Polymer alloy fiber and fiber structure formed from same

An alloy fiber, polymer technology, applied in the direction of conjugated synthetic polymer rayon, fiber processing, single-component polyolefin rayon, etc., can solve the problem of reduced wear resistance, reduced mechanical properties, compatibility Low problems such as excellent abrasion resistance, suppression of fiber diameter deviation, and suppression of uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

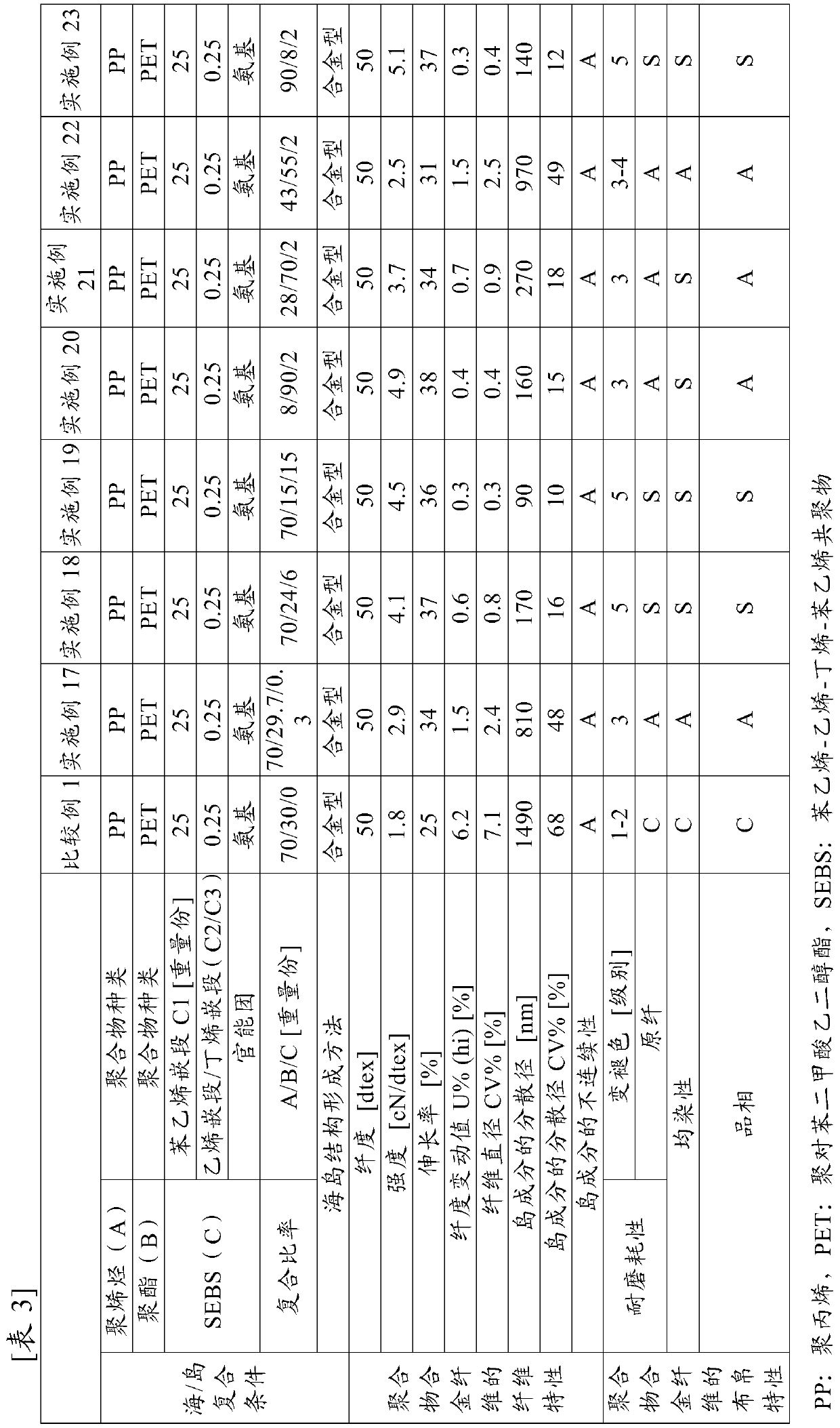

Embodiment 1

[0117] Add 70 parts by weight of polypropylene (PP) ("Novatec" (registered trademark) MA2 manufactured by Japan Polypropylene Corporation), 28 parts by weight of polyethylene terephthalate (PET) (T701T manufactured by Toray), 2 parts by weight Parts of styrene-ethylene-butylene-styrene copolymer (C) (25 parts by weight of styrene block, ethylene block / butylene block=0.25), using a twin-screw extruder, at a mixing temperature of 280 °C for mixing. After the strands discharged from the twin-screw extruder were cooled with water, they were cut into about 5 mm in length using a pelletizer to obtain pellets. After the obtained pellets were vacuum-dried at 150° C. for 12 hours, they were supplied to an extruder-type melt spinning machine to be melted, and the spinning temperature was 285° C., and the discharge amount was 31.5 g / min. 0.18mm, the length of the discharge hole is 0.23mm, the number of holes is 36, and the circular hole) is discharged to obtain the spun yarn. The spun ...

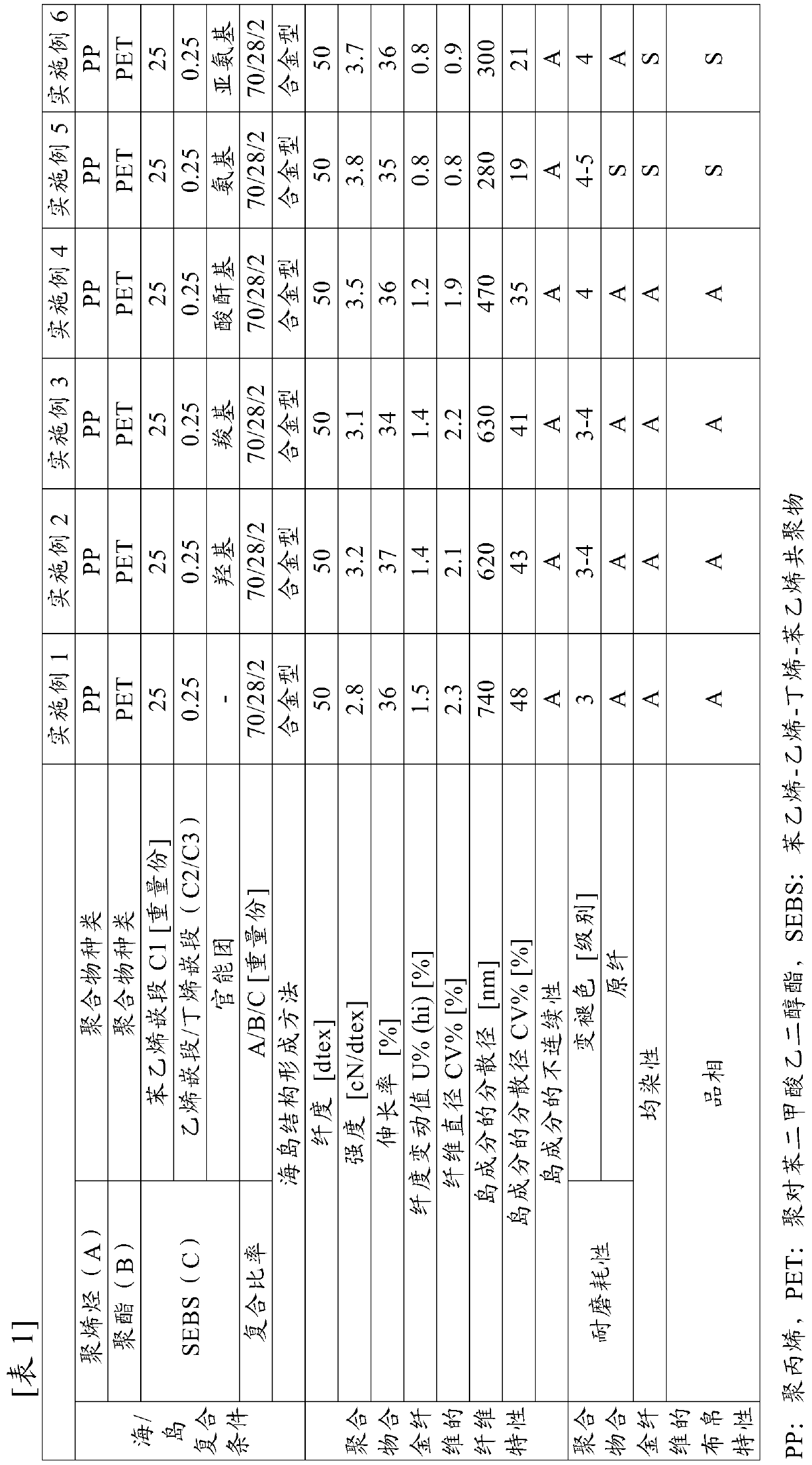

Embodiment 2~6

[0119] A stretched yarn was produced in the same manner as in Example 1 except that the functional group of the styrene-ethylene-butylene-styrene copolymer (C) was changed as shown in Table 1. Table 1 shows the evaluation results of fiber properties and fabric properties of the obtained fibers.

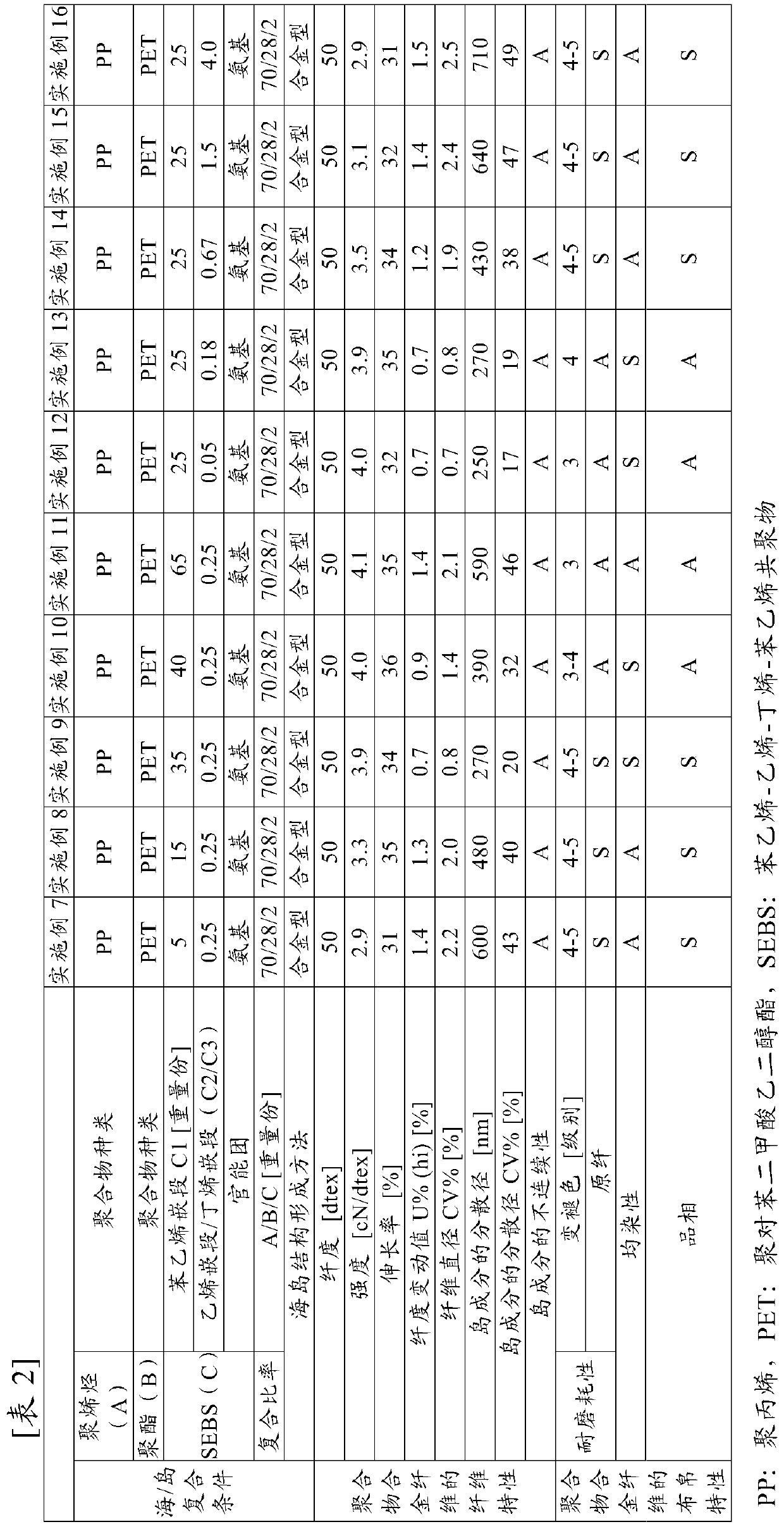

Embodiment 7~11

[0121] A stretched yarn was produced in the same manner as in Example 5 except that the content of the styrene block (C1) in the styrene-ethylene-butylene-styrene copolymer (C) was changed as shown in Table 2. Table 2 shows the evaluation results of fiber properties and fabric properties of the obtained fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com