Fiber having phase separation structure and manufacturing method for such fiber

A phase separation, fiber technology, applied in rayon manufacturing, fiber chemical characteristics, conductive/antistatic filament manufacturing, etc., can solve problems such as insufficient antistatic properties, lack of hygroscopicity, and stuffiness The effect of suppressing the occurrence of fuzz, excellent in antistatic properties, and small unevenness in fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

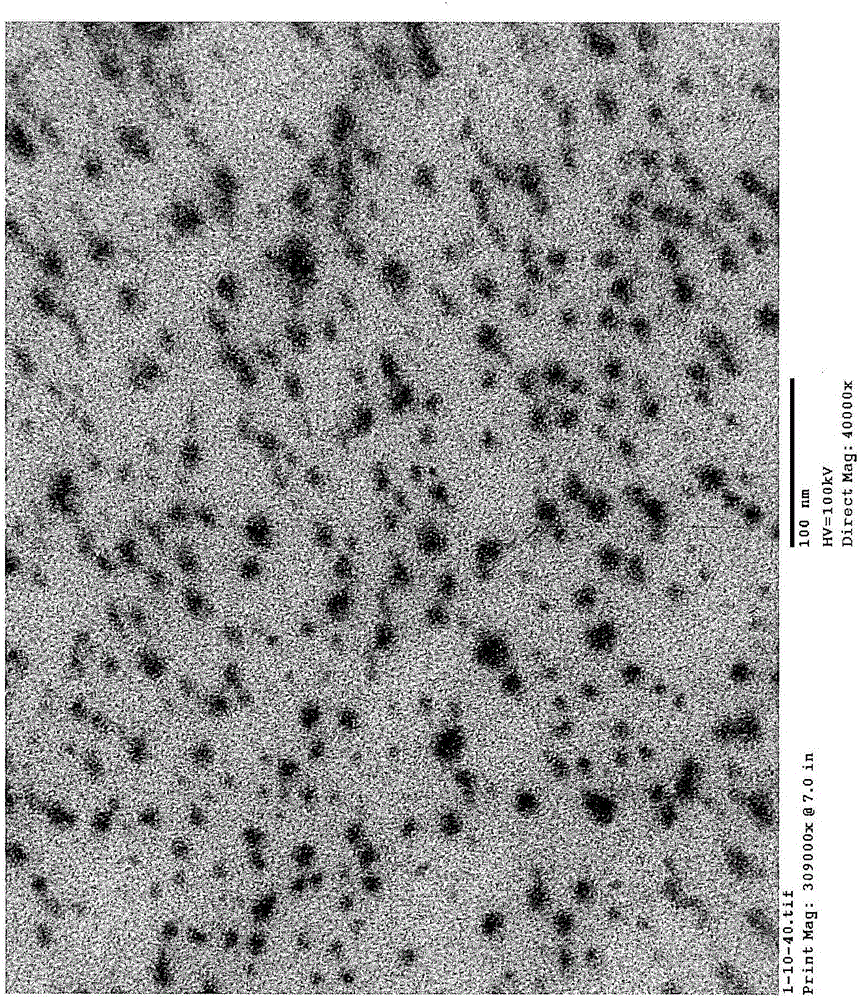

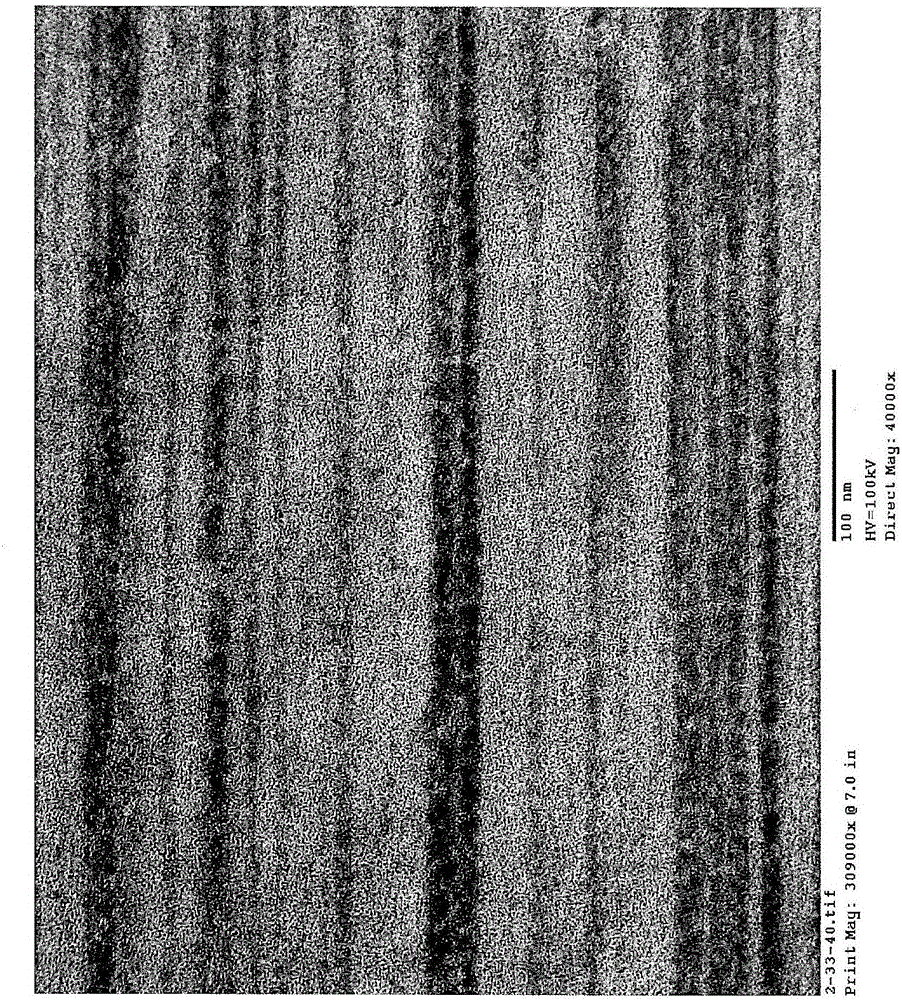

[0156]About 100 kg of bis(β-hydroxyethyl) terephthalate was charged into the esterification reaction tank, and after maintaining at a temperature of 250° C., 89.2 kg of high-purity terephthalic acid (manufactured by Mitsui Chemicals) and ethyl alcohol were sequentially supplied over 2.5 hours. A slurry of 39.8 kg of diol (manufactured by Nippon Shokubai). After completion of supply, esterification reaction was performed for 2 hours to obtain an esterification reaction product. Next, 13.6 kg of ethylene glycol (manufactured by Nippon Shokubai) and 16.8 kg of melted polyethylene glycol with a number average molecular weight of 8300 (manufactured by Sanyo Chemical Industry Co., Ltd. PEG6000S) heated to 70° C. were successively charged into the polycondensation tank, and then passed The transfer piping of the esterification reaction tank and the polycondensation tank was connected, and 110.6 kg of the obtained esterification reaction product was transferred to the polycondensation...

Embodiment 2~4

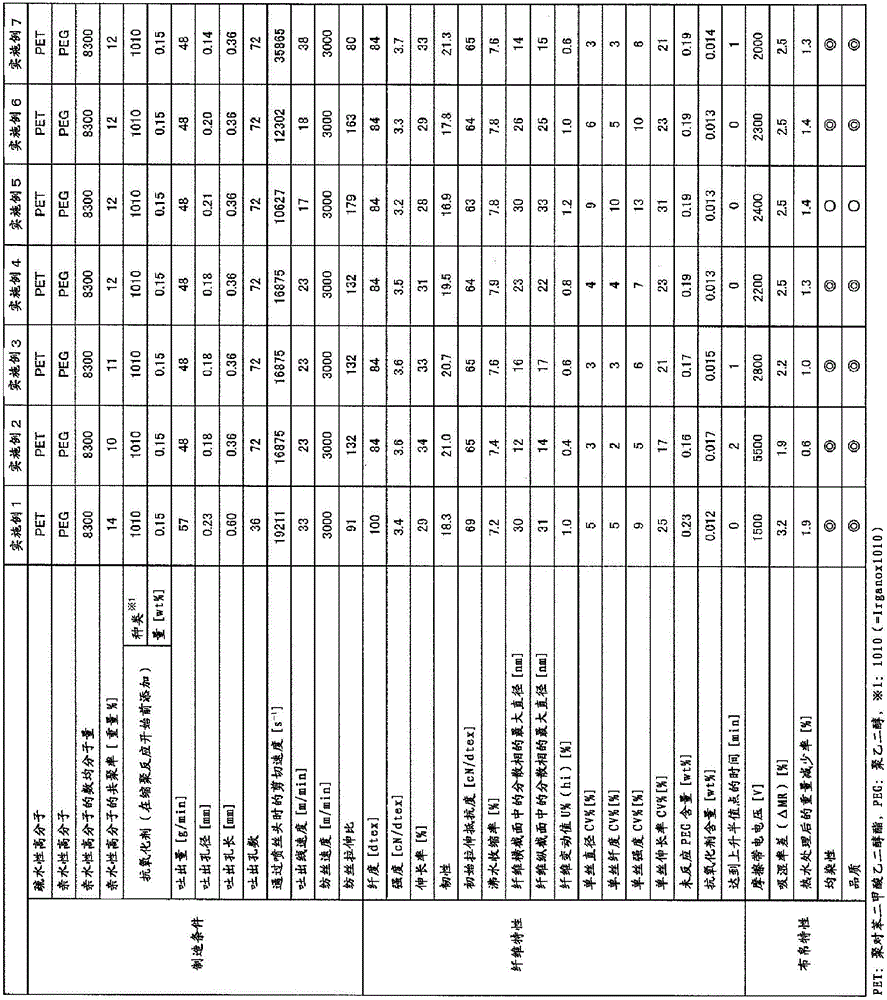

[0160] As shown in Table 1, the copolymerization ratio of the hydrophilic polymer, the discharge amount, and the spinneret (discharge hole diameter, discharge hole length, and number of discharge holes) were changed, and a drawn yarn was produced in the same manner as in Example 1. .

[0161] Table 1 shows the evaluation results of fiber properties and fabric properties of the obtained fibers. As the copolymerization rate of the hydrophilic polymer decreases, fiber properties such as strength and toughness increase, the maximum diameter of the dispersed phase in the fiber cross section and fiber longitudinal section decreases, and U%(hi) becomes good. On the other hand, as the copolymerization ratio of the hydrophilic polymer becomes higher, the antistatic property and hygroscopicity become better.

Embodiment 5~7

[0163] As shown in Table 1, except that the discharge hole diameter of the spinneret was changed, it carried out similarly to Example 4, and produced the drawn yarn.

[0164] Table 1 shows the evaluation results of fiber properties and fabric properties of the obtained fibers. As the discharge aperture becomes smaller, the shear velocity when passing through the spinneret becomes higher, the fiber properties such as strength and toughness increase, and the maximum diameter of the dispersed phase in the fiber cross section and fiber longitudinal section decreases, U%(hi) become good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com