Water absorbent resin suitable for wood-pulp-core paper diaper and preparing method thereof

A technology of water-absorbent resin and diapers, applied in applications, absorbent pads, medical science, etc., can solve the problems of easy fracture, large local absorption, poor air permeability of diapers, etc., and achieve the effect of strengthening the degree of cross-linking and improving the liquid permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

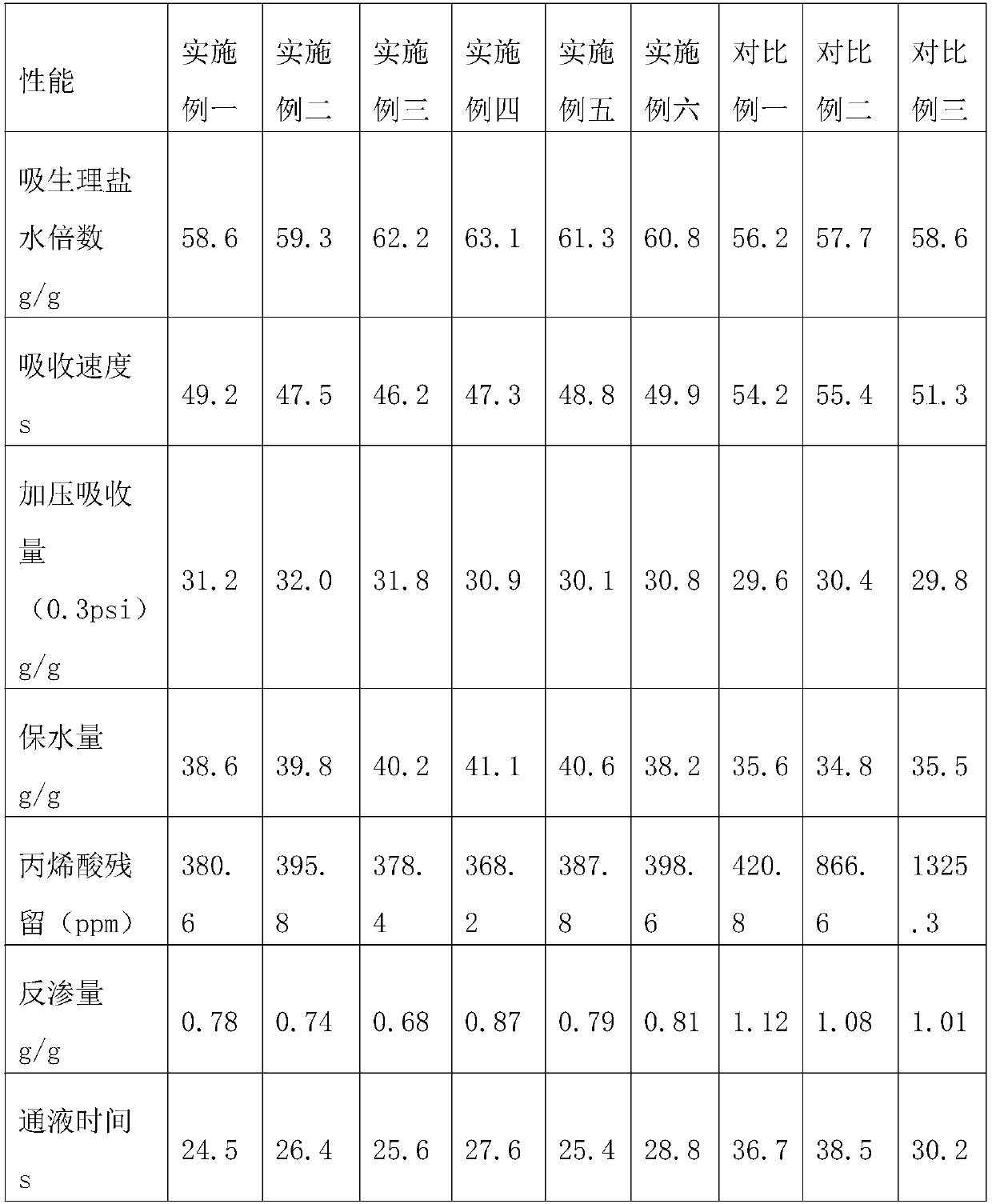

Examples

Embodiment 1

[0036] A water-absorbent resin suitable for paper diapers with a wood pulp core, comprising the following components in parts by weight:

[0037] 30 parts of acrylic acid, 30 parts of 32% sodium hydroxide aqueous solution, 7.5 parts of 40% mass fraction of sodium metasilicate aqueous solution, 2 parts of acrylamide, cross-linking agent N, N-methylenebisacrylamide and polyethylene glycol 800 0.5 parts of the mixture, 0.5 parts of the photoinitiator 2-hydroxy-2-a-1-phenyl-1-acetone, 0.1 parts of the initiator sodium azobisisobutyramide hydrochloride, 0.4 parts of sodium metaaluminate, surface treatment solution 4 parts, 20 parts of deionized water.

[0038] The preparation method comprises the following steps:

[0039] (1) Mix 30 parts of acrylic acid and 20 parts of deionized water, then add 30 parts of 32% sodium hydroxide aqueous solution for neutralization reaction, and control the reaction temperature to less than 40°C;

[0040] (2) Add 7.5 parts of 40% mass fraction of s...

Embodiment 2

[0046] A water-absorbent resin suitable for paper diapers with a wood pulp core, comprising the following components in parts by weight:

[0047] 30 parts of acrylic acid, 40 parts of 32% sodium hydroxide aqueous solution, 12.5 parts of 40% mass fraction of sodium metasilicate aqueous solution, 5 parts of acrylamide, cross-linking agent N,N-methylenebisacrylamide and polyethylene glycol 800 1 part of the mixture, 0.8 part of the photoinitiator 2-hydroxy-2-a-1-phenyl-1-acetone, 0.2 part of the initiator sodium azobisisobutylamidine hydrochloride, 0.6 part of sodium metaaluminate, and 6 parts of the surface treatment solution Parts, 25 parts of deionized water.

[0048] (1) Mix 30 parts of acrylic acid and 25 parts of deionized water, then add 40 parts of 32% sodium hydroxide aqueous solution for neutralization reaction, and control the reaction temperature to less than 40°C;

[0049] (2) 12.5 parts of 40% mass fraction of sodium metasilicate aqueous solution, 5 parts of acryla...

Embodiment 3

[0055] A water-absorbent resin suitable for paper diapers with a wood pulp core, comprising the following components in parts by weight:

[0056] 40 parts of acrylic acid, 50 parts of 32% sodium hydroxide aqueous solution, 20 parts of 40% mass fraction of sodium metasilicate aqueous solution, 8 parts of acrylamide, cross-linking agent N, N-methylenebisacrylamide and polyethylene glycol 800 1.5 parts of the mixture, 1 part of the photoinitiator 2-hydroxy-2-a-1-phenyl-1-acetone, 0.3 parts of the initiator sodium azobisisobutylamidine hydrochloride, 1 part of sodium metaaluminate, and 8 parts of the surface treatment solution parts, 30 parts of deionized water.

[0057] (1) Mix 40 parts of acrylic acid and 30 parts of deionized water, then add 50 parts of 32% sodium hydroxide aqueous solution for neutralization reaction, and control the reaction temperature to less than 40°C;

[0058] (2) 20 parts of 40% mass fraction of sodium metasilicate aqueous solution, 8 parts of acrylamid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com