Wipe and making method thereof

A manufacturing method, technology of wipes, applied in the direction of chemical instruments and methods, non-woven fabrics, wood layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

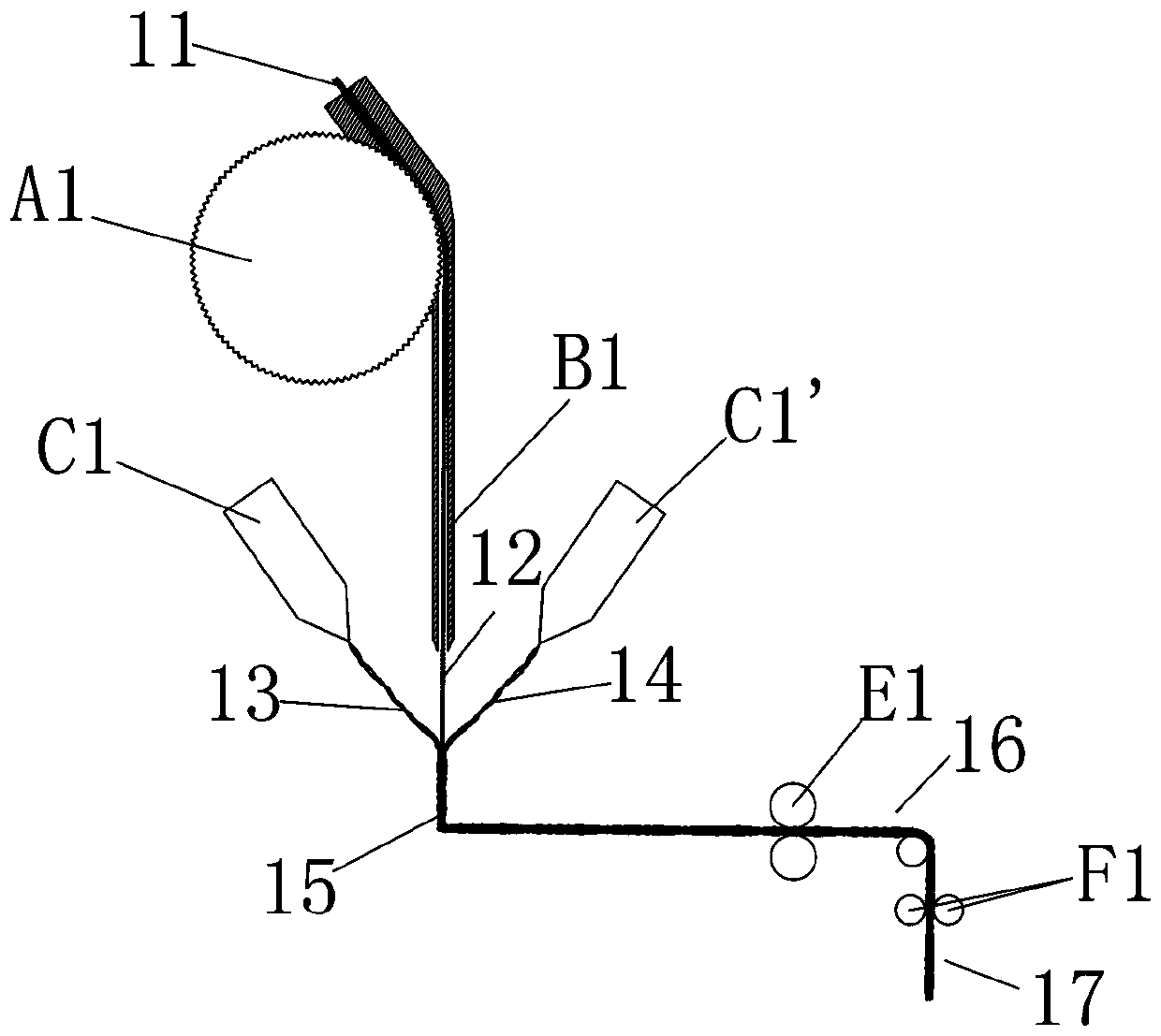

[0062] Such as figure 1 Shown, the present invention discloses a kind of manufacturing method of wipes, comprises the following steps:

[0063] (1) The wood pulp 11 is loosened by the opening roller A1, and the wood pulp fiber web 12 is formed through the nozzle B1 under the action of the auxiliary airflow.

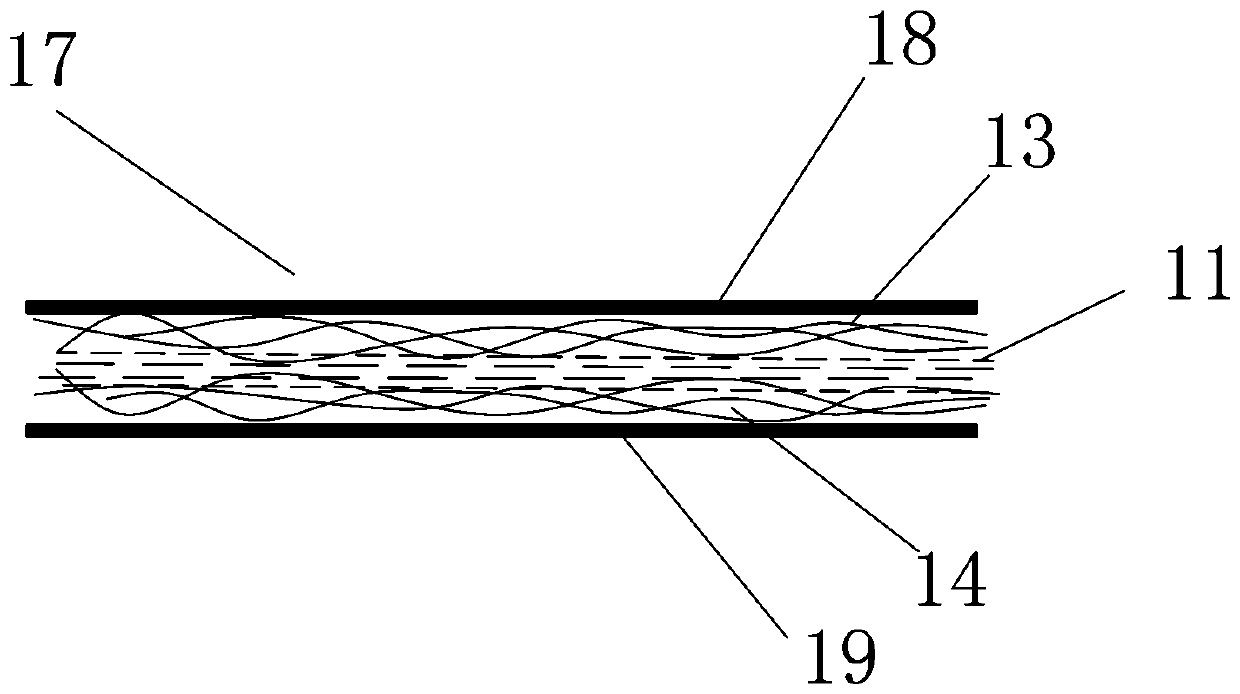

[0064] (2) Using the melt-blowing process, heat and melt the thermoplastic resin, and use high-temperature, high-speed hot air to blow the melted stream of thermoplastic resin sprayed from the spinnerets C1 and C1' into fibers with a fiber diameter of ≤10 μm Bundle, the melt-blown fiber web 13,14 that is formed along with the hot air flow, and the two side faces of the wood pulp fiber web 12 intersect to form both sides as the melt-blown fiber web 13,14, and the middle is the wood pulp fiber web 12 A multi-layer structure fiber web 15, wherein the melt-blown fiber webs 13 and 14 are composed of single-component melt-blown fibers whose fiber surface is a high-melting poin...

Embodiment 2

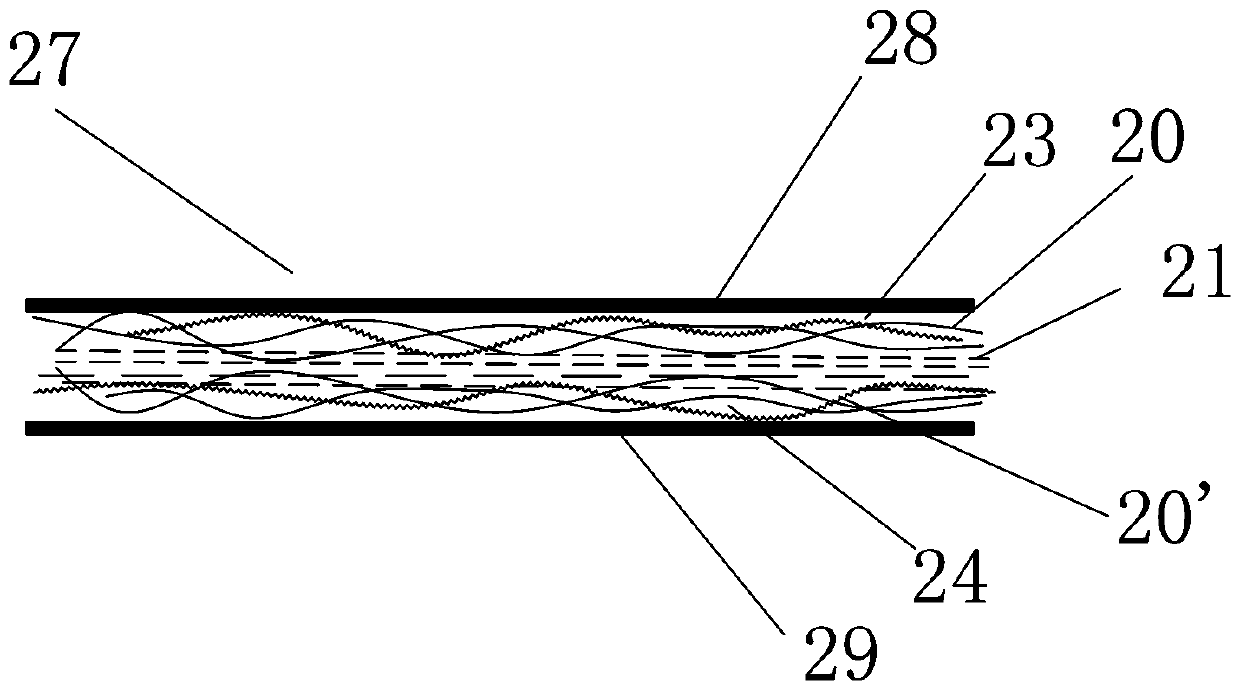

[0070] Such as image 3 As shown, the present invention discloses a wiper 27, which has a layered structure. The upper and lower layers of the wiper are melt-blown fiber webs 23, 24, and the middle layer is a wood pulp fiber web 21. Adhesives 28, 29 are attached to the surface of the sprayed fiber webs 23, 24, and the melt-blown fibers of the melt-blown fiber webs 23, 24 are interspersed in the wood pulp fiber web 21; The single-component melt-blown fiber 20 and the melt-blown fiber 20' containing a low-melting resin on the surface of the fiber are blended. The melt-blown fiber 20' containing low-melting-point resin on the surface of the fiber can be a single-component melt-blown fiber, a two-component melt-blown fiber or a blend of the two. The two-component melt-blown fiber can be a sheath-core type melt-blown fiber 31, a two-component pie-shaped melt-blown fiber 33 or a two-component side-by-side melt-blown fiber 32, and as Figure 4A to Figure 4C As shown, the melting po...

Embodiment 3

[0073] Such as Figure 5 Shown, the present invention discloses a kind of manufacturing method of wipes, comprises the following steps:

[0074] (1) The wood pulp 41 is loosened by the opening roller A4, mixed with the hot-melt adhesive substance 42, and then passed through the nozzle B4 under the action of the auxiliary airflow to form a wood pulp fiber web containing the hot-melt adhesive substance 42 43.

[0075] (2) Using the melt-blown process, the thermoplastic resin is heated separately, melted and then enters the spinning box, and the melt of the thermoplastic resin sprayed from the spinneret C4 and C4' is sprayed from the spinneret C4 and C4' by using high temperature and high-speed hot air in the spinning box The fine stream is blown into fiber bundles with a fiber diameter≤10 μm, and the melt-blown fiber webs 44, 45 are formed with the hot air flow, and then the melt-blown fiber webs 44, 45 formed are placed on the wood pulp fiber web 43 containing the hot-melt adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com