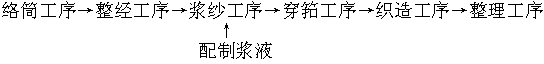

Warp backed weave double cloth weaving process

A double-layer fabric and warp double-layer technology is applied in fabrics, multi-strand fabrics, textiles, and papermaking. It can solve the problems of uncomfortable wearing, poor moisture absorption and perspiration, and static electricity caused by friction, and achieves simple process and difficult weaving. Small, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the weaving process of the double-layered fabric of the present invention. There are two kinds of warp yarns, one is JC27.8Tex+40D warp yarn, and the other is JC / H(60 / 40)21.6Tex warp yarn. During garment production and processing, the fabric reveals one side of JC27.8Tex+40D warp yarn as The outer layer ensures the crispness and shape retention of the garment; the side that reveals the C / H (60 / 40) 21.6Tex warp yarn is used as the inner layer. The hemp fiber has excellent hygroscopicity and moisture drainage. The sweat and water vapor can be absorbed and discharged in time, which improves the wearing comfort of the clothing.

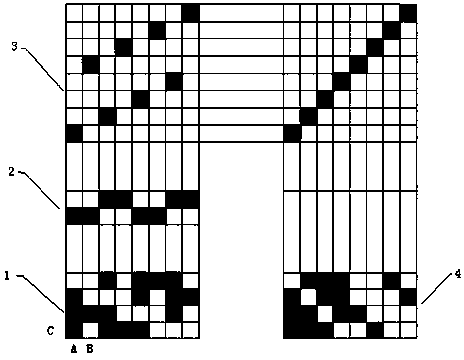

[0027] In the present invention figure 1 , figure 2 In the shown embodiment: the fabric design uses two kinds of warp yarns, JC27.8Tex+40D warp yarn and JC / H(60 / 40)21.6Tex warp yarn, and the fabric weave is a double weave. Heald drawing method: A1, B5, A2, B6, A3, B7, A4, B8 (the numbers represent the number of heald frames on which the warp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com