A kind of composite nonwoven material and preparation method thereof

A technology of non-woven materials and material layers, applied in non-woven fabrics, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of abnormal spinning, polluting the spinning board surface, long process, etc., and achieve improved anti-aging performance And antibacterial performance, good barrier and breathability, good material strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

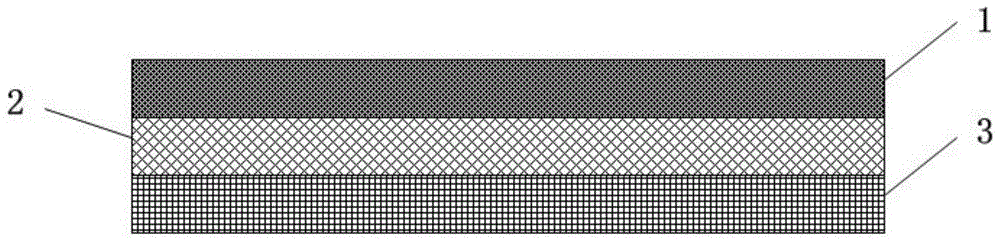

[0036] The preparation method of the present application has simple operation, and compared with the post-finishing method, the process is simple, it can be carried out on a general nonwoven material production line, and the production cost is low. Moreover, by coating the surface of the PP spunbonded nonwoven material layer with a nano-titanium dioxide photocatalyst coating, the antibacterial effect is achieved; by coating the surface of the composite material with an ultraviolet absorber and an antibacterial agent, the anti-aging performance and antibacterial performance of the material are improved; Electrospinning and spunbonded nonwoven materials are combined to realize the barrier and air permeability of the material; the final composite nonwoven material has the characteristics of high strength, good air permeability, and durable weather resistance and antibacterial properties; no need to use blended spinning, and avoid The impact on the production process and product qu...

Embodiment 1

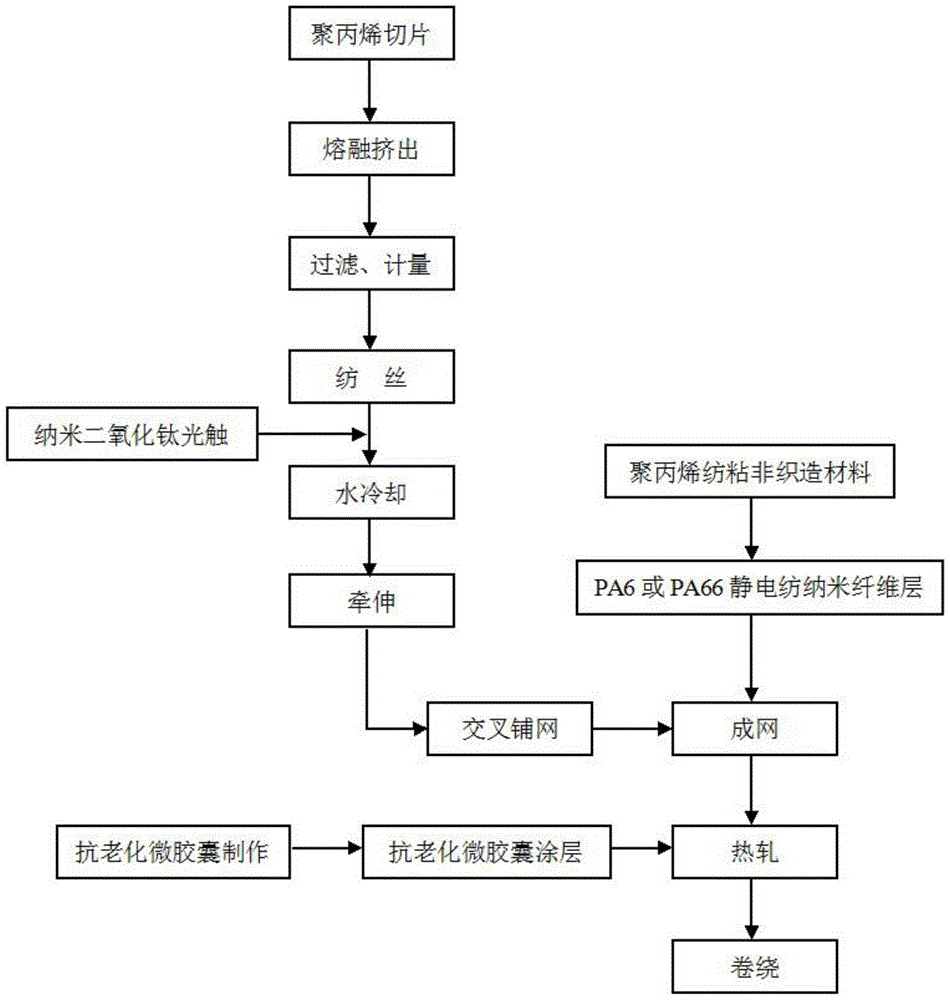

[0043] The process flow of this example, such as figure 1 As shown, it includes the preparation of nano-titanium dioxide photocatalyst coating, electrospinning, preparation and compounding steps of anti-aging microcapsules. The preparation method of the PP spunbonded nonwoven material layer refers to the conventional spunbond process, including polypropylene slicing, melt extrusion, filter metering, spinning, cooling, drawing, and web laying.

[0044] The concrete preparation method of the composite nonwoven material of this example is as follows:

[0045] (1) Choose the medical-grade nano-titanium dioxide photocatalyst provided by Hong Kong Kangli Medical Center, uniformly disperse the titanium dioxide photocatalyst in water, and prepare a suspension with a titanium dioxide content of 0.75%; spray the nano-titanium dioxide photocatalyst suspension through a 0.5mm nozzle, The sprayed suspension is atomized into droplets of different sizes under the clamping of compressed air ...

Embodiment 2

[0051] The process flow of this example is the same as that of Example 1, wherein, in the preparation process of the nano-titanium dioxide photocatalyst coating, the nano-titanium dioxide suspension is impacted into 5nm droplets by adjusting the pressure of the compressed air; The grammage of the nonwoven material layer is 28g / m 2 , the thickness is 0.3mm. In the electrospinning process, the thickness of the PP spunbonded nonwoven material layer laid on the surface of the aluminum plate receiver is 0.32mm, and the weight is 32g / m 2, dissolving PA66 resin slices in a solvent to obtain 0.4g / ml spinning solution, applying 40KV high-voltage positive charge to the spinning solution nozzle, and grounding the aluminum plate receiver covered with PP spunbond nonwoven material layer, and conducting the spinning solution Electrospinning, the extrusion rate of the spinning solution is 3ml / h, the spinning voltage is set to 40KV, and the receiving distance is 35cm. The fibers formed by el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com