High-temperature anti-oxidation composite nano-pps/ti-siox short fiber and preparation method thereof

A high-temperature anti-oxidation and short fiber technology, which is applied in fiber processing, melt spinning, spinneret assembly, etc., can solve problems such as narrow temperature range, achieve improved anti-oxidation performance, increase orientation degree and crystallinity, and orientation The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples are only preferred technical solutions of the present invention, and are not intended to limit the present invention in any way. Various modifications and variations of the present invention will occur to those skilled in the art. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

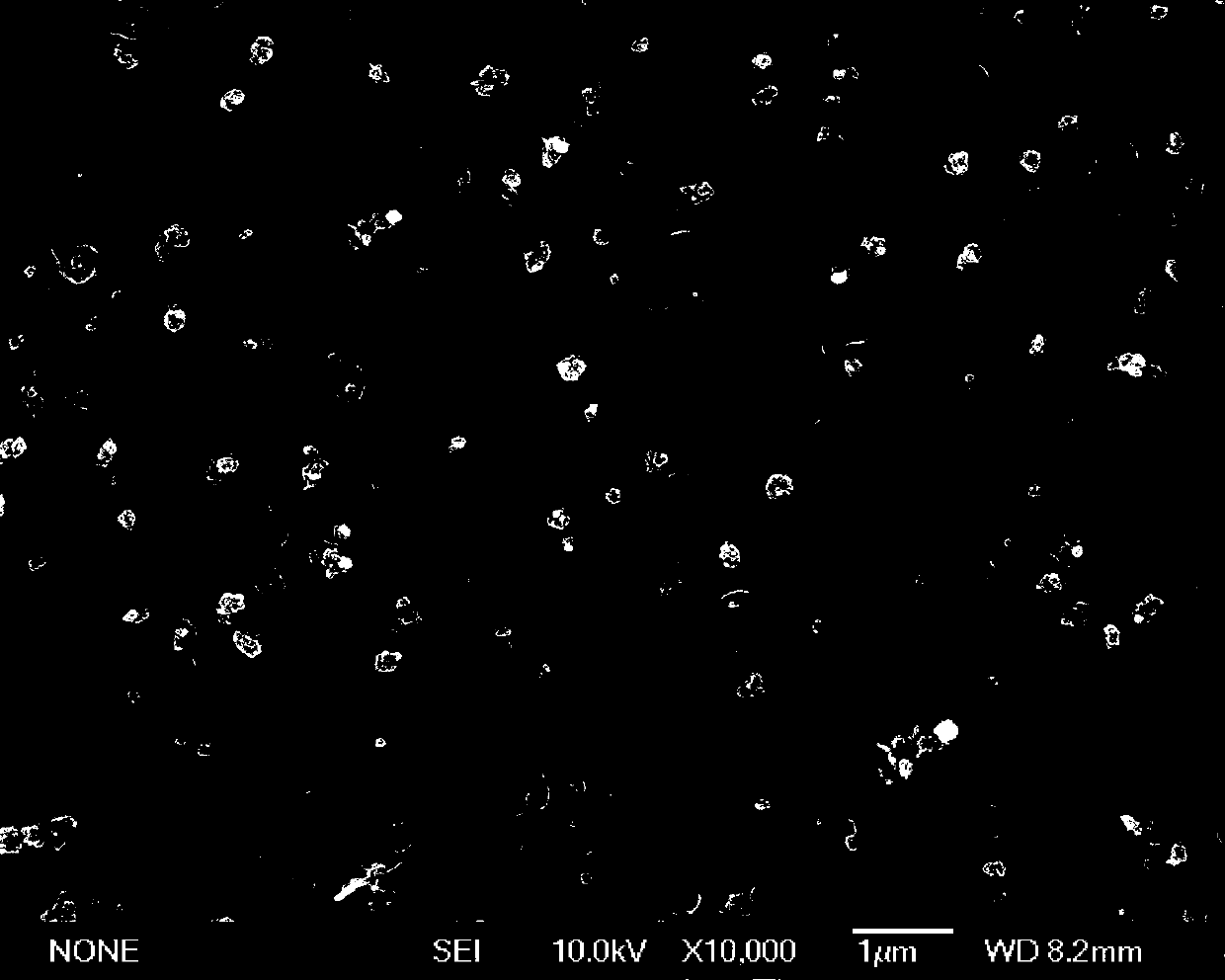

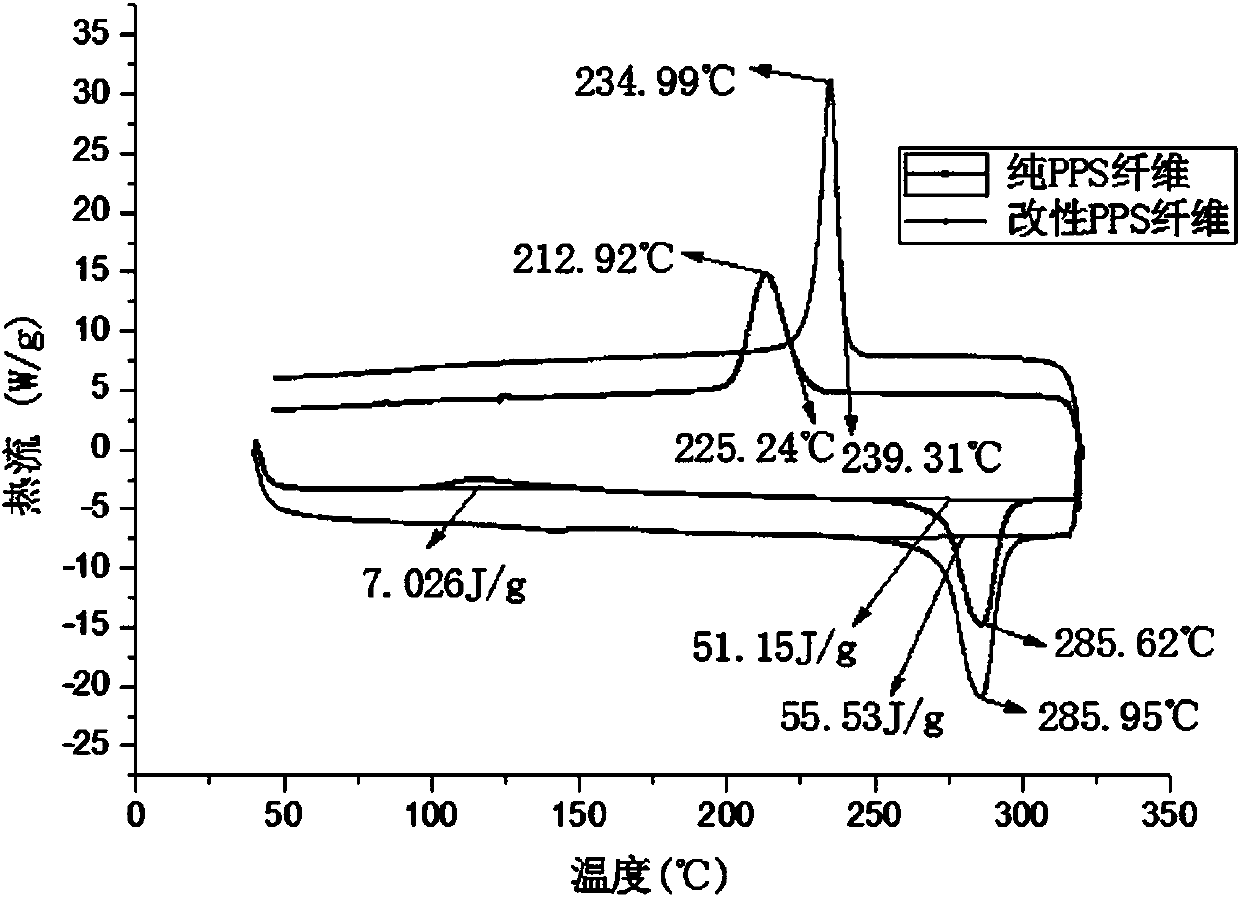

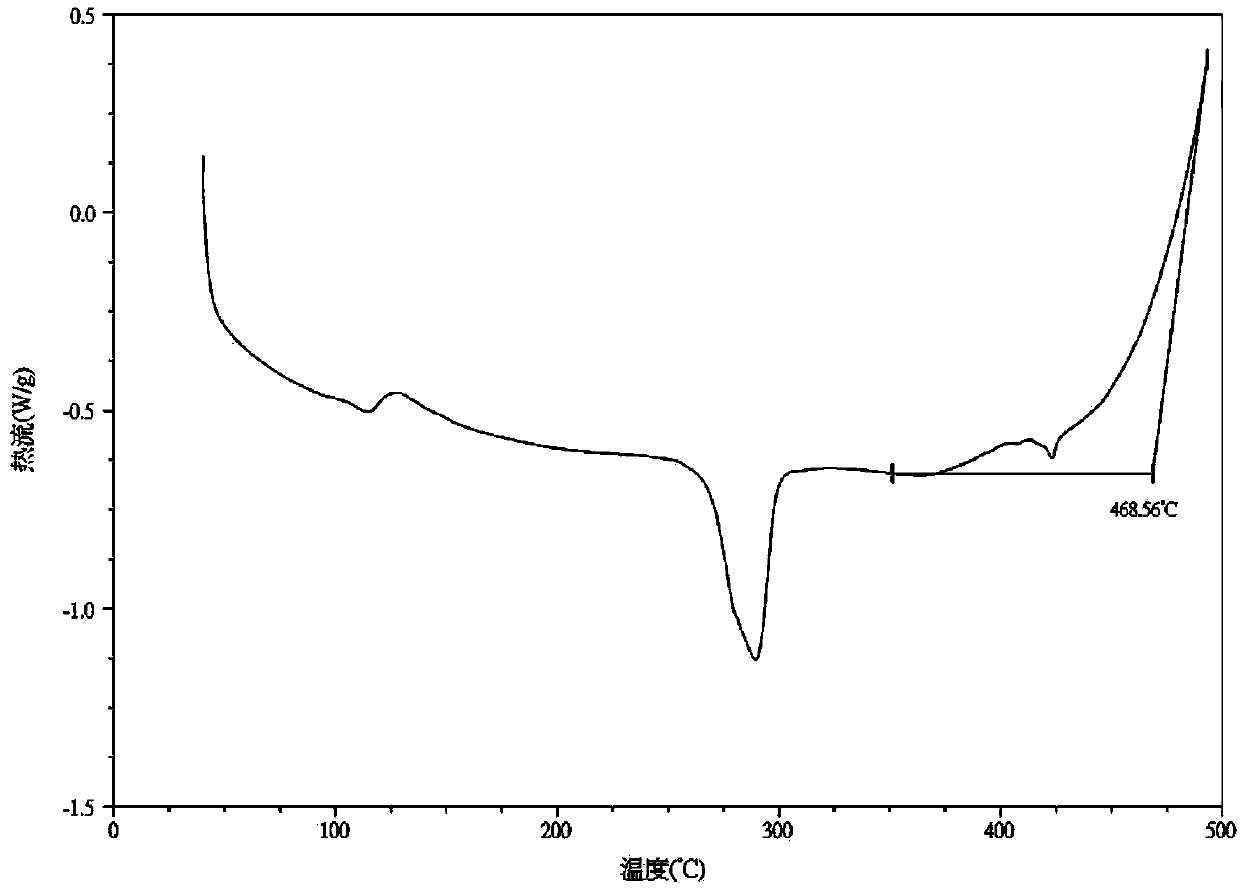

[0036] The raw material linear PPS resin used in this embodiment has a melt index of 160-190 g / 10 min, a glass transition temperature of 95-96°C, a melting point of 280-282°C, and a decomposition temperature of 488.2°C. The average particle size of nano Ti-SiOx is 20-50nm, and the specific surface area is 120m 2 / g, nano titanium dioxide content 1%.

[0037] Set the temperature of the melting and mixing zone of the twin-screw extruder at 190-240° C., and continue to keep warm and balance for 3 hours after the temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com