Super-light foam concrete and preparation method thereof

A technology of foam concrete and ultra-fine fly ash, which is applied in the field of foam concrete, can solve the problems of slow hydrogen peroxide decomposition, increased production cost, and low foaming efficiency, so as to speed up the setting and hardening speed, speed up the turnover speed, and improve the production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

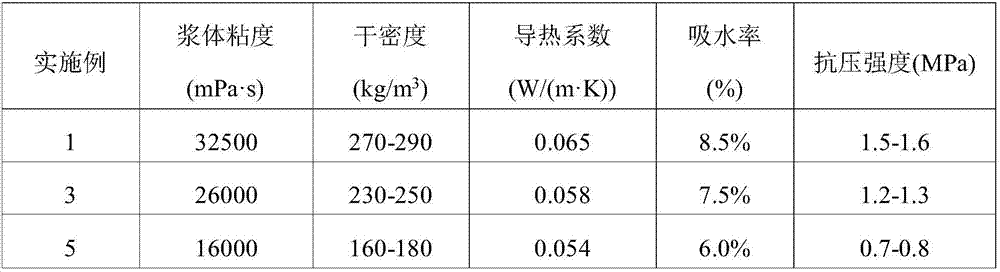

Examples

Embodiment 1

[0072] In this embodiment, the ultra-light foamed concrete adopts the following materials by mass:

[0073] Ordinary Portland cement: 80 parts

[0074] Rapid hardening sulfoaluminate cement: 10 parts

[0075] Silica fume: 2 parts

[0076] Superfine fly ash: 8 parts

[0077] Polycarboxylate superplasticizer: 0.5 parts

[0078] Redispersible latex powder: 1 part

[0079] Hydroxypropyl methylcellulose ether: 0.1 parts

[0080] Polypropylene fiber: 0.4 parts

[0081] Slow-release catalyst: 0.01 parts

[0082] Capsule disintegration time limit 10min

[0083] Hydrogen peroxide: 4 parts

[0084] Water: 50 parts.

[0085] Ordinary Portland cement, rapid hardening sulphoaluminate cement, silica fume and ultra-fine fly ash together constitute the composite cementitious material. The mass ratio of the sum of the masses of the four. It can be seen from the above that among the components of the above-mentioned ultra-light concrete (higher price, relatively poor carbonation resi...

Embodiment 2

[0093] In this embodiment, the ultra-light foamed concrete adopts the following materials by mass:

[0094] Ordinary Portland cement: 75 parts

[0095] Rapid hardening sulfoaluminate cement: 10 parts

[0096] Silica fume: 5 parts

[0097] Superfine fly ash: 10 parts

[0098] Polycarboxylate superplasticizer: 0.6 parts

[0099] Redispersible latex powder: 1.5 parts

[0100] Hydroxypropyl methylcellulose ether: 0.05 parts

[0101] Polypropylene fiber: 0.3 parts

[0102] Ultrafine MnO 2 Catalyst: 0.01 parts

[0103] Capsule disintegration time limit 8min

[0104] Hydrogen peroxide: 4.5 parts

[0105] Water: 50 parts.

[0106] The preparation method is the same as in Example 1.

Embodiment 3

[0108] In this embodiment, the ultra-light foamed concrete adopts the following materials by mass:

[0109] Ordinary Portland cement: 70 parts

[0110] Rapid hardening sulfoaluminate cement: 12 parts

[0111] Silica fume: 3 parts

[0112] Superfine fly ash: 15 parts

[0113] Polycarboxylate superplasticizer: 0.7 parts

[0114] Redispersible latex powder: 1.5 parts

[0115] Hydroxypropyl methylcellulose ether: 0.1 parts

[0116] Polypropylene fiber: 0.3 parts

[0117] Ultrafine MnO 2 Catalyst: 0.015 parts

[0118] Capsule disintegration time limit 7min

[0119] Hydrogen peroxide: 5 parts

[0120] Water: 55 parts.

[0121] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com