Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194results about How to "Improve production quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

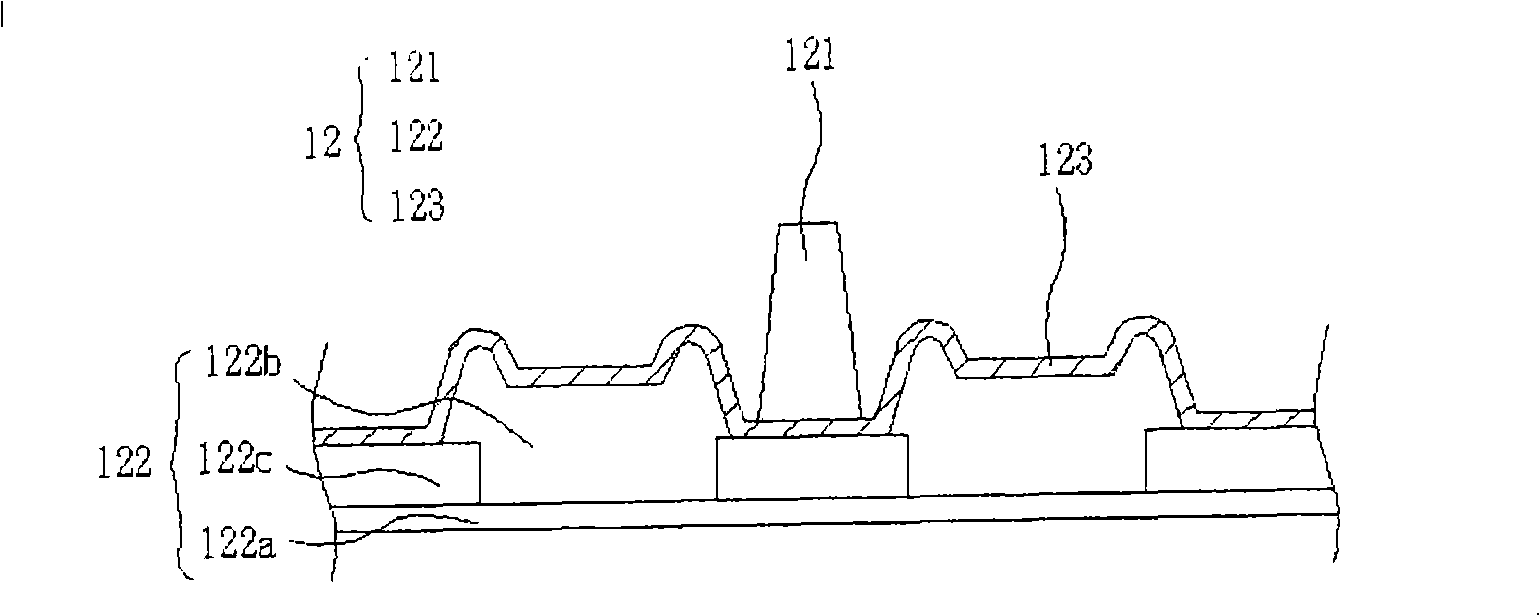

Colorful optical filter and manufacturing method thereof

InactiveCN101276011AImprove pressure resistanceImprove production qualityNon-linear opticsOptical elementsColor gelLight filter

The present invention discloses a colorful optical filter which comprises a colorful optical filtering substrate, a conducting layer and a spacer. The colorful optical filter is provided with a shading layer and a colorful filtering layer. The conducting layer is provided on the colorful optical filtering substrate, and the conducting layer is provided with at least one opening at the position relative to the shading layer and / or colorful filtering layer. The spacer is provided in the opening. The invention also discloses a method for preparing the colorful optical filter.

Owner:INNOLUX CORP

Super-light foam concrete and preparation method thereof

InactiveCN107324735AImprove production qualityFast setting and hardeningCeramicwareHydroxypropylmethyl celluloseSilica fume

The invention discloses super-light foam concrete. The super-light foam concrete is characterized by comprising the following materials in parts by mass: 60-80 parts of ordinary Portland cement, 10-20 parts of rapid hardening sulphoaluminate cement, 2-5 parts of silica fume, 8-15 parts of ultra-fine fly ash, 0.5-1.0 part of a polycarboxylate superplasticizer, 1-2 parts of redispersible powder, 0.05-0.2 part of hydroxypropyl methyl cellulose ether, 0.1-0.4 part of polypropylene fibers, 0.02-0.05 part of a superfine MnO2 catalyst, 4-6 parts of hydrogen peroxide and 50-60 parts of water, wherein a sustained-release gelatin capsule is filled with the superfine MnO2 catalyst and has the collapse time limit of 5-10 min. The invention also discloses a preparation method of the super-light foam concrete. The preparation method is characterized by comprising the steps of weighing, mixing, stirring and pouring. The super-light foam concrete has the advantages of high percentage of close area, low water absorption, high compressive strength and low heat conduction coefficient. The preparation method of the super-light concrete has the advantages that the hydrogen peroxide decomposition efficiency can be improved, and the hydrogen peroxide decomposition speed can be effectively controlled.

Owner:CHONGQING UNIV +2

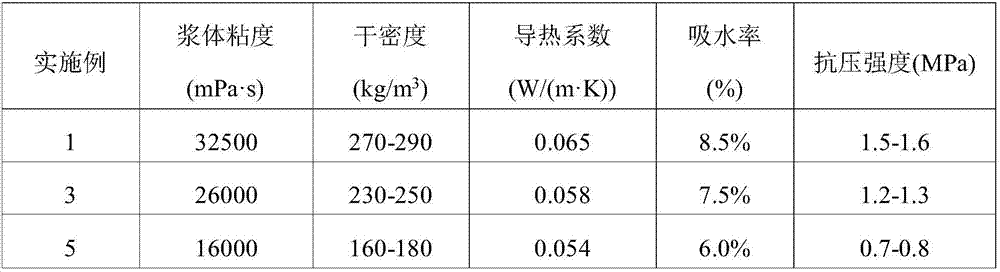

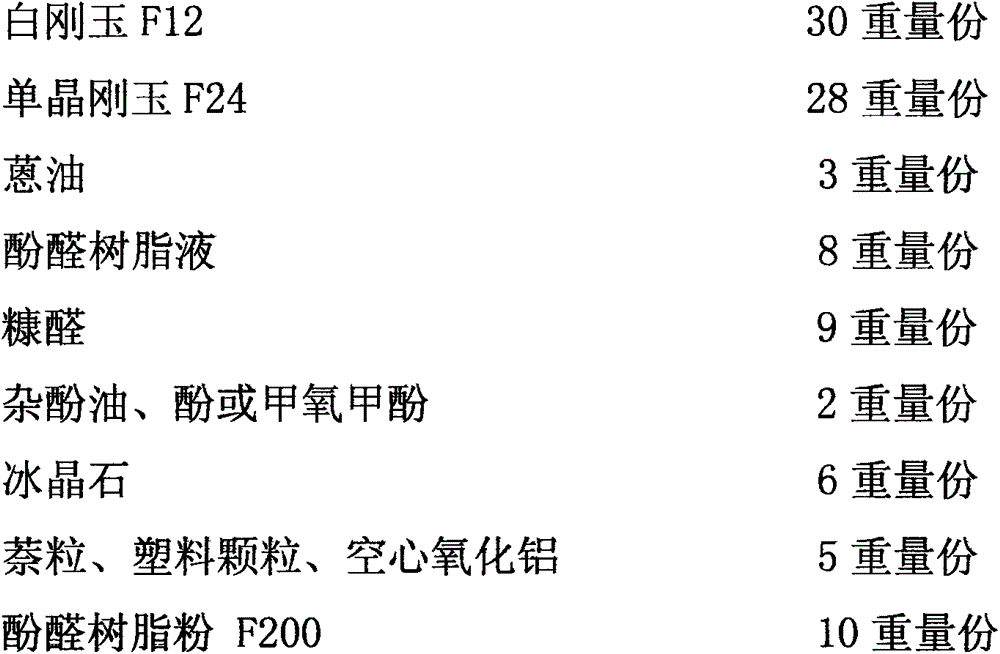

Resin grinding wheel preparation method

ActiveCN104128894AImprove production qualityGood chemical stabilityAbrasion apparatusGrinding devicesWettingPhenols

The invention provides a resin grinding wheel preparation method. A resin grinding wheel is prepared by combining multi-granularity white corundum, monocrystalline fused alumina, anthracene oil and phenolic resin liquid with furfural, kreosote, phenol or kreosol and cryolite, naphthalene grains, plastic particles and hollow alumina filling according to a certain weight ratio. By implementing the method, powder cannot be wrapped by wet materials in the process of mixing of materials, and influence on quality of a resin grinding wheel product due to the fact that the materials are not dispersed and cake is avoided. In addition, a certain weight part of silicon carbide is added in raw materials of mixed grinding materials, and grinding wheel cutting pieces different in performance can be acquired by controlling proportioning content of a silicon carbide grinding material, mixed white corundum and monocrystalline fused alumina and adjusting content of a wetting agent and phenolic resin powder within a certain range.

Owner:NINGBO DAHUA GRINDING WHEEL

Stirring device for processing health food

InactiveCN105688711AImprove mixing effectImprove production qualityTransportation and packagingRotary stirring mixersProduct processingEngineering

A stirring device for processing health food comprises a kettle, wherein a rotating shaft is arranged in the kettle; the top of the rotating shaft is connected with a variable frequency motor positioned above the kettle; two mounting columns are symmetrically arranged on the upper part and the lower part of the rotating shaft; a sliding groove is formed in each mounting column; the sliding grooves are T-shaped; a sliding block is arranged in each sliding groove; the sliding blocks are also T-shaped and are matched with the sliding grooves; one sides, which are close to the rotating shaft, of each sliding block and the corresponding sliding groove are fixedly connected with each other through a first spring; a stirring rod is fixedly connected between the two sliding blocks positioned above and below the same side of the rotating shaft; a plurality of connecting rods are uniformly arranged on the stirring rod; a slider sleeves each connecting rod; and each slider is fixedly connected with the stirring rod through a second spring. The stirring device for processing the health food has the beneficial effect that the stirring range can be changed as needed, the stirring effect is expanded, the product processing quality is improved, and production efficiency is also improved.

Owner:金柯楠

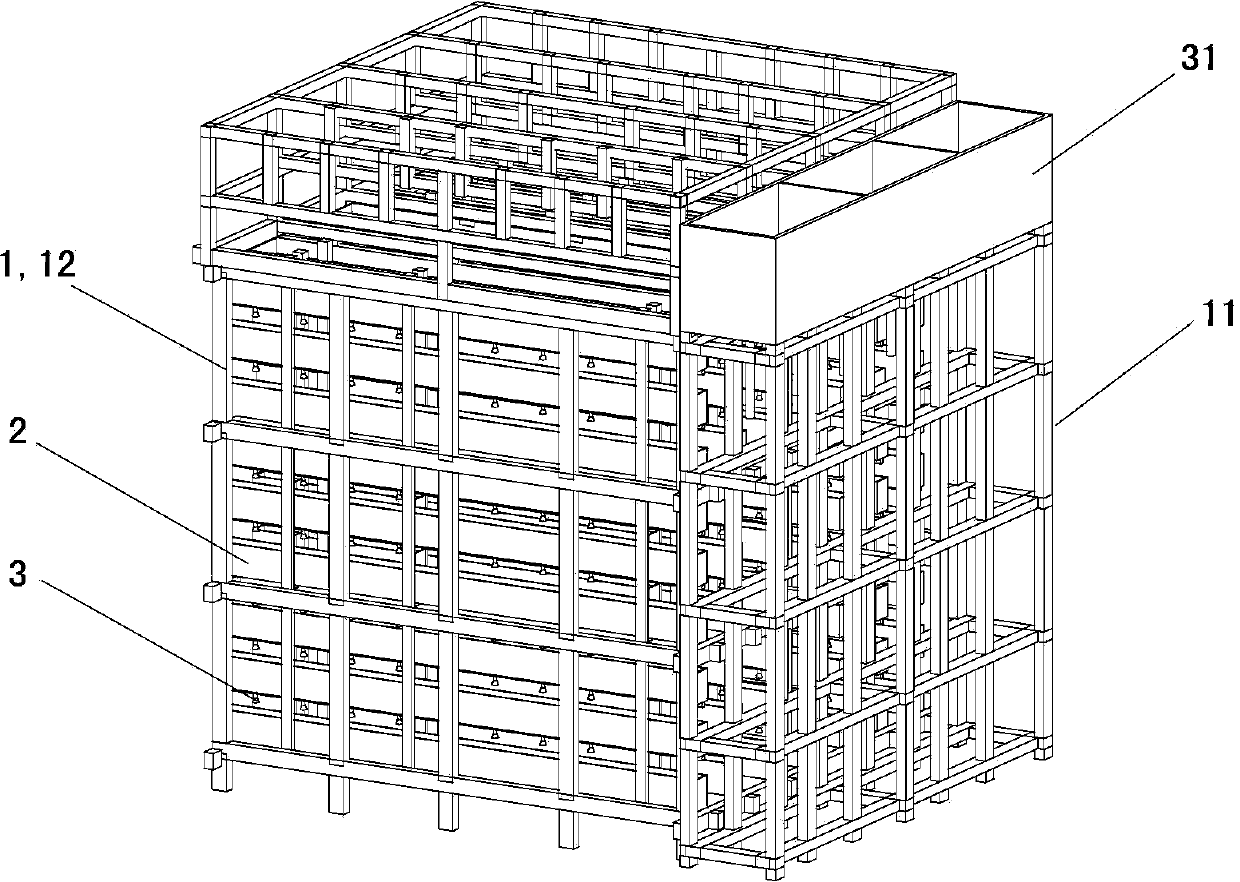

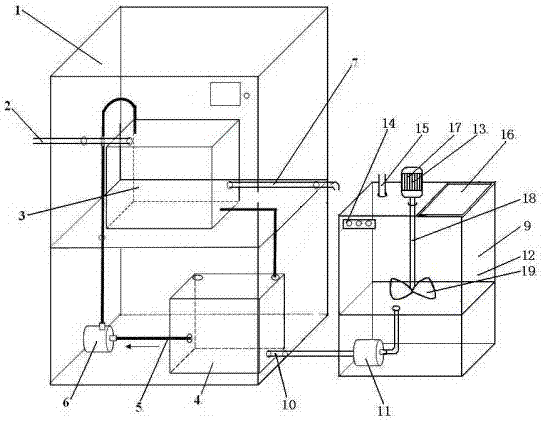

Agricultural greenhouse type three-dimensional cultivation system

InactiveCN103385136ASave spaceImprove production qualityClimate change adaptationAgriculture gas emission reductionAgricultural engineeringEnvironmental geology

The invention provides an agricultural greenhouse type three-dimensional cultivation system, which comprises a greenhouse framework, a crop cultivation system, a nutrient solution supply system and a product picking and transportation system. The crop cultivation system comprises a plurality of planting grooves, the planting grooves are respectively suspended on each crop cultivation framework, each crop cultivation framework is provided with a plurality of layers of planting grooves suspended from top to bottom to form a plurality of vertical planting lines. The nutrient solution supply system provides nutrient solution flow irrigation and nutrient solution drip irrigation. Picking and transportation of products in the planting grooves on the two sides of each channel can be realized by the product picking and transportation system through picking vehicles. By adopting the agricultural greenhouse type three-dimensional cultivation system, vegetable bases can be constructed in cities or in peripheral areas of the cities, local sale and wholesale of agricultural products can be realized, transit phases can be reduced, the cost can be decreased, and the equipment utilization rate and space utilization rate can be increased.

Owner:宋世荣

PCB (printed circuit board) spraying and etching production line

InactiveCN103369850AOvercoming the pool effectImprove production qualityConductive material chemical/electrolytical removalManufacturing qualityPrinted circuit board

The invention provides a PCB (printed circuit board) spraying and etching production line, which comprises upper and lower rows of opposite spraying heads and upper and lower rows of opposite rollers, wherein the spraying heads are used for spraying an etching liquid; the rollers are located between the upper and lower opposite spraying heads and used for clamping and transmitting PCBs; and at least a part of the rollers in the upper row is provided with a negative pressure structure and used for pumping the etching liquid at the upper surfaces of the PCBs. The PCB spraying and etching production line provided by the invention improves the manufacturing quality of the PCBs.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Automatic coating production line for steel spare parts

InactiveCN103846176AImprove labor productivityImprove production qualityLiquid surface applicatorsCoatingsEngineeringSpare part

The invention provides an automatic coating production line for steel spare parts. The automatic coating production line comprises an annular track, wherein the annular track is aerially and fixedly provided with an automatic sealing coating box and a drying box; the annular track is erected with at least one rotary work platform frame which can move along the track; the path of the annular track is respectively provided with a loading region and an unloading region; the rotary work platform frame is moved to the loading region along the annular track to be loaded with the steel spare parts, and then is moved to the automatic sealing coating box to be coated; then the rotary work platform frame is moved to the drying box to be dried and then is moved to the unloading region to be unloaded, so as to finish the automatic coating of the steel spare parts. With the adoption of the automatic coating production line for the steel spare parts, pollution-free and harmless automatic and streamlined work of an anti-corrosion coating process of the common steel spare parts can be realized. The labor production efficiency is improved, the production quality is improved and the injuries to a human body can also be reduced.

Owner:SHANGHAI JIANZHIZHEN ANTI CORROSION TECH DEV

Method for producing sophorolipid by continuous feeding and fermentation

InactiveCN101845469AShorten the fermentation cycleImprove production qualityFungiMicroorganism based processesMyceliumFermentation broth

The invention relates to a method for producing sophorolipid by continuous feeding and fermentation, including the following steps: (1) preparation of spore suspension: torulopsosis TJZKBA10326 is inoculated onto a slope and cultured at 30 DEG C for 2-4 days, and 0.75% physiological saline is added to wash mycelium, so as to obtain fungus suspension, 105-106 spores are contained in suspension; (2) the fungus suspension is used for being inoculated into liquid seed culture medium after sterilization, so as to obtain liquid seed; (3) the liquid seed culture medium is used for being inoculated into a 5L fermentation tank after sterilization to be fermented; (4) in the time period of 24-72h of fermentation, oil with the concentration of 30-60g / L is fed every 12h; in the fermentation process, glucose with the concentration of 30-60g / L is fed, so as to control the concentration of glucose to be 5-10g / L; dissolved oxygen is 20-30%, pH value is 3.3-3.8; (5) after fermentation for 72h, mixed organic solvent ethyl acetate / isopropanol with the same volume of fermentation liquid, ratio of 4:1 and unit of v / v is used for extracting sophorolipid, and vacuum-pumping method is used for removing organic solvent, and yield of sophorolipid is 200-240g / L. The method shortens fermentation period and improves production efficiency and yield.

Owner:天津实发中科百奥工业生物技术有限公司

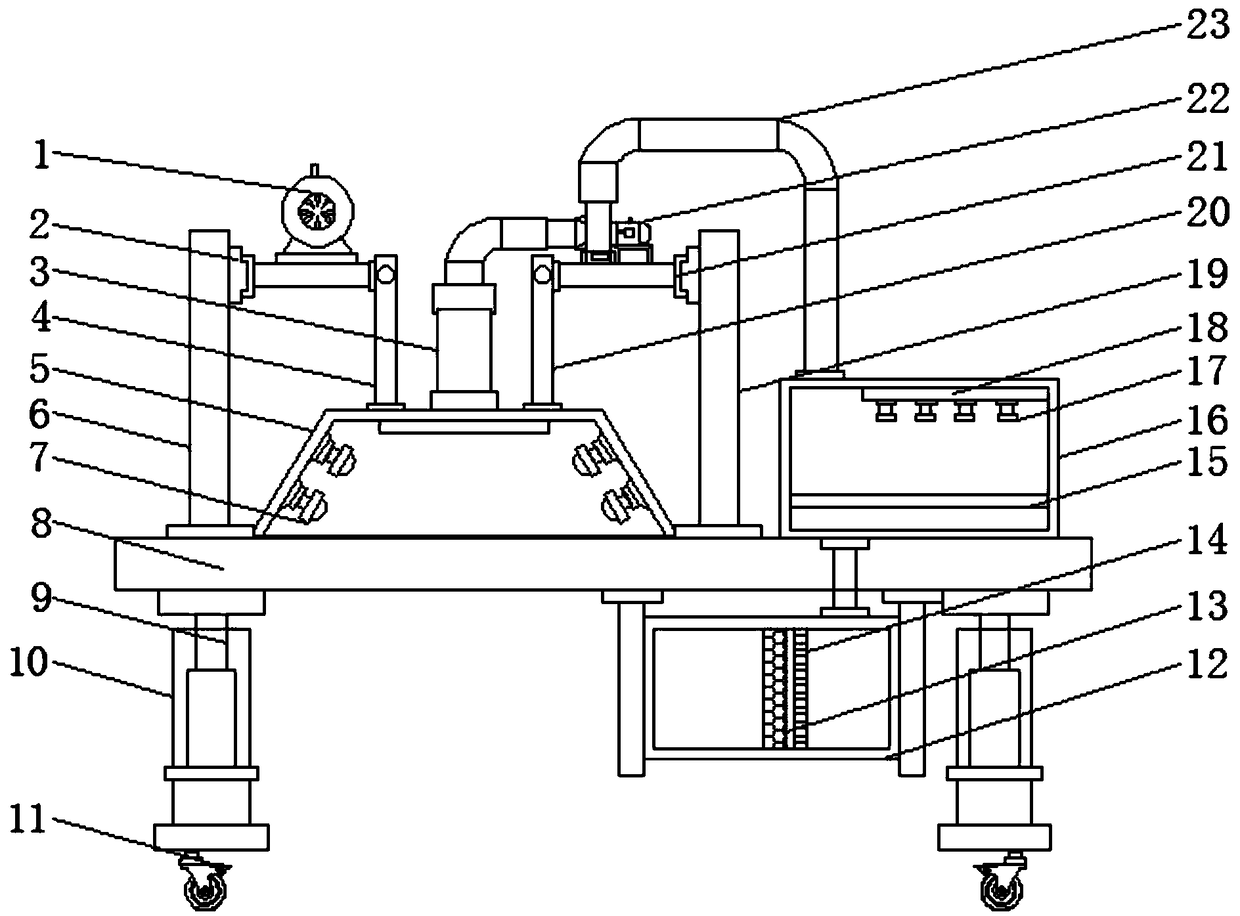

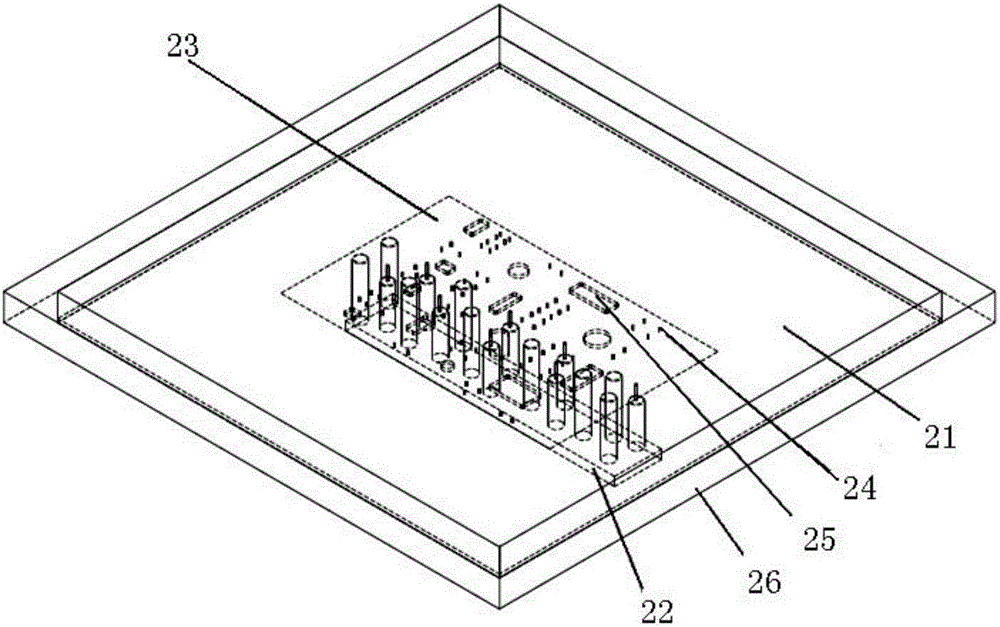

Lithium battery pole piece coating production processing system

ActiveCN112221852AImprove production qualityPrevents wrinkling and interfoldingLiquid surface applicatorsElectrode collector coatingPhysicsChemistry

The invention relates to a lithium battery pole piece coating production processing system. The lithium battery pole piece coating production processing system comprises a mounting table, winding mechanisms, a smoothing roller, tensioning mechanisms, a slurry coating mechanism and a drying mechanism, the winding mechanisms are mounted at the left end and the right end of the mounting table, the tensioning mechanisms are symmetrically mounted on the mounting table on the opposite inner sides of the winding mechanisms, the smoothing roller is arranged between the winding mechanism on the left side of the mounting table and the tensioning mechanisms through a roller frame, and the slurry coating mechanism and the drying mechanism are sequentially mounted on the mounting table between the twotensioning mechanisms from left to right. According to the lithium battery pole piece coating production processing system, gas with a certain pressure is introduced into a slurry box through a gas inlet pipe, and a certain pressure is generated in the slurry box to push slurry in the slurry box to flow, so that the flow of the slurry extruded from a slurry extrusion port is fixed, and the coatingthickness of the lithium battery pole piece is controlled.

Owner:湖南亿等新能源有限公司

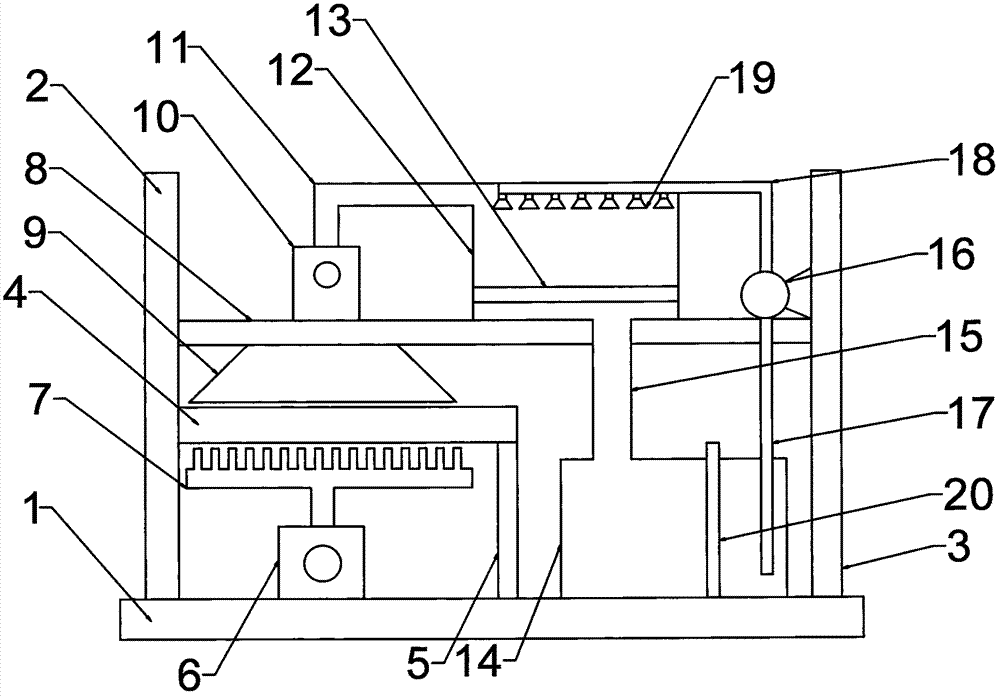

Textile mechanical dust removal device

InactiveCN106994275AImprove production qualityGood for collection and cleaningGas treatmentUsing liquid separation agentAerospace engineeringWater tanks

The invention discloses a textile mechanical dust removal device which comprises a base, a left upright column, a right upright column, a textile workbench, a horizontal platform and a water pump; a supporting column is arranged at the lower part of the right end of the textile workbench; an air blower is arranged on the left side of the upper part of the base; a blowhole platform is arranged at the upper part of the air blower; an air suction opening is formed in the left side of the lower end of the horizontal platform; an exhaust fan is arranged on the left side of the upper end of the horizontal platform; a ventilation pipe is arranged at the air outlet end of the upper end of the exhaust fan; the right end of the ventilation pipe is provided with a dust accumulation tank in a connecting manner; a filter screen is arranged at the lower part in the dust accumulation tank; a water tank is arranged on the right side of the upper part of the base; and a double-layer filter plate is vertically arranged in the water tank. According to the textile mechanical dust removal device, by matching densely distributed air blowing pipelines with the exhaust fan at the upper end, thread ends, fluffs and dust generated in the textile process can be rapidly and effectively eliminated, and the quality of production can be effectively improved.

Owner:杨露萍

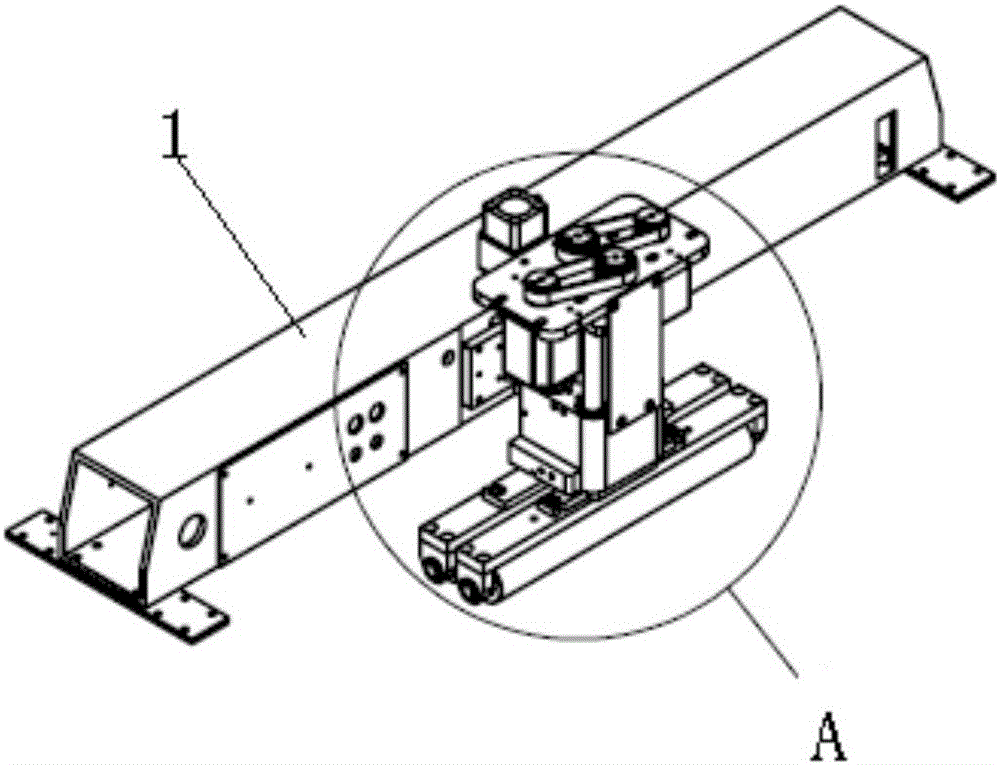

Single-phase automatic verification line technological layout

InactiveCN106628927AImprove Utilization and Production EfficiencyImprove production qualityStacking articlesDe-stacking articlesSingle phaseManufacturing engineering

The invention relates to a single-phase automatic verification line technological layout. According to the single-phase automatic verification line technological layout, a roller line and verification conveyor lines are adopted to accomplish the task in an assistance mode, and a combined parallel layout is adopted. Materials are conveyed from the same material warehouse outlet to the corresponding verification conveyor lines, the closed-loop working cycle of the materials on the conveyor lines is accomplished, and then the materials are collected to enter the roller line; and the materials are collected to enter the same material warehouse inlet so as to enter a vertical warehouse. The verification working efficiency of a single-phase meter production line can be improved to the maximum extent, the superiority of automation is made full use of, the resources are controlled and deployed according to the overall layout, the working resource utilization and the production efficiency are improved, and the production quality is improved.

Owner:EAST INNER MONGOLIA ELECTRIC POWER COMPANY

Dust blowing device for spinning machine

InactiveCN108607854AImprove production qualityGood for collection and cleaningUsing liquid separation agentTreatment involving filtrationEngineeringWater tanks

The invention discloses a dust blowing device for a spinning machine. The dust blowing device comprises a dust blowing cover, supporting stand columns, a circulation water tank and a dust collecting box. The output ends of hydraulic telescopic rods penetrate the top ends of the supporting stand columns and are horizontally provided with an installing platform. An installing frame is arranged at one end of the bottom end of the installing platform. The circulation water tank is arranged in the installing frame. The end, away from the installing frame, of the top end of the installing platform is vertically provided with a first vertical plate 6. The dust blowing cover is arranged at the bottom ends of a second installing frame and a first installing frame. Two dust blowing sprayers are arranged on the inner wall of each of the two sides of the dust blowing cover. The dust collecting box is arranged at the top end of the installing platform part on the side, away from the first verticalplate 6, of a first vertical plate 19. According to the dust blowing device, rapid dust blowing can be achieved, meanwhile, flying dust is collected in an air pumping manner, thread residues, flock and dust generated in the spinning process can be rapidly and effectively removed, and the production quality can be effectively improved.

Owner:JIANGSU BEILIN TEXTILE CO LTD

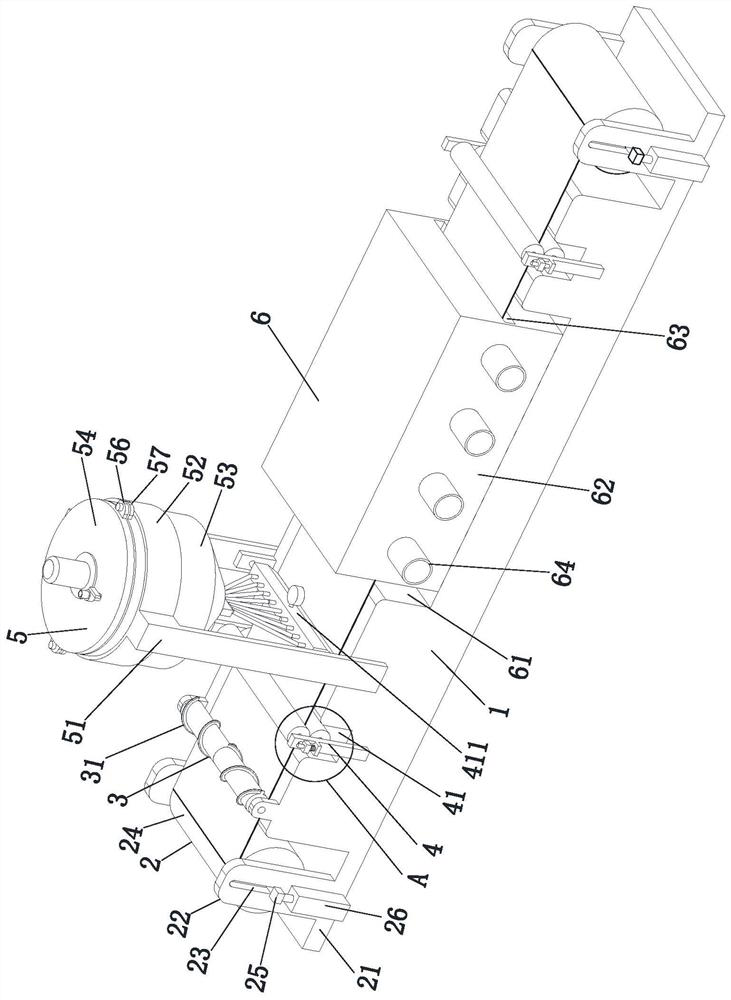

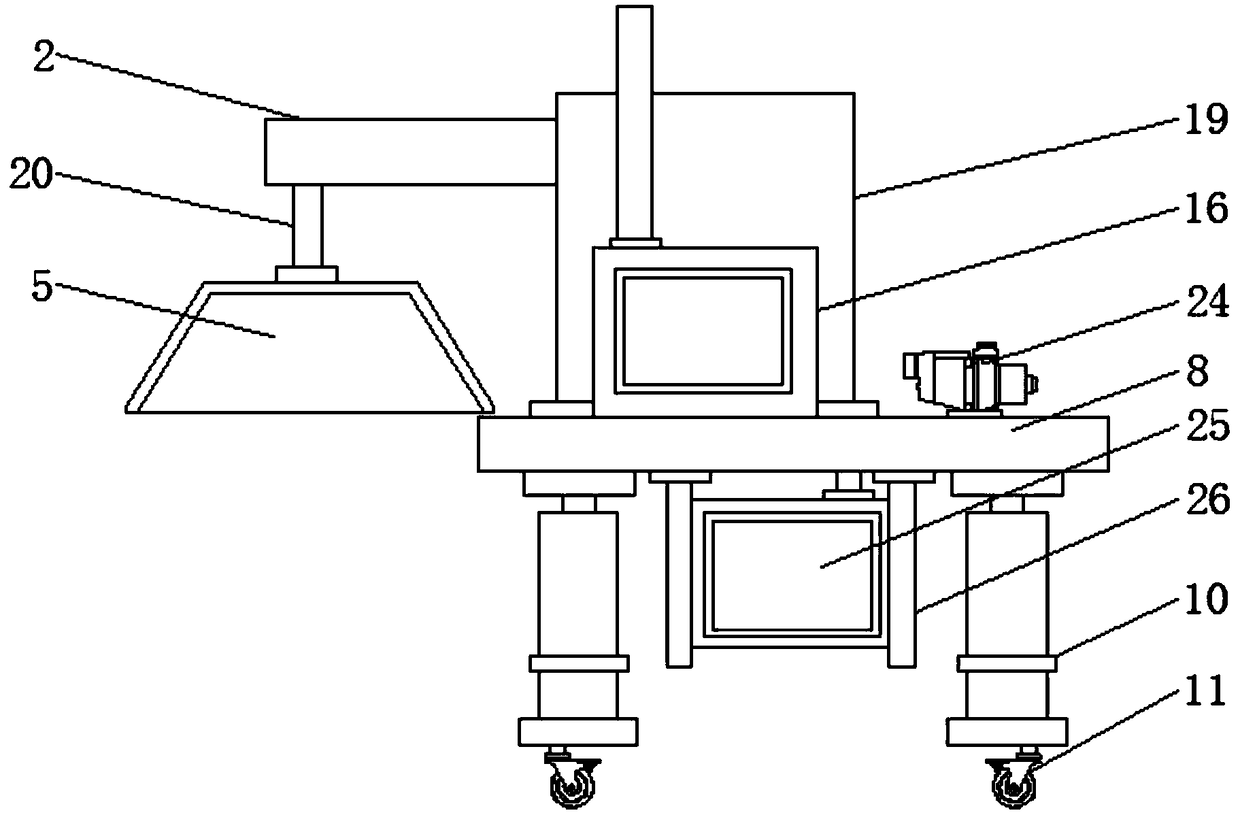

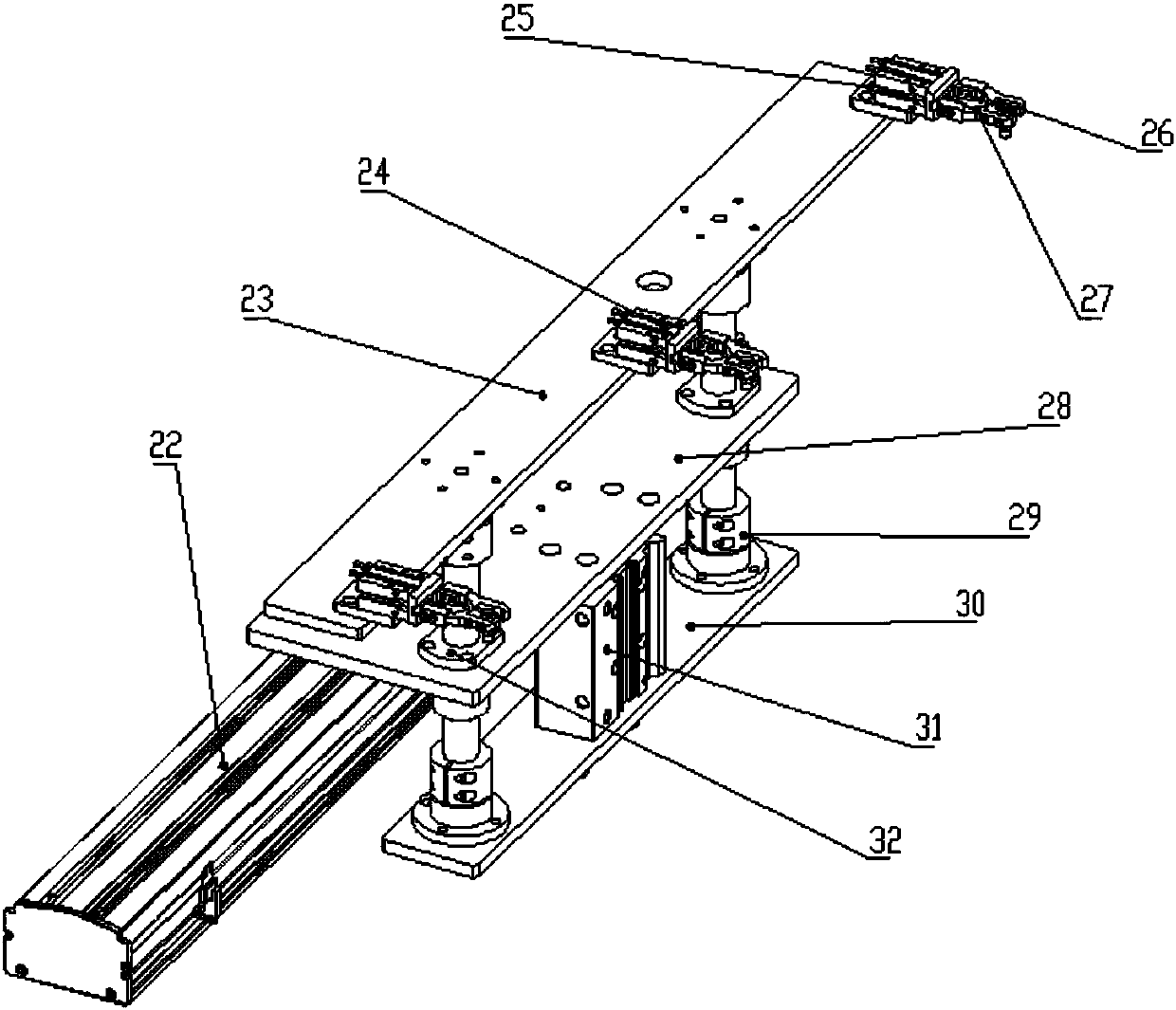

Burr detector for valve body

PendingCN107817247AImprove production qualityWide range of applicationsOptically investigating flaws/contaminationSortingMaterial transferGlitch

The invention discloses a burr detector for a valve body. A platform surface of a frame is provided with a feeding device, a transfer device, a locating device, an edge pressing device, a detection device and a discharge device in an uniform distribution manner; the transfer device is arranged on the outer sides of discharge opening ends of a valve body I feeding track and a valve body II feedingtrack of the feeding device; the right side of the feeding device is provided with the locating device; further, a locating tool that the locating device comprises is arranged under pneumatic claws ofthe transfer device; the rear side of the locating device is provided with the edge pressing device; a pressing head that the edge pressing device comprises is arranged right above an XY servo mobileplatform of the locating device; the detection device is arranged on the right sides of the locating device and the edge stamping device; the right side of the detection device is provided with the discharge device. By adopting the technical scheme, the key structure of a product can be subjected to sharp edge removal; the burr characteristic of a key surface is detected and the production quality is improved.

Owner:WUHAN CHRIS OPTOELECTRONICS TECH

Communication cabinet production line supervision system based on big data

PendingCN113793050AImprove production qualityImprove production stabilityResourcesManufacturing computing systemsProcess engineeringManufacturing line

The invention discloses a communication cabinet production line supervision system based on big data, relates to the technical field of communication cabinet production line supervision, solves the technical problem of high difficulty in cabinet production line supervision in the prior art. Natural environment and equipment environment are analyzed to judge whether a production line is influenced by the environment, the collected influence factors of the production line are convenient for the control of the production line, and the production quality of the communication cabinet can be improved; workers corresponding to the abnormal production signals are detected, so that the phenomenon of abnormal production of the production line caused by the abnormal workers is prevented, the production stability of the production line is improved, and the situation that the production of the production line is abnormal, the production cost is wasted, reworking is caused, and the production progress is hindered is avoided; the pollution of each production line is analyzed to prevent the pollution influence of the production line from exceeding the standard, so that the integral cost is increased, the production cost is increased, and the production efficiency of the production line is indirectly reduced.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

Efficient cooling device for aluminum veneer processing

InactiveCN110948285AImprove production qualityAvoid operating errorsMaintainance and safety accessoriesEngineeringWater tanks

The invention discloses an efficient cooling device for aluminum veneer processing and relates to the technical field of cooling. The efficient cooling device for aluminum veneer processing comprisesa water tank, a clamped-connection part is mounted on the inner wall of one side of the water tank in a welded mode, a filter plate is mounted on one side of the clamped-connection part in a clamped connection mode, the other end of the filter plate transversely penetrates through the inner wall of the water tank and extends outside the water tank, a water inlet pipe is mounted on the position, onone side of the clamped-connection part, of the inner side wall of the water tank in a welded mode, a stop valve is mounted on the water inlet pipe in a welded mode, a submersible pump is fixedly mounted on the inner side of the bottom of the water tank, and a first hard pipe is mounted at the output end of the submersible pump in a welded mode. Through cooperative use of the submersible pump, the first hard pipe, a telescopic hose pipe, a second hard pipe and a spray head, the device can be effectively cooled in the operating process, so that the production quality of products is improved toa certain extent, and meanwhile misoperation caused by overheating processing is also avoided to a certain extent.

Owner:湖州好灵通铝业有限公司

Corn kernel processing impurity removing machine

InactiveCN107695026ASimple device structureImprove production qualityGas current separationGranular material dryingNozzleVibration motor

The invention discloses a corn grain processing and removing machine, which comprises a cleaning box, a first motor, a three-way pipe, a cover, a transmission wheel and a wind cover. A water outlet hole is arranged on the left side of the bottom of the cleaning box. The first motor The first bearing and the first chain are respectively rotatably connected to the screw rod, the second motor is installed above the cover, the second motor is rotatably connected to the second bearing through the second chain, and the top of the three-way pipe is respectively installed There is a water valve and a water injection port, a discharge port is provided at the lower right corner of the cleaning box, a third motor is installed on the right side of the vibration motor, and a first conveyor belt and a second conveyor belt are respectively installed between the transmission wheels. A sundry collection box is installed above the wind shield, and the wind shield is located above the first conveyor belt. The corn kernel processing impurity removal machine can quickly clean and remove corn kernels, and can also screen corn kernels to further improve the quality of corn production.

Owner:陈银芳

Wafer positioning device and method

ActiveCN107393855AImprove production qualitySimple structureSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringMulti point

The invention provides a wafer positioning device and related method. The device comprises a wafer rotation mechanism, a mark detector and a control module, wherein the wafer rotation mechanism is provided with a rotation center and comprises driving wheels, the driving wheels are in contact with wafers and are used for driving the wafers to rotate around the rotation center, the mark detector is used for detecting positioning marks on the wafers and sending a detection result to the control module, and the control module is used for controlling the driving wheels according to the detection result of the mark detector so as to achieve wafer positioning. In the wafer positioning device, a traditional suction disc suction mode is substituted by employing the driving wheels to drive the wafers, the damage to the wafers can be prevented during positioning, multi-point detection and positioning can be achieved, multi-segment speed control is achieved, and the wafer positioning device is high in efficiency and accuracy, simple in structure and low in cost.

Owner:ZING SEMICON CORP

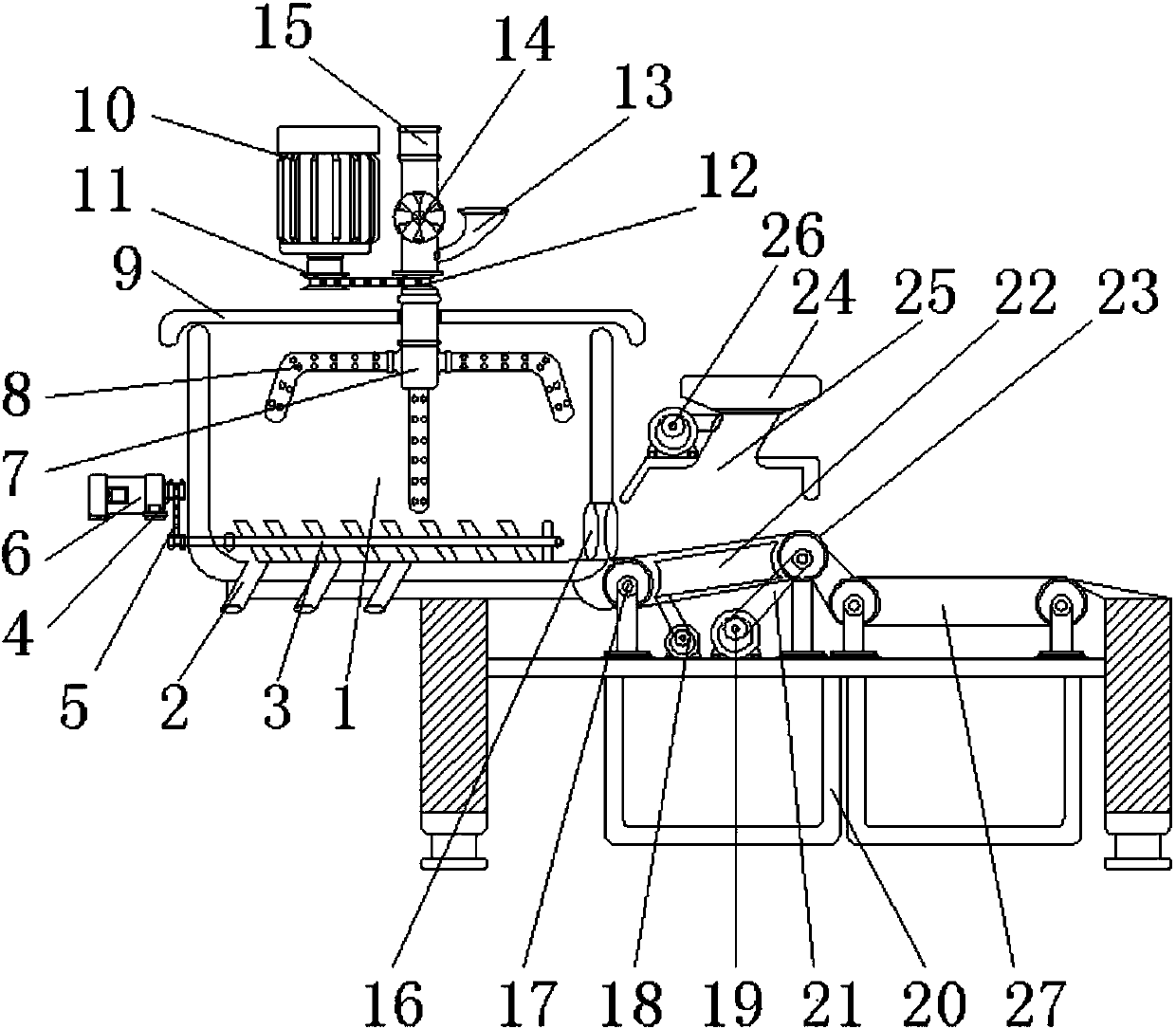

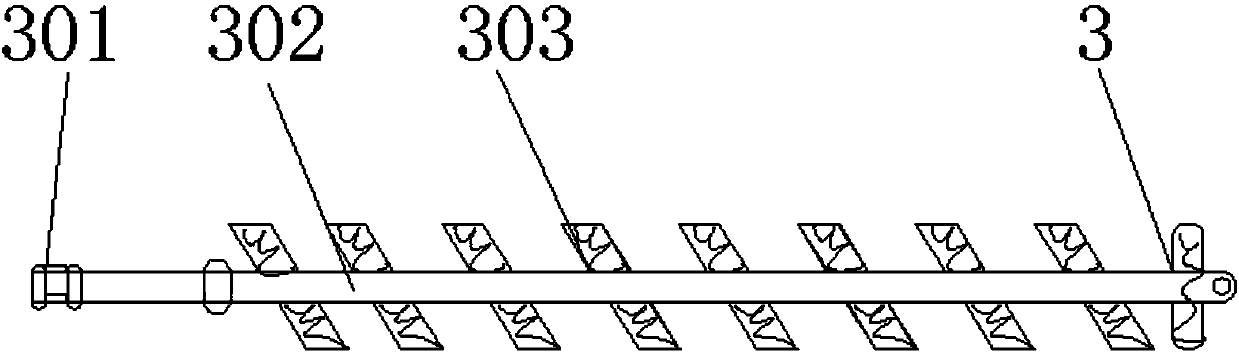

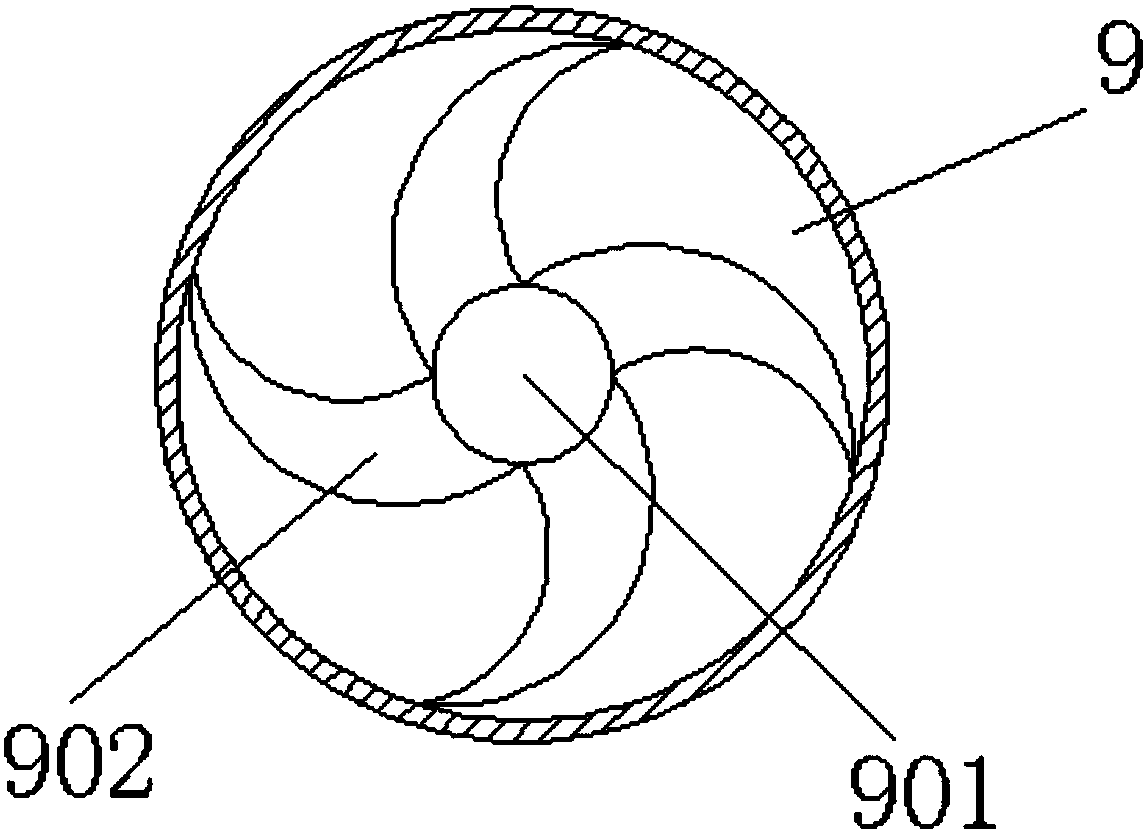

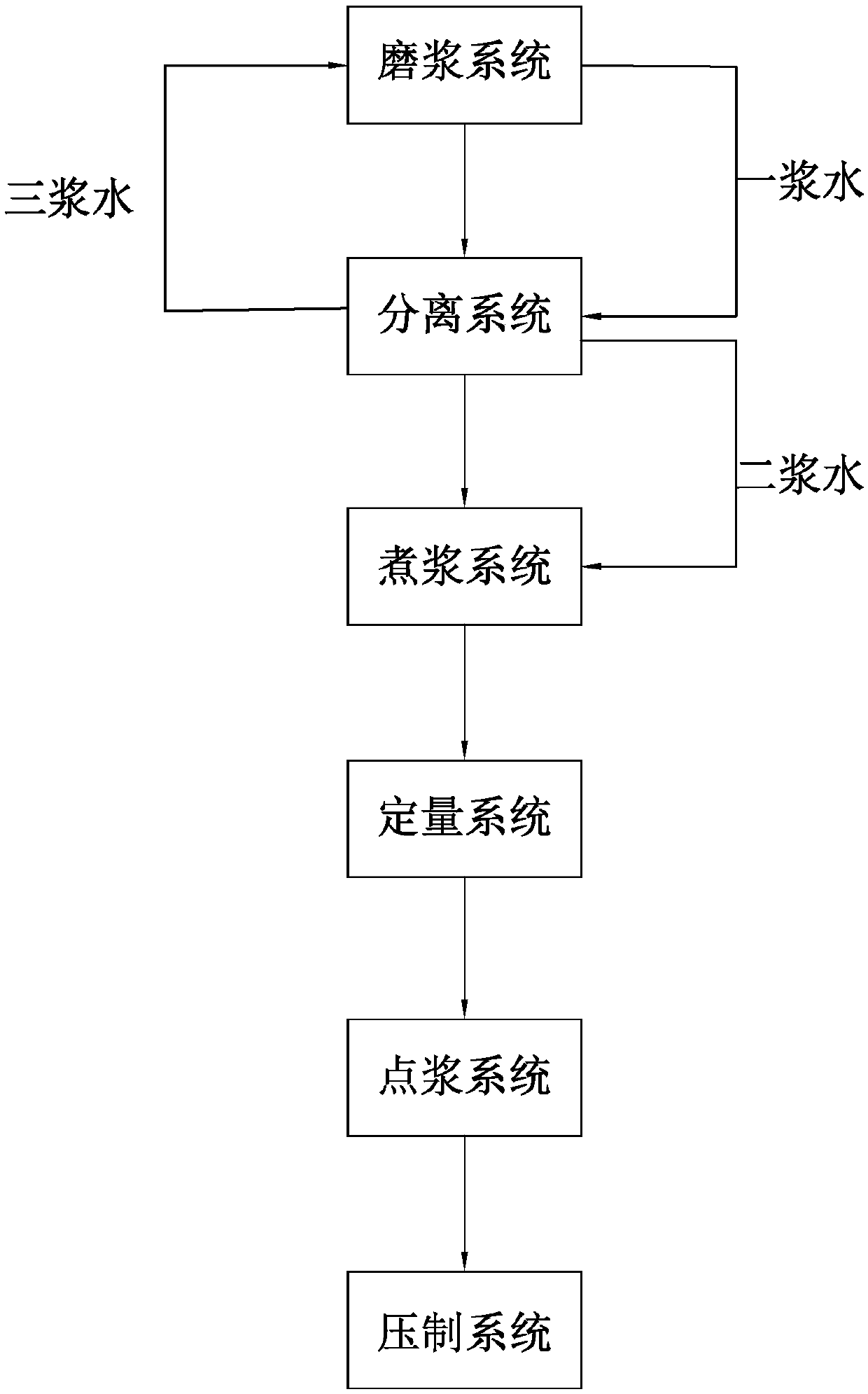

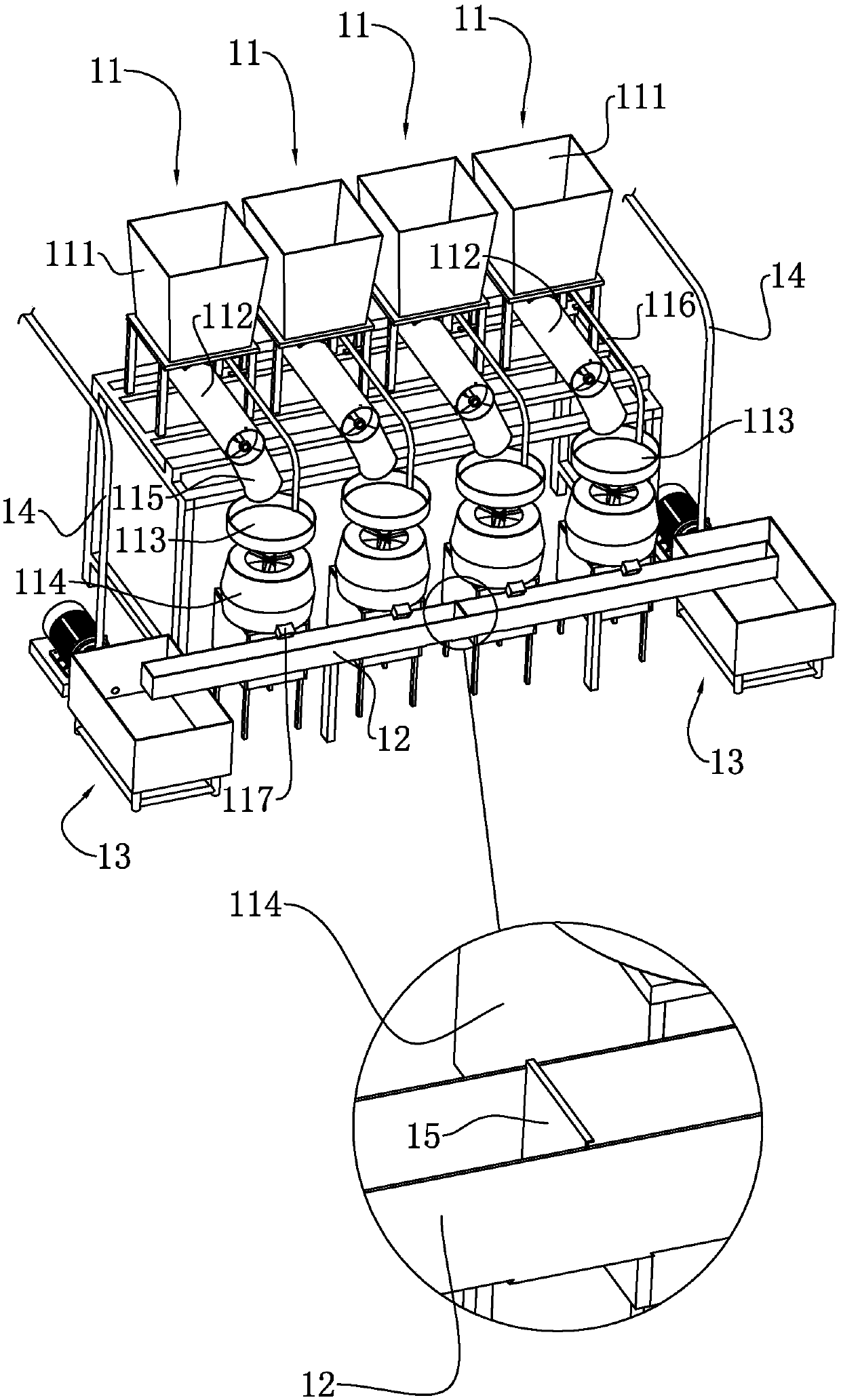

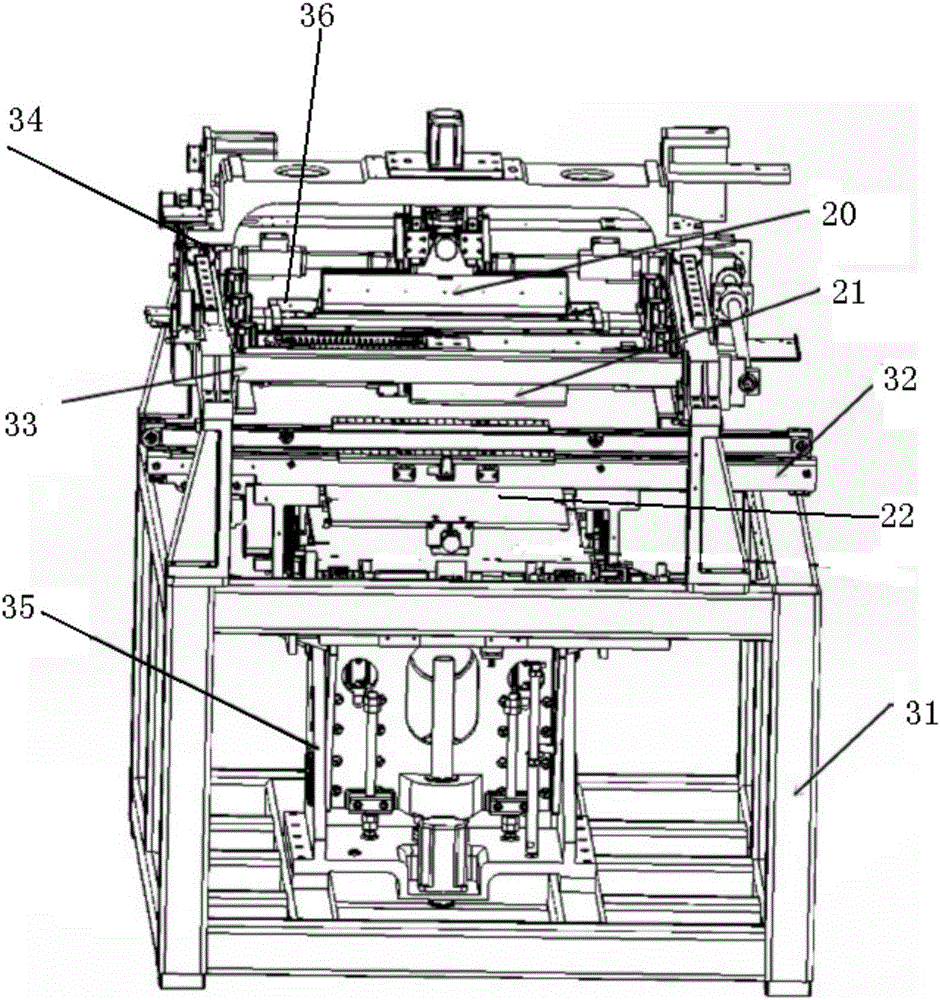

Bean curd production line

ActiveCN107668218AImprove production qualityIncrease productivityProtein composition from vegetable seedsCheese manufactureRefluxFiltration

The invention discloses a bean curd production line. The key points of the technical scheme are that the production line comprises a pulp grinding system, a separation system, a pulp boiling system, aquantification system, a pulp adding system and a pressing system which are sequentially arranged; the separation system comprises a separation device, a separation driving device, and a bean dreg treatment device which is arranged below the separation device and communicates with the separating device; the bottom of the separation device communicates with a fluid-discharge pipe and a dreg-discharge pipe; the fluid-discharge pipe conveys pulp water separated by the separation device to the pulp boiling system; the dreg-discharge pipe conveys bean dregs separated by the separation device to the bean dreg treatment device; the bean dreg treatment device is used for stirring and filtering the bean dregs falling from the separation device; the bean dreg treatment device communicates with thepulp grinding system through a three-pulp reflux pipe; and the pulp grinding system communicates with the separation device through a conveying pipe. The bean dreg treatment device conducts extractionand filtration on the bean dregs so as to form three-pulp water, and the three-pulp water is reused by the pulp grinding system to form a one-pulp water, so that production quality and production efficiency of bean curd are improved.

Owner:北京二商希杰食品有限责任公司

Three-roll plug steadier

ActiveCN102601117AImprove center coincidenceImprove production qualityMandrelsMetal rolling arrangementsSteel tubeTransmission ratio

The invention discloses a three-roll plug steadier, which comprises three corresponding rolls, three swing rods and three sets of linkage mechanisms. The output end of any swing rod is in pivoted connection with one corresponding roll, the input end of any swing rod is in fixed connection with one end of an output rod of one corresponding linkage mechanism and hinged on the fixed rotation shaft of the output rod, the input rods of the three linkage mechanisms share the same fixed rotation shaft and are in linkage, the transmission ratios of any two linkage mechanisms are 1, and the transmission ratio of the other linkage mechanism is -1 plus or minus 0.5%. The three-roll plug steadier provided by the invention can improve equipment utilization rate and service life and lower production costs while greatly improving production quality of seamless steel tubes.

Owner:TAIYUAN HEAVY IND

Sewing auxiliary tool for embedding braid into clothes

The invention relates to a sewing auxiliary tool for embedding a braid into clothes. The sewing auxiliary tool is provided with a pipe-shaped auxiliary part for threading the braid and a connecting plate for fixing the auxiliary part, wherein the connecting plate is fixedly connected with the auxiliary part. One part of the pipe-shaped auxiliary part, which is closely connected with the connecting plate, is provided with an open slit which is communicated with the hollow inner part of the pipe-shaped auxiliary part and is used for conveniently keeping flat when thin fabric on the braid moves. When the connecting plat is horizontally placed, the distance of the bottom face of the auxiliary part, which is higher than the bottom face of the connecting plate, is the same as or slightly greater than the thickness of sewed clothes fabric, so that the sewing of embedding the braid into the clothes can be finished at one time and the working efficiency is improved; and the pipe-shaped auxiliary part enables the position of a decorative braid to be fixed and does not deviate, so that the sewing position is controlled, the width of the sewed decorative braid is fixed and the production quality is improved.

Owner:JIANGSU LIBURUI GARMENT

Multifunctional printing machine

InactiveCN105799314AImprove production qualityPrinted PCB board through hole is convenientScreen printersPrinting press partsMovement controlEngineering

The invention discloses a multifunctional printing machine. The multifunctional printing machine comprises a machine frame. An adjustable conveying rail device which is used for conveying products is arranged on the machine frame, and the vertical position of the adjustable conveying rail device can be adjusted according to the thickness of the products. A steel mesh movement device is arranged over the adjustable conveying rail device. A scraper movement control device is arranged over the steel mesh movement device. The steel mesh movement device is used for controlling a steel mesh. The scraper movement control device is used for controlling a rigid or flexible scraper bit. A product lifting device is arranged under the adjustable conveying rail device. A top PING structure is arranged on the product lifting device. The steel mesh movement device, the adjustable conveying rail device, the scraper movement control device, the product lifting device and the scraper bit are all controlled by a control device. The control device is provided with two control systems. Free switching between the two control systems is achieved through a switching button. The two control systems include the PCB printing control system and the SMT board printing control system. When the PCB printing control system is in use, the scraper bit is flexible; and when the SMT board printing control system is in use, the scraper bit is rigid.

Owner:东莞市创威自动化科技有限公司

Process for producing carbon fibers with less damage

InactiveCN110499551AAvoid fuzzImprove production qualityTextile treatment carriersArtificial filament chemical after-treatmentSizingSurface finishing

The invention discloses a process for producing carbon fibers with less damage. The process comprises the following steps of a, unwinding of filaments and collection of lines, wherein raw filaments are selected, and new filaments and old filaments are connected through heat-resistant fibers after bundle separation and erected on a line collecting plate; b, initial drying, wherein the line collecting plate and the raw filaments are conveyed into a drying device for drying to remove moisture contained in the raw filaments; c, pre-oxidation, wherein the dried raw filaments are fed into three pre-oxidation ovens arranged continuously for pre-oxidation; d, carbonization; e, surface treatment; f, sizing; g, filament collection. The process has the advantages that by adopting yarn expanding equipment adjustable in height in a sizing process and adjusting the height of yarn expanding fixed rollers, the tension of yarn can be adjusted, so that the stress of the carbon fibers is released, the carbon fibers are protected from fuzzing, damage and twisting, and therefore the production quality of the carbon fibers is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

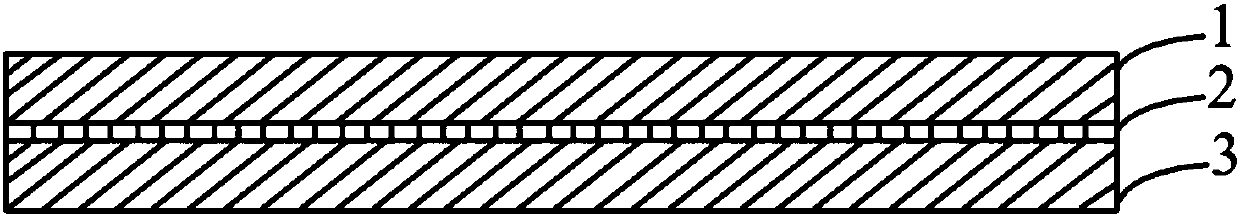

Laminated film and preparation method thereof

InactiveCN108039314APrevent falling offImprove production qualityVacuum evaporation coatingSputtering coatingMetalContact layer

The invention provides a laminated film and a preparation method thereof. The preparation method comprises the following steps that: a first film layer is deposited on a substrate, wherein the first film layer can be a metal layer or a semiconductor layer; a loose and porous force-release contact layer is formed on the first film layer; and a second film layer is formed on the force-release contact layer, wherein the second film layer can be a semiconductor layer or a metal layer. According to the laminated film and the preparation method thereof provided by the invention, the force-release contact layer is deposited, so that stress between the metal layer and the semiconductor layer can be released, the film layers can be prevented from falling off, and production quality is improved.

Owner:LINGFAN RENEWABLE ENERGY TECH BEIJING CO LTD

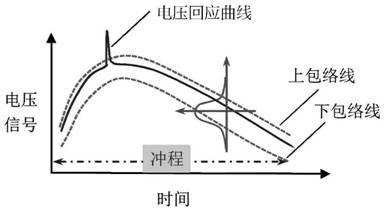

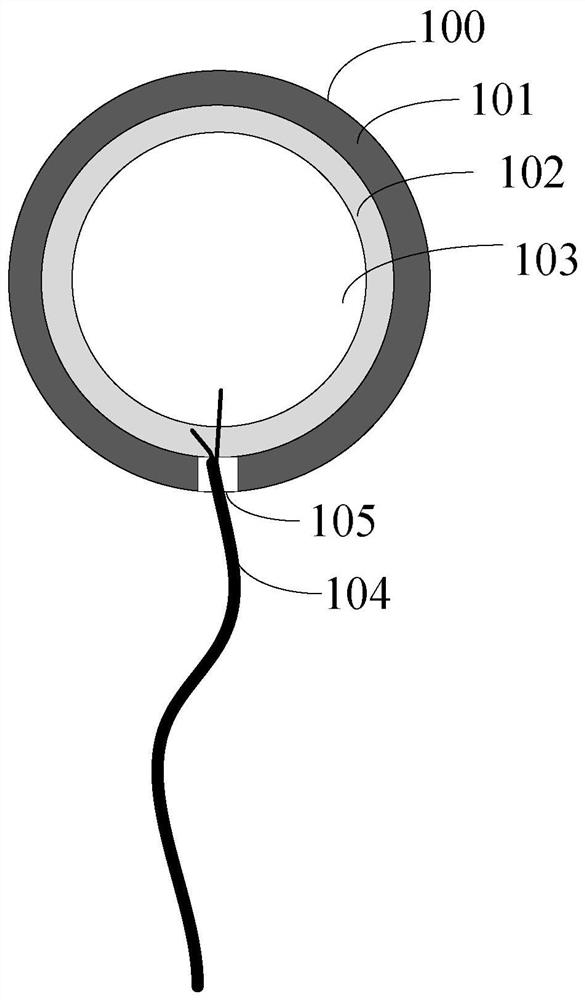

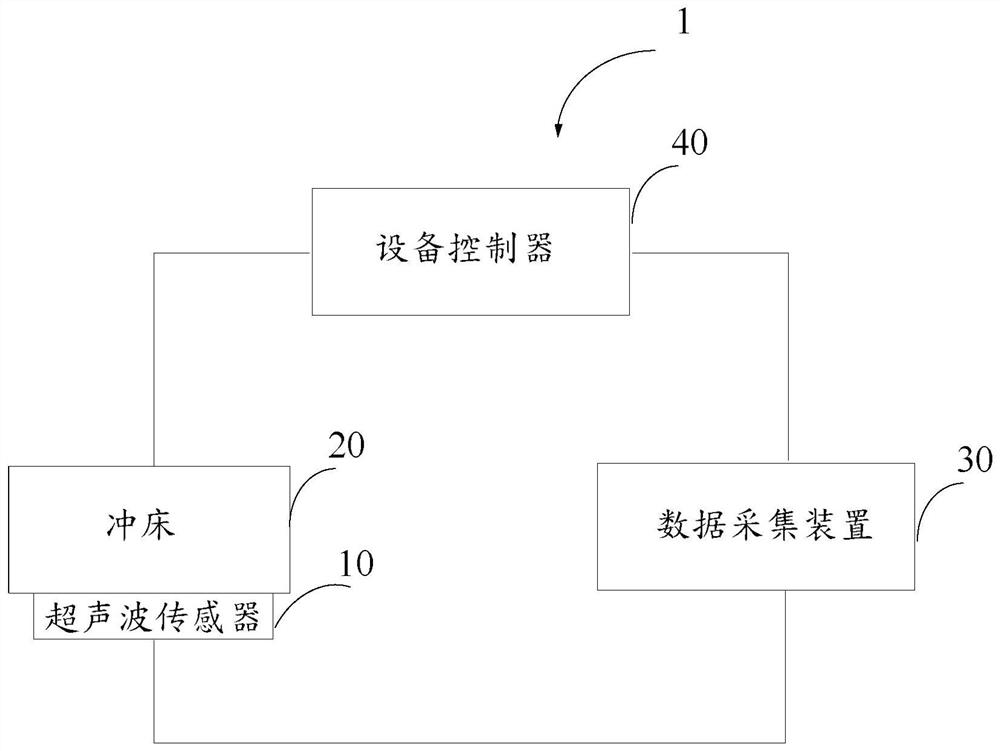

Press abnormality detection system

PendingCN114433656AImprove production qualityImprove product qualityMaterial analysis using acoustic emission techniquesSubsonic/sonic/ultrasonic wave measurementReal time acquisitionVoltage response

A punching abnormity detection system comprises a punching machine which generates a vibration signal when working; the ultrasonic sensor is fixed on the punching machine and is used for converting the vibration signal into a voltage response signal; the data acquisition device is electrically connected to the ultrasonic sensor and is used for acquiring the voltage response signal in real time, generating a monitoring envelope curve, analyzing whether the voltage response curve deviates from the monitoring envelope curve or not, judging that the punching machine is abnormal when the voltage response curve exceeds the monitoring envelope curve and outputting an abnormal signal; and long-term vibration parameters of the production equipment are monitored, so that production interruption caused by abnormity of the equipment in the production process is predicted, and the production quality is improved.

Owner:SHENZHEN FUGUI PRECISION IND CO LTD

Mixing device capable of improving quality of nanometer material

InactiveCN106955620AImprove production qualityImprove liquidityRotary stirring mixersTransportation and packagingNozzleProduction quality

The invention discloses a mixing device capable of improving the quality of a nanometer material. The mixing device comprises a mixing drum body, the diameter of the mixing drum body is gradually reduced from up to bottom; a drum cap is arranged above the mixing drum body, the drum cap is an upward raised curved surface, and the inner wall of the drum cap is connected with a flat nose spray board; the flat nose spray board is an upward raised arc, a nozzle of the flat nose spray board is downward, and the arc length of the flat nose spray board is matched with the arc length of the inner wall of the drum cap; the drum cap and the mixing drum body are in movable connection, the drum cap rotates around the axis of the mixing drum body; a mixing shaft is connected with the lower side of the drum cap, the mixing shaft extends out from the drum cap and is connected with a motor; multiple vertically arranged mixing blades are connected on the mixing shaft; and multiple dispersion holes are formed on the mixing blades. The mixing device disclosed by the invention firstly can realize uniform feeding, so that the materials are unfirmly mixed, the production quality is improved; and the fluidity among the materials are enhanced, the agglomeration is avoided, and the quality of the material is improved.

Owner:四川纳诺科技有限公司

Production device and production method of biomass organic carbon-based potash fertilizer

ActiveCN103755466AImprove production qualityReduce pollutionFertilizer mixturesLong actingPulverizer

The invention relates to a production device and a production method of a biomass organic carbon-based potash fertilizer. The production device comprises a placement tank, pretreatment equipment, a pelletizer, a dryer, a packing machine and a control system, wherein a feeding conveyer is arranged between the placement tank and the pretreatment equipment; the pretreatment equipment comprises a stirring mixer, a screening machine and a pulverizer; the control unit comprises a control panel, a programmable controller and a metering unit; the control unit controls starting and stopping of the pretreatment equipment, the pelletizer, the dryer and the packing machine. By adopting the production device and the production technology, the required biomass organic carbon-based potash fertilizer is finally obtained in manners of screening, stirring and mixing by the pelletizer and the dryer. The fertilizer is not only healthful and clean, but also small in pollution on environment, high in production efficiency, high in automatic degree, convenient to control, and economical in cost; the produced fertilizer mainly contains a carbon element, which can be decomposed in soil, is free of residue absolutely, and has long-acting characteristics of improving the soil.

Owner:河南金土地科技服务有限公司

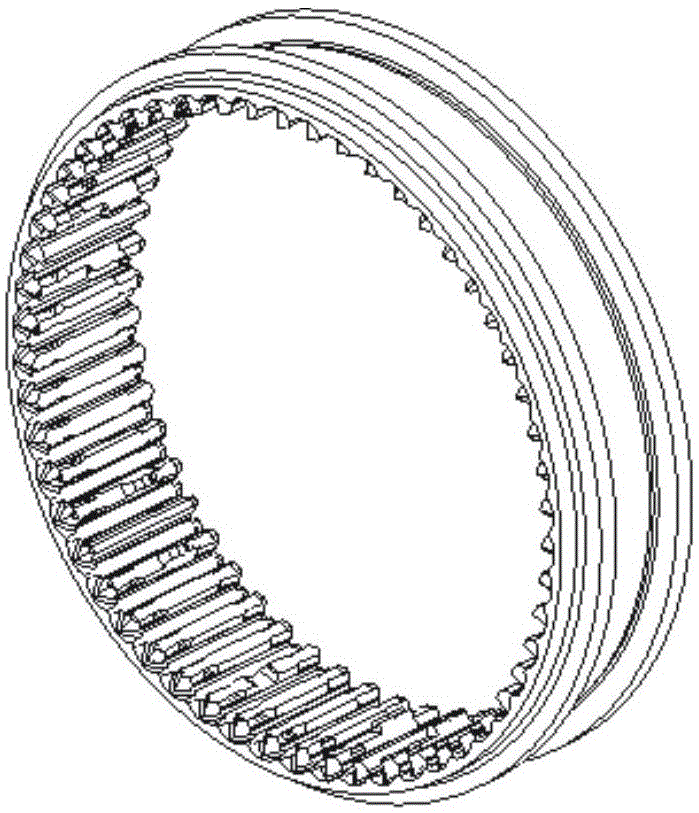

Torque test auxiliary tool of synchronizer

ActiveCN105067258AImprove production qualityLow manufacturing costMachine gearing/transmission testingTest benchFlange

The invention discloses a torque test auxiliary tool of a synchronizer. The torque test auxiliary tool of the synchronizer comprises a torque bearing wheel and a torque input shaft, wherein the torque bearing wheel comprises a flange, a middle shaft and a gear sleeve fixing disk which are fixed in sequence, the flange is capable of being fixedly connected with a test bench, the gear sleeve fixing disk is capable of being fixed to a synchronizer gear sleeve to be detected, and the synchronizer gear sleeve is in tooth engagement with a synchronizer gear hub; and one end of the torque input shaft is coaxially fixed to a power input shaft, and the other end is provided with a driving gear engaged with the synchronizer gear hub. According to the invention, the synchronizer gear sleeve and the synchronizer gear hub are engaged, the torque input shaft and the synchronizer gear hub are engaged, the power input shaft is enable to apply a dynamic and bidirectional load, and in this way, the reliability of a synchronizer is detected, and the production quality of the synchronizer is improved; in addition, the torque test auxiliary tool is capable of ensuring the production quality of the synchronizer in a synchronizer production process, so that the problem that the quality problem of the synchronizer is not found until in a complete vehicle test is solved, so that the manufacturing cost of an integral vehicle is lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Strong basic electrolysis water generating device for controlling temperature of electrolyte

InactiveCN107055698AImprove production qualityIncrease production outputWater treatment parameter controlTreatment control/steeringEnvironmental chemistryElectrolysed water

The invention discloses a strong basic electrolysis water generating device for controlling the concentration of electrolyte and belongs to the technical field of electrolysis water production. The strong basic electrolysis water generating device is characterized in that an electrolyte solution concentration real-time replenishing device is arranged on an existing strong basic electrolysis water generating device and comprises a liquid replenishing pipe, a liquid replenishing pump, a liquid preparing tank and a stirrer; the stirrer is arranged in the liquid preparing tank and is used for stirring to enable the concentration of the electrolyte solution to be uniform; the liquid replenishing pump is arranged on the liquid replenishing pipe; the liquid preparing tank is communicated with an electrolyte solution storing tank by the liquid replenishing pipe. The strong basic electrolysis water generating device has the beneficial effects that the concentration of the electrolyte solution in the electrolysis process can be effectively controlled, the concentration of the electrolyte solution is enabled to meet the requirements, and the production quality of electrolysis water is improved; electrolysis equipment is enabled to continuously work, and production output of the electrolysis water is greatly increased; a concentration sensing device can be used for controlling and stabilizing the concentration of electrolyte in real time.

Owner:重庆七口泉生物医药科技有限公司

Production process and method of fruit-flavored coffee beverage

PendingCN110859235ARich drinking experienceImprove production qualityRoasted coffee treatmentCoffee extractionOrange juiceCoffea

The invention discloses a production process and method of a fruit-flavored coffee beverage. The production process and method of the fruit-flavored coffee beverage comprise the following steps: pretreating coffee beans, crushing and grinding the coffee beans by using a grinder, performing sieving by using a 200-mesh sieve to obtain coffee bean powder, spreading the coffee bean powder in an oven according to a thickness of 6-10mm, performing baking for 40-60 minutes at a temperature of 225-235 DEG C, performing natural cooling, and then collecting the coffee bean powder for later use. According to the production process and method of a fruit-flavored coffee beverage, the beverage is produced by taking the coffee beans and oranges as main raw materials, so that the beverage has a taste of orange fruits while the taste of coffee is kept, and drinking experience of the beverage is enriched; orange juice is processed by adopting an enzymolysis and fermentation mode, so that nutrient elements in an orange beverage can be sufficiently extracted; and the fruit-flavored coffee beverage is prepared by a low-temperature freeze-drying mode, so that nutrition is not damaged.

Owner:安徽省金宜食品有限公司

Enveloping all-in-one machine

InactiveCN111977456AImprove production qualityQuality impactFilament handlingFibre cleaning/openingRotational axisYarn

The invention discloses an enveloping all-in-one machine. The enveloping all-in-one machine comprises a supporting base, a first transverse supporting frame is fixedly connected to the bottom of the inner side of the supporting base, a second transverse supporting frame is fixedly connected to the top of an enveloping barrel, and a limiting block is fixedly connected to the top of the second transverse supporting frame. The enveloping all-in-one machine is provided with a wrap yarn winding drum and a winding drum limiting ring, wherein the right end of a rotating shaft is movably connected with a rotating shaft supporting column, the rotating shaft is fixedly connected with a rotating motor, the outer surface of the rotating shaft is sleeved with the wrap yarn winding drum firstly, at themoment, the wrap yarn winding drum is movably connected with the rotating shaft, the winding drum limiting ring is connected with the rotating shaft in a sleeve mode, then the two ends of the wrap yarn winding drum are clamped through buckles of the winding drum limiting ring, meanwhile, the wrap yarn winding drum and the rotating shaft are further clamped through magnetic blocks inside the winding drum limiting ring, the situation that when a rotating motor suddenly stops rotating, the wrap yarn winding drum still rotates due to inertia is effectively avoided, and the production quality of the device is greatly improved.

Owner:江苏衣道科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com