Nonwoven fabric

A non-woven fabric and segmented technology, applied in non-woven fabrics, textiles, papermaking, medical science, etc., can solve problems such as difficult liquid permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1 and 2

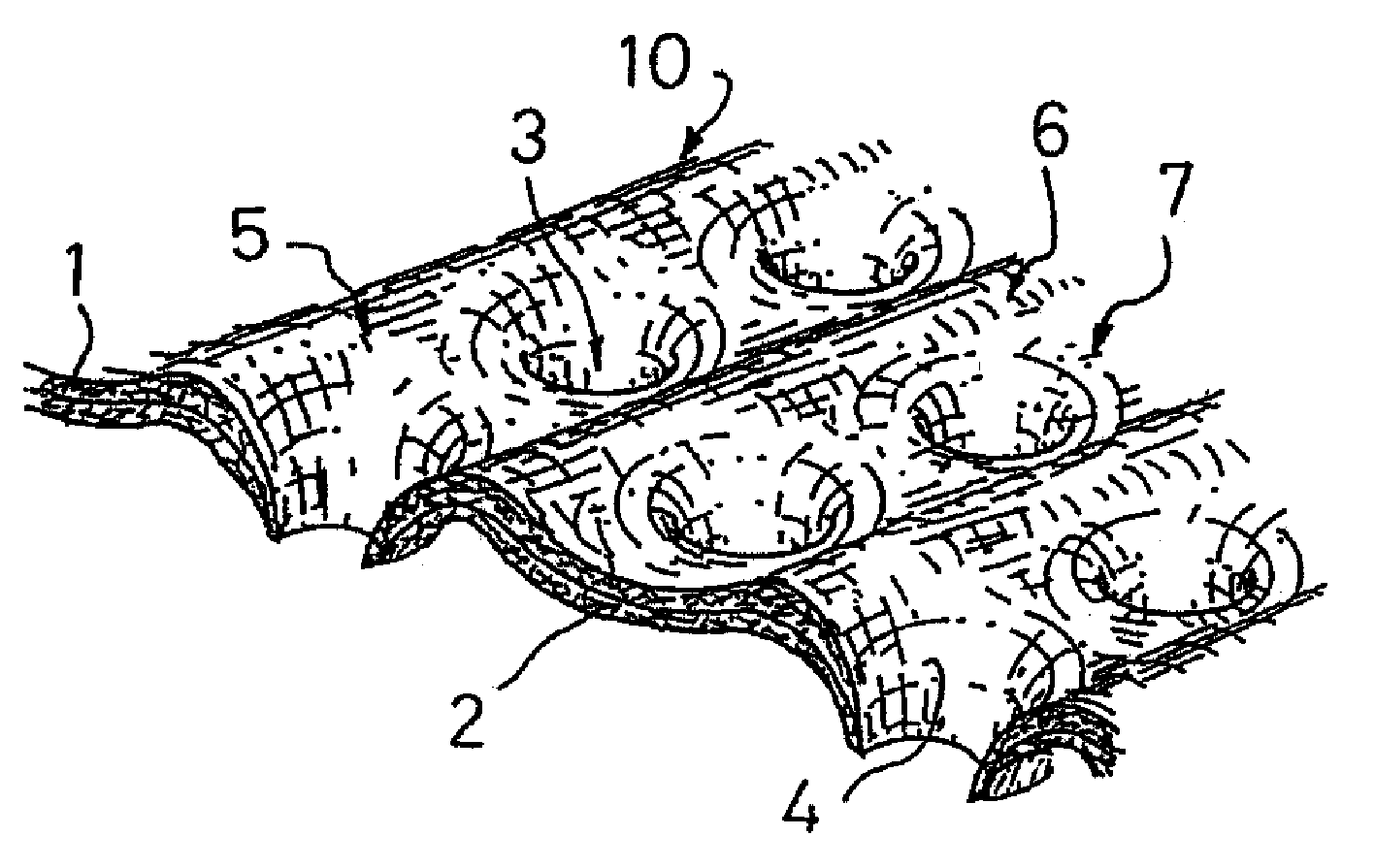

[0032] Next, using the fibers shown in Table 1 and Table 2, fiber webs of the first layer and the second layer were formed by a carding method. Details of the fibers in Table 1 are shown in Table 2. After overlapping the fiber webs, hot air heated to 140° C. was blown to melt the intersection points of the constituent fibers to obtain a double-layer nonwoven fabric raw material. Then, using a drilling pin with a diameter of 1.5mm heated to 125°C, a large number of openings are formed on the non-woven fabric raw material, and ridges and grooves are formed to obtain figure 1 Nonwovens in the form shown. The diameter of the opening ends of the openings in the obtained nonwoven fabric was about 1 mm, and the opening ratio was 10%. In addition, the distance between the openings along the grooves was 2.6 mm, and the distances between the grooves and the ridges were both 2.3 mm. And, 0.5g / cm 2 The thickness under load is 0.6 to 1.0 mm.

[0033] Regarding the obtained nonwoven fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com