Papermaking auxiliary agent and production method thereof

A papermaking aid, a technology of carboxymethyl chitosan, which is applied in the field of papermaking, can solve the problems of difficult long-term preservation, complicated formula, easy to mold and the like, and achieves the effects of improving dry strength, simple technological process and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

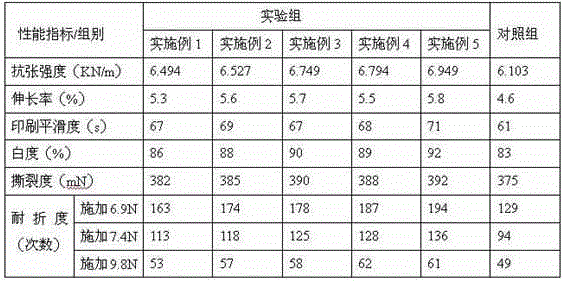

Examples

Embodiment 1

[0046] Example 1 A papermaking aid was prepared from the following main raw materials (20kg each): 10 parts carboxymethyl chitosan, 6 parts polyacrylamide, 12 parts talc powder, 8 parts quartz powder, poly 3 parts of ethylene glycol, 1 part of lauryl ester, 2 parts of alkylphenol polyoxyethylene ether, 1 part of polyoxypropylene glycerol ether, 1 part of sodium benzoate, 2 parts of wood wax oil, 1 part of ammonium sulfate, hydrogen phosphate 2 parts of disodium and 3 parts of lactitol.

[0047] A preparation method of a papermaking aid, the steps are as follows:

[0048] (1) Put polyoxypropylene glyceryl ether and wood wax oil in a nitrogen atmosphere, stir at 76°C (stirring rate is 630 revolutions / min) for 2 hours, add water (the amount is polyoxypropylene glyceryl ether and wood wax oil) 4 times the mass), add lauryl alcohol ester and alkylphenol polyoxyethylene ether, mix at 58°C for 5 minutes, and cool to normal temperature;

[0049] (2) Mix carboxymethyl chitosan and quartz po...

Embodiment 2

[0055] Example 2 A papermaking aid was prepared from the following main raw materials (10kg each): 16 parts of carboxymethyl chitosan, 10 parts of polyacrylamide, 16 parts of talc powder, 18 parts of quartz powder, poly 5 parts of ethylene glycol, 4 parts of lauryl ester, 5 parts of alkylphenol polyoxyethylene ether, 4 parts of polyoxypropylene glycerol ether, 2 parts of sodium benzoate, 4 parts of wood wax oil, 2 parts of ammonium sulfate, hydrogen phosphate 3 parts of disodium and 6 parts of lactitol.

[0056] A preparation method of a papermaking aid, the steps are as follows:

[0057] (1) Put polyoxypropylene glyceryl ether and wood wax oil in a nitrogen atmosphere, stir at 94℃ (stirring rate is 720 rpm) for 4 hours, add water (the amount is polyoxypropylene glyceryl ether and wood wax oil) 6 times the mass), add lauryl alcohol ester and alkylphenol polyoxyethylene ether, mix at 65°C for 8 minutes, and cool to normal temperature;

[0058] (2) Mix carboxymethyl chitosan and quar...

Embodiment 3

[0064] Example 3 A papermaking aid was prepared from the following main raw materials (15kg each): 12 parts carboxymethyl chitosan, 7 parts polyacrylamide, 13 parts talc powder, 12 parts quartz powder, poly 3.5 parts of ethylene glycol, 2 parts of lauryl ester, 3 parts of alkylphenol polyoxyethylene ether, 2 parts of polyoxypropylene glycerol ether, 1.3 parts of sodium benzoate, 2.5 parts of wood wax oil, 1.3 parts of ammonium sulfate, hydrogen phosphate 2.3 parts of disodium and 4 parts of lactitol.

[0065] A preparation method of a papermaking aid, the steps are as follows:

[0066] (1) Put polyoxypropylene glyceryl ether and wood wax oil in a nitrogen atmosphere, stir at 82°C (stirring rate is 660 revolutions / min) for 2.5 hours, add water (the amount is polyoxypropylene glyceryl ether and wood wax oil) 4.5 times the mass), add lauryl alcohol ester and alkylphenol polyoxyethylene ether, mix at 60°C for 6 minutes, and cool to normal temperature;

[0067] (2) Mix carboxymethyl chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com