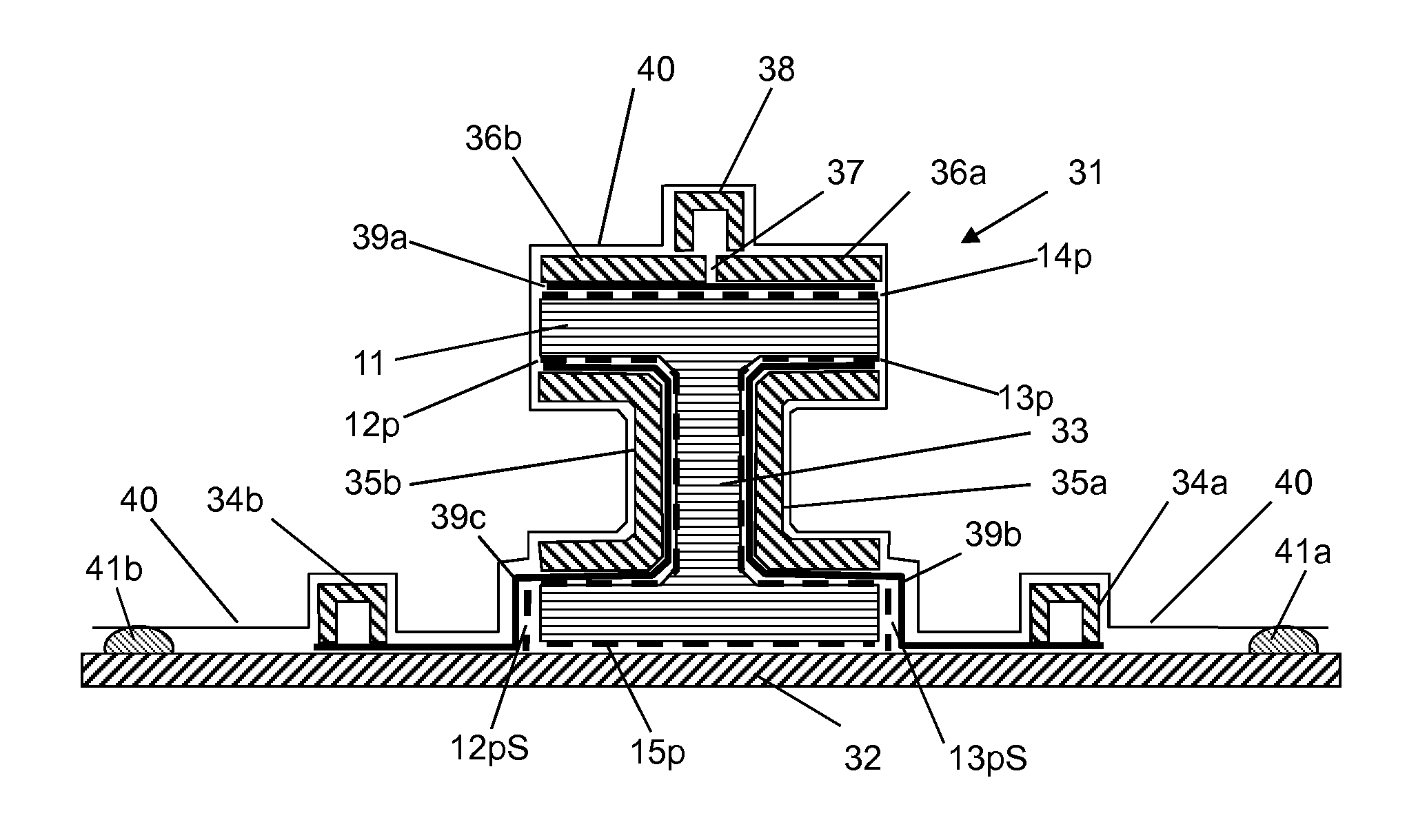

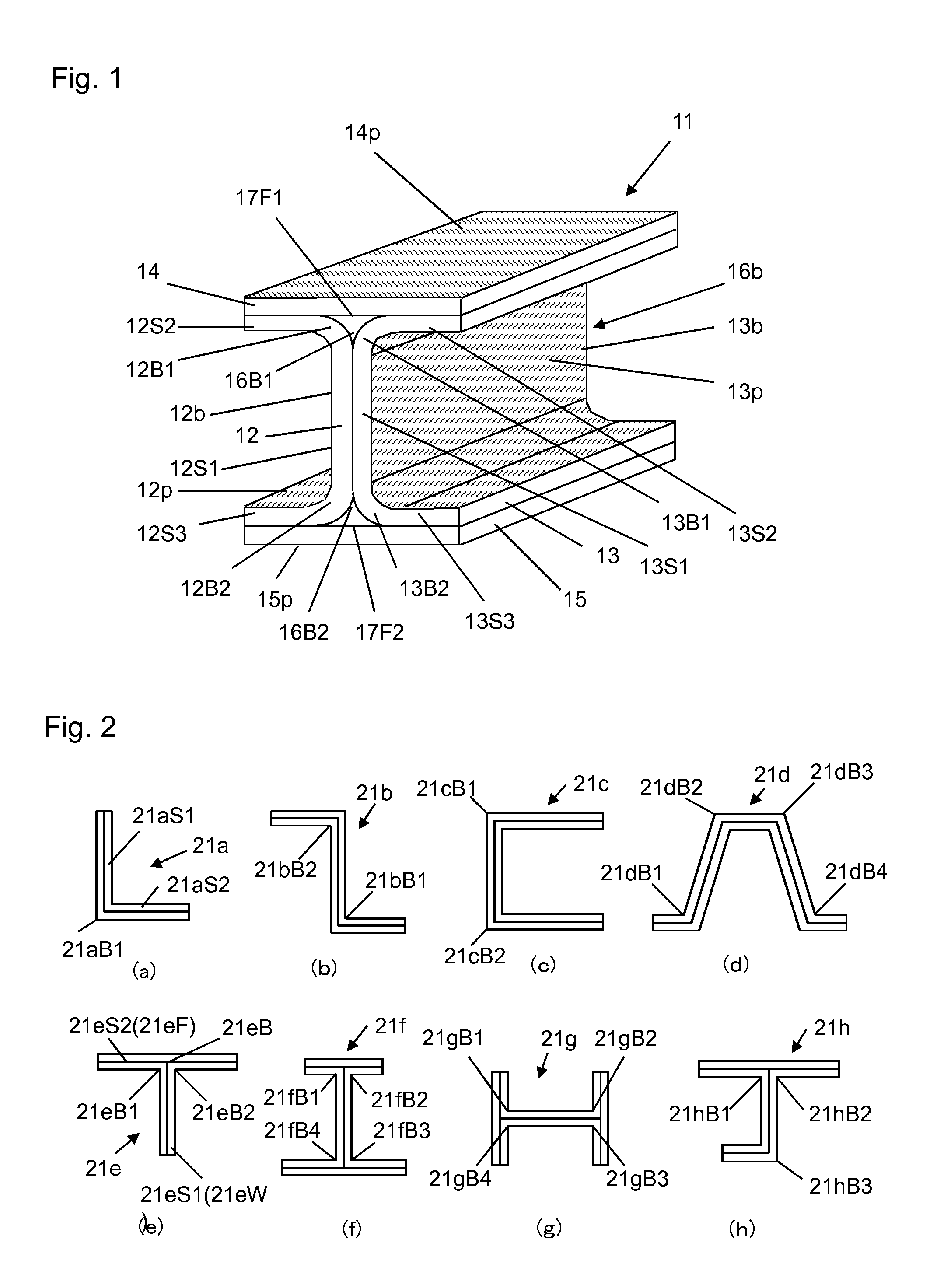

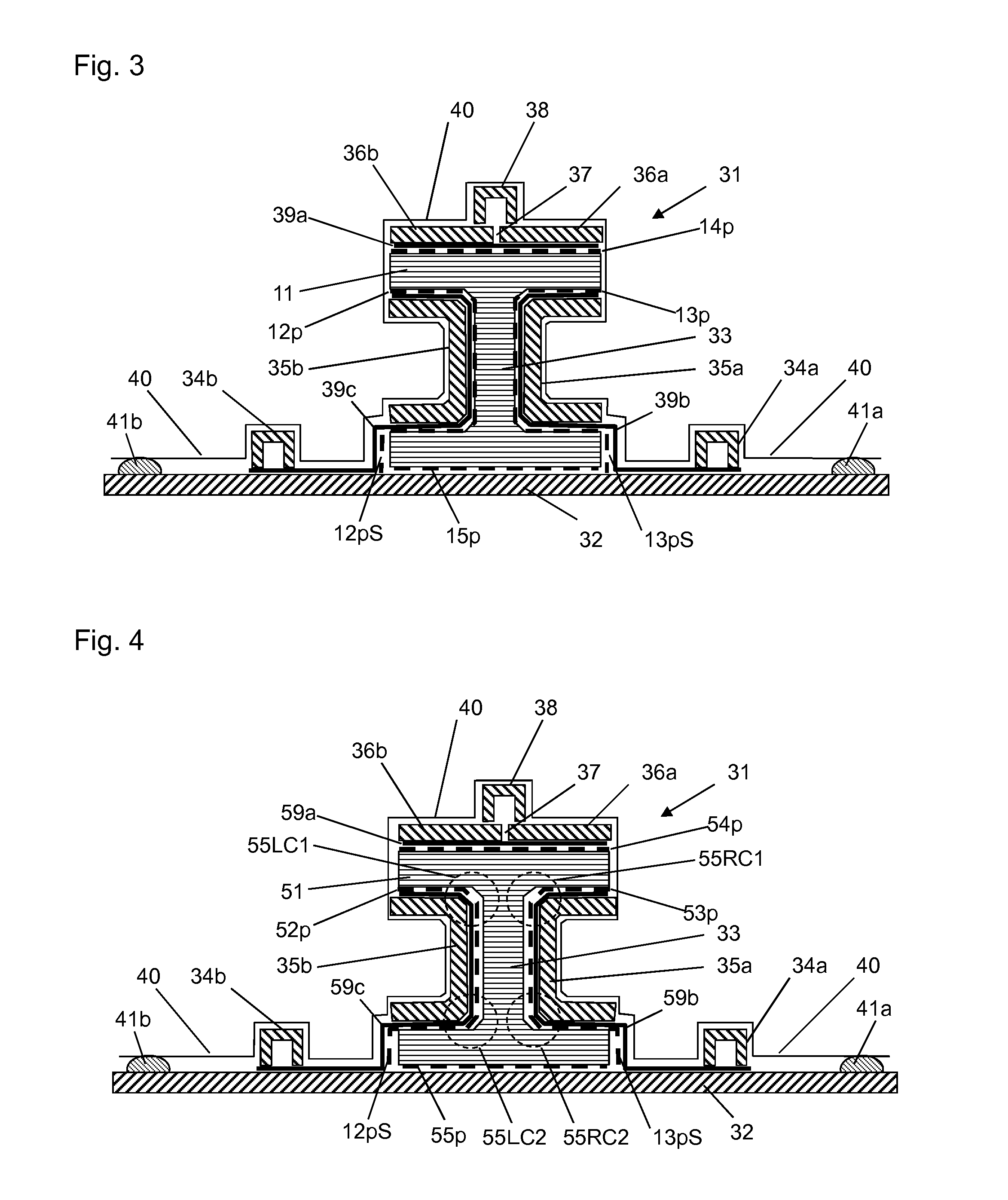

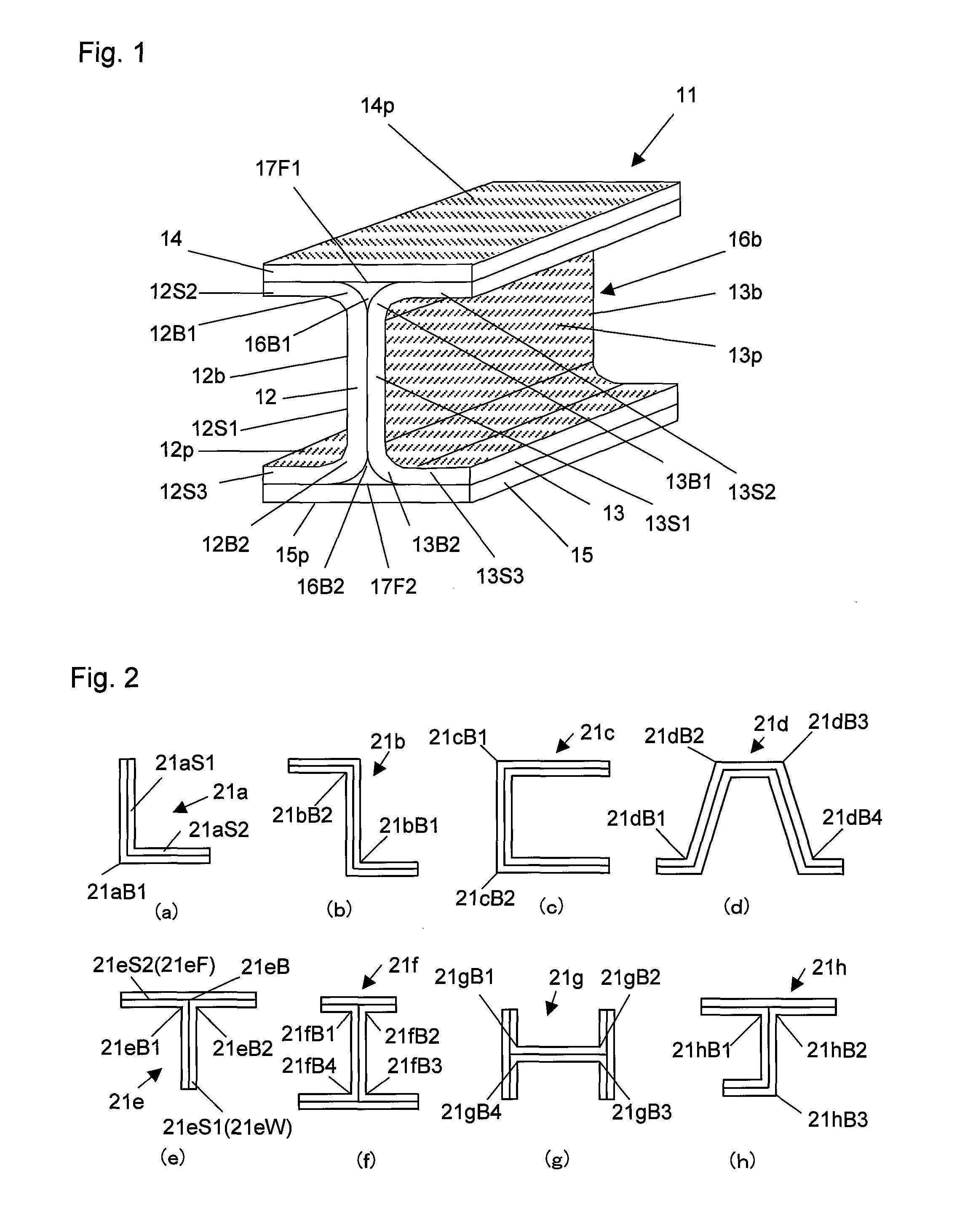

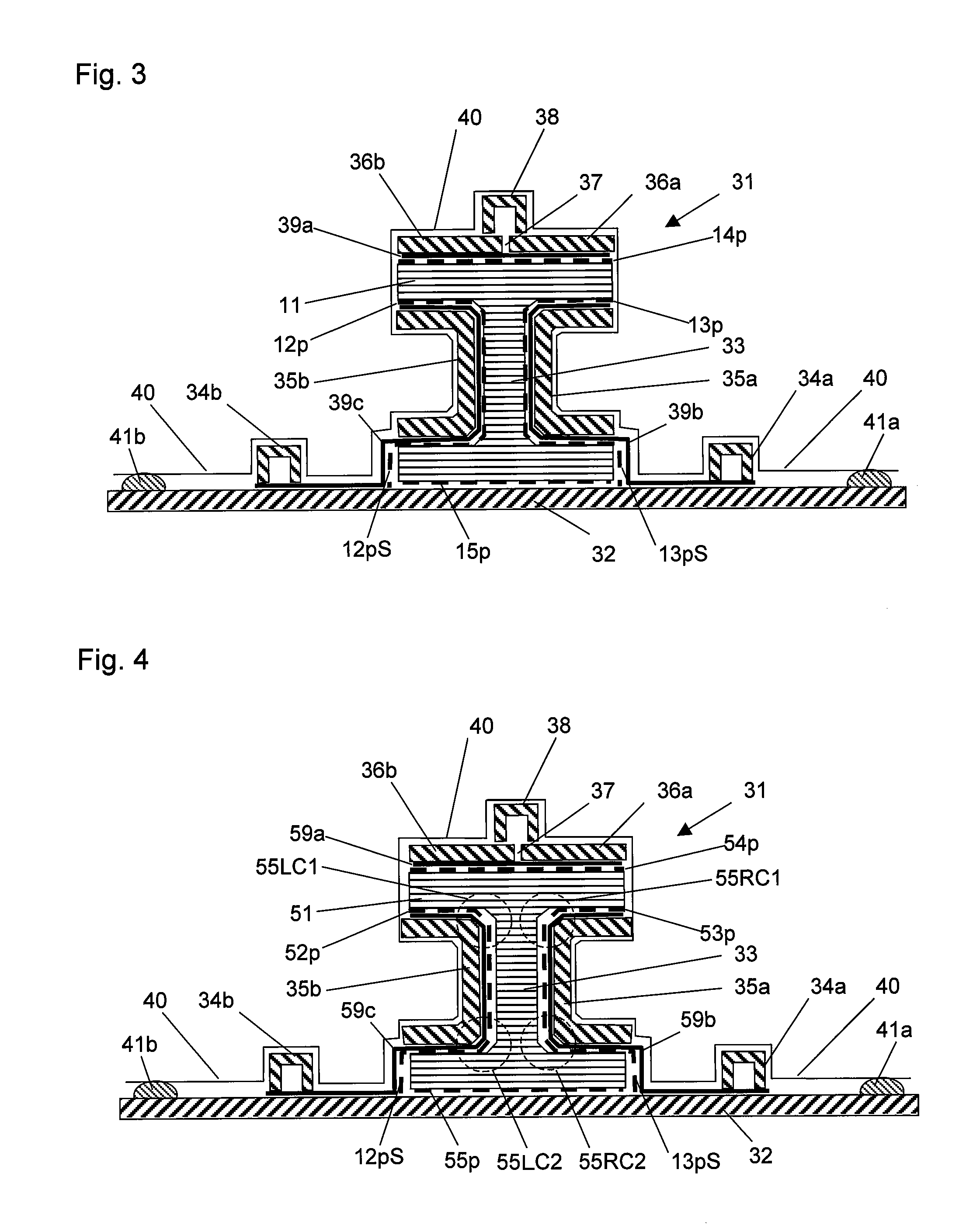

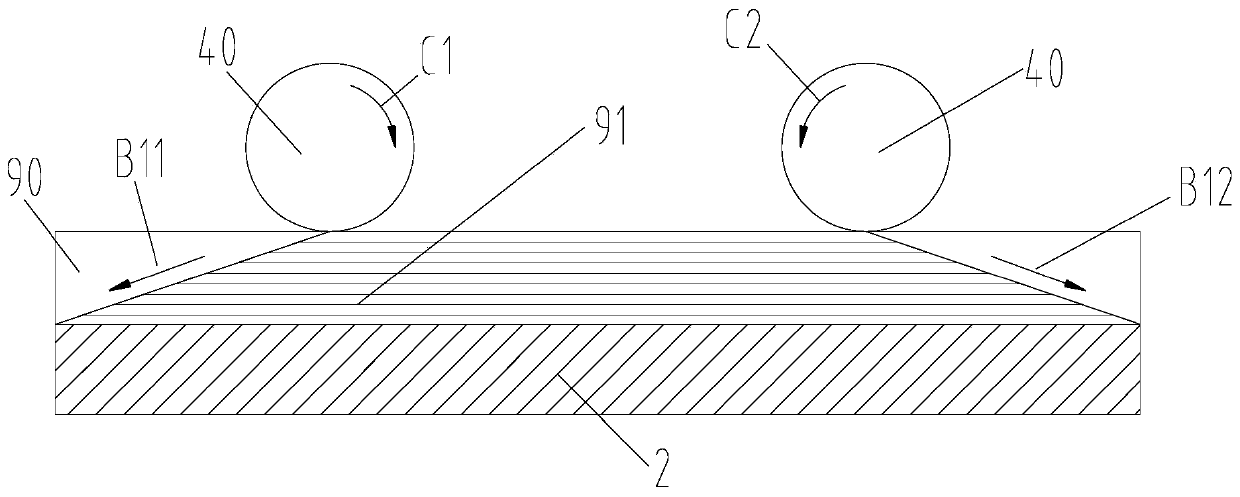

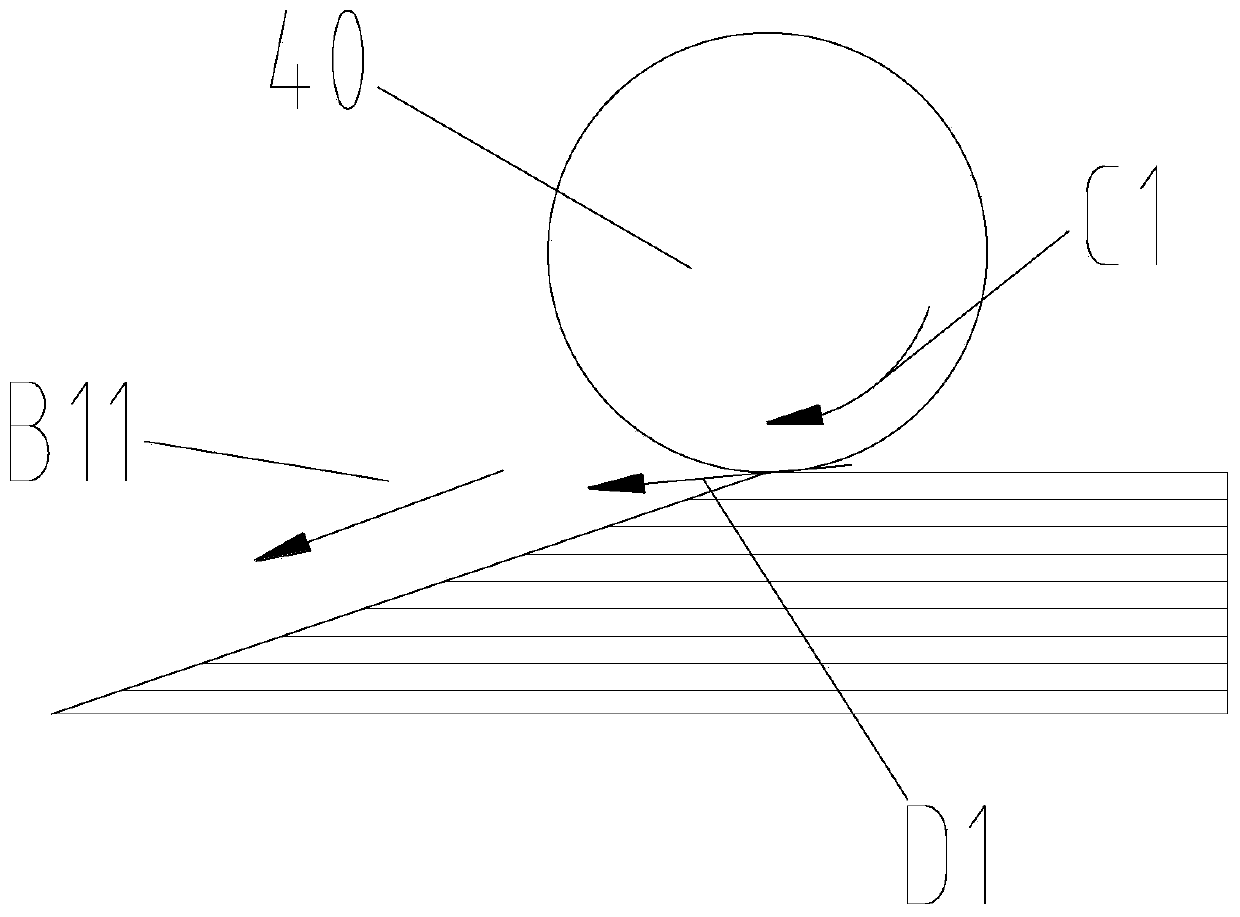

Preform for molding fiber-reinforced resin beam, process for producing the same, apparatus for producing the same, and process for producing fiber-reinforced resin beam

ActiveUS20100080952A1Work lessQuality improvementLayered productsDomestic articlesFiber reinforcement

A preform for the molding of a fiber-reinforced resin beam, the preform comprising: a reinforcing-fiber beam which has been formed from a reinforcing-fiber base made up of many reinforcing fibers and has a cross-sectional shape comprising at least one linear part and at least one curved part connected to the linear part; and a release sheet bonded and united through an adhesive resin to at least part of a surface of the reinforcing-fiber base along the lengthwise direction for the base. A process for producing a preform comprises: a step in which a continuous flat reinforcing-fiber base having a release sheet bonded and united to a surface thereof is shaped so that the cross-sectional shape of the base comes to have a curved part to thereby produce a preshaped object; and a preshaped-object uniting step in which the preshaped object is bonded and united to another preshaped object.

Owner:TORAY IND INC

Fiber size, sized reinforcements, and articles reinforced with such reinforcements

InactiveUS20070082199A1Good processing characteristicsImprove adhesionFibre typesYarnHigh intensitySizing

The present invention relates to fiber-size compositions for coating glass or other reinforcing fiber materials that are used in the manufacturing of composites. The fiber-size composition contains at least about 4% by weight of a polyvinylpyrrolidone film former, at least one lubricant and a coupling agent. The sizing composition gives the fibers desirable properties such as high strength, improved flexibility, fuzz formation resistance, and fiber smoothness and softness.

Owner:OCV INTELLECTUAL CAPITAL LLC

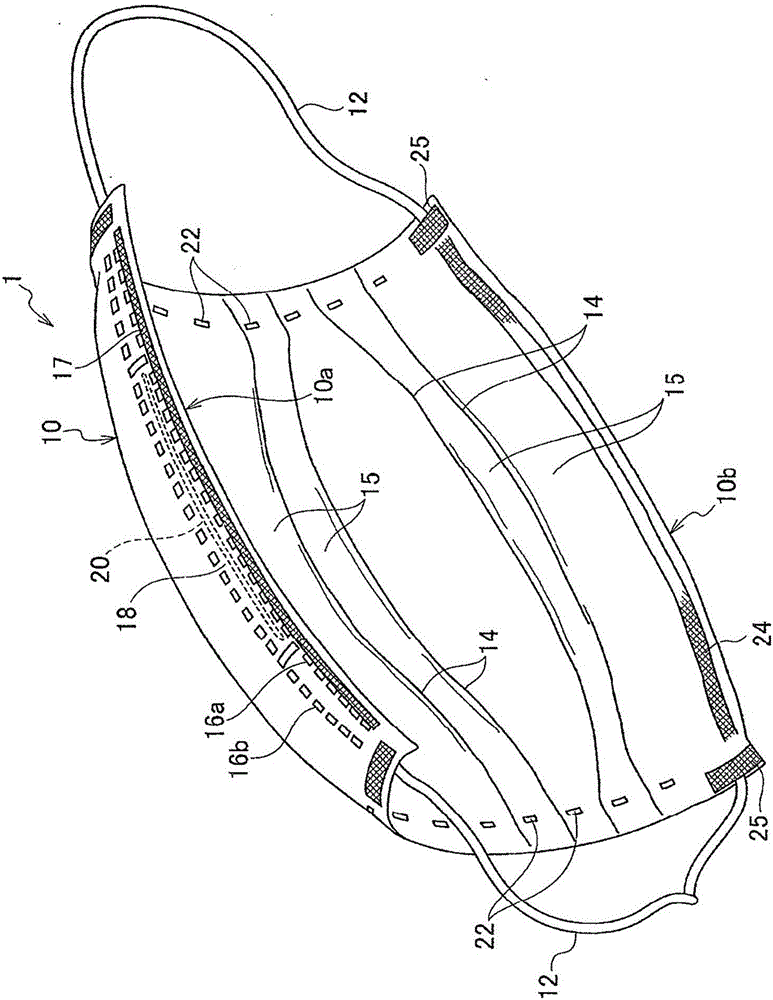

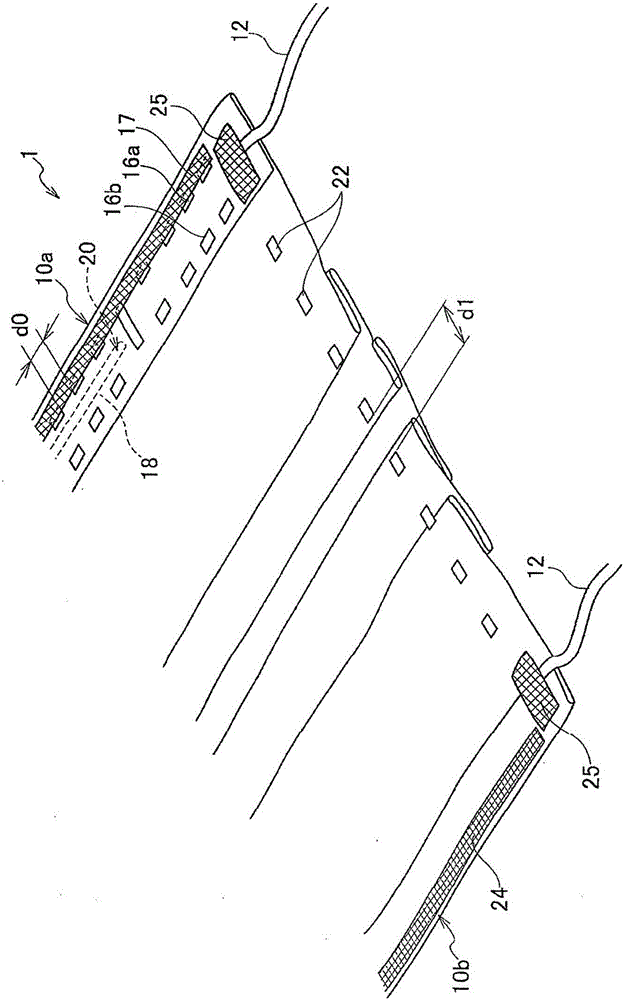

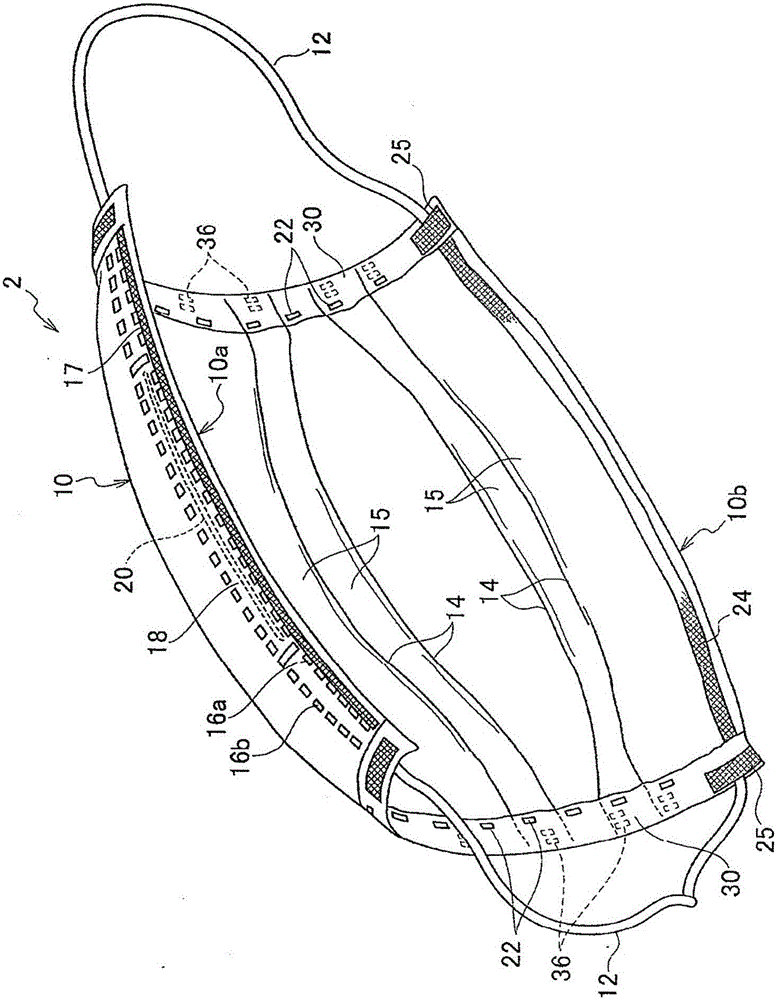

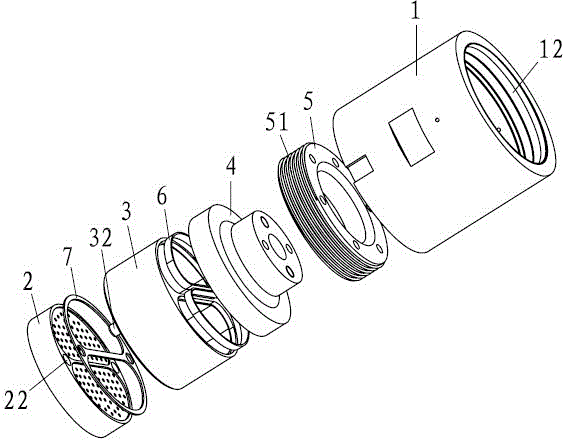

Mask

ActiveCN105813696APrevent intrusionExcellent adhesionBreathing masksProtective garmentRespiratorBiomedical engineering

Provided is a mask that inhibits particles from entering into the mask by keeping the mask body side portion in good contact with the face and suppressing the gap between the mask body and the face. The present invention is a mask (1) which comprises a mask body (10) and an ear hooking portion (12) formed on both ends of the mask body (10) in the lateral direction and has a plurality of pleats (15) formed thereon, wherein the mask is formed so that: the plurality of pleats (15) are stopped by fused portions (22) formed by way of heat sealing; the fused portions (22) are formed to be linear in the longitudinal direction and equally spaced on both sides of the mask body (10) in the lateral direction; and the space between adjacent fused portions is no less than 3 mm.

Owner:KOWA CO LTD +1

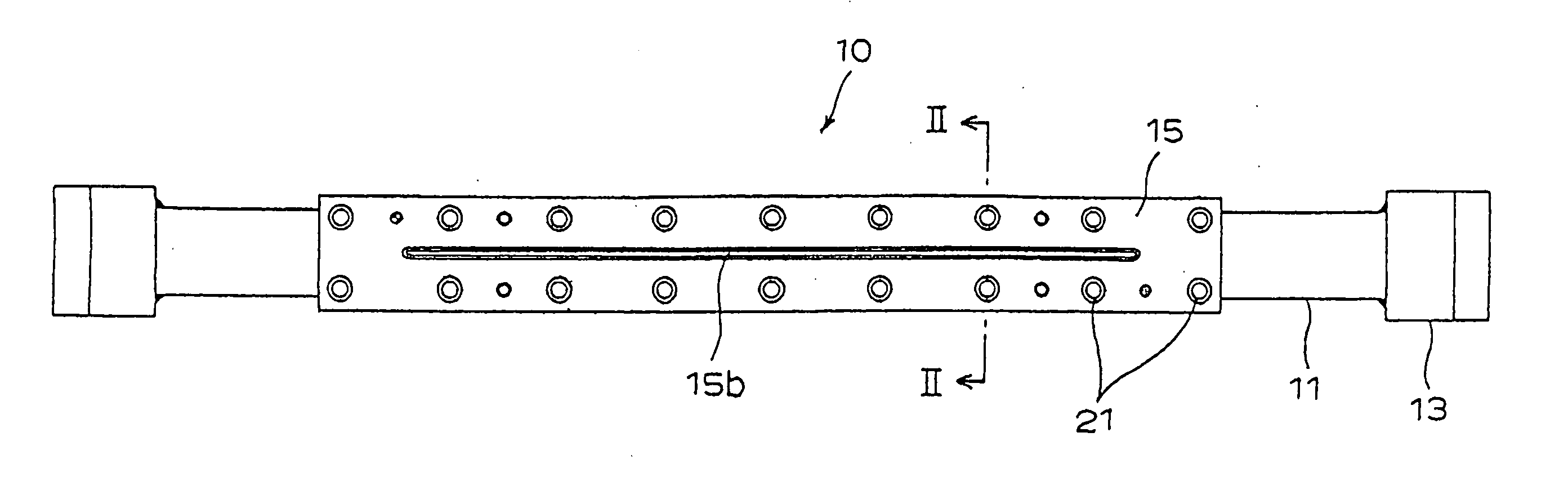

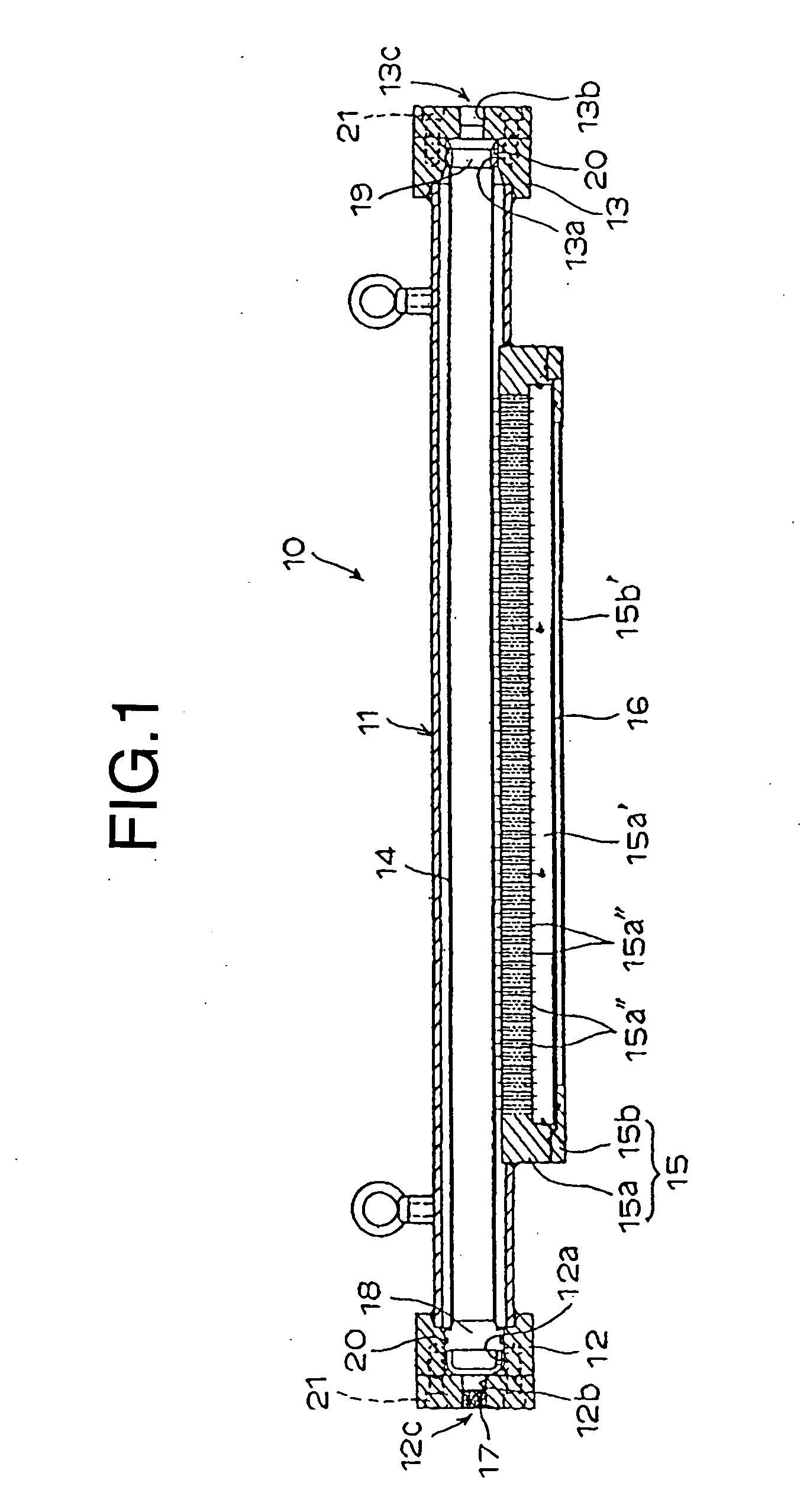

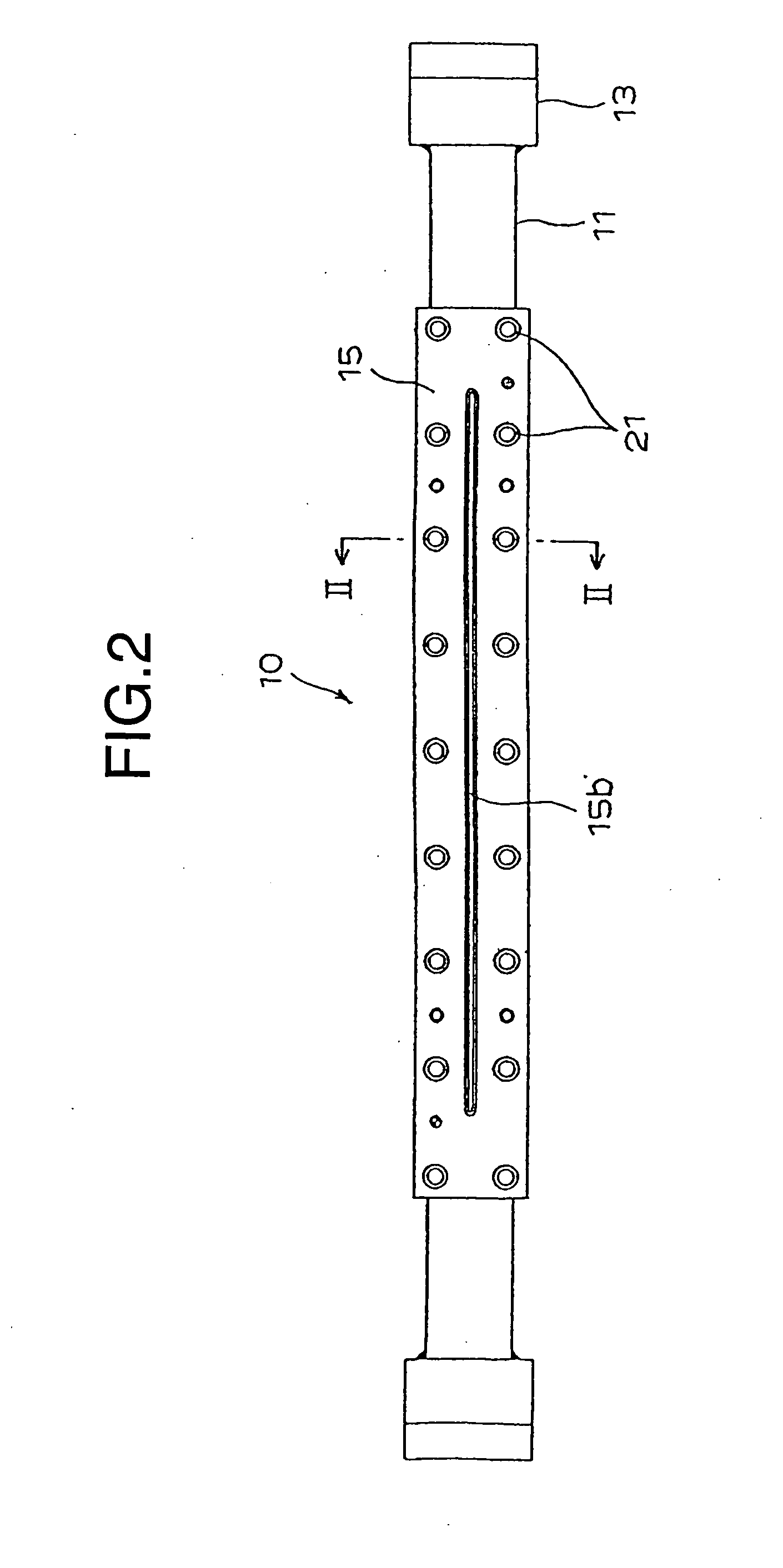

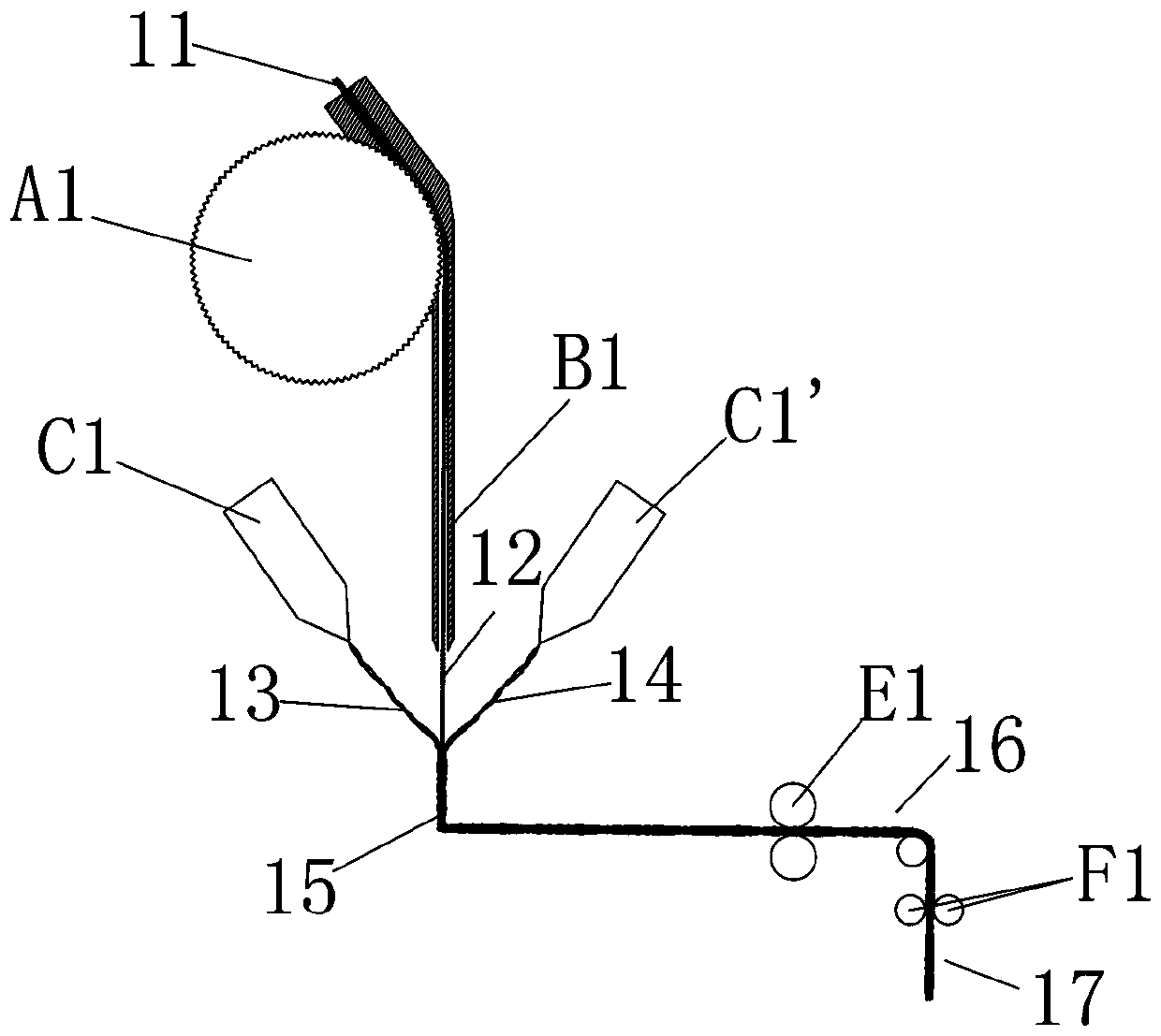

Pressurized steam-jetting nozzle, and method and apparatus for producing nonwoven fabric using the nozzle

ActiveUS20060042057A1Facilitate entanglementReduce distancePattern makingDrying machines with progressive movementsEngineeringNonwoven fabric

The present invention relates to a nozzle suitable for jetting high pressure and high temperature steam, and a method and an apparatus for producing an entangled nonwoven fabric using the nozzle. According to the apparatus, a steam inlet side main conduit (c1) and a steam outlet side conduit (c3) are connected with both end parts of a tubular nozzle holder (11) in a longitudinal direction provided integrally with nozzle members (15, 16, 23) having a plurality of nozzle holes (16a, 26). A steam outlet side conduit (c2) is provided with an opening / closing valve (55) and a trap conduit (57) is branched from a conduit at an upstream side from the opening / closing valve (55). By opening the opening / closing valve (55), a rapid temperature rise of the nozzle holder (11) can be enabled at a time of starting a production of a nonwoven fabric. Furthermore, even in the opening / closing valve (55) is closed in a regular operation, drainage generated inside the nozzle holder (11) can always be discharged to outside so that steam can be jetted stably and continuously, and thus a high quality entangled fiber nonwoven fabric can be produced continuously from the fiber web by the steam.

Owner:MITSUBISHI CHEM ENG CORP

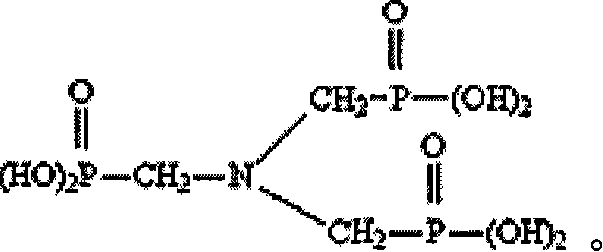

Automobile body undercover

Disclosed is an automobile body undercover having durability against damage from foreign objects such as flying stones even in a case where a nonwoven fabric is used on an outer surface on a road surface side in order to achieve sound absorbing characteristics with respect to engine noise leaked outside a car, road noise originating from the road surface side, or the like. The automobile body undercover includes at least: a base material layer (11) that includes a mixture of a fiber reinforcing material and a first thermoplastic synthetic resin (13); and a nonwoven fabric layer (15) of a thermoplastic synthetic fiber that is stacked on a surface that is a road surface side of the base material layer (11), surface portions of both the layers being bonded by thermal fusion, and both the layers being compression-molded into a predetermined shape to form a fiber molded body, wherein the first thermoplastic synthetic resin (13) of the base material layer (11) has a melting point for melting in a heating process at the time of molding, and wherein the nonwoven fabric layer (15) includes a mixture of a second thermoplastic synthetic fiber (16) having a melting point for melting in the heating process at the time of molding and a third thermoplastic synthetic fiber (17) having a melting point for non-melting in the heating process at the time of molding.

Owner:HOWA TEXTILE IND

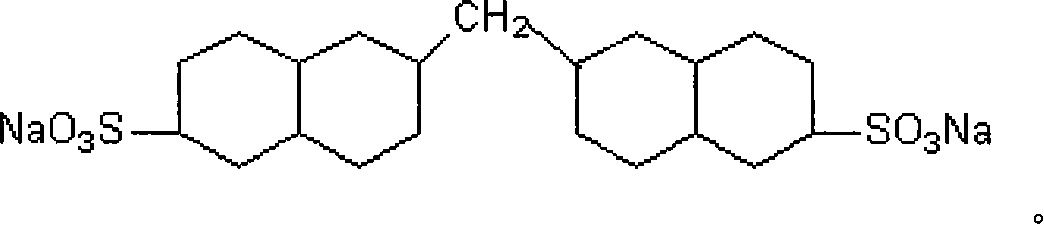

Auxiliary agent of formulation for dyeing Terylene

This invention discloses an aid used in terylene dyeing characterizing in including the following components in weight percentage: acid aid 10-20%, organic phosphonic acid 2-5%, organic carboxylic acid 3-7%, naphthalenesulfonate 10-18%, PEG 400 single oleic acid ester 5-8%, non-ion PAA 0-2%, polytrimethylene polyethenoxy aether 0-3% and water.

Owner:夏建明 +1

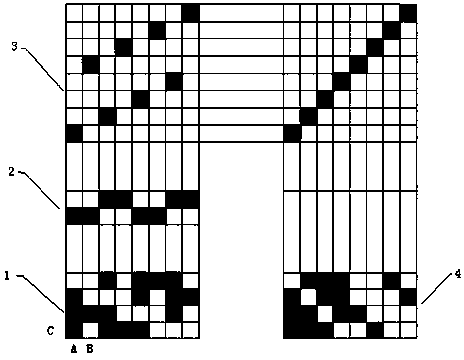

Warp backed weave double cloth weaving process

ActiveCN104278407AEasy to operatePrevent static electricityFibre treatmentMulti-ply fabricsHemp fiberSizing

The invention discloses a warp backed weave double cloth weaving process. The process comprises the following processing steps of spooling, warping, preparing size, sizing, denting, weaving and finishing. According to the process, one side, exposing JC27.8Tex+40D warp yarns, of a fabric formed by processing the JC27.8Tex+40D warp yarns and JC / H(60 / 40)21.6Tex warp yarns serves as an outer layer to ensure the stiffness and smoothness and the style keeping property of clothes, the other side exposing the JC / H(60 / 40)21.6Tex warp yarns serves as an inner layer, hemp fibers have high moisture absorption and moisture exhaust properties, the inner layer of the fabric can timely absorb and exhaust sweat of a human body and water vapor, and the wearing comfort of the clothes is improved.

Owner:JIHUA 3542 TEXTILE CO LTD

Bamboo charcoal profiled fiber and preparation method thereof

InactiveCN102154715AGuaranteed to meltGuaranteed compressionHollow filament manufactureFilament/thread formingYarnPolyester

The invention discloses bamboo charcoal profiled fiber with good product quality and low production cost, and a preparation method thereof. The fiber comprises the following components in percentage by weight: 94-99 percent of melt-spun slices, 1-6 percent of bamboo charcoal fine particles, 0.05-0.5 percent of surfactant and 0.1-1 percent of antioxidant, wherein the melt-spun slices are polyester, polyamide, polypropylene, polyethylene and modified polymers of polyester, polyamide, polypropylene and polyethylene; and the bamboo charcoal fine particles are black bamboo charcoal or white bamboo charcoal with the particle sizes of less than 2 mum. The preparation method comprises the following steps of: (1) preparing the bamboo charcoal fine particles according to a certain proportion, adding the surfactant and the antioxidant into a double-screw machine in a mixed conveying way, and directly putting the dried melt-spun slices into the hybrid double-screw machine; (2) melting and extruding the melt-spun slices in the double-screw machine, uniformly mixing the melt-spun slices with the bamboo charcoal fine particles and an aid, and conveying the mixture into a spinning box for direct spinning, by means of connection of a flange bent pipe; (3) spinning a blend melt with a spinning component from a spinneret plate, cooling, blowing and winding to obtain bamboo charcoal profiled nascent fibers; and (4) performing stretching twice and heat setting according to a continuous yarn or short yarn post-processing procedure. The invention is suitable for the bamboo charcoal profiled fiber and preparation thereof.

Owner:浙江三马锦纶科技股份有限公司

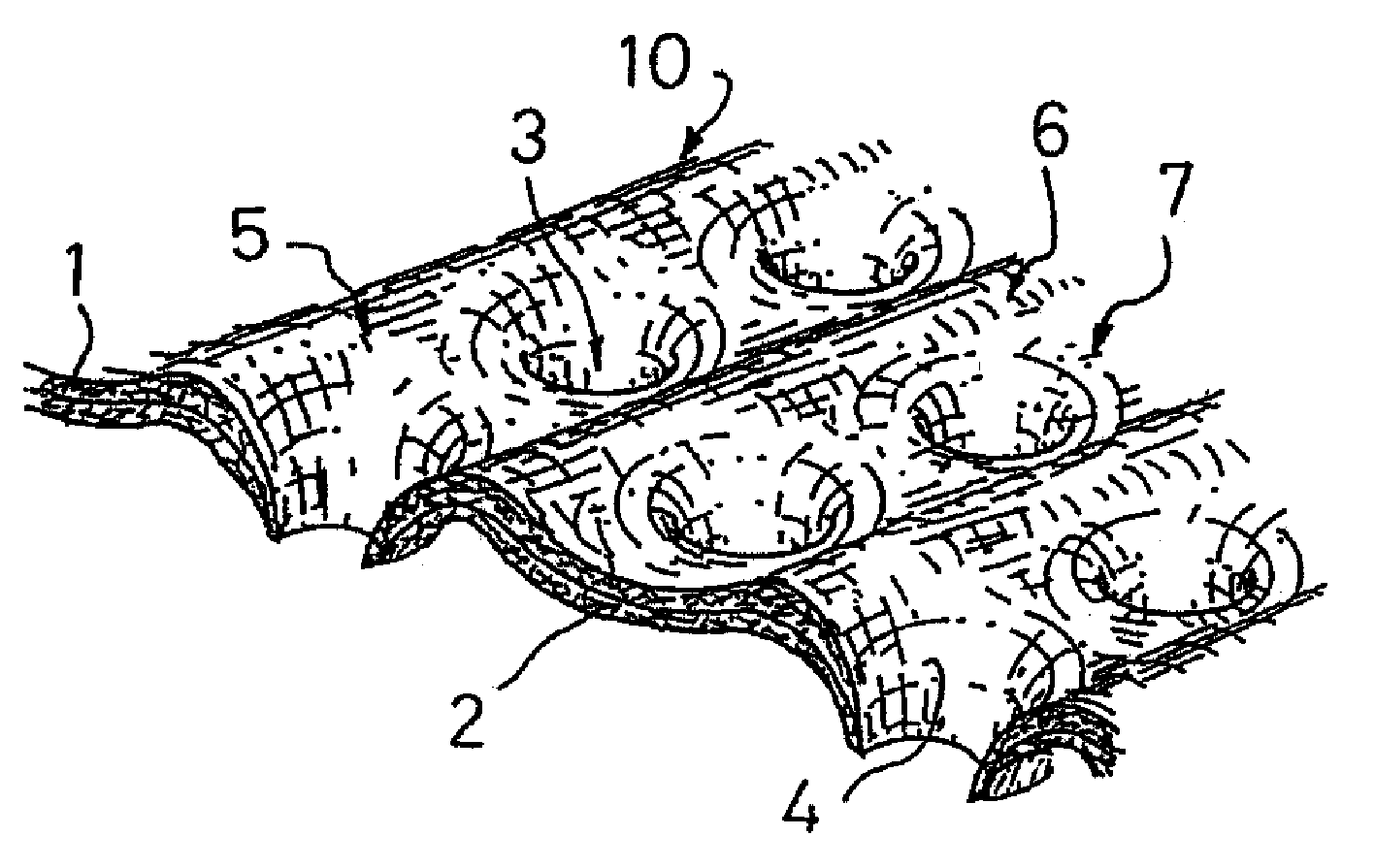

Nonwoven fabric

Nonwoven fabric (10) having a multilayer structure including first layer (1) constituting one outer layer and second layer (2) constituting the other outer layer, which nonwoven fabric (10) is comprised of split type conjugate fibers and hot melt fibers. Split type conjugate fibers are contained in an amount of 20 wt.% or less in the first layer (1) and contained in greater amount in the second layer (2). The nonwoven fabric (10) is provided with a multiplicity of openings (3). The split type conjugate fibers lying at the periphery of openings (3) have constituent resins thereof split and spaced, and the extent of splitting and spacing thereof is greater than that of split type conjugate fibers at other parts of the nonwoven fabric (10)

Owner:KAO CORP

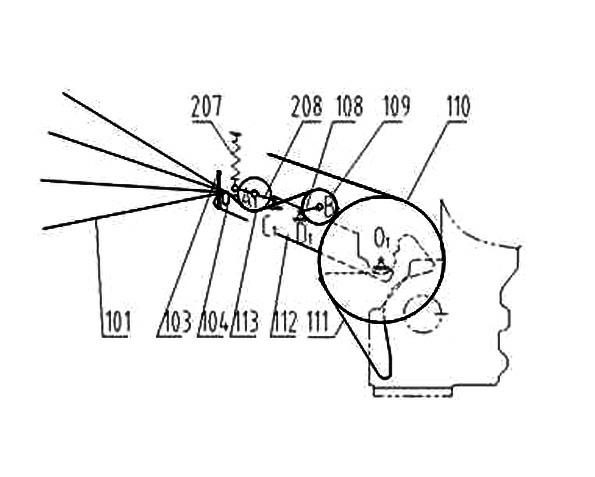

Wipe and making method thereof

PendingCN109629118ASmall fiber finenessClosely arrangedPersonal careWood layered productsFiberAdhesive

The invention discloses a wipe. Melt-blown fiber webs are arranged on the upper layer and the lower layer of the wipe, a wood pulp fiber web is arranged on the middle layer, an adhesive is attached tothe surfaces of the melt-blown fiber webs, and melt-blown fibers of the melt-blown fiber webs interpenetrate into the wood pulp fiber web. The invention further provides a making method of the wipe.The making method can be used for making the water-absorbing wipe; because the adhesive is attached to the surfaces of the melt-blown fiber webs, adhesive films are formed on the surfaces of the melt-blown fiber webs respectively, fuzzing and raising, caused by friction, of the surface melt-blown fibers are prevented in use, moreover, the situation that short wood pulp fibers on the middle layer drop out, and the picking phenomenon occurs in the using process is further prevented.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

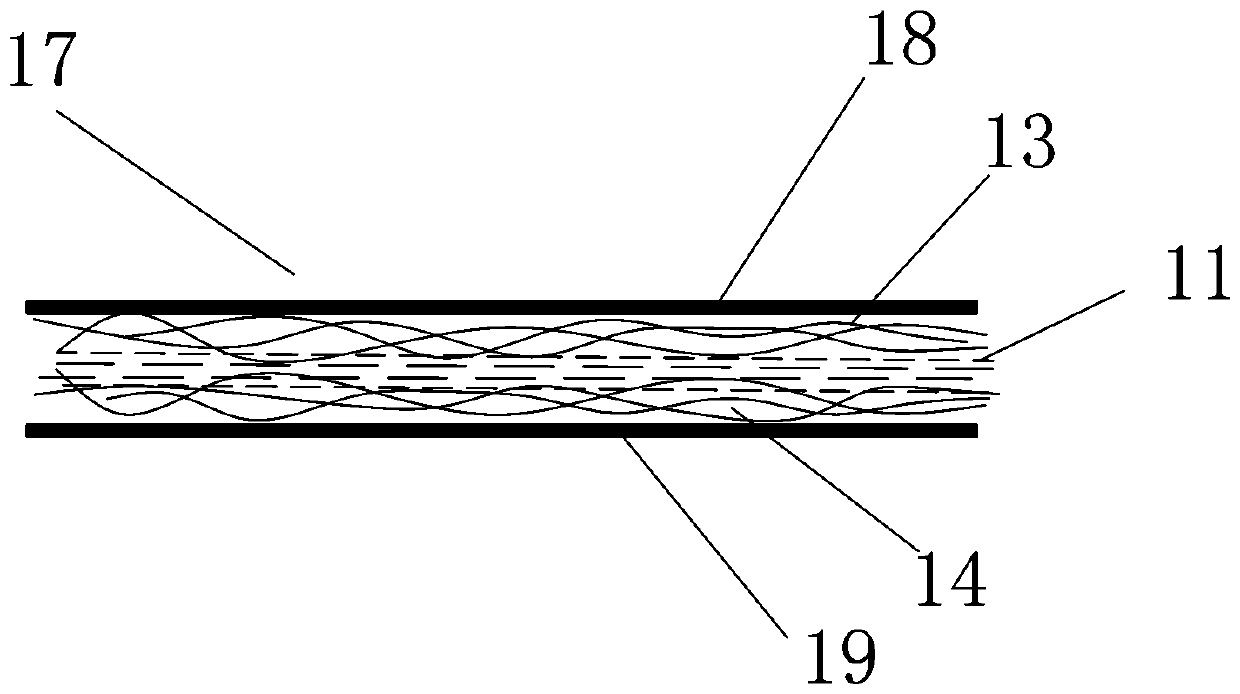

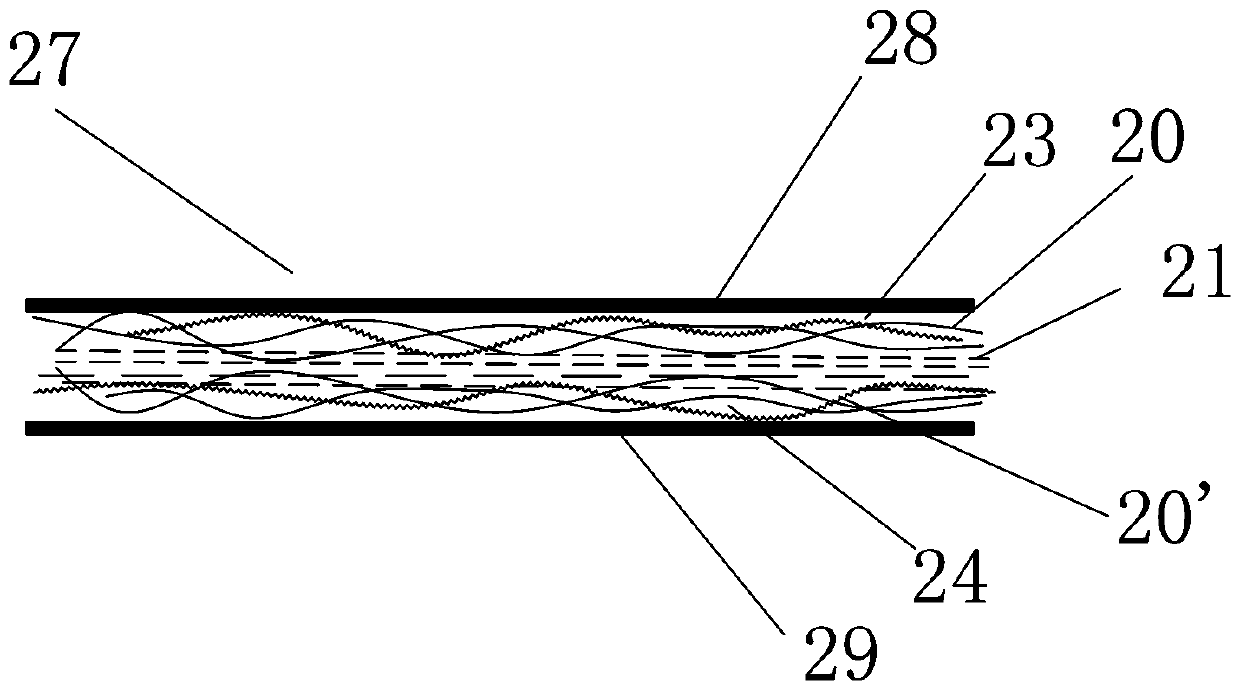

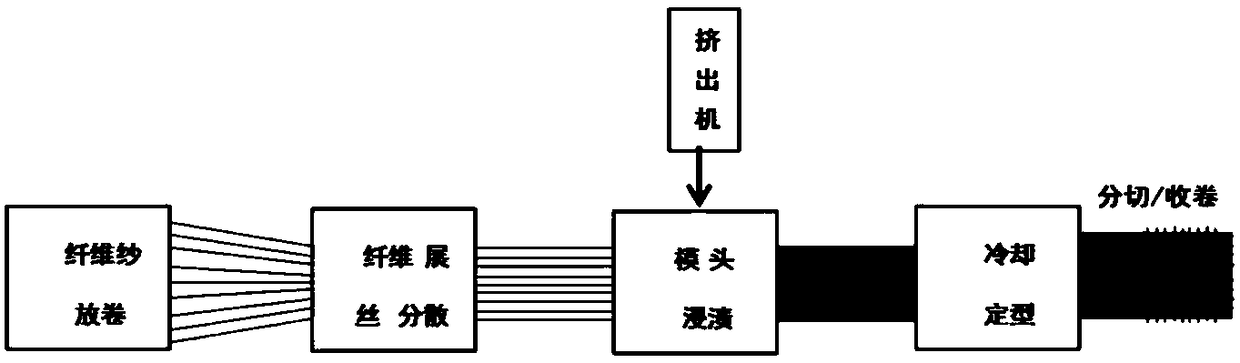

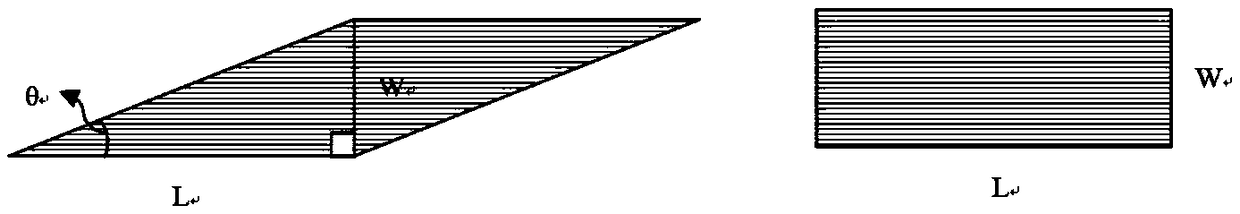

Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

The invention provides a discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and a preparation method thereof. The mold pressing precast body comprises slices formed by slitting / cutting of continuous fiber reinforced thermoplastic composite material preimpregnated sheets / preimpregnated yarns, wherein the length L range of the slices is 5-200 mm, the width W range of the slices is 2-30 mm, and the weight percentage content of fibers in the slices is 20-90 wt%; and high-strength isotropous complicated parts with high size stability can be prepared through secondary mold pressing of the precast body, so that the defects of easy warpup, fiber length loss, weaker part performances, anisotropic mechanical performances of continuous fiber reinforced composite materials and difficult machining of different-thickness complicated parts after mold pressing injection molding of short-fiber and long-fiber particles are made up.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

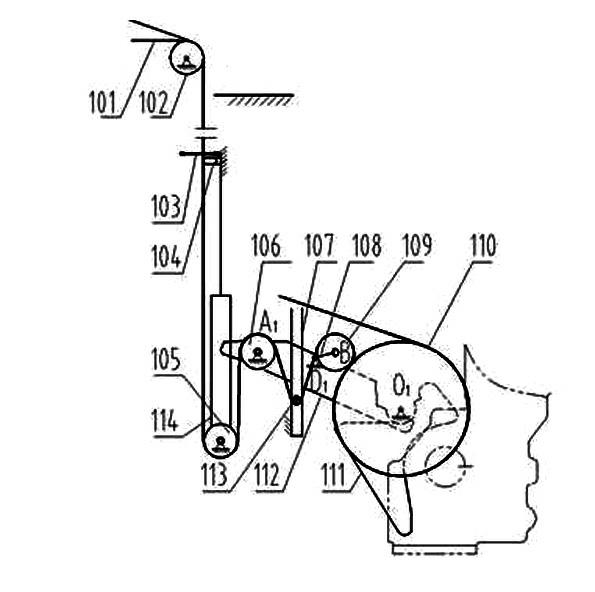

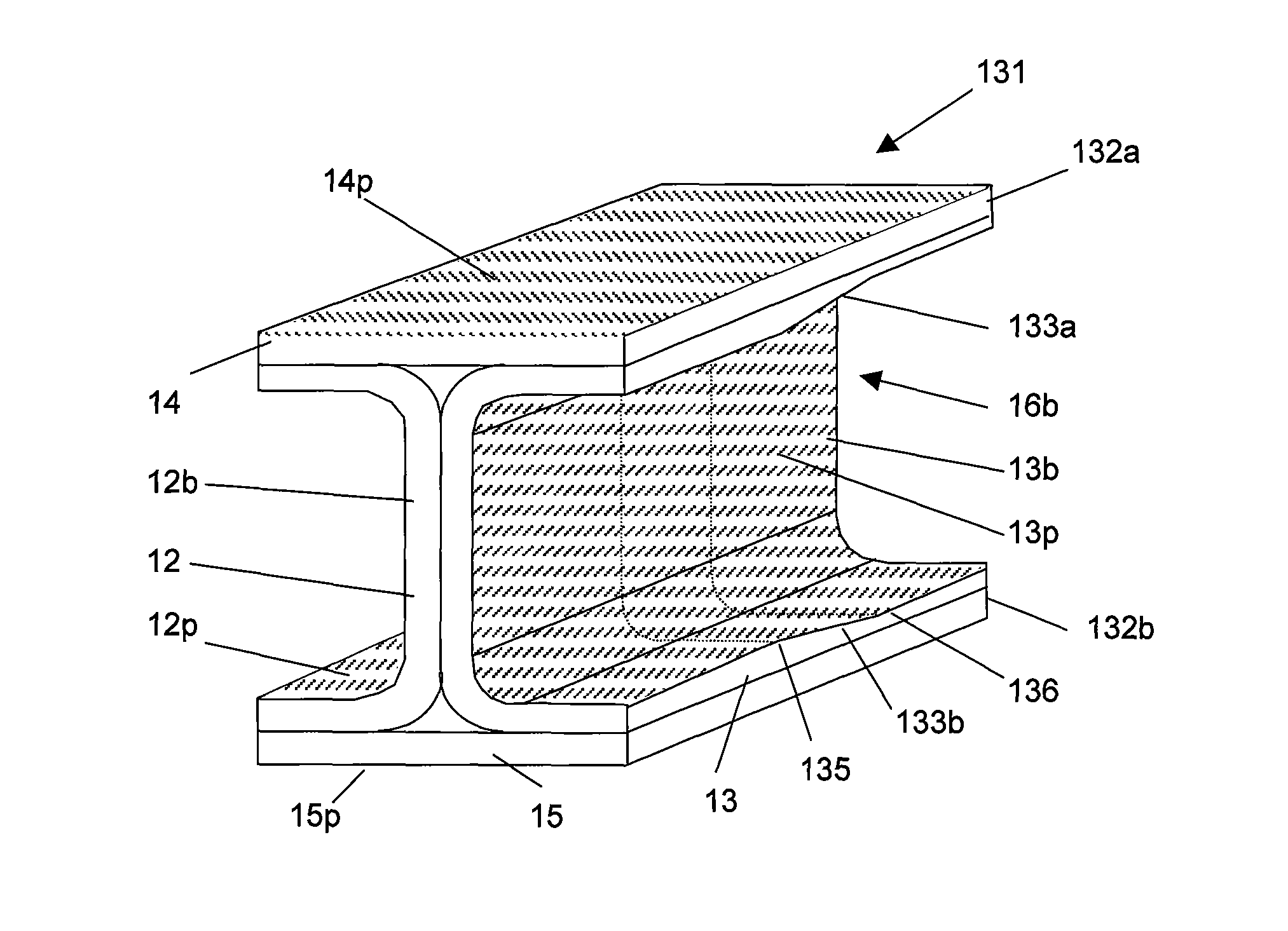

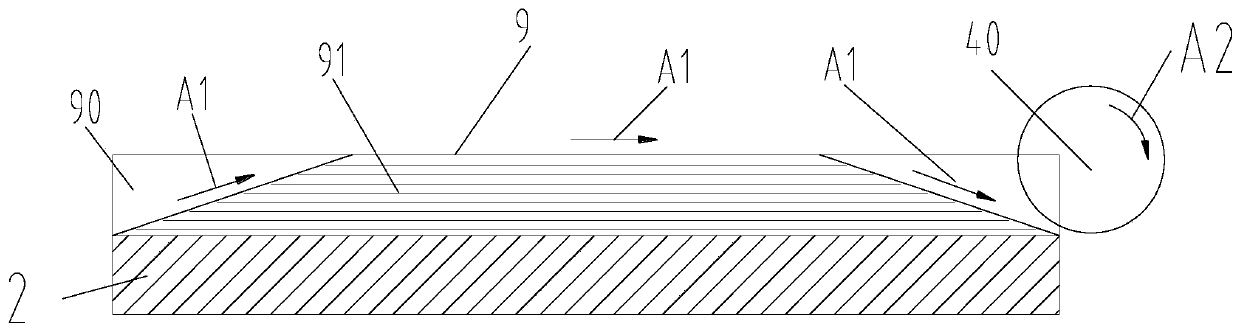

Preform for molding fiber-reinforced resin beam, process for producing the same, apparatus for producing the same, and process for producing fiber-reinforced resin beam

InactiveUS20130240150A1Work lessQuality improvementDomestic articlesThin material handlingFiber reinforcement

A preform for the molding of a fiber-reinforced resin beam, the preform comprising: a reinforcing-fiber beam which has been formed from a reinforcing-fiber base made up of many reinforcing fibers and has a cross-sectional shape comprising at least one linear part and at least one curved part connected to the linear part; and a release sheet bonded and united through an adhesive resin to at least part of a surface of the reinforcing-fiber base along the lengthwise direction for the base. A process for producing a preform comprises: a step in which a continuous flat reinforcing-fiber base having a release sheet bonded and united to a surface thereof is shaped so that the cross-sectional shape of the base comes to have a curved part to thereby produce a preshaped object; and a preshaped-object uniting step in which the preshaped object is bonded and united to another preshaped object.

Owner:TORAY IND INC

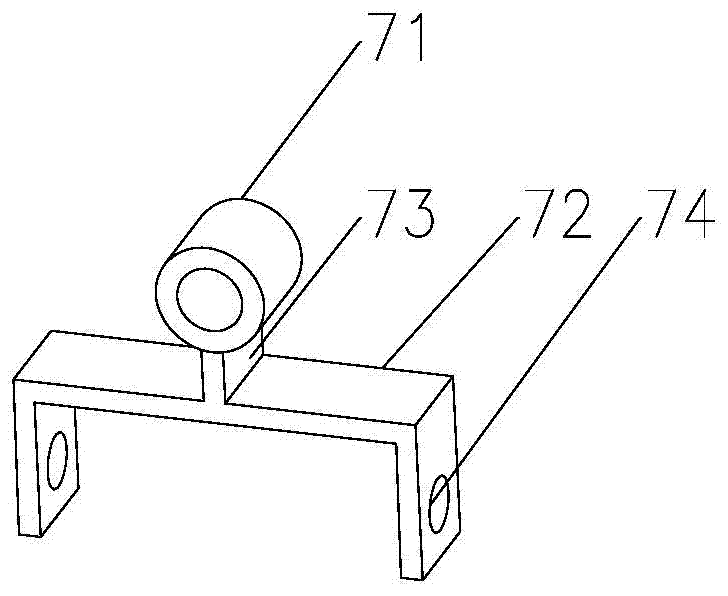

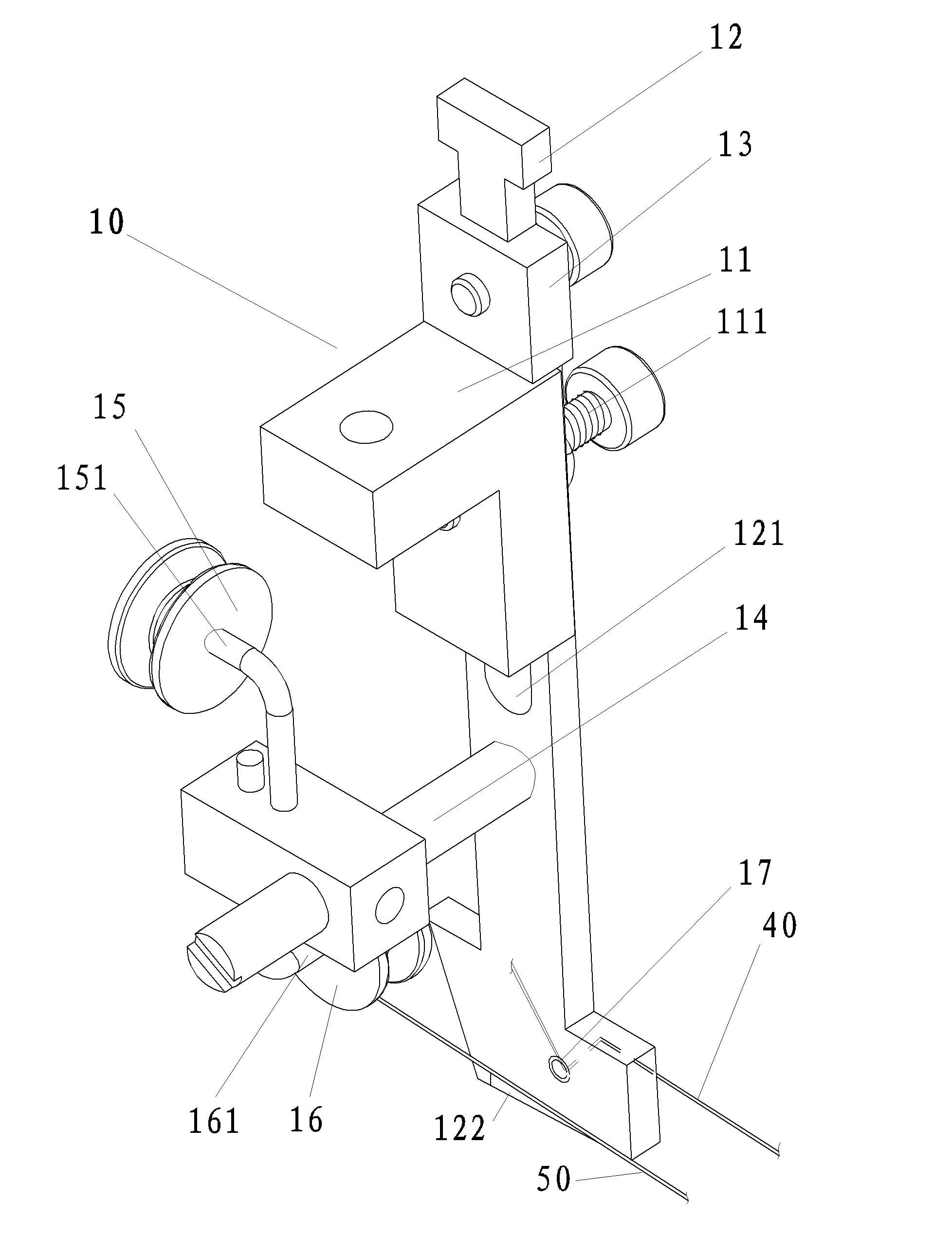

Warp knitting machine creel

InactiveCN103696117AImprove continuous working timeIncreased durabilityWarp knittingGlass fiberPolyether ether ketone

The invention relates to a warp knitting machine creel, comprising supports, wherein a plurality of groups of yarn guide plates are fixed between the supports; a plurality of yarn guide holes are formed in the yarn guide plates; cylindrical tension adjusting cross beams are arranged above cross beams; each group of yarn guide plates correspond to one tension adjusting cross beam; a tension adjuster is arranged on each tension adjusting cross beam in a sliding way and can rotate around the corresponding cross beam. According to the warp knitting machine creel, a whole glass fiber yarn drum is placed under the creel in a supporting way, the continuous working duration of a warp knitting machine is increased, the carry times of the yarn drum are greatly reduced, the labor intensity is greatly reduced, the yarn guide is stable, the production efficiency is improved, a wear-proof casing which is made of polyether-ether-ketone resin is adopted, the condition that the intensity of yarns is reduced due to the friction is prevented, the fuzzing of the yarns is effectively prevented, and the durability of the creel is improved.

Owner:JIANGSU CTC TECHN FABRICS

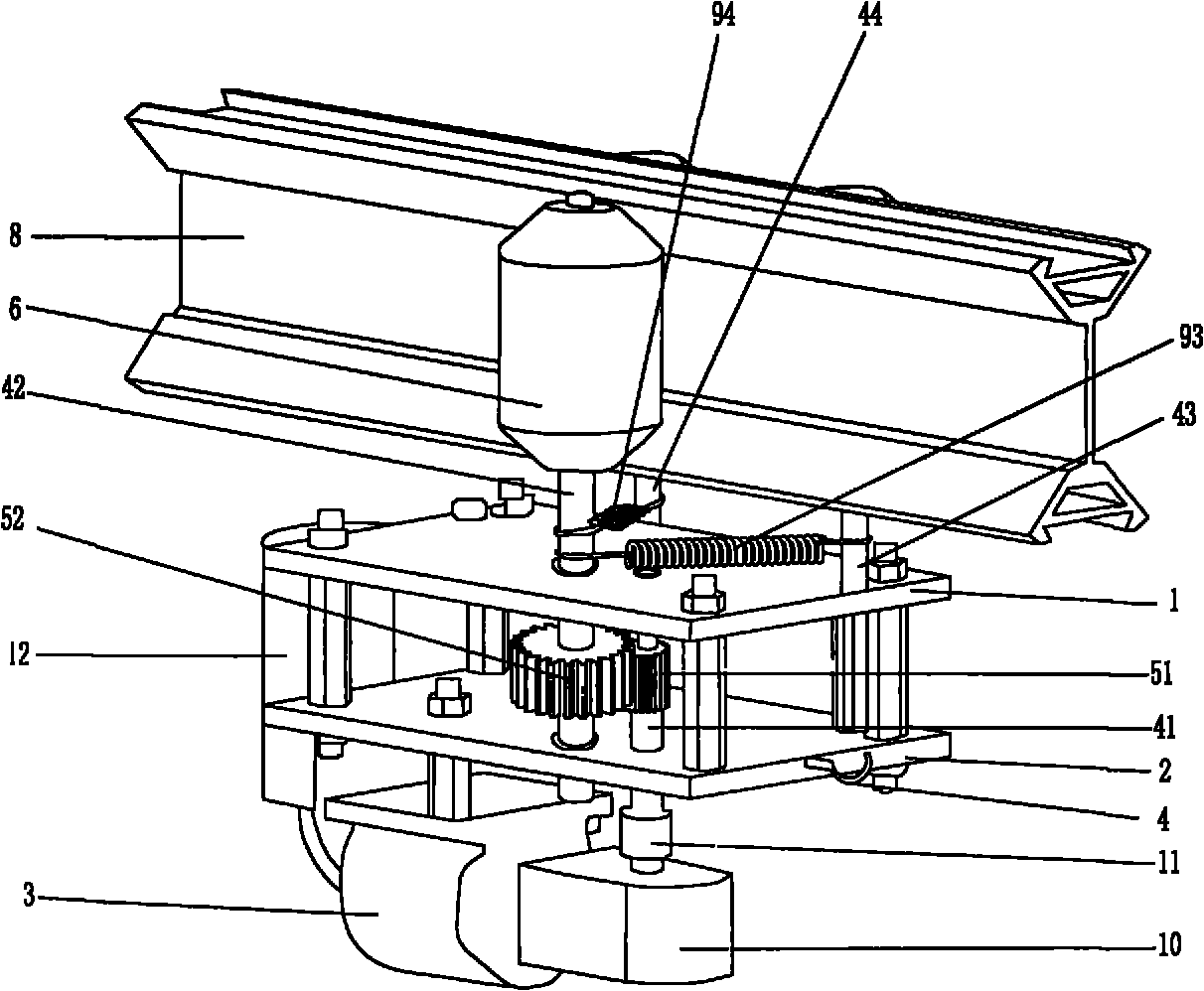

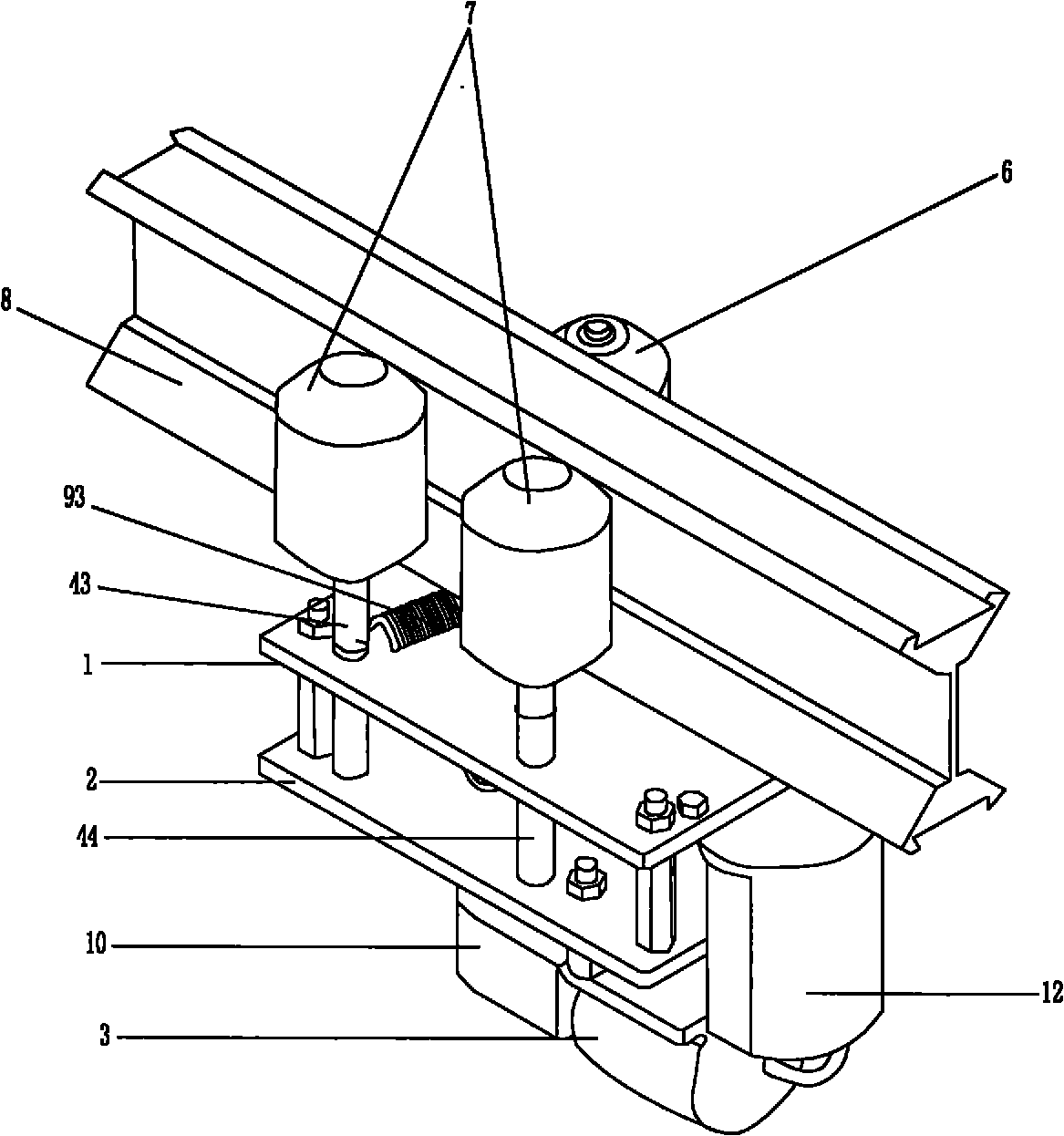

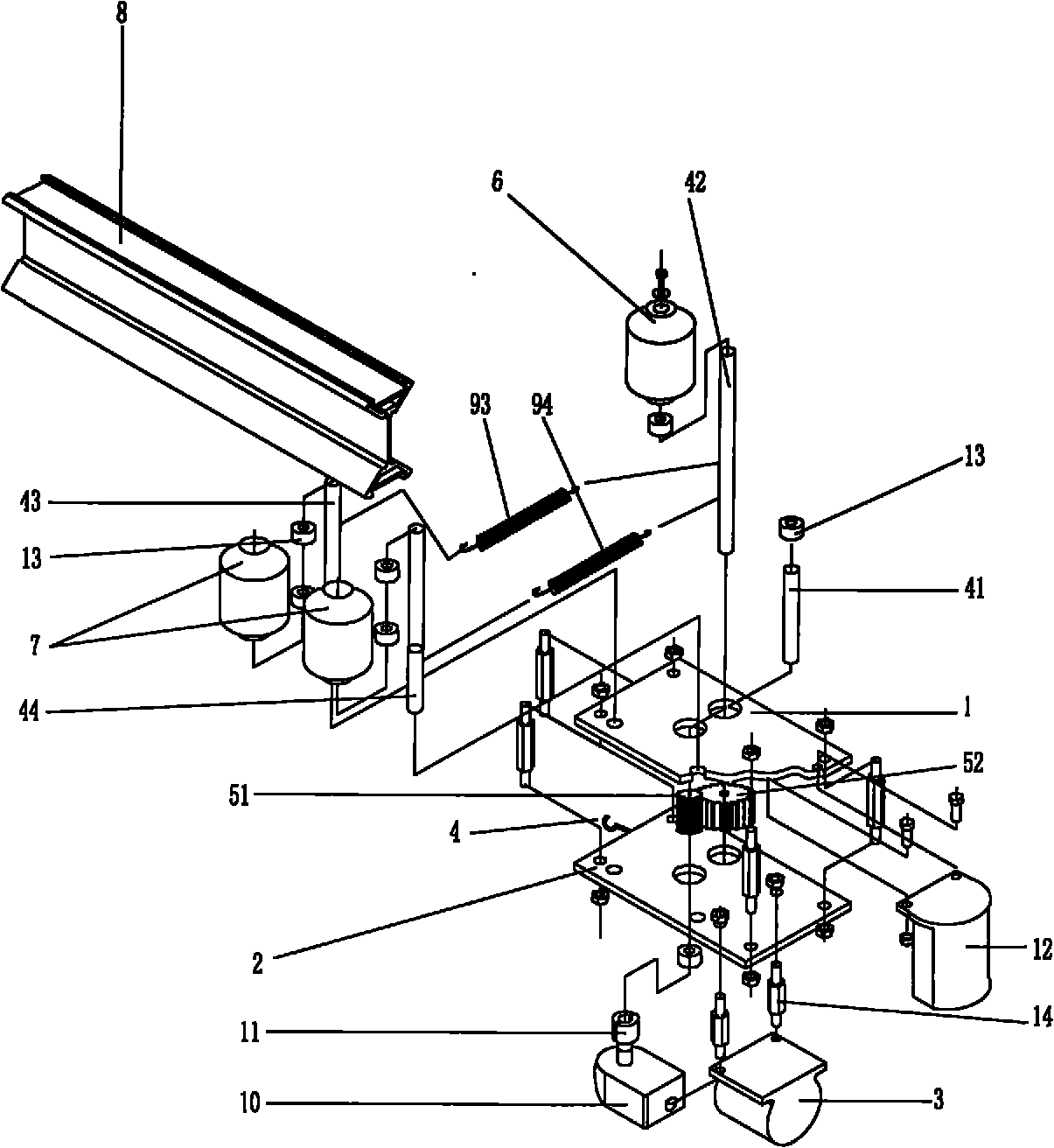

Rough yarn conveying device

InactiveCN102001516AAvoid shipments to the wrong production stationAvoiding wrong production station situationsMechanical conveyorsYarnDrive shaft

The invention relates to a rough yarn conveying device. The device comprises an upper frame plate, a lower frame plate, a motor, a transmission mechanism, a rail and eccentric auxiliary shafts, wherein the upper frame plate and the lower frame plate are fixedly connected through a connecting column; the motor is arranged on the bottom surface of the lower frame plate; the transmission mechanism is connected with the motor and comprises a driving transmission shaft, a driven transmission shaft, and a driving gear and a driven gear which are positioned between the upper frame plate and the lower frame plate; the lower end of the driving transmission shaft passes through the lower frame plate and is connected with the motor, and the upper end of the driving transmission shaft passes through the driving gear and is fixedly connected with the driving gear; the lower end of the driven transmission shaft movably passes through the lower frame plate, and the upper end of the driven transmission shaft passes through the upper frame plate; the driven gear is fixedly sleeved on the driven transmission shaft; the top end of the driven transmission shaft is fixedly provided with a driving wheel; the eccentric auxiliary shafts pass through the upper frame plate and the lower frame plate respectively, and the top ends of the eccentric auxiliary shafts are fixedly provided with auxiliary wheels; and the rail is arranged above the upper frame plate, connected with the transmission mechanism and hung between the driving wheel and the auxiliary wheels. The rough yarn conveying device reduces labor intensity and optimizes the quality of finished products.

Owner:ZHONGHUA GRP

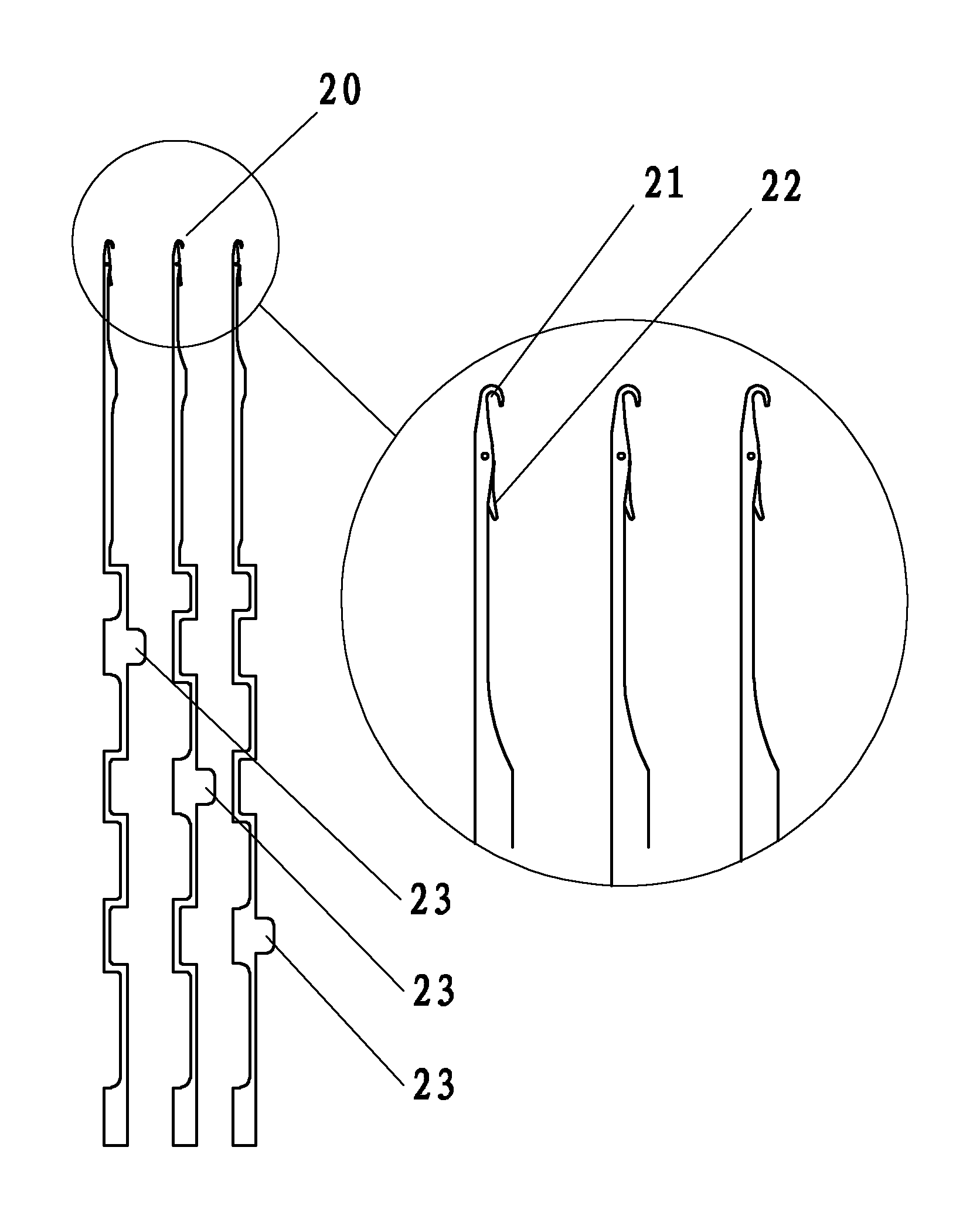

Novel overcoat lint machine

InactiveCN102182001AReduce frictional resistanceClear clothCircular knitting machinesBiomedical engineeringNeedle track

The invention discloses a novel overcoat lint machine comprising a needle cylinder capable of rotating around the axis. A needle groove extending along the axial direction is arranged on the outer cylinder wall of the needle cylinder, a knitting needle capable of sliding is arranged in the needle groove, a plurality of triangular blocks are arranged around the needle cylinder, and a needle track capable of sliding up and down by matching with the knitting needle is arranged on each triangular block, wherein the stroke between the highest ascending point and the lowest descending point of the needle track is 12-13cm, the length of a needle latch of the knitting needle is 7mm, and the diameter of the needle cylinder is 34' and 28G / inch. The novel overcoat lint machine can weave high-densityovercoat lint, and the lint pattern is clear and smooth.

Owner:福建台帆实业有限公司

Internal warp uniformizing system suitable for fiberglass yarn weaving

An internal warp uniformizing system suitable for fiberglass yarn weaving comprises a lease reed, a warp uniformizing mechanism and an imitation warp beam. The lease reed allows a warp unwound from a creel to pass through. The warp uniformizing mechanism mainly comprises a tension roller, a warp beam pressure roller and a warp one-way limiting roller or an intermediate transitional roller. The imitation warp beam is capable of driving the warp to enter a weaving area to be woven. The warp uniformizing mechanism is fixed on a slanting support plate fixedly connected with a loom wallboard. The warp beam pressure roller is connected with a pressure roller support arm through a rolling bearing. The pressure roller support arm is fixed on the slanting support plate through a bearing. The warp beam pressure roller contently contacts with the imitation warp beam under the action of warp tension and dead weight. The slanting support plate is fixed on a warp beam bracket fixedly connected with the loom wallboard. The internal warp uniformizing system has the advantages that the system is simple in structure and convenient and reliable in use, the contact procedure of fiberglass with mechanical parts can be omitted so as to prevent fiberglass fluffing as far as possible, and the like.

Owner:浙江万利纺织机械有限公司

Die cutting device for porous ultrathin single-sided adhesive tape

The invention relates to a die cutting device for porous ultrathin single-sided adhesive tape. The die cutting device comprises a first die cutting unit and a second die cutting unit which are sequentially arranged in the moving direction of a single-sided adhesive tape material strap, and waste discharging adhesive tape is arranged on the lower surface of the single-sided adhesive tape material strap. The first die cutting unit comprises a circular knife die cutting mechanism and a first waste discharging mechanism which are sequentially arranged in the moving direction of the single-sided adhesive tape material strap, and the second die cutting unit comprises a flat knife die cutting mechanism and a second waste discharging mechanism which are sequentially arranged in the moving direction of the single-sided adhesive tape material strap. The single-sided adhesive tape material strap is perforated through the first die cutting unit and then subjected to punching forming in the seconddie cutting unit. Compared with the prior art, the die cutting device for the porous ultrathin single-sided adhesive tape is advantageous in that in the die cutting process of circular holes, a flat knife punching mode is changed into a circular knife punching mode, so that the broken filament phenomenon occurring during die cutting is effectively avoided, meanwhile, continuous and automatic wastedischarging is achieved, complicated steps of intermittent waste discharging at regular intervals are avoided, working efficiency is greatly improved, labor cost is lowered, the die cutting speed canbe changed, and product quality is good.

Owner:上海昊佰智造精密电子股份有限公司

Anti-fuzzing and anti-pilling polyester sportswear fabric and preparation method thereof

InactiveCN112941699AGood anti-pillingCohesion is smallGrip property fibresAbrasion resistant fibresPolyesterFiber

The invention discloses an anti-fuzzing and anti-pilling polyester sportswear fabric. The polyester sportswear fabric is formed by weaving warp yarns and weft yarns; both the warp yarns and the weft yarns contain anti-fuzzing and anti-pilling polyester fibers; and the anti-fuzzing and anti-pilling polyester fibers are obtained by sequentially modifying polyester fibers with anthocyanin and camphorsulfonic acid. A preparation method of the anti-fuzzing and anti-pilling polyester fibers comprises the following steps of 1, adding the polyester fibers into alkali liquor for soaking and washing to obtain porous polyester fibers; 2, performing grafting treatment on the porous polyester fibers and the anthocyanin to obtain glycosidated porous polyester fibers; and 3, carrying out binding reaction on the glycosidated porous polyester fibers and the camphorsulfonic acid to obtain the anti-fuzzing and anti-pilling polyester fibers. By modifying the polyester fibers, the cohesive force between the polyester fibers and the flexibility of the polyester fibers are increased, so that the polyester fibers are not prone to scratching the surface of the fabric, and the effect of avoiding fuzzing and pilling is achieved.

Owner:宁波共振运动科技有限公司

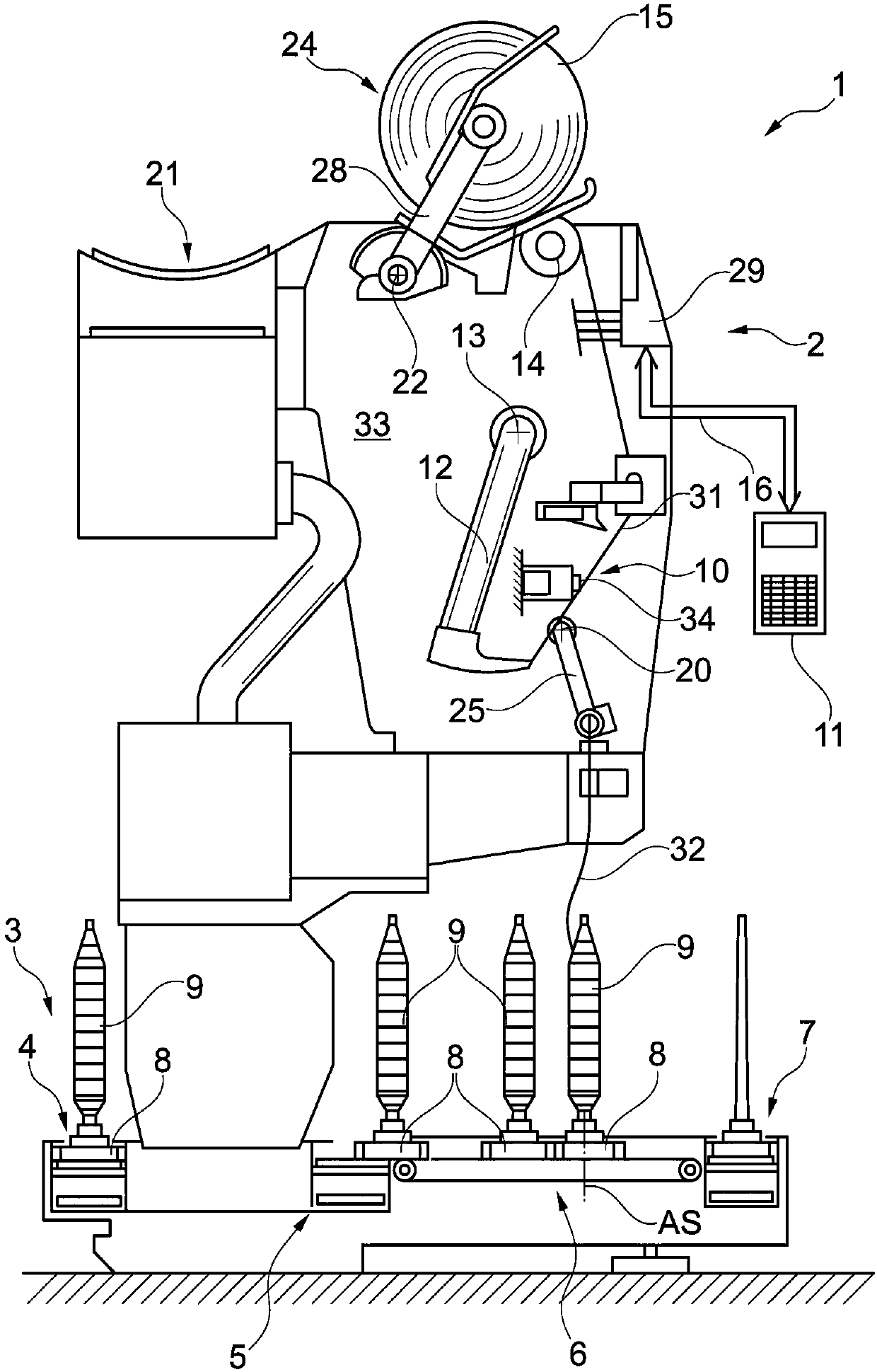

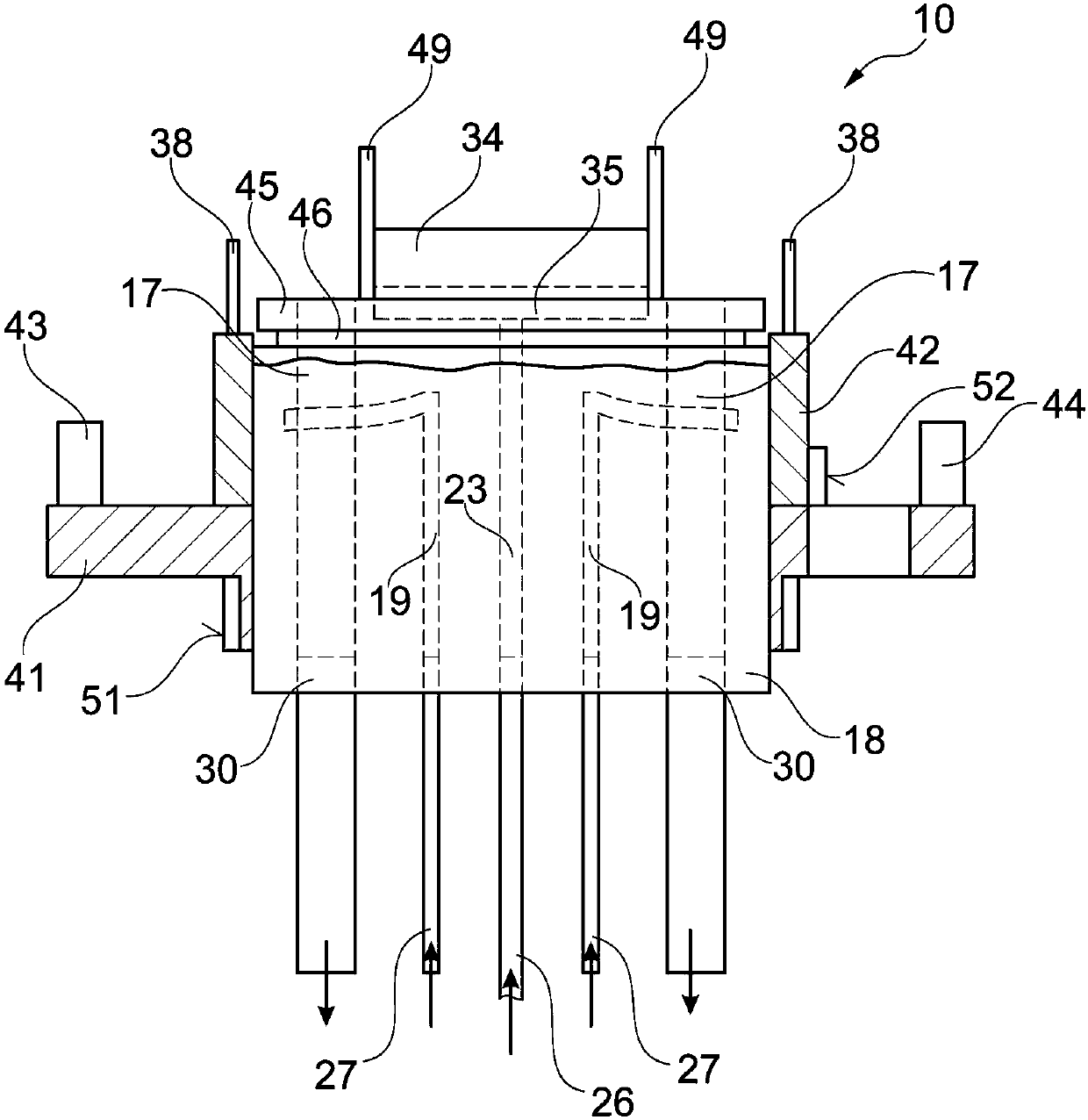

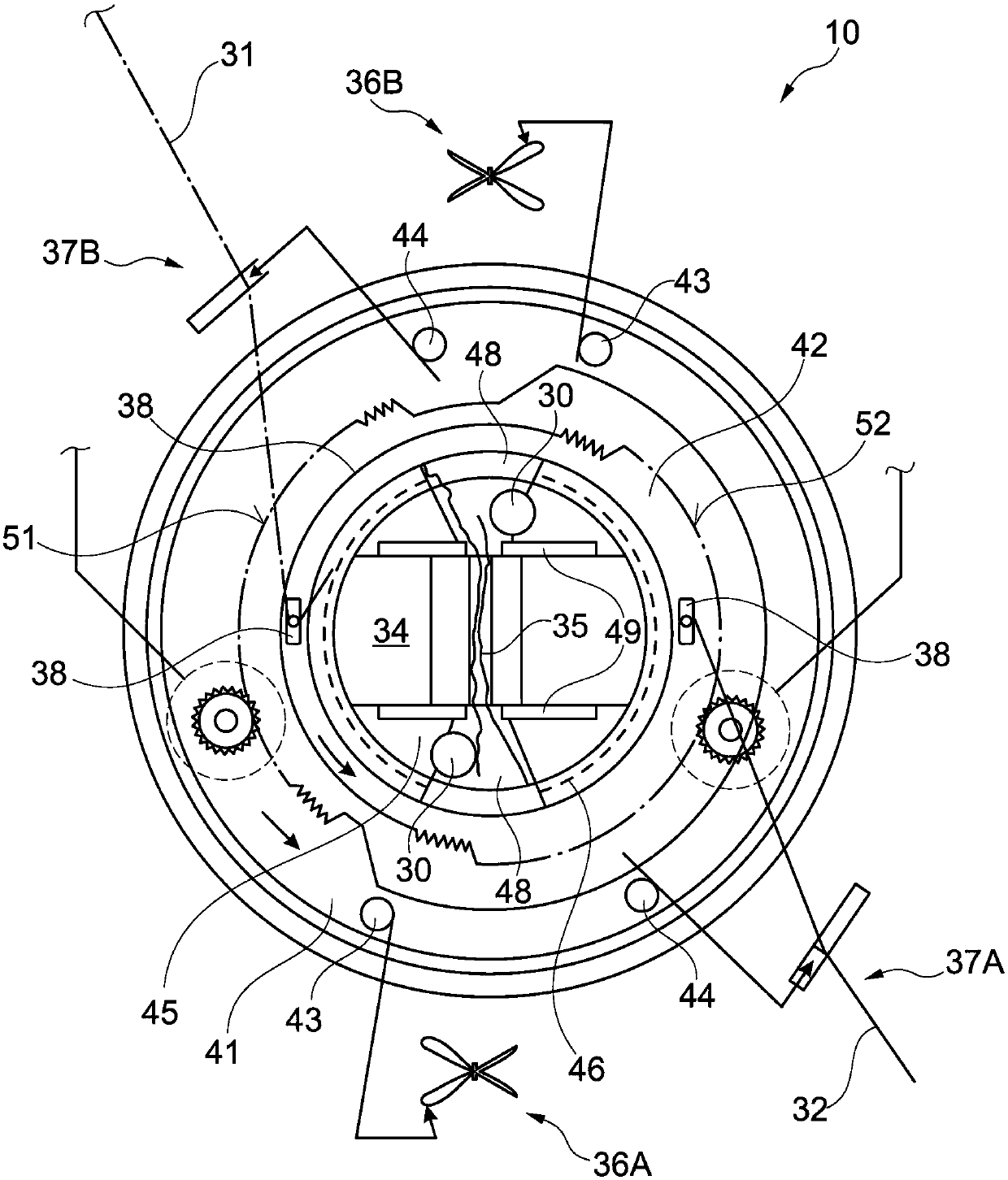

Yarn splicing device for a workstation of a textile machine producing cross-wound bobbins

The invention relates to a yarn splicing device (10) for a workstation (2) of a textile machine (1) producing cross-wound bobbins. The yarn splicing device (10) includes a yarn splicing prismoid (34)and a yarn feeder (38), wherein the yarn splicing prismoid (34) is fastened to an air distributor (18) and is provided with a yarn receiving channel (35) which can receive compressed air. The yarn feeder is arranged at a distance from the yarn splicing prismoid (34) and is limited-rotatably installed. According to the invention, there is a yarn guiding trough (46) for receiving yarn headers of upper yarns (31) and lower yarns (32) in the zone of the yarn splicing prismoid (34). A tunnel outlet (48) is arranged at each outlet side of the yarn receiving channel (35) of the yarn splicing prismoid(34). Each outlet (48) is provided with an accommodating hole (30) which is used for holding an opening small tube (17).

Owner:SAURER GERMANY GMBH & CO KG

Method for modifying fibers

A method for modifying fibers is provided, which method comprises suspending and dispersing in water under shear force a cellulose ether having such a low degree of substitution that a molar degree of substitution with an alkyl group and / or a hydroxyalkyl group ranges from 0.05 to 1.3, applying the resulting dispersion and a crosslinking agent or an aqueous resin emulsion to fibers, and thermally treating the applied fibers.

Owner:AICHI PREFECTURE +2

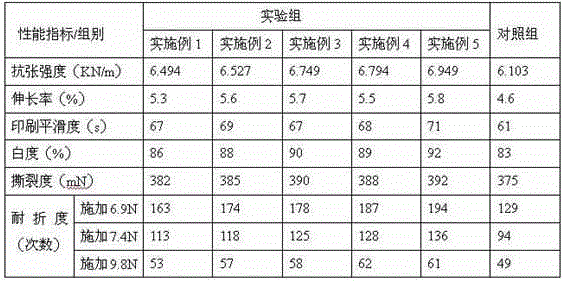

Papermaking auxiliary agent and production method thereof

InactiveCN105862504ASimple processGood dispersionNon-macromolecular organic additionWax additionFolding endurancePolyethylene glycol

The invention discloses a papermaking auxiliary agent. The papermaking auxiliary agent is prepared from the following main raw materials in parts by weight: 10-16 parts of carboxymethyl chitosan, 6-10 parts of polyacrylamide, 12-16 parts of talcum powder, 8-18 parts of quartz powder, 3-5 parts of polyethylene glycol, 1-4 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 2-5 parts of alkylphenol ethoxylates, 1-4 parts of polyoxypropylene glycerol ether, 1-2 parts of sodium benzoate, 2-4 parts of vegetable wax oil, 1-2 parts of ammonium sulfate, 2-3 parts of disodium hydrogen phosphate and 3-6 parts of lactitol. The papermaking auxiliary agent disclosed by the invention adopts a simple process flow; and bad foams in a preparation process of paper pulp can be eliminated and the pulp is dispersed very well, so that paper sheets have very good tensile strength, elongation percentage, printing smoothness, whiteness, tearing strength and folding endurance.

Owner:商孝霞

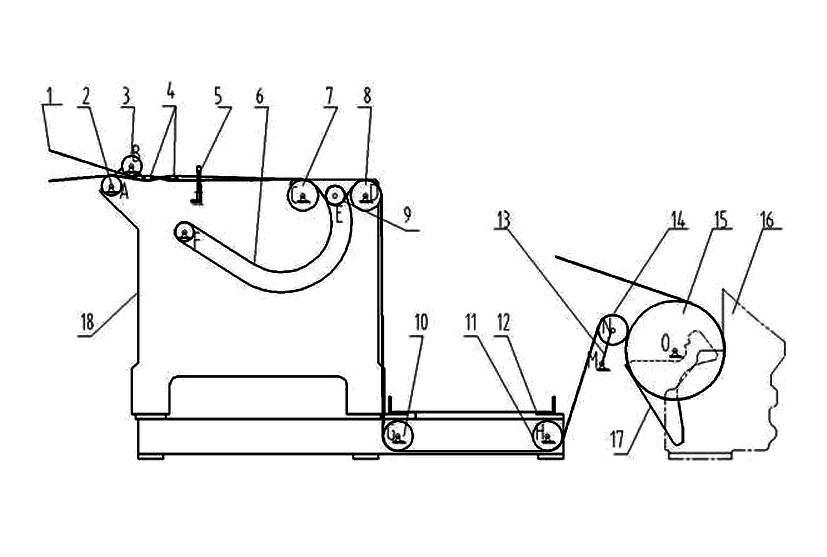

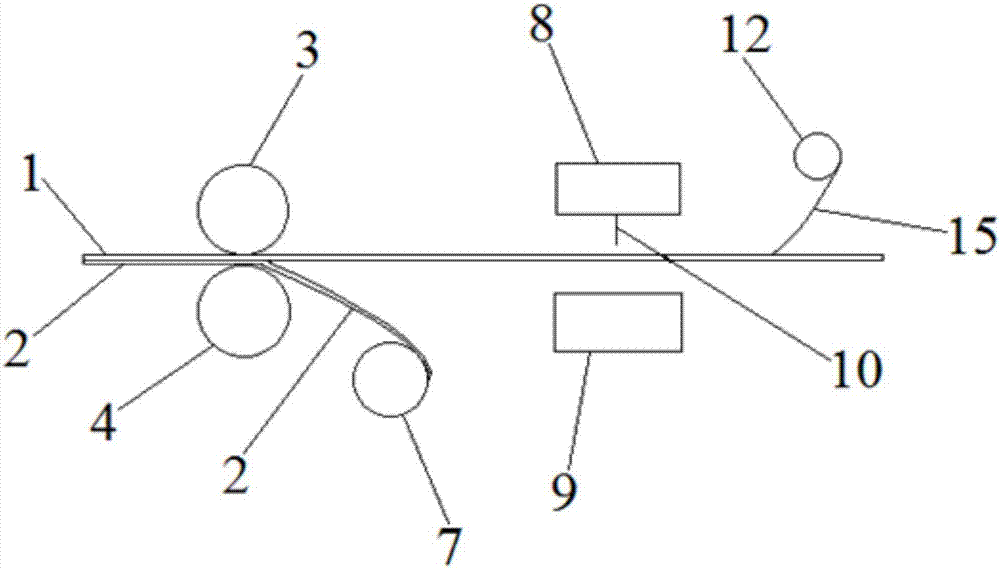

Process for producing carbon fibers with less damage

InactiveCN110499551AAvoid fuzzImprove production qualityTextile treatment carriersArtificial filament chemical after-treatmentSizingSurface finishing

The invention discloses a process for producing carbon fibers with less damage. The process comprises the following steps of a, unwinding of filaments and collection of lines, wherein raw filaments are selected, and new filaments and old filaments are connected through heat-resistant fibers after bundle separation and erected on a line collecting plate; b, initial drying, wherein the line collecting plate and the raw filaments are conveyed into a drying device for drying to remove moisture contained in the raw filaments; c, pre-oxidation, wherein the dried raw filaments are fed into three pre-oxidation ovens arranged continuously for pre-oxidation; d, carbonization; e, surface treatment; f, sizing; g, filament collection. The process has the advantages that by adopting yarn expanding equipment adjustable in height in a sizing process and adjusting the height of yarn expanding fixed rollers, the tension of yarn can be adjusted, so that the stress of the carbon fibers is released, the carbon fibers are protected from fuzzing, damage and twisting, and therefore the production quality of the carbon fibers is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

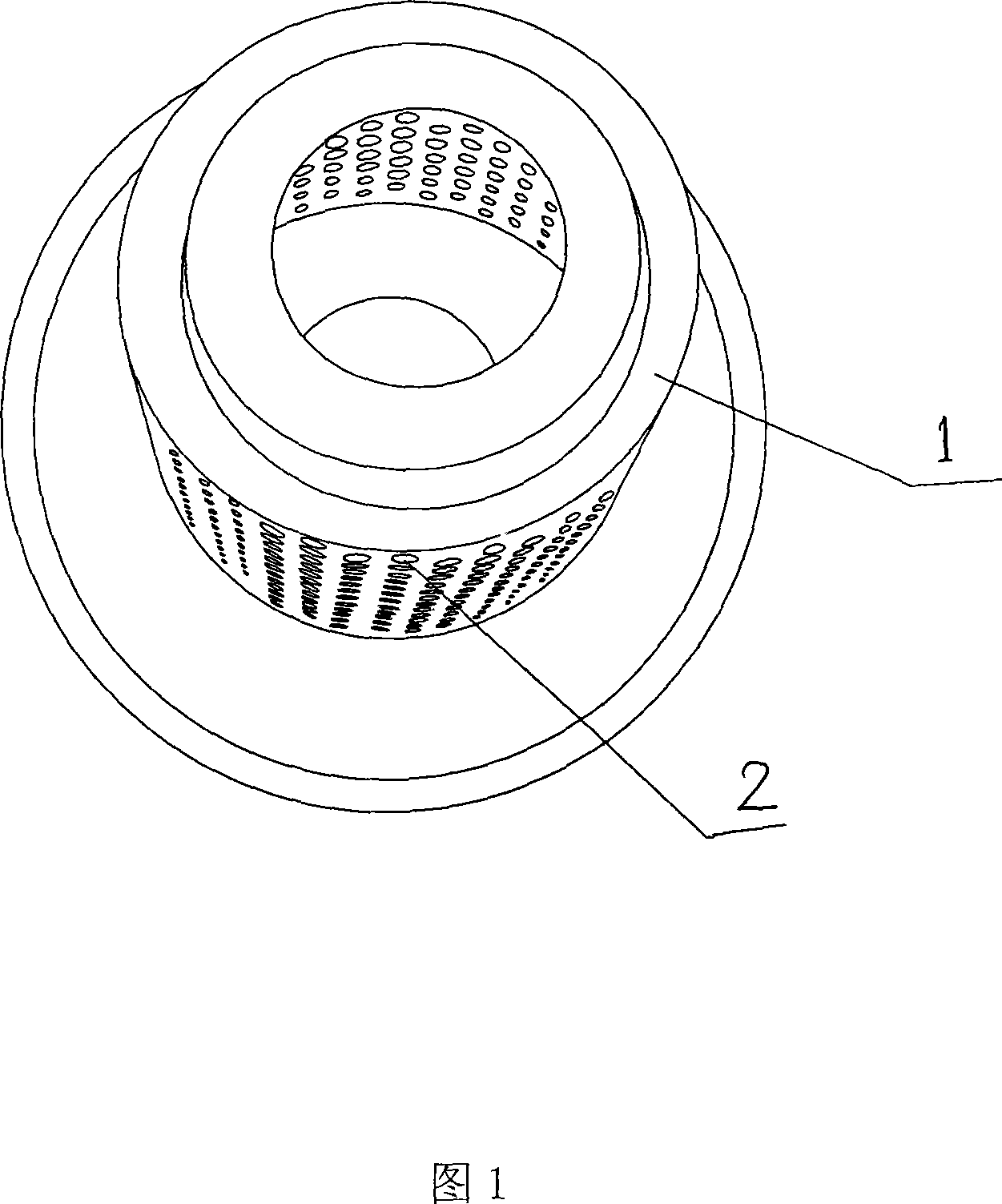

Chemical fibers dyeing technique

InactiveCN101144234APrevent fuzz and lossImprove product qualityFibre treatmentTextile treatment carriersElectricityDyeing

The present invention discloses a chemical fiber dyeing new process. The present invention has the process procedure that ring filament produced by a chemical fiber factory is directly filled in a dyeing and filling device, and then the ring filament is delivered in a dyejigger to perform refining, dyeing and post collation, at last, the ring filament is taken out for dewatering, drying and winding, the selected ring filament comforts to the following conditions: the height is not larger than 120 millimeter, the external diameter is not larger than 175 millimeter, the internal diameter is not smaller than 110 millimeter, and the weight of the single ring filament is 540-750 g. The present invention greatly reduces the consumption of a color and an additive compared with the working procedures of a traditional loose barrel, a skeining and a turn-over yarn, the water, the electricity and the vapor are saved, and the waste water effluent is decreased.

Owner:平湖市心缘贸易有限公司

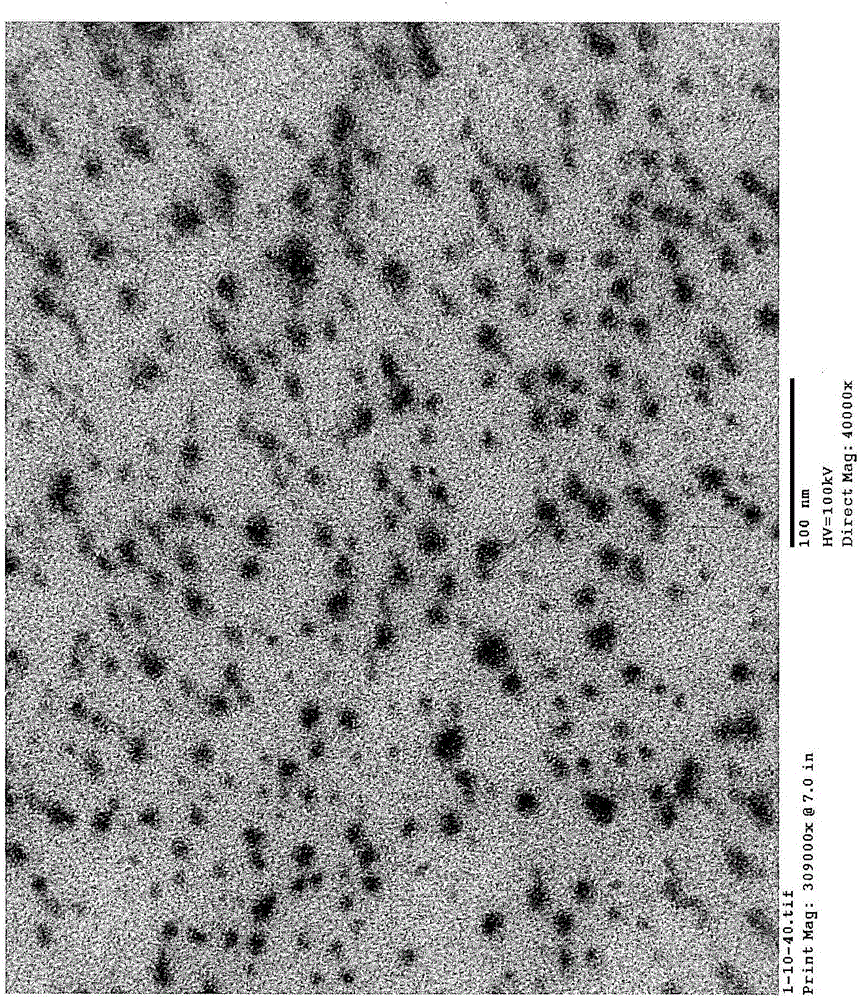

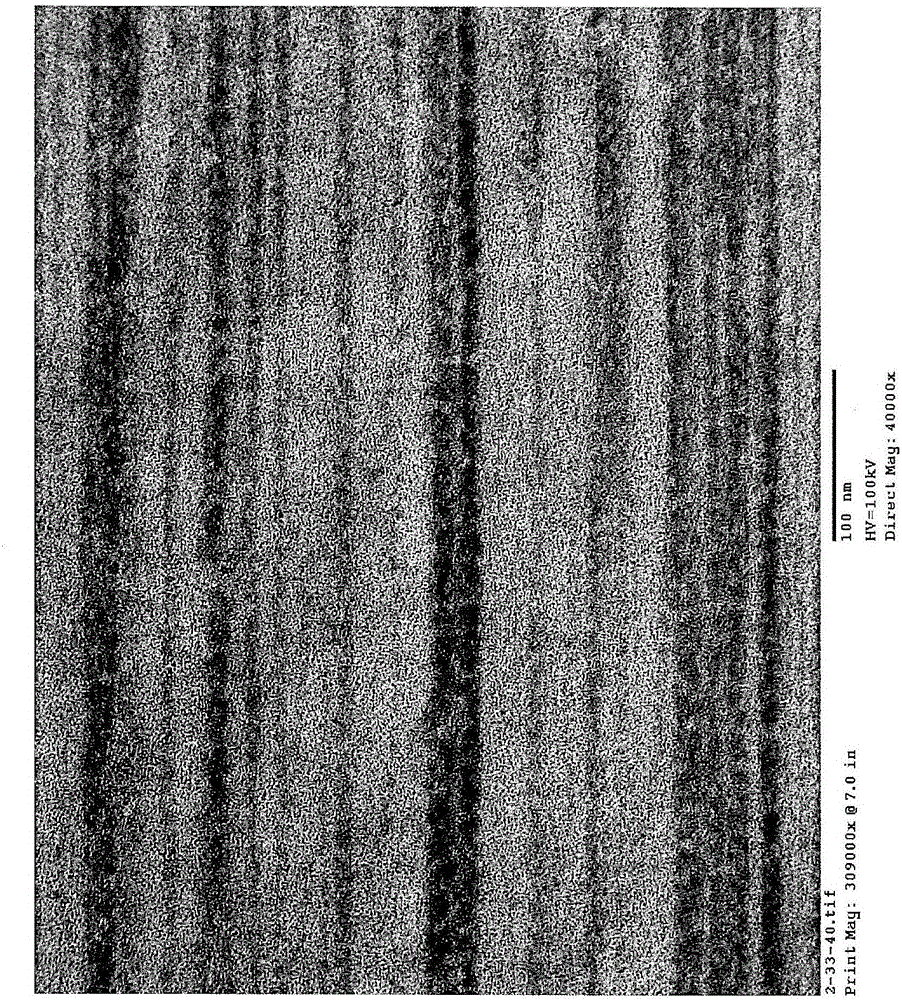

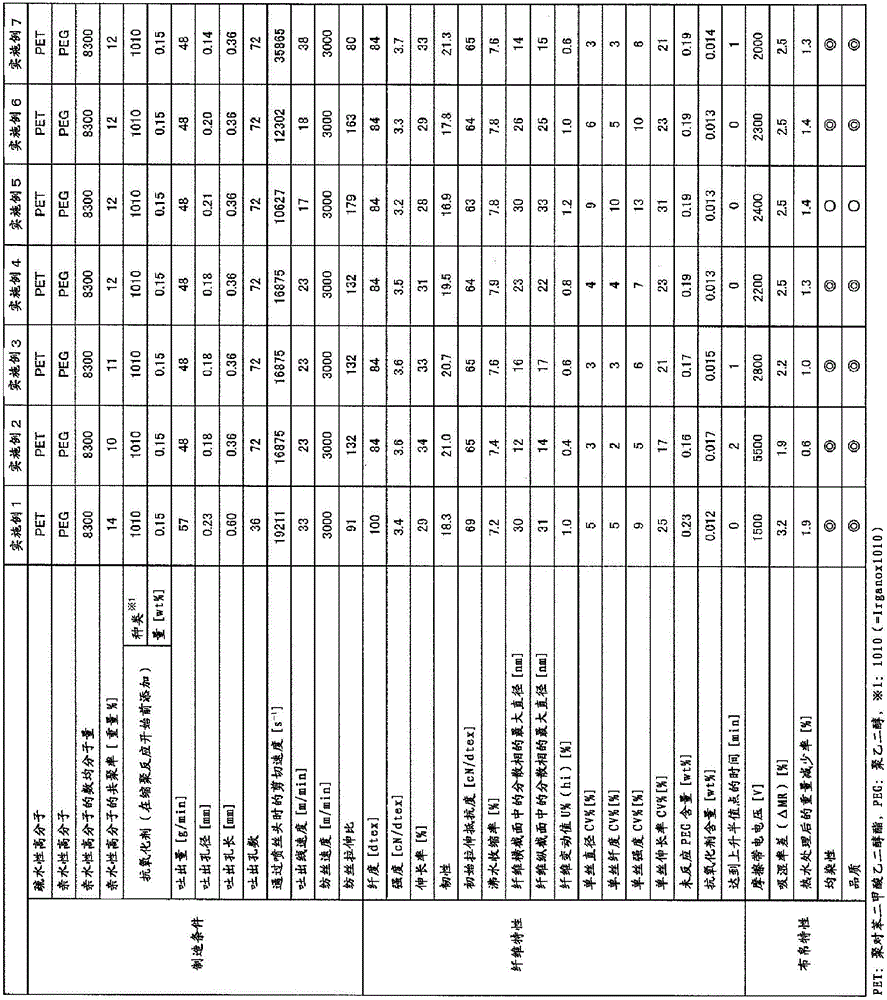

Fiber having phase separation structure and manufacturing method for such fiber

ActiveCN106164349AUneven finenessSuppression of uneven stainingElectroconductive/antistatic filament manufactureMonocomponent polyetheresters artificial filamentFiberElectricity

The problem addressed by the present invention is to provide a fiber for which, despite having a phase separation structure, unevenness in fineness is small, dyeing unevenness and nap are suppressed, the durability of fiber characteristics with respect to long term storage and tumble drying are excellent, moisture absorption characteristics are excellent, anti-electricity characteristics in low temperature and low humidity environments are excellent, and elution of a hydrophilic compound when dyeing or using the fiber is suppressed. Provided is a fiber having a phase separation structure. The fiber is characterized by the following: comprising a copolymer of a hydrophobic polymer and a hydrophilic polymer; having a continuous phase and a dispersed phase according to a phase separation structure; the dispersed-phase maximum diameter in a fiber transverse cross-section being 1-40nm; and the fineness fluctuation value U%(hi) being 0.1-1.5%.

Owner:TORAY IND INC

Preform for molding fiber-reinforced resin beam

ActiveUS8455089B2Work lessQuality improvementSynthetic resin layered productsDomestic articlesFiber reinforcementComposite material

A preform for the molding of a fiber-reinforced resin beam includes a reinforcing-fiber beam which has been formed from a reinforcing-fiber base made up of many reinforcing fibers and has a cross-sectional shape with at least one linear part and at least one curved part connected to the linear part; and a release sheet bonded and united through an adhesive resin to at least part of a surface of the reinforcing-fiber base along the lengthwise direction for the base. A process for producing a preform includes shaping a continuous flat reinforcing-fiber base having a release sheet bonded and united to a surface thereof so that the cross-sectional shape of the base has a curved part to thereby produce a preshaped object; and bonding and uniting the preshaped object to another preshaped object.

Owner:TORAY IND INC

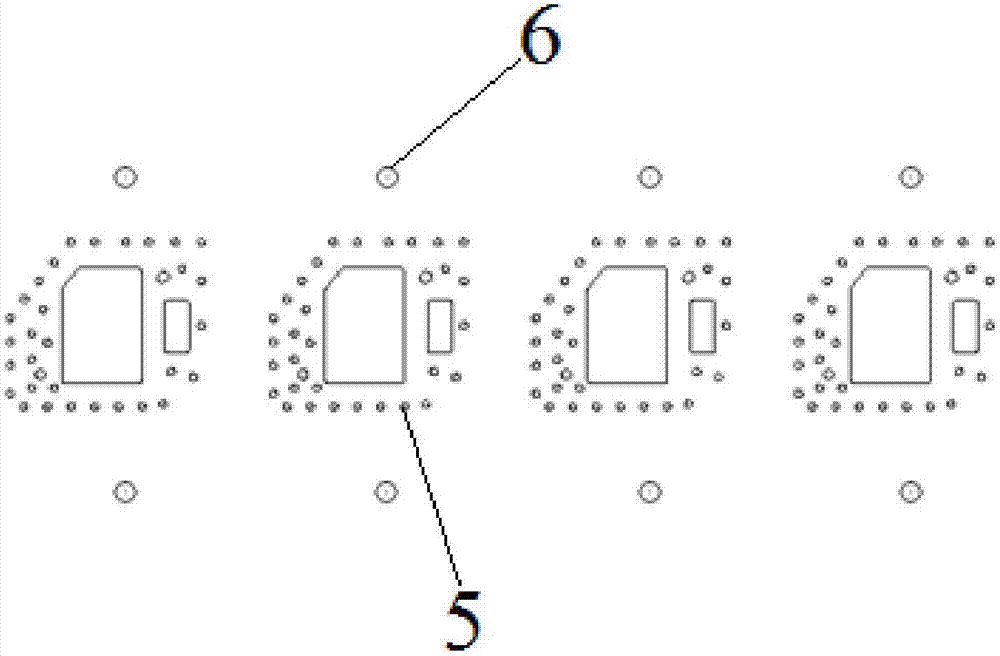

Receiving base band of chip electronic element

The invention relates to a paper band with several chambers for containing chip electronic elements. The invention is characterized in that: the surface of said band that closing the top sealing band of said chamber has a coat with fluff-prevent resin and selective soluble resin; said fluff-prevent resin contains at least one of phenylethene-maleic acid polymer resin, alkene-maleic acid polymer resin, acrylic ester-acrylic acid polymer resin and phenylethealkenene-alkene-acrylic polymer resin. Said inventive band has high adhesive strength, without fluff when removing the top sealing band.

Owner:OJI PAPER CO LTD

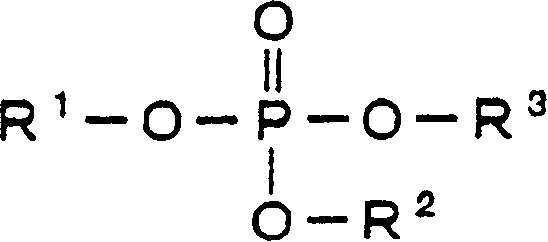

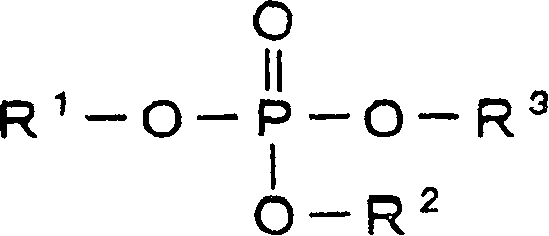

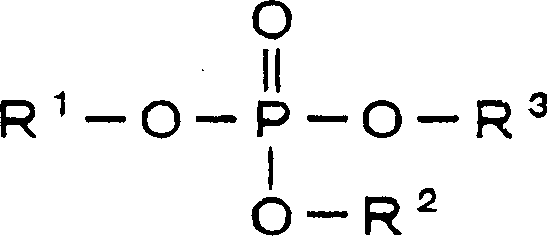

Processing agent for synthetic fibre and method for processing synthetic fibre

The invention provides a treating agent for synthetic fibers sufficiently preventing the occurrence of fluff or yarn breakage corresponding to speedup of a spinning step or a texturing step of the synthetic fibers in recent years and to provide a method for treating the synthetic fibers. The treating agent for the synthetic fibers comprises a lubricant and a functionality improving agent. The treating agent contains 0.05-20 wt.% of a specific phosphorus compound having 1-3 residues after removing all the hydroxy groups from an alkylene glycol or a polyalkylene glycol having an oxyalkylene group or a polyoxyalkylene group composed of 1-50 total of 2-4C oxyalkylene units in the molecule as at least a part of the functionality improving agent.

Owner:TAKEMOTO YUSHI KK

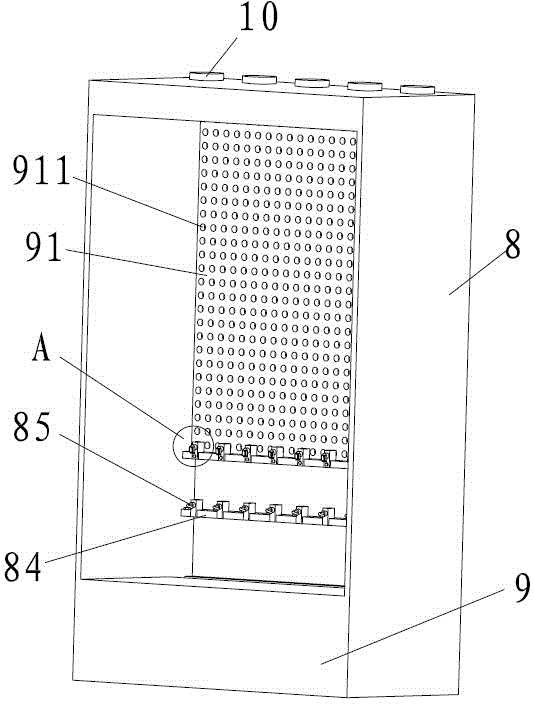

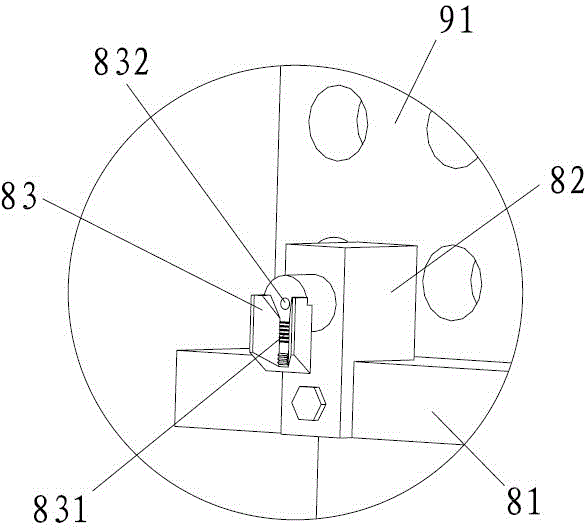

Grinding method and grinding device suitable for wind blade girder plate

PendingCN111168497AAvoid fuzzThere will be no stuck phenomenonGrinding carriagesGrinding drivesFiberStructural engineering

The invention discloses a grinding device suitable for a wind blade girder plate. The grinding device is characterized in that the rotating mode of a grinding head of a grinding machine is press-typerotation in the fiber direction of the girder plate, and it is ensured that the grinding head of the grinding machine grinds girder plate fibers downwards in the grinding process; when the two ends ofthe girder plate are ground, the track of the grinding head of the grinding machine is slash grinding motion in the fiber direction of the girder plate; the slash grinding motion can be divided intovertical direction motion and horizontal direction motion; specifically, the track of the grinding head of the grinding machine along the vertical direction motion is from top to bottom in the heightdirection of the girder plate; when the grinding head of the grinding machine grinds and moves from right to left, the rotating direction of the grinding head of the grinding machine is clockwise; andwhen the grinding head of the grinding machine grinds and moves from left to right, the rotating direction of the grinding head of the grinding machine is anticlockwise.

Owner:南京诺尔泰复合材料设备制造有限公司

Method for modifying fibers

InactiveUS20060000026A1Improve securityHigh tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

A method for modifying fibers is provided, which method comprises dispersing in water or a dilute alkali aqueous solution under shear a cellulose ether having such a low degree of substitution that a molar degree of substitution with an alkyl group and / or a hydoxyalkyl group ranges from 0.05 to 1.3, applying the resulting dispersion to fibers, and drying the applied fibers.

Owner:SHIN ETSU CHEM IND CO LTD

Spinning box

InactiveCN102912465AReduce frictionAvoid breakingSpinnerette packsArtificial thread manufacturing machinesYarnFiber

The invention relates to mechanical manufacturing of chemical fiber filament, in particular to a spinning box. According to the invention, the spinning box is achieved by the following technical scheme: the spinning box comprises a frame, a yarn spraying tank, an air blowing mechanism, a yarn guide module, a yarn leading module and a yarn collecting box, wherein the yarn spraying tank is arranged at the upper part of the frame; the air blowing mechanism is used for blowing air to yarns; the yarn guide module is arranged between the two sides of the frame; the yarn leading module is arranged between the two sides of the frame and positioned below the yarn guide module; the yarn collecting box is arranged below the frame; the yarn spraying tank comprises a tank cylinder and a yarn spraying plate, a yarn cup and a fluid passing body, wherein the yarn spraying plates are mounted in the tank cylinder and are provided with at least two yarn spraying areas with a plurality of fine holes; the yarn cup is provided with fluid passages corresponding to the yarn spraying areas one to one; the fluid passing body is provided with a fluid inlet and provided with shunting passages, which are communicated with the fluid inlet and corresponding to the fluid passages one to one; and the bottom of each fluid passage is a filter plate with a plurality of micro holes. According to the invention, the yarn spraying tank has no flowing dead point so that broken filaments and broken ends are prevented; moreover, as high yarn yield is obtained, the spinning box provided by the invention is beneficial for increasing production efficiency.

Owner:ZHEJIANG HUATESI POLYMER TECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com