Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Titanium nickel alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture of Shape Memory Alloy Cellular Materials and Structures by Transient-Liquid Reactive Joining

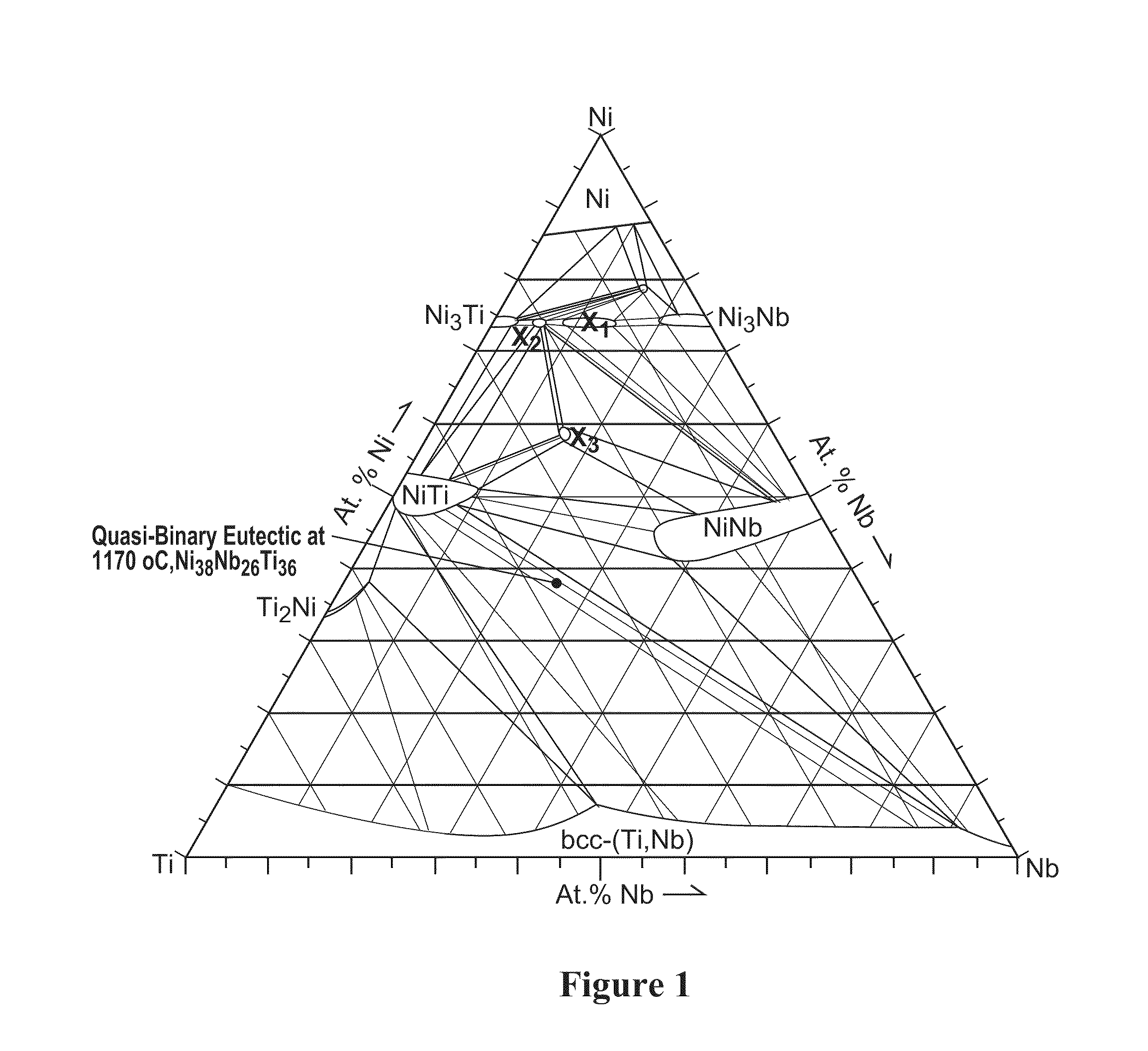

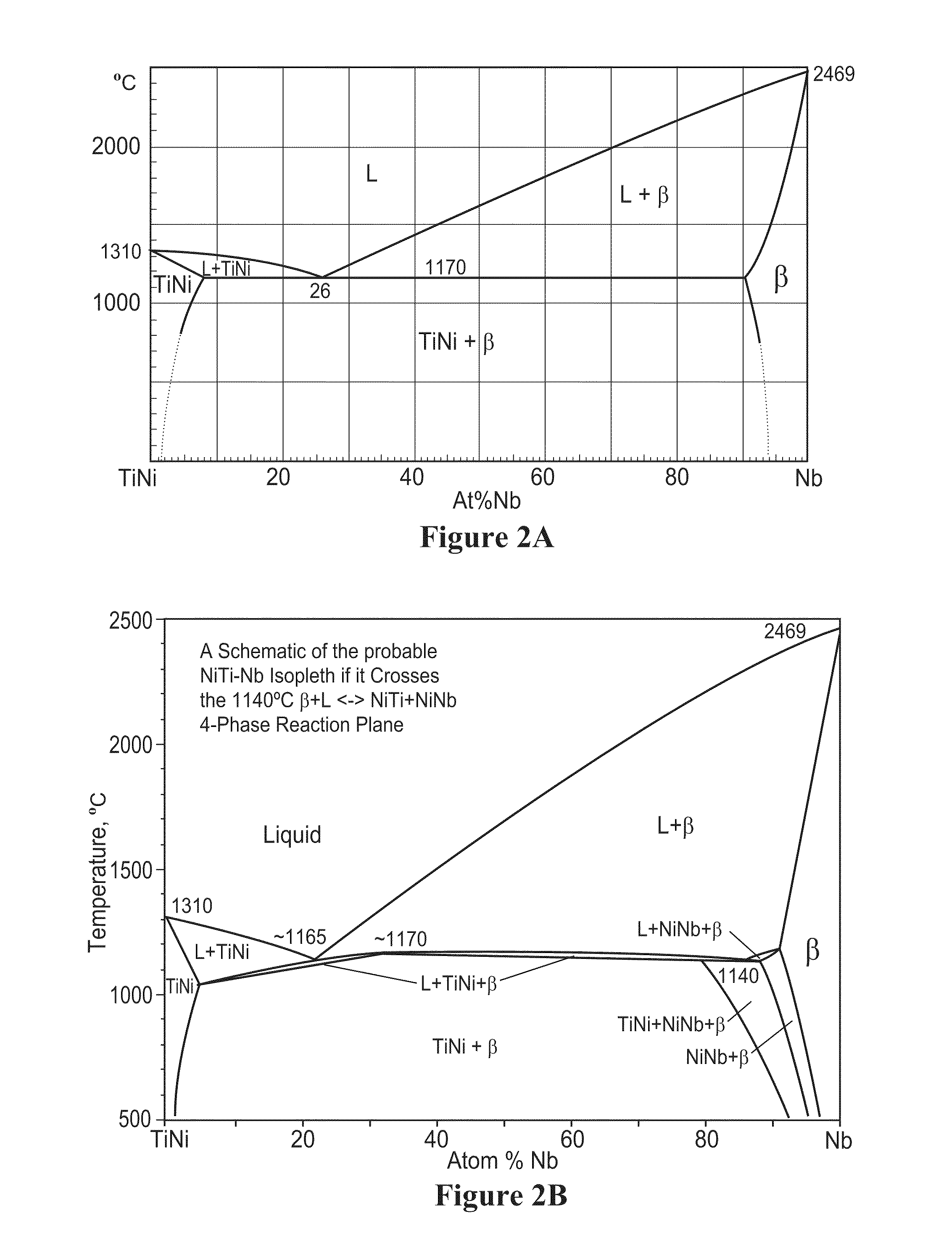

ActiveUS20080290141A1Low densityMaintain good propertiesPortable framesLayered productsNiobiumHoneycomb structure

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +1

4D printing method and application of titanium-nickel shape memory alloy

ActiveCN109648082AHigh strengthHigh elongationAdditive manufacturing apparatusTransportation and packaging4d printingNickel alloy

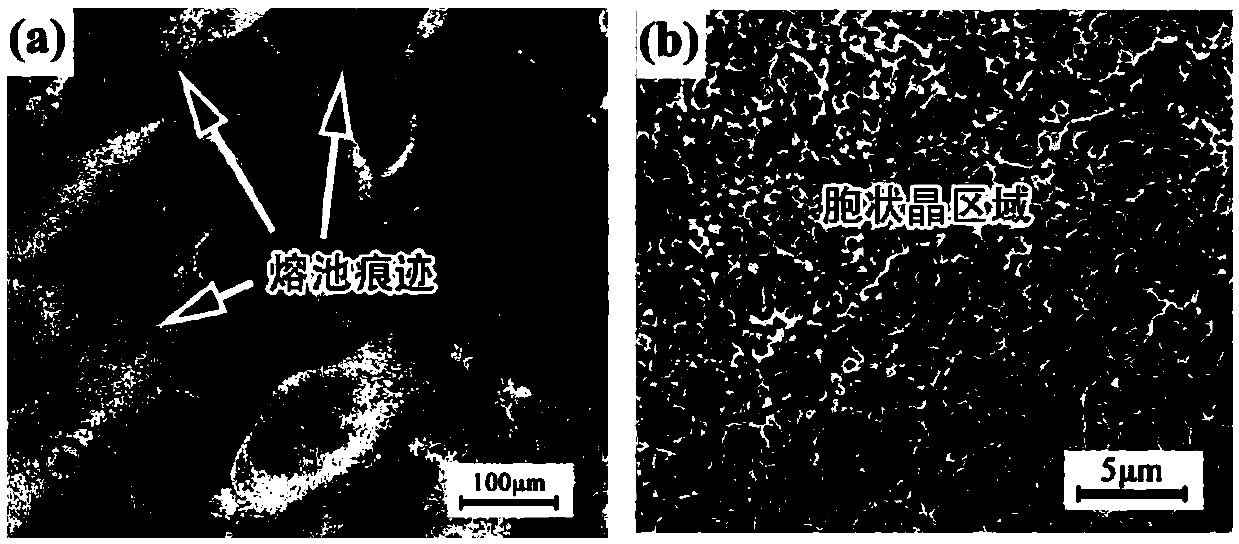

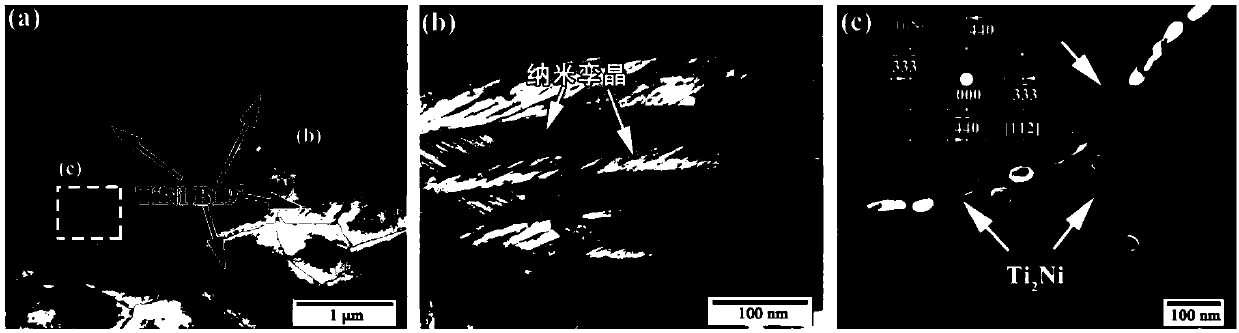

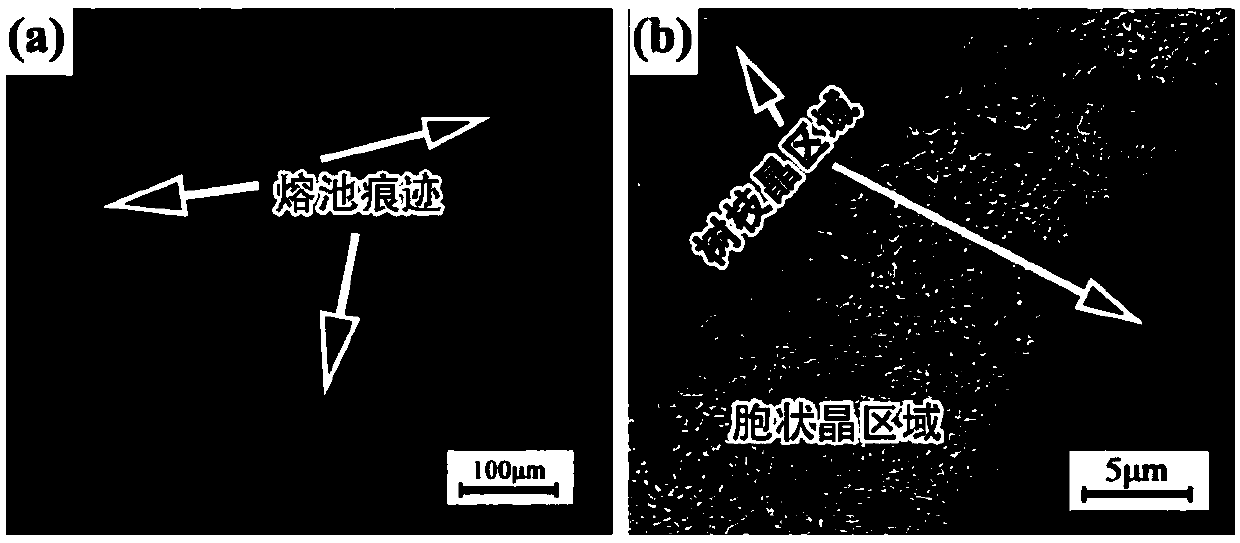

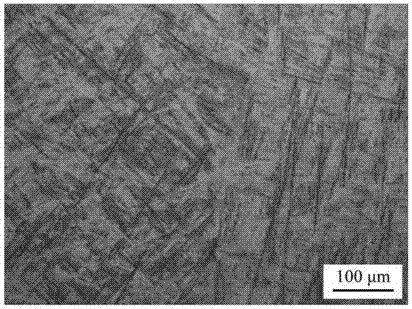

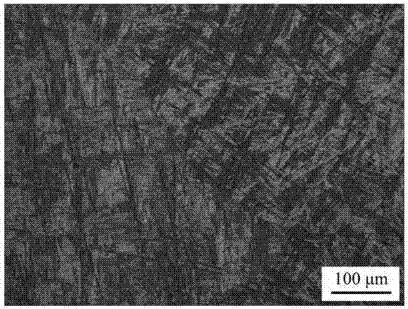

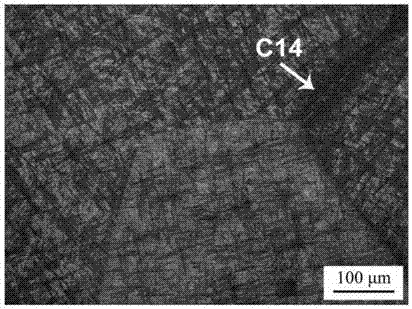

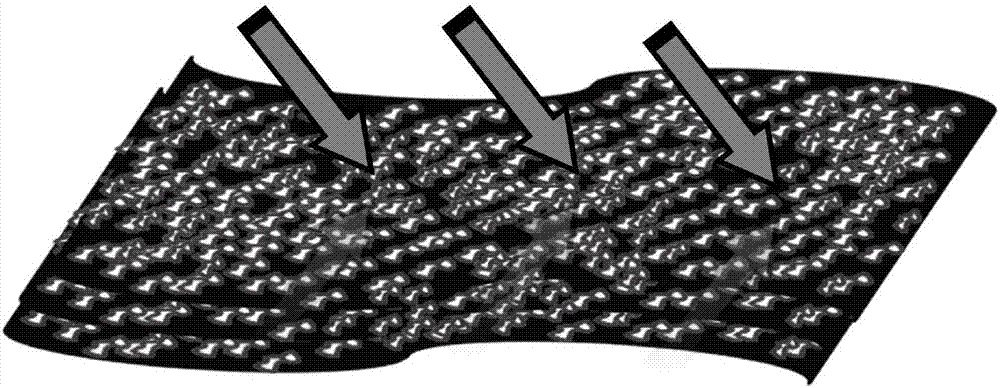

The invention belongs to the technical field of preparation of shape memory alloys, and discloses a 4D printing method and application of a titanium-nickel shape memory alloy. Pure titanium and pure nickel are matched and smelted, and titanium-nickel alloy bars are obtained; then alloy powder is prepared through a rotating electrode atomization method, the powder is screened, and titanium-nickel alloy powder with the grain size of 15 micrometers to 53 micrometers is obtained; and the obtained titanium-nickel alloy powder is placed in a discharge plasma assisted ball mill to be subjected to discharge treatment, the powder is subjected to surface modification, and finally the titanium-nickel shape memory alloy is formed by means of SLM forming. The phase composition of the obtained titanium-nickel shape memory alloy is composed of a B2 austenite phase of a CsC1 type structure, a B19' Martensite phase of a monocline structure and a Ti2Ni precipitated phase. The microstructure comprises nano-sized afterbirth-like crystals and micro dendrite, and the afterbirth-like crystals and the dendrite are alternately distributed in a layered manner. The advantages of being unique in organizationstructure, nearly fully dense and ultrahigh in performance are achieved.

Owner:SOUTH CHINA UNIV OF TECH

High-purity titanium-nickel alloys with shape memory

The invention includes an alloy containing equivalent amounts of nickel and titanium. The alloy has shape memory and a metallic purity of at least about 99.995%, and comprises less than about 200 ppm of gases. The invention also includes an alloy comprising titanium and nickel where the titanium and nickel amounts are non-equivalent. The alloy has shape memory and has a metallic purity of at least 99.995%, and contains less than about 200 ppm of gases. The invention further includes a method of producing a shape memory alloy. Titanium is provided having a metallic purity of at least 99.999% and nickel is provided having a metallic purity of at least 99.99%. The titanium and nickel are combined utilizing at least one melting event independently selected from e-beam melting, vacuum arc melting, vacuum induction melting, induction skull melting and plasma melting.

Owner:HONEYWELL INT INC

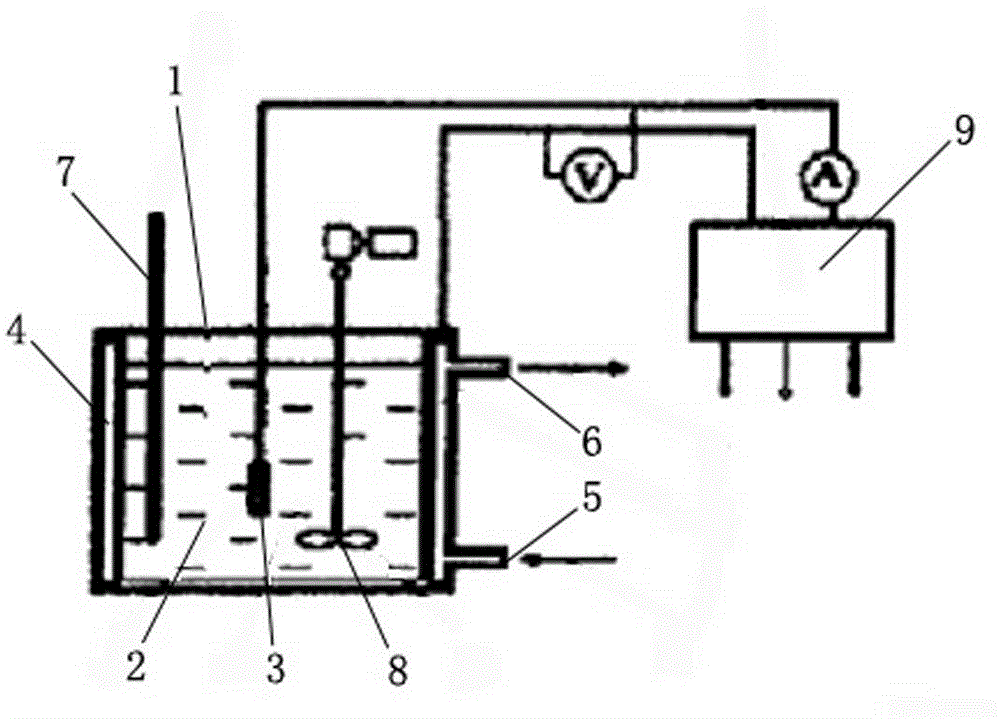

Titanium-nickel alloy electrochemical polish liquid

The invention relates to electrochemical polishing solution formula for Ti-Ni alloy, which has no water, and comprises a plurality of alcohols, perchloric acid and additive. It not only can remove thick oxide layer, lubricant (such as graphite) layer and inclusion benefit to obtain well polish surface, but also has high process efficiency, strong practice and long service time fit to all Ti-Ni alloys. This invention has wide application arrange.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

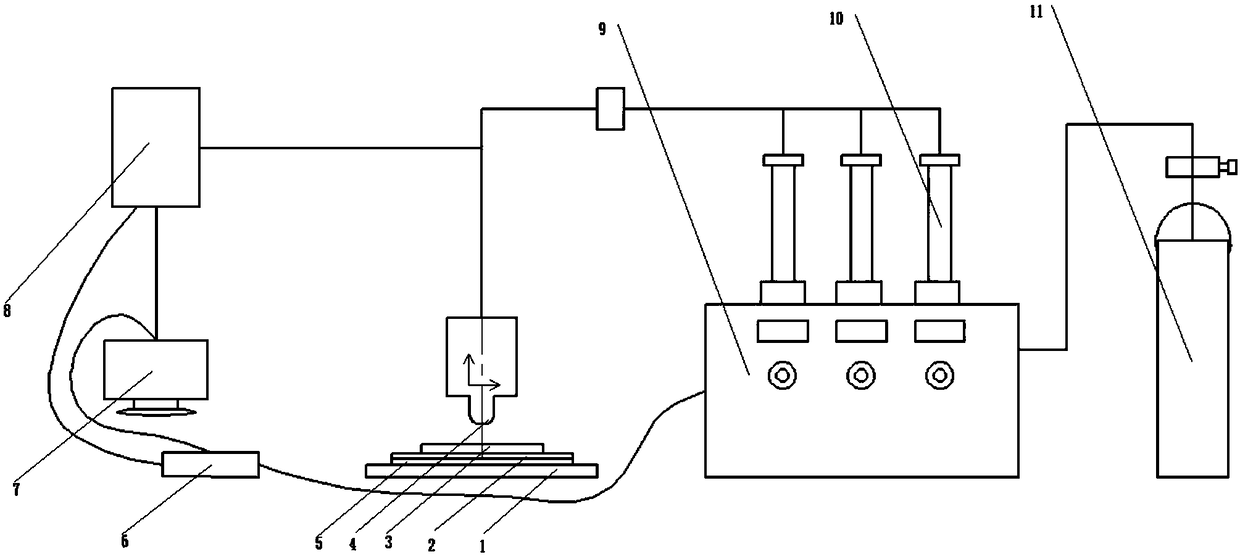

Method for ultrasonic-assistance laser near-net shape forming of titanium-nickel alloy gradient material

ActiveCN108356266AReduce porosityReduce defects such as shrinkage cavitiesAdditive manufacturing apparatusIncreasing energy efficiencyGradient materialTitanium alloy

The invention discloses a method for ultrasonic-assistance laser near-net shape forming of a titanium-nickel alloy gradient material and belongs to the technical field of additive manufacturing. The titanium-nickel based alloy gradient material is manufactured through an ultrasonic-assistance laser near-net shape forming system in an additive manufacturing mode. The method includes the steps thatan ultrasonic generator is fixed to a machine tool working table, a pre-heater is fixed to the ultrasonic generator, and a base plate is fixed to the pre-heater. During forming, the ratio of two typesof powder is changed constantly with the volume fraction of 10% as the step length, and gradient transition from a titanium alloy to a nickel-based alloy is achieved step by step. Through ultrasonicassistance and pre-heating, the defects such as air holes and shrinking holes in a sample can be reduced, and the brittle phase is uniformly distributed on a substrate,; and meanwhile the hardness, the abrasion resistance and other properties of the substrate can be improved, the temperature gradient can be reduced during forming through assistant pre-heating, and the possibility of cracks is greatly lowered. The gradient material prepared through the method is not limited by the shape and the size, and the production efficiency is improved while the cost is reduced.

Owner:DALIAN UNIV OF TECH

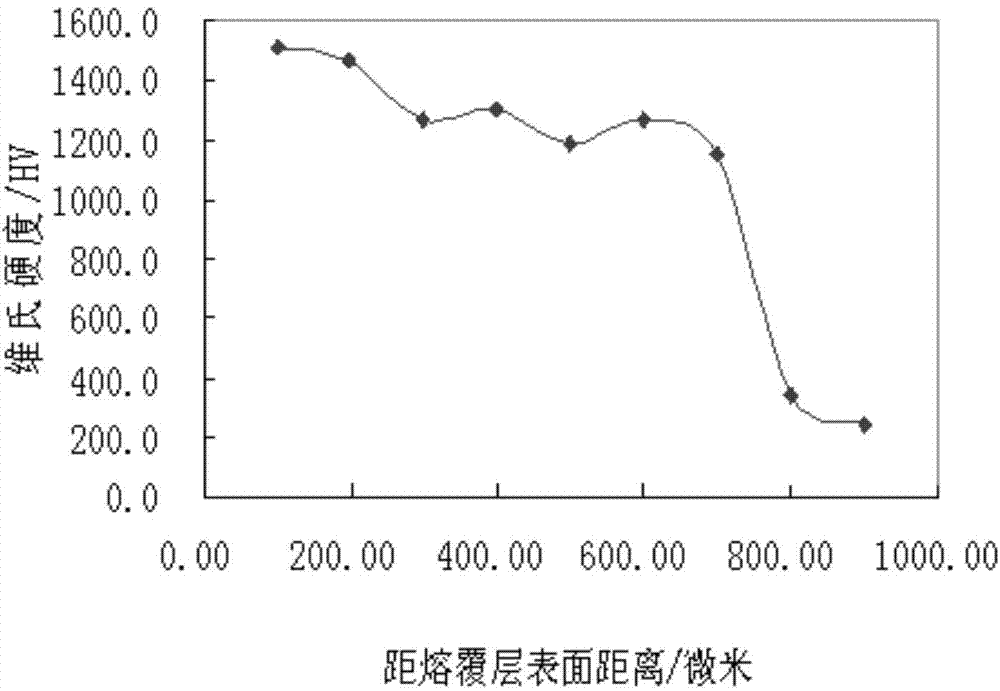

Powder material for boiler tube high temperature resistance and wear resistance protecting and preparation method thereof

InactiveCN103878363AHigh hardnessImprove wear resistanceMetallic material coating processesSurface engineeringWear resistant

The invention relates to powder material for boiler tube high temperature resistance and wear resistance protecting and a preparation method thereof, and belongs to the technical field of surface engineering. The power material comprises the following components, by weight percentage, 10-20% of titanium-nickel alloy powder, 1.5-3.5% of graphite powder, 0.5-1% of silica powder, 8-25% of nickel-chromium alloy powder Ni80Cr20, 5-10% of iron boride powder and the balance of tri-chromium dicarbide powder. The preparation method comprises the following steps that power material is prepared, mix powder is formed, liquid-containing binders are prepared, sizing agents are prepared from the mix powder, prilling is completed through spray drying, and finished product powder is prepared from screening the prilling powder and is used for preparing a cladding layer. The metal cladding layer with high wear resistant duplex ceramic is formed through laser cladding, and the hardness ranges from 1100 HV to 1600 HV, so that the powder material for boiler tube high temperature resistance and wear resistance protecting and the preparation method thereof has the advantages that efficiency of the laser cladding is higher, loss of powder spattering is low, grain of the cladding layer is tiny, wear resistance of the cladding layer is high and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Manufacture of Shape-Memory Alloy Cellular Materials and Structures by Transient-Liquid Reactive Joining

ActiveUS20110008643A1Constant gainFine surfaceThermometers using material expansion/contactionSoldering apparatusNiobiumHoneycomb structure

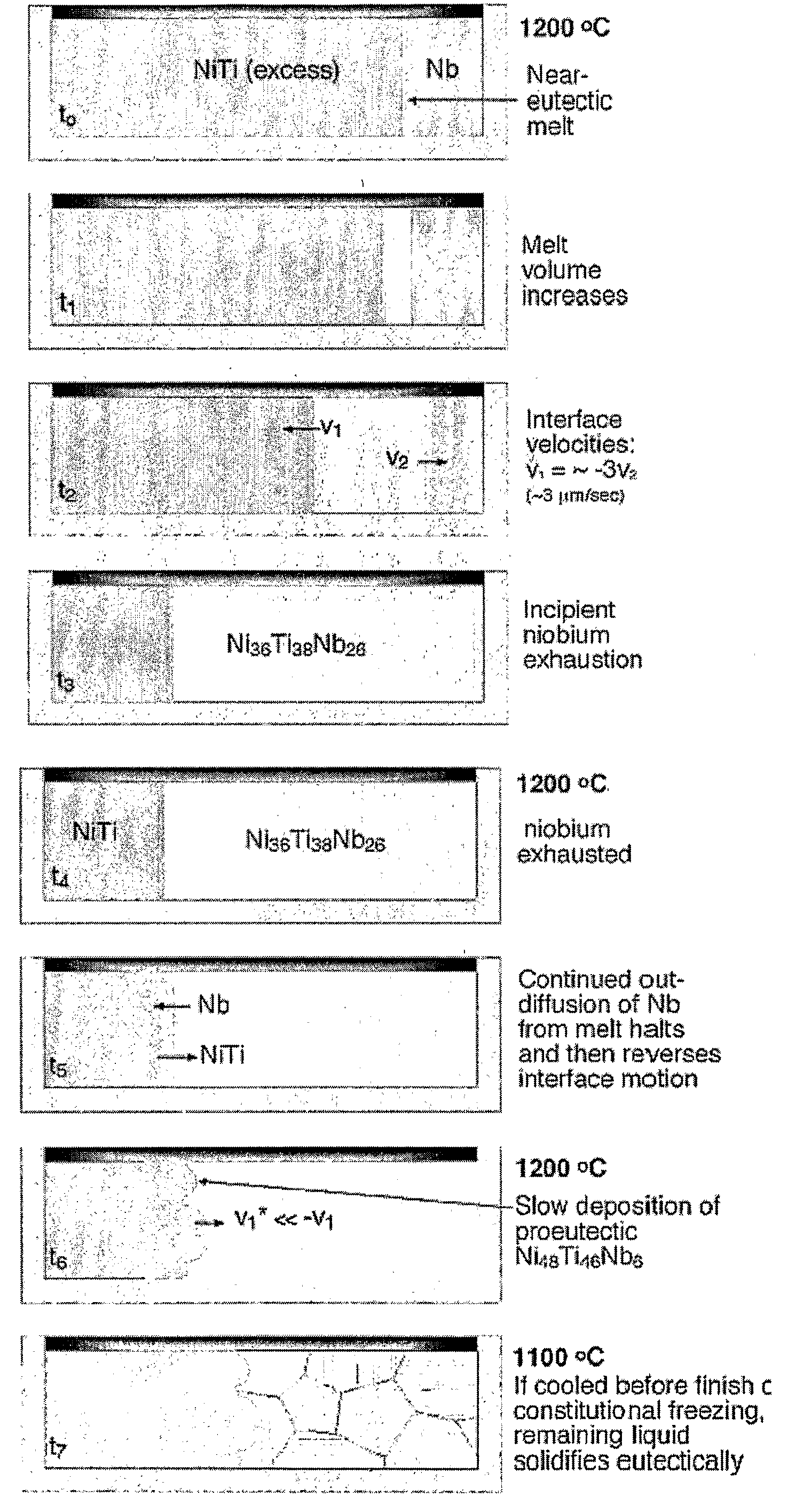

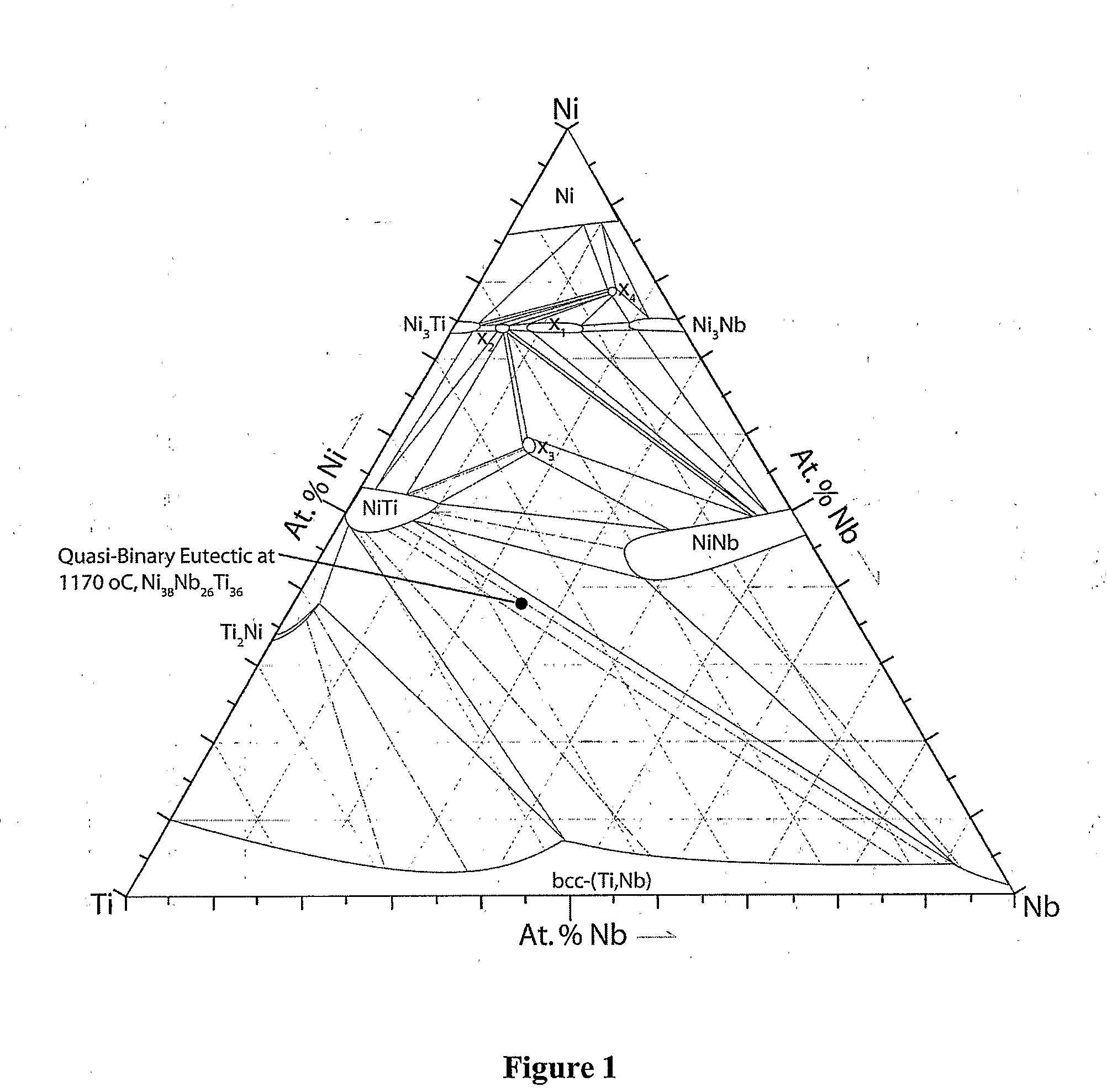

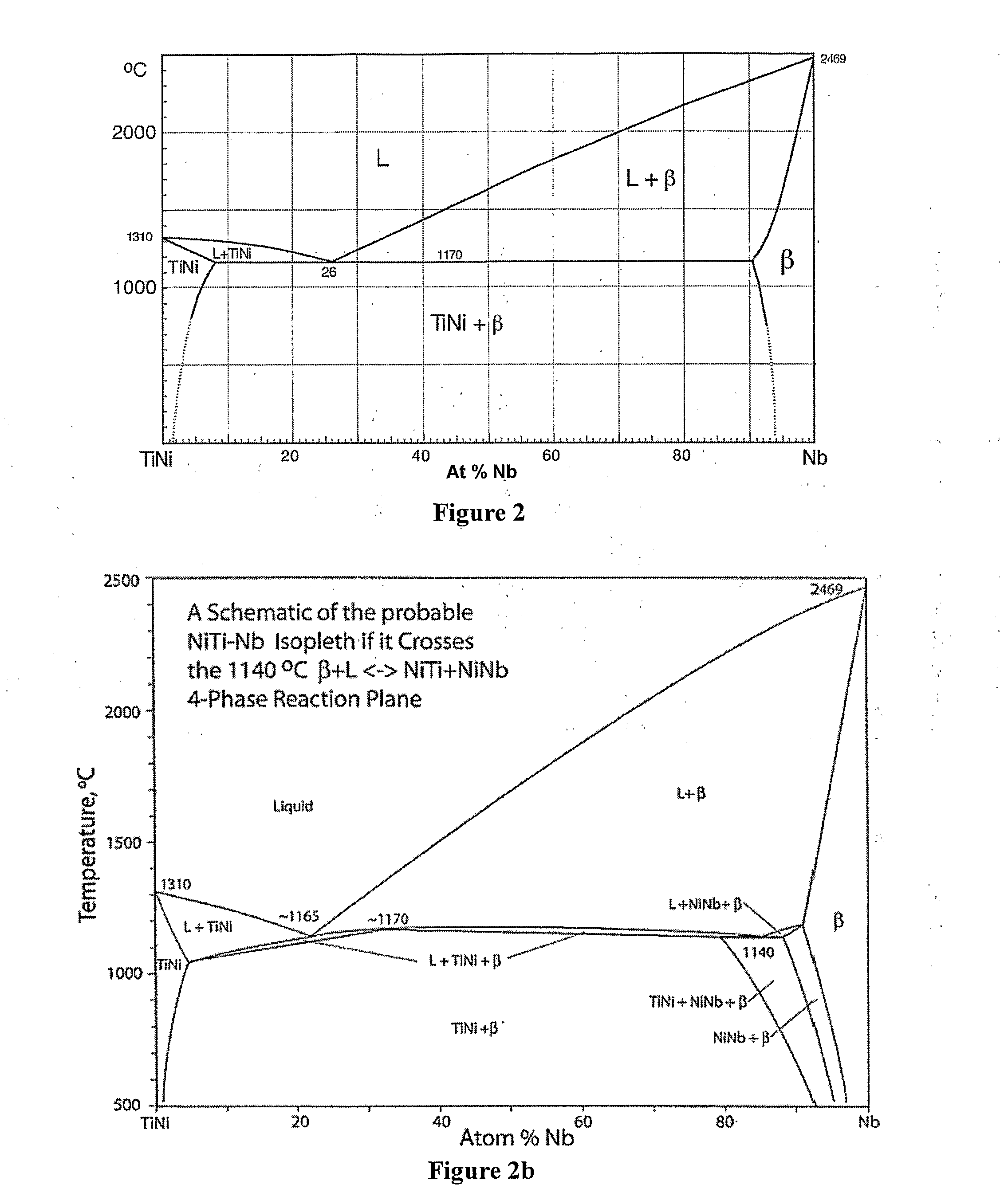

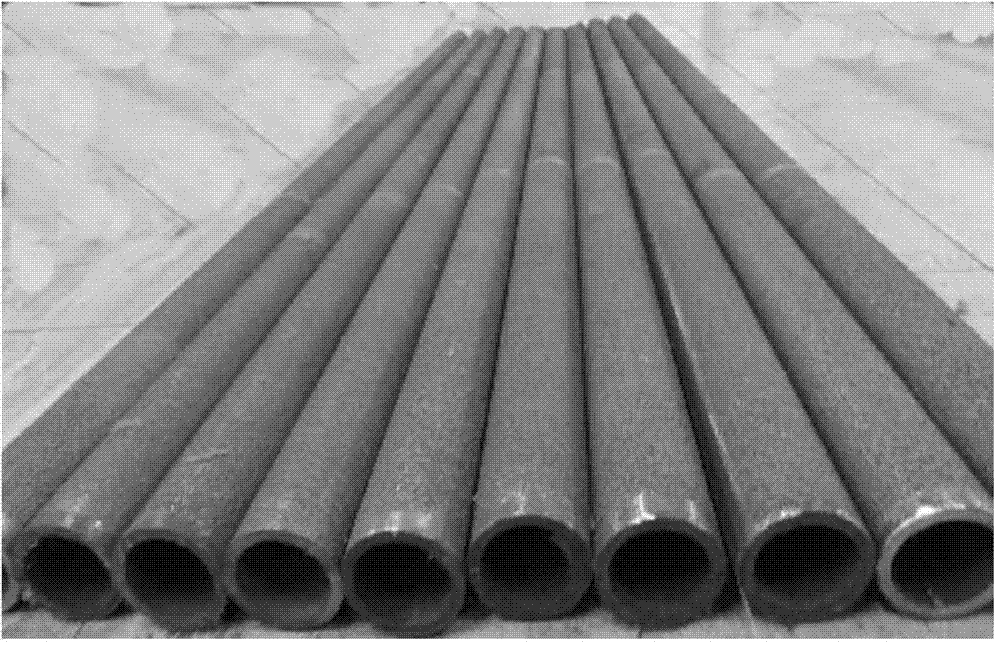

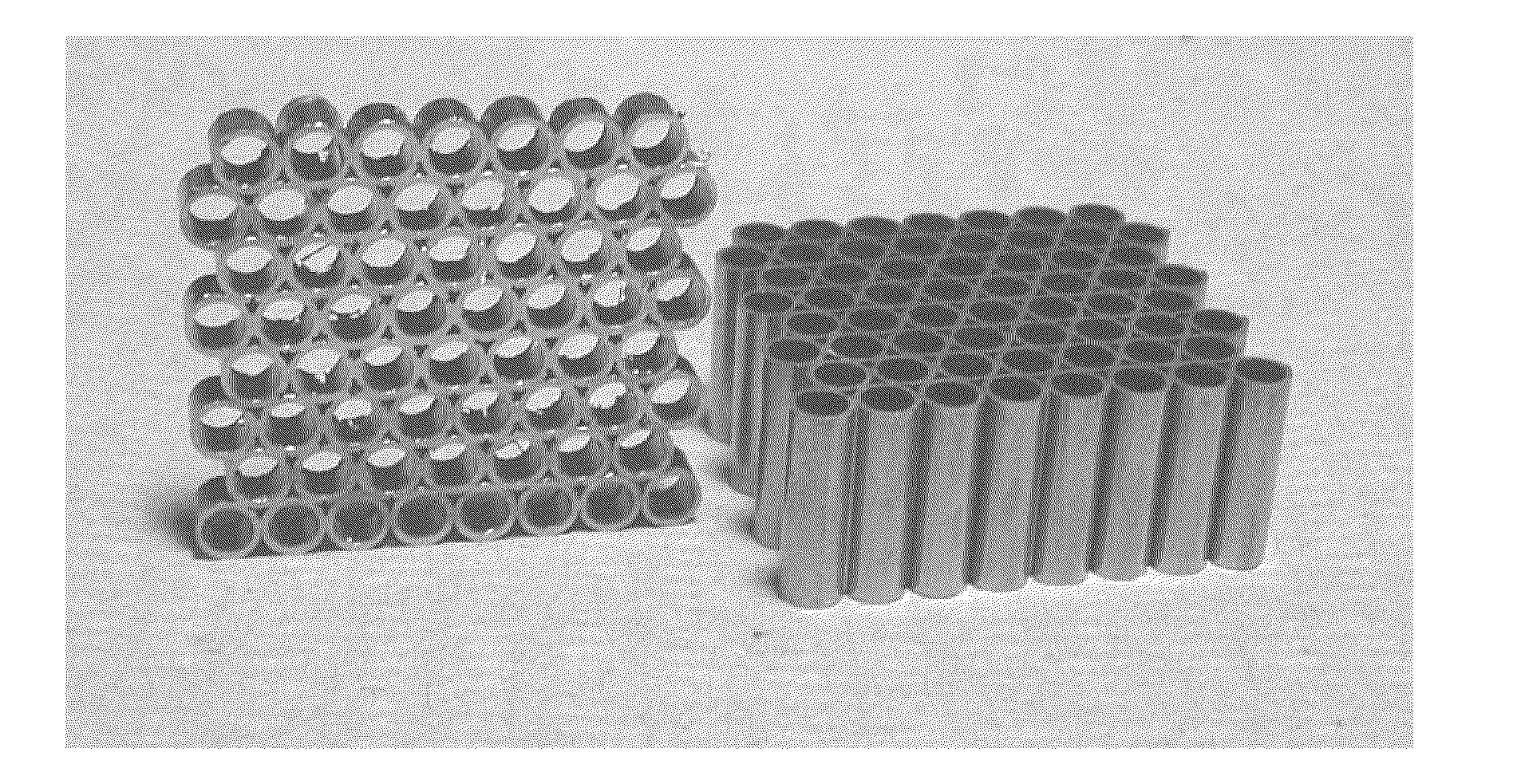

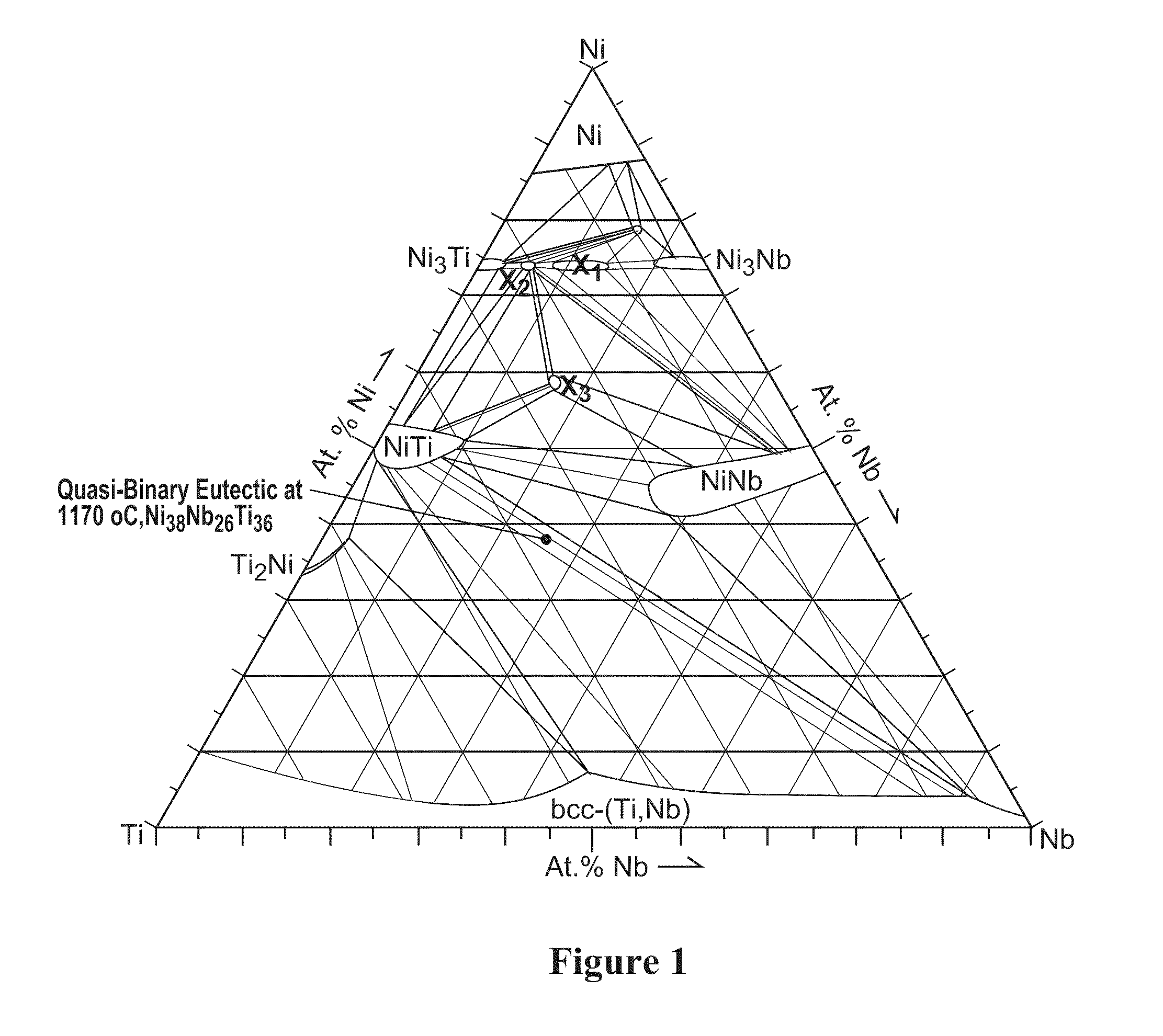

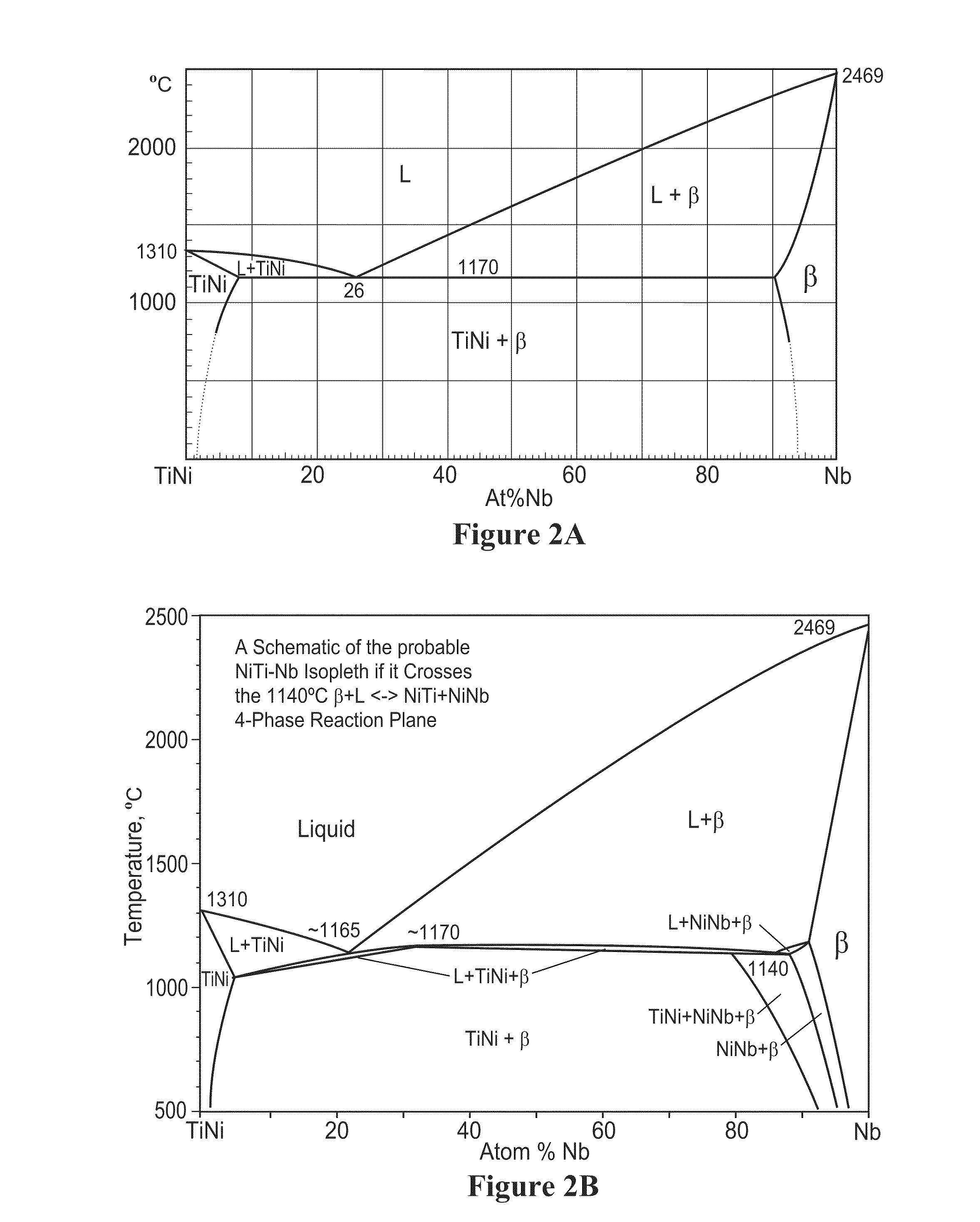

This invention discloses a method, using pure niobium as a transient liquid reactive braze material, for fabrication of cellular or honeycomb structures, wire space-frames or other sparse builtup structures or discrete articles using Nitinol (near-equiatomic titanium-nickel alloy) and related shape-memory and superelastic alloys. Nitinol shape memory alloys (SMAs), acquired in a form such as corrugated sheet, discrete tubes or wires, may be joined together using the newly discovered joining technique. Pure niobium when brought into contact with nitinol at elevated temperature, liquefies at temperatures below the melting point and flows readily into capillary spaces between the elements to be joined, thus forming a strong joint.

Owner:RGT UNIV OF MICHIGAN +1

Method for preparing vacuum hotpressing sintered wear-resistant coating on surface of metallic titanium and titanium alloy base material

InactiveCN101418444AHigh fatigueCoordinated performanceHeat inorganic powder coatingWear resistantAxial pressure

The invention provides a method for preparing vacuum hot-pressed sintered wear-resistant coatings on the surfaces of metallic titanium and titanium alloy substrates. The method comprises the following steps of well mixing and then smearing titanium powder, nickel powder and titanium diboride powder on block metallic titanium or titanium alloy, putting the block metallic titanium or the titanium alloy in a graphite mold, placing the graphite mold in a vacuum hot-pressing furnace, applying axial pressure to the block metallic titanium or the titanium alloy in thegraphite mold, heating the graphite mold together with the block metallic titanium or the titanium alloy and mixed powder to 899.85 to 999.85 DEG C, unloading after preserving heat for 30 minutes, cooling to lower than 399.85 DEG C under a vacuum condition, opening the vacuum hot-pressing furnace, taking out and cooling the graphite mold to a room temperature, taking out the metallic titaniumor the titanium alloy from the graphite mold, and forming a complex wear-resistant coating of titanium-nickel alloy and titanium diboride on the surface of the metallic titanium or the titanium alloy. The wear-resistant coating of the invention is characterized in that the coating has high wear properties of wear-resistant materials, has a TiNi (beta) phase matrix with stable superelasticity performance, and can effectively improve the fatigue properties of the metallic titanium and the titanium alloy.

Owner:SHENYANG UNIV

High-tenacity oxidation-resistant anti-friction coating on substrate surface and preparation method thereof

ActiveCN102021513AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingDiamond-like carbonLow speed

The invention discloses a high-tenacity oxidation-resistant anti-friction coating on a substrate surface and a preparation method thereof. The coating is characterized in that nano-crystalline AlCrCN particles of a face-centered cubic structure are embedded into grids of diamond-like carbon with nano-thickness to form the composite coating, wherein the diameter of each nano-crystalline AlCrCN particle is 5-50 nanometers, the thickness of each grid of the diamond-like carbon is 1-5 nanometers, and the molar ratio of Al atoms to Cr atoms is greater than 1. The coating has higher oxidation resistance, also combines higher tenacity of ceramic composite materials and excellent friction performance of diamond-like carbon, can reduce the adhesion between abrasive dust and a substrate, is suitable for surfaces of cutters, molds and other substrates, and is especially suitable for low-speed processing of titanium-nickel alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Manufacture of Shape-Memory Alloy Cellular Materials and Structures by Transient-Liquid Reactive Joining

ActiveUS20110009979A1Constant gainFine surfaceCooking-vessel materialsBone implantNiobiumTitanium alloy

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Preparation method of novel titanium-nickel medical implantation material

InactiveCN104087935AIsolationSolve the problem of difficult direct micro-arc oxidationSurface reaction electrolytic coatingSolid state diffusion coatingMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a preparation method of a novel titanium-nickel medical implantation material, particularly a composite treatment method for preparing a titanium dioxide / aluminum oxide mixture by depositing titanium on a titanium-nickel surface and performing micro-arc oxidation. The method comprises the following steps: firstly, by using a titanium-nickel alloy base as a workpiece, eliminating the oxide film on the workpiece surface by a mechanical-chemical mixed method; secondly, depositing titanium on the workpiece surface by a plasma surface alloying technique; thirdly, carrying out micro-arc oxidation on the workpiece in a micro-arc oxidation device; and finally, carrying out ultrasonic cleaning on the workpiece, and drying to obtain the finished product. The material can effectively isolate the precipitation of the nickel element in the titanium-nickel alloy, and the ceramic film layer of the titanium base surface subjected to micro-arc oxidation has the advantages of fewer surface voids, high hardness, high corrosion resistance, favorable insulativity and high binding force with the base metal. The method has the characteristics of favorable technical repetitiveness, controllable quality and the like, is simple to operate, can be widely used for surface modification treatment of titanium-nickel alloys, and effectively improves the application range and level.

Owner:TAIYUAN UNIV OF TECH

Micron fine-grained titanium-nickel alloy block material isodiametric corner extrusion preparing method

InactiveCN1528940AReduce temperature dropReduce sliding frictional resistanceMechanical propertyNickel based

The invention is an isometric angle squeezing producing method for a kind of micron tiny crystal titanium nickel alloy block materials. Titanium and nickel whose atom percentage are 45%-52% and 48%-55% are melted in vacuum, produces the titanium nickel base alloy cast ingot, cuts the block materials into blanks, and carries on surface finish process, and paints with glass lubricate, uses squeezing mould with 90-120 degrees angle, the surface of mould cavity is painted with black lead lubricate, the blank, mould are heated, and they are taken out from the stove and carried on with angle squeezing, finally acquires the titanium nickel base alloy block materials with excellent intensity and plasticity. The invention enhances the mechanical property of alloy, and reduces the cost.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of ZTA particle enhanced steel-based composite liner plate based on chemical activation treatment

ActiveCN106735100AHigh bonding strengthEnhanced interface bindingSuperimposed coating processBiological activationInterfacial bonding

The invention discloses a preparation method of a ZTA particle enhanced steel-based composite liner plate based on chemical activation treatment. The preparation method comprises the following steps: (1) carrying out high temperature salt-bath plating on ZTA particles, and obtaining uniform titanium plated layers on the surfaces of the ZTA particles; (2) forming nickel layers at the peripheries of the titanium plated layers; (3) sintering the plated ZTA particles, and mutually connecting the ZTA particles to form a porous prefabricated part; and (4) fixing the prefabricated part on the end surface or the working surface of a cast, pouring a steel base material metal solution through a casting-penetrating process, and carrying out cooling to obtain the ZTA particle enhanced steel-based composite liner plate. During the salt-bath titanium plating, titanium and the surfaces of the ZTA ceramic particles form metallurgical bonding, so that the interfacial bonding property between the titanium layers and the ZTA ceramic particles is enhanced. The ZTA ceramic particles subjected to the salt-bath titanium plating is then subjected to chemical nickel plating, and a titanium-nickel alloy can be generated at a titanium-nickel bonding part; and the titanium-nickel alloy layers achieve the effect of a flexible transitional layer between a metal base body and the ZTA particles, so that the bonding strength of the interface is greatly enhanced.

Owner:陕西明熙康普科技有限公司

Preparation method of equal-atomic-ratio titanium-nickel alloy ingots

The invention discloses a preparation method of equal-atomic-ratio titanium-nickel alloy ingots. The preparation method comprises the following steps of: firstly, melting and preparing primary titanium-nickel alloy ingots by utilizing a vacuum induction furnace; and secondly, carrying out group welding on the primary titanium-nickel alloy ingots to form consumable electrodes, and carrying out consumable electrode vacuum furnace melting on the consumable electrodes to form secondary titanium-nickel alloy ingots. According to the preparation method, titanium-nickel binary alloys with the nickel content of 49-52 at% or ternary or complex alloy ingots containing elements such as Fe, V, Al, Nb and Cr can be prepared; and the alloy components are uniform, the impurity content is low, and the requirements on the titanium-nickel alloys in the fields of electrons, machineries, space navigation, energy sources, medical treatment and public health, daily necessities and the like are met.

Owner:西安赛特新材料科技股份有限公司

Preparation method of low-carbon and low-oxygen titanium-nickel alloy large ingot

The invention discloses a preparation method of a low-carbon and low-oxygen titanium-nickel alloy large ingot. The preparation method comprises the steps of: preparing a titanium-nickel alloy primary ingot through smelting in a vacuum induction furnace, installing and welding the titanium-nickel alloy primary ingot to obtain a consumable electrode, and implementing consumable melting in vacuum to obtain a titanium-nickel alloy secondary ingot. The method is suitable for casting a titanium-nickel binary alloy in which the nickel content accounts for 49-52at%, and is capable of effectively controlling the contents of impurities, wherein C% is not greater than 0.05%, O+N% is not greater than 0.05%, H% is not greater than 0.005%, and the like. The preparation method can meet demands of medical health and other fields on the titanium-nickel alloy.

Owner:西安赛特新材料科技股份有限公司

Titanium nickel alloy workpiece chemical polishing working solution and production method thereof

The invention discloses a titanium nickel alloy workpiece chemical polishing working solution. 1000L of the titanium nickel alloy workpiece chemical polishing working solution comprises following raw materials, 8g of sodium thiosulfate, 200L of hydrofluoric acid, 30L of fluosilicic acid, 380L of nitric acid, 150L of hydrogen peroxide, 200L of phosphoric acid, and 40L of water. A production method comprises following steps: weighed deionized water is delivered into a reaction vessel, and is heated to 45 DEG C; a stirrer is turned on, and rotating speed is controlled to be 60r / min; weighed sodium thiosulfate, hydrofluoric acid, fluosilicic acid, nitric acid, hydrogen peroxide, and phosphoric acid are delivered into the reaction vessel successively with stirring until uniform mixing is realized; and an obtained solution is cooled to room temperature, and is collected and packaged.

Owner:DALIAN SANDAAOKE CHEM

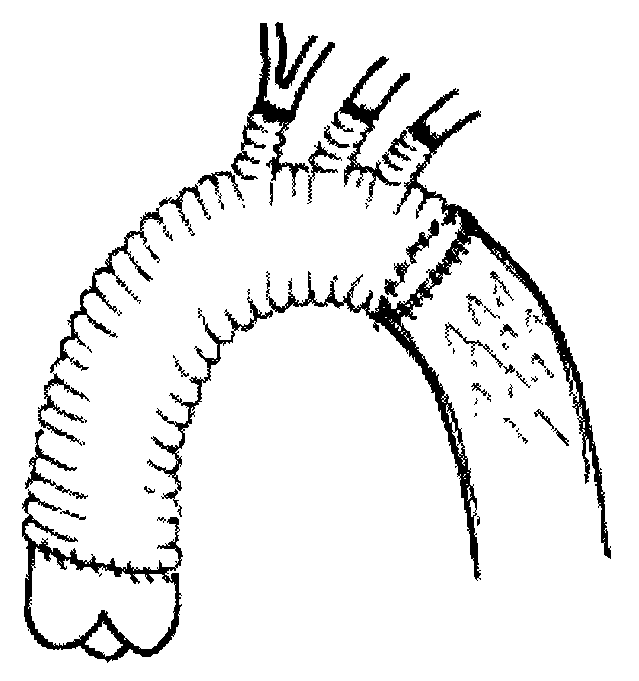

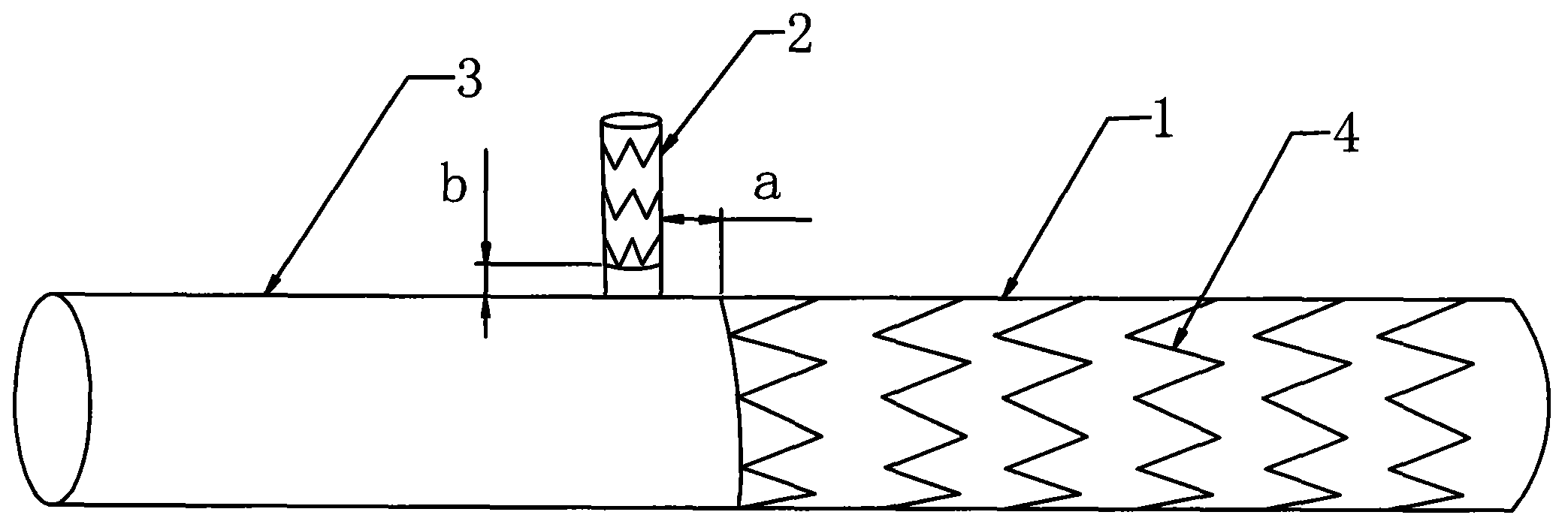

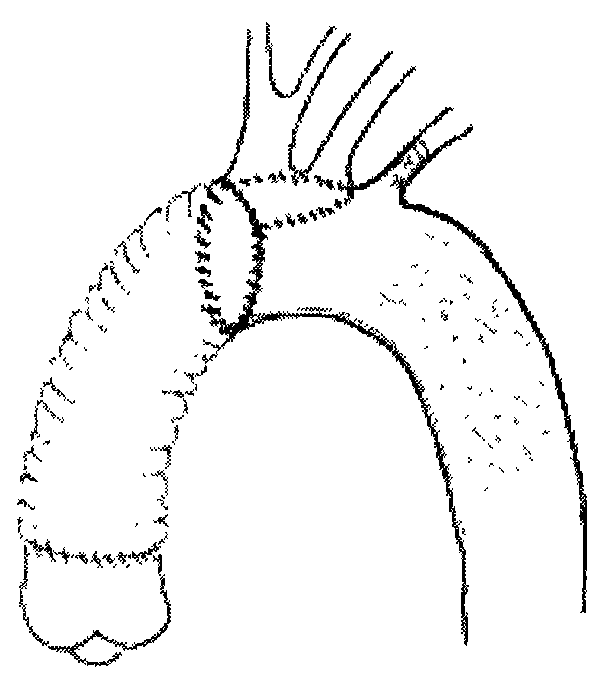

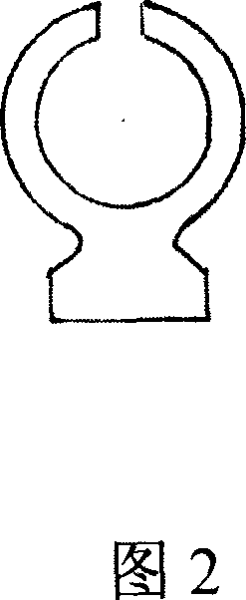

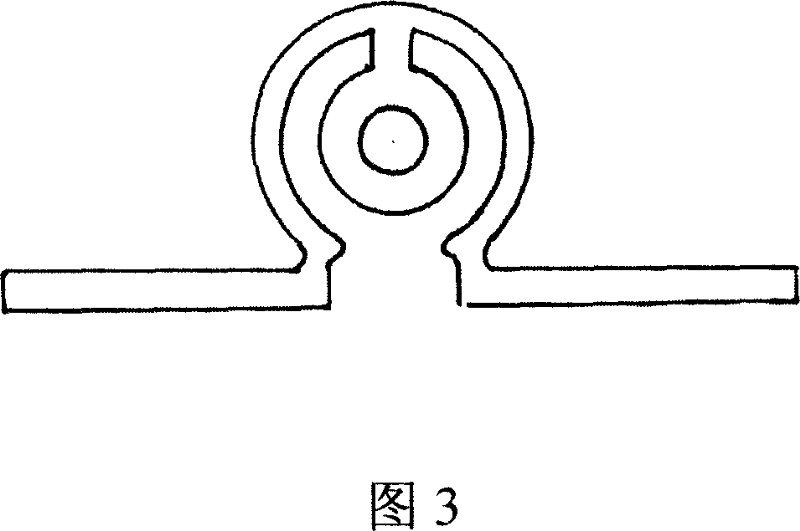

Improved support artificial blood vessel

The invention provides an improved support artificial blood vessel. The improved support artificial blood vessel comprises a dacron artificial blood vessel body and a support artificial blood vessel body. One end of the dacron artificial blood vessel body is communicated with one end of the support artificial blood vessel body. The pipe wall of the dacron artificial blood vessel body is communicated with a branch artificial blood vessel body. The side, close to the support artificial blood vessel body, of the outer pipe wall of the branch artificial blood vessel body is 1 cm away from the support artificial blood vessel body. A W-shaped titanium-nickel alloy metal support with a self-expansion function is fixed to the inner surface of the support artificial blood vessel body. A W-shaped titanium-nickel alloy metal support with a self-expansion function is fixed to the inner surface of the branch artificial blood vessel body. When the improved support artificial blood vessel with the branch is used for conducting DeBakey I type aortic dissection treatment, the effect of replacing the aortic dissection without replacing the branch of the aortic dissection can be achieved, surgery operation can be simplified, and the improved support artificial blood vessel is easy to master and has important clinical application value.

Owner:柳克祥

Cast-infiltration method for improving surface corrosion resistance of casting

A cast-infiltration method for improving surface corrosion resistance of a casting comprises the following steps that firstly, titanium-nickel alloy particles, polyvinyl butyral and ethyl alcohol are weighed and mixed to form a composite coating, and then the casting cavity is coated with the composite coating and corresponds to the part, with the abrasion resistance to be improved, of the casting. The casting thickness ranges from 6 mm to 8 mm. After coating is finished, the composite coating is ignited, the composite coating is cured and bonded into the casting cavity, then the casting is placed in a casting tank, and the casting tank is inflated with argon. A metal base body to be poured is melted to the set temperature, then the molten metal base body is poured in the casting for pouring, and after natural cooling, a titanium-nickel particle strengthened metal base composite material is obtained. The cast-infiltration method is high in operability and simple in technological process, precious metal is effectively saved, and the production cost of the industry is reduced.

Owner:HENAN UNIV OF SCI & TECH

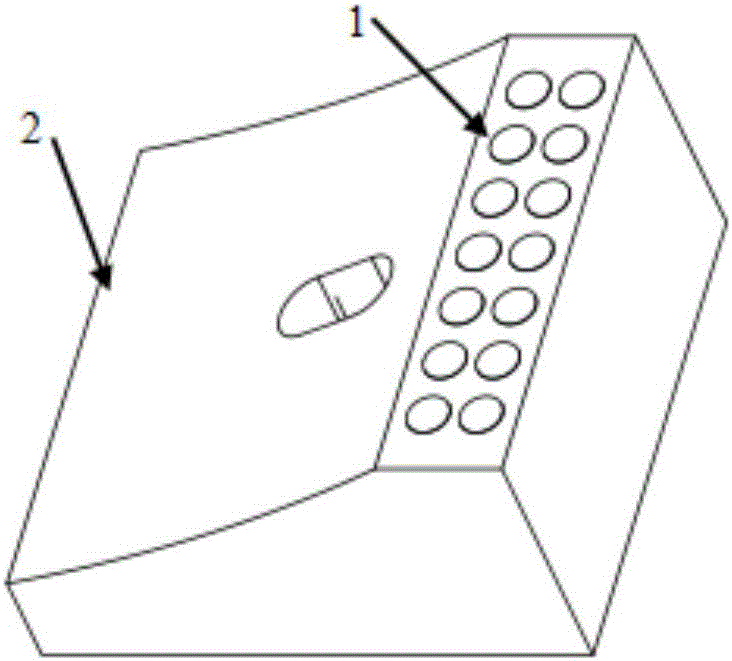

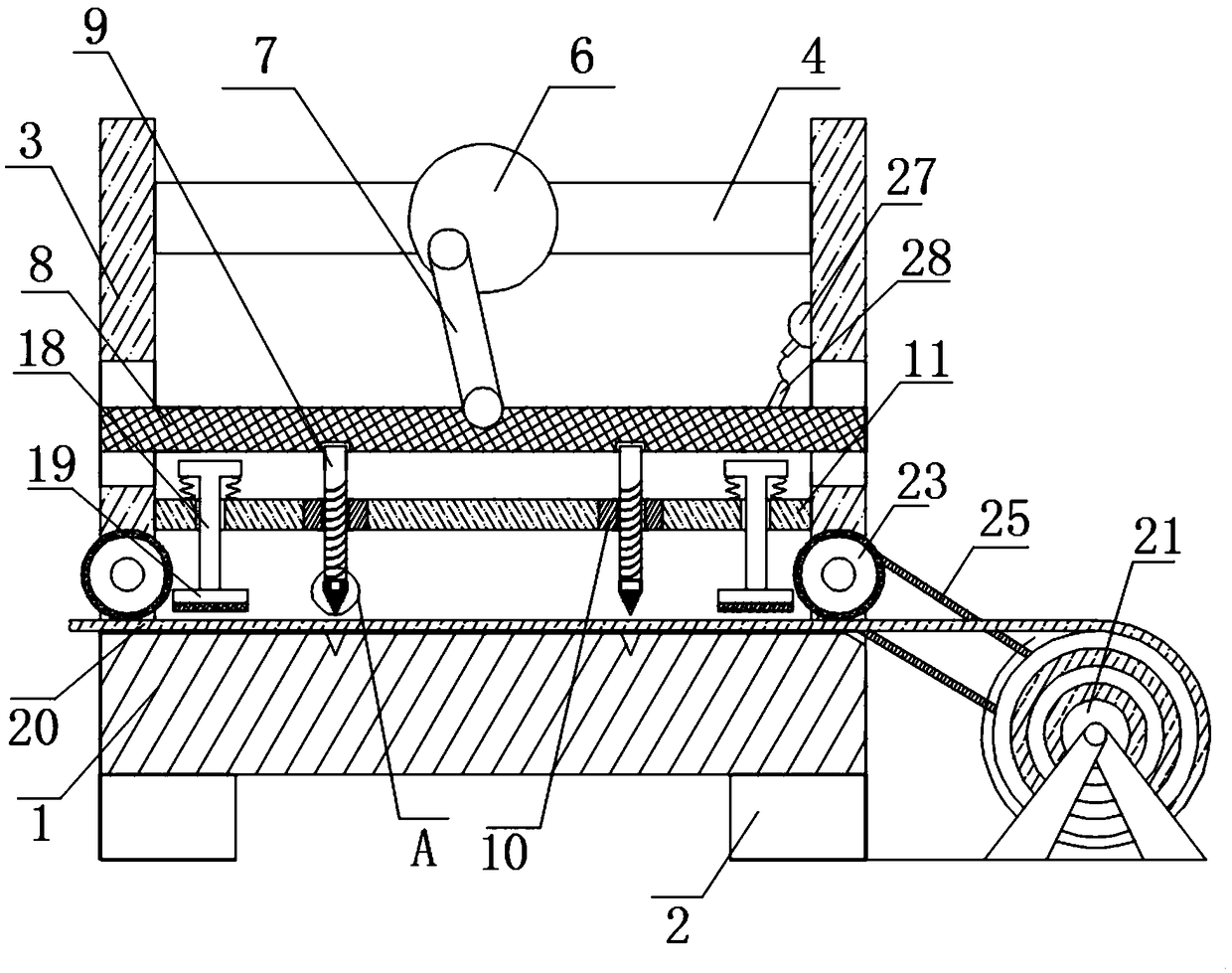

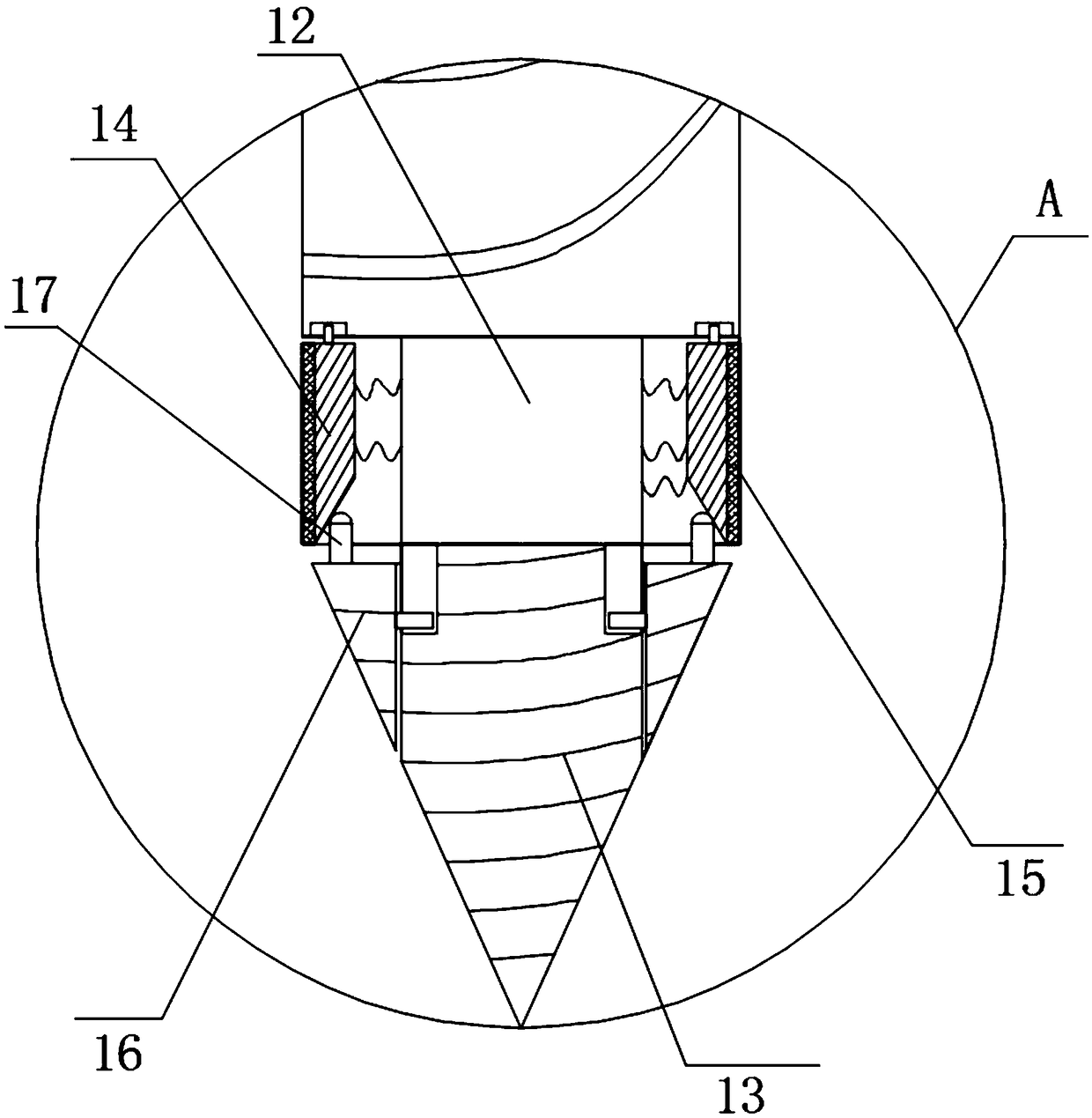

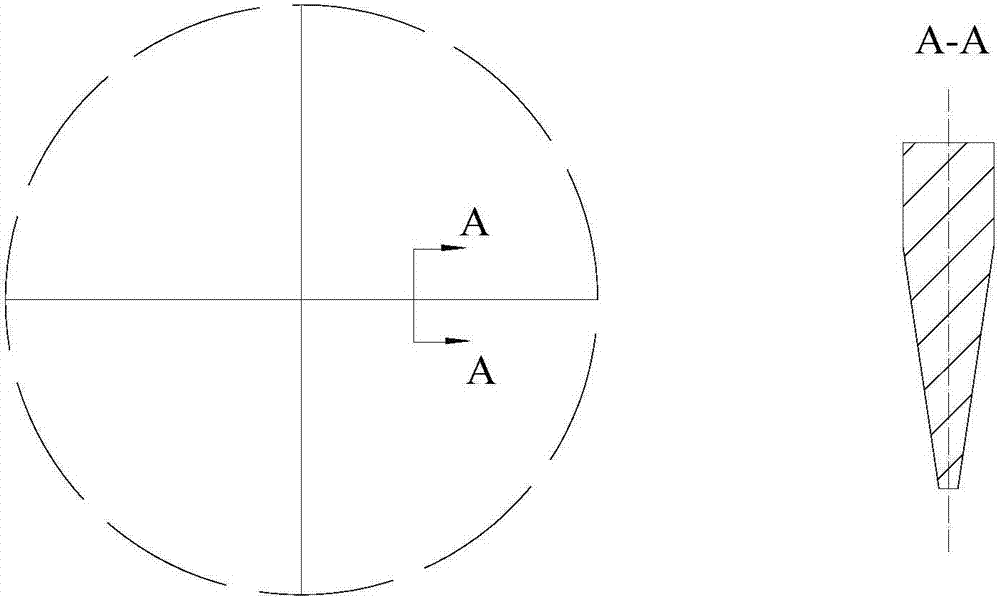

Efficient perforation device for processing shape memory titanium-nickel alloy coiled material

InactiveCN108857441AUniform feedingReduce manual operationsEdge grinding machinesMachine tool componentsAutomatic controlMotor drive

The invention discloses an efficient perforation device for processing a shape memory titanium-nickel alloy coiled material. The efficient perforation device has the advantages that the device is simple in structure, a first motor drives a slide plate to move vertically, the slide plate moves downwardly to drive screws to move downwardly, the screws drive drill bit to move downwardly to be abuttedagainst the titanium-nickel alloy coiled material and start rotating to drill the titanium-nickel alloy coiled material due to the fact that the screws are connected with nuts in a threaded manner, and titanium-nickel alloy coiled material abutting sliders move upwardly at the same time to allow polishing pieces to be abutted against the holes and start polishing the holes so as to achieve smoothholes; the slide plate moves upwardly to drive the screws and the drill bits to move upwardly to leave the titanium-nickel alloy coiled material, a touch rod is abutted against and pushes a shiftingpiece on a switch to start a second motor to perform feeding again, and accordingly automatic control, efficient perforation and hole polishing are achieved, and perforation device is high in practicality.

Owner:梁玉燕

Nano silver intrauterine device

The present invention relates to an intrauterine device containing nano silver. It is characterized by that the nano silver can be used and added into the material for making intrauterine device. If it is a plastic support intrauterine device, the nano silver antibacterial plastic mother granules or nano silver powder can be added in the plastics, then injection-moulded so as to obtain intrauterine device with various forms; if it is a stainless steel wire or titanium-nickel alloy wire intrauterine device, the nano silver solution can be used and applied to the surface layer of stainless steel wire or titanium-nickel alloy wire.

Owner:河南雅康药业有限公司

Preparation method for large titanium-nickel alloy ingots

The invention discloses a preparation method for large titanium-nickel alloy ingots. According to the method, a mold cavity is used, and a detachable auxiliary support is placed in the mold cavity and is used for dividing the inner space of the mold cavity into N grids which are horizontally arranged; 3-12.7 mm sponge titanium and square blocky electrolytic nickel are used as raw materials and are proportioned according to the composition proportion of titanium-nickel alloy to be prepared so as to obtain N parts of mixed raw materials; and each part of the mixed raw materials is poured into the corresponding grid; the auxiliary support is taken out from the mold cavity; electrode blocks for smelting the titanium-nickel alloy is formed by one-time vertical pressing; and the above steps are repeated to obtain a plurality of electrode blocks for smelting the titanium-nickel alloy, the electrode blocks are assembled and welded to form consumable electrodes, and then the consumable electrodes undergo vacuum smelting to obtain the large titanium-nickel alloy ingots. According to the method, the large titanium-nickel alloy ingots with equal atomic ratios, uniform alloy components and low impurity content can be produced.

Owner:西安赛特思迈钛业有限公司

Forging method for equal-atomic-ratio titanium-nickel alloy large cast ingot

The invention discloses a forging method for an equal-atomic-ratio titanium-nickel alloy large cast ingot. The titanium-nickel alloy large cast ingot is subjected to homogenization treatment, the technological parameter is 930-980 DEG C, and heat preservation time is 10-12 h, and air cooling is conducted; the air-cooled titanium-nickel alloy large cast ingot is subjected to the first heating number of forging, the heating temperature is 900-920 DEG C, heat preservation is conducted for 4-5 h, deformation is phi460-phi320, the strain rate is (0.05-0.10) s<1>, and a forging blank is obtained after the first heating number in a breaking mode; the forging blank is subjected to the second heating number of forging, the heating temperature is 880-900 DEG C, heat preservation is conducted for 3-3.5 h, deformation is phi320-phi200, the strain rate is (0.10-0.25) s<1>, and the forging blank is obtained after the second heating number in a breaking mode; and the forging blank is subjected to the third heating number of forging, the heating temperature is 850-880 DEG C, heat preservation is conducted for 2-2.5 h, deformation is phi200-phi110, the strain rate is (0.05-0.20) s<1>, and a titanium-nickel alloy square billet is obtained in a breaking mode. The method of the low strain rates, the multiple heating numbers and increasing deformation is adopted, forging of the titanium-nickel alloy large cast ingot is achieved, the cracking phenomenon in forging is eliminated, and the good structure and performance of materials are achieved.

Owner:西安赛特思迈钛业有限公司

Preparation method of ZTA particle enhanced steel-based composite grinding roller based on chemical activation treatment

ActiveCN106735101AHigh bonding strengthEnhanced interface bindingSuperimposed coating processInterfacial bondNickel alloy

The invention discloses a preparation method of a ZTA particle enhanced steel-based composite grinding roller based on chemical activation treatment. The preparation method comprises the following steps: (1) carrying out high temperature salt-bath plating on ZTA particles, and obtaining uniform titanium plated layers on the surfaces of the ZTA particles; (2) forming nickel layers at the peripheries of the titanium plated layers; (3) sintering the plated ZTA particles, and mutually connecting the ZTA particles to form a porous prefabricated part; and (4) fixing the prefabricated part on the end surface or the working surface of a cast, pouring a steel base material metal solution through a casting-penetrating process, and carrying out cooling to obtain the ZTA particle enhanced steel-based composite grinding roller. During the salt-bath titanium plating, titanium and the surfaces of the ZTA ceramic particles form metallurgical bonding, so that the interfacial bonding property between the titanium layers and the ZTA ceramic particles is enhanced. The ZTA ceramic particles subjected to the salt-bath titanium plating is then subjected to chemical nickel plating, and a titanium-nickel alloy can be generated at a titanium-nickel bonding part; and the titanium-nickel alloy layers achieve the effect of a flexible transitional layer between a metal base body and the ZTA particles, so that the bonding strength of the interface is greatly enhanced.

Owner:XI AN JIAOTONG UNIV

Method of preparing carbon nano tube reinforced composite ceramic layer on surface of titanium-nickel alloy

ActiveCN105039982ASolve the problem that it is difficult to prepare bioactive coatings by micro-arc oxidation technologyAddressing performance mismatchesSurface reaction electrolytic coatingSolid state diffusion coatingPlasma electrolytic oxidationMicro arc oxidation

The invention belongs to the technical field of metal material surface modification, and particularly relates to a method of preparing a carbon nano tube reinforced composite ceramic layer on the surface of a titanium-nickel alloy. The method of preparing the carbon nano tube reinforced composite ceramic layer on the surface of the titanium-nickel alloy comprises the steps that the surface of the titanium-nickel alloy is carburized by adopting a double glow discharge plasma surface alloying technique to form a titanium carbide modification layer; the surface of the titanium-nickel alloy is carburized by adopting the double glow discharge plasma surface alloying technique to form a titanium carbide / titanium gradient modification layer; and by taking the titanium carbide / titanium gradient modification layer as an anode, adopting a micro-arc oxidation technique, and adding a carbon nano tube to a micro-arc oxidation electrolyte, the carbon nano tube reinforced composite ceramic layer is obtained. The bonding strength of the carbon nano tube reinforced composite ceramic layer to a matrix is high, and the hardness, the abrasive resistance, the corrosion resistance and the biocompatibility of the modification layers are improved effectively.

Owner:TAIYUAN UNIV OF TECH

Zirconium-titanium-nickel alloy and preparation method thereof

The invention discloses zirconium-titanium-nickel alloy which is prepared from the following chemical components in percentage by mass: 47 percent to 50.5 percent of zirconium, 47 percent to 50.5 percent of titanium, 0.5 percent to 5.5 percent of nickel, and the balance of inevitable impurities. A preparation method of the zirconium-titanium-nickel alloy comprises the following steps: mixing the raw materials to obtain a mixture, putting the mixture into a vacuum non-consumable melting furnace and smelting for 6 times to ensure that the vacuum degree is 5.0x10<-3> Pa; carrying out arc striking on a tungsten electrode, enabling the current of a smelting electrode to be kept at 190A and 220 A, wherein the smelting time is 3 minutes every time; waiting casting ingots to be cooled to a room temperature after each smelting is finished, and then smelting again to ensure that zirconium-titanium-nickel alloy ingot with uniform components is obtained. The method disclosed by the invention is simple and easy to operate, and the strength and the hardness of the crystals can be improved; wherein the compressive strength of the crystal is 1691MPa to 1900MPa, the elongation rate is 2.6 percent to 19.0 percent, and the Vickers hardness is 312HV to 370HV.

Owner:YANSHAN UNIV

Hot rolling cogging process of Ti-Ni alloy ingot

The present invention relates to high efficiency and low power consumption hot rolling cogging process of Ti-Ni alloy ingot, and features that the technological process includes the steps of: heat treatment of the Ti-Ni alloy ingot, cogging and rolling Ti-Ni alloy rod. The heat treatment before cogging has temperature of 750-950 deg.c, and during the cogging, the deformation region of the Ti-Ni alloy ingot is applied with circumferential symmetrical rolling force and longitudinal continuous gradient rolling force. The rolling process has short period, great rolling deformation rate and high efficiency, and is suitable for industrial production, and the rolled Ti-Ni alloy rod has high sized precision and high finished product rate.

Owner:西安赛特金属材料开发有限公司

Preparation method of multilayer titanium-nickel alloy filter film

The invention provides a preparation method of a multilayer titanium-nickel alloy filter film. The method is characterized by including the steps of: (1) mixing high purity titanium hydride powder and high purity nickel carbonyl powder according to certain proportion; (2) preparing the high purity titanium hydride and nickel carbonyl mixed powder and a polyvinyl butyral liquid into a mixed slurry according to certain mass ratio, covering a smooth quartz surface with a film by a film formation apparatus, and performing standing drying in nitrogen; (3) using thin-layer zinc stearate for spacing on a dried prefabricated film layer, using the mixed slurry for film covering successively, and performing standing drying; and (4) removing the product from the quartz panel surface to form a multilayer titanium-nickel green film, controlling the temperature raising program, and carrying out vacuum sintering, thus obtaining the multilayer titanium-nickel alloy filter film. The method provided by the invention has a simple process, and the obtained material has stable performance, therefore the method is suitable for industrial production.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

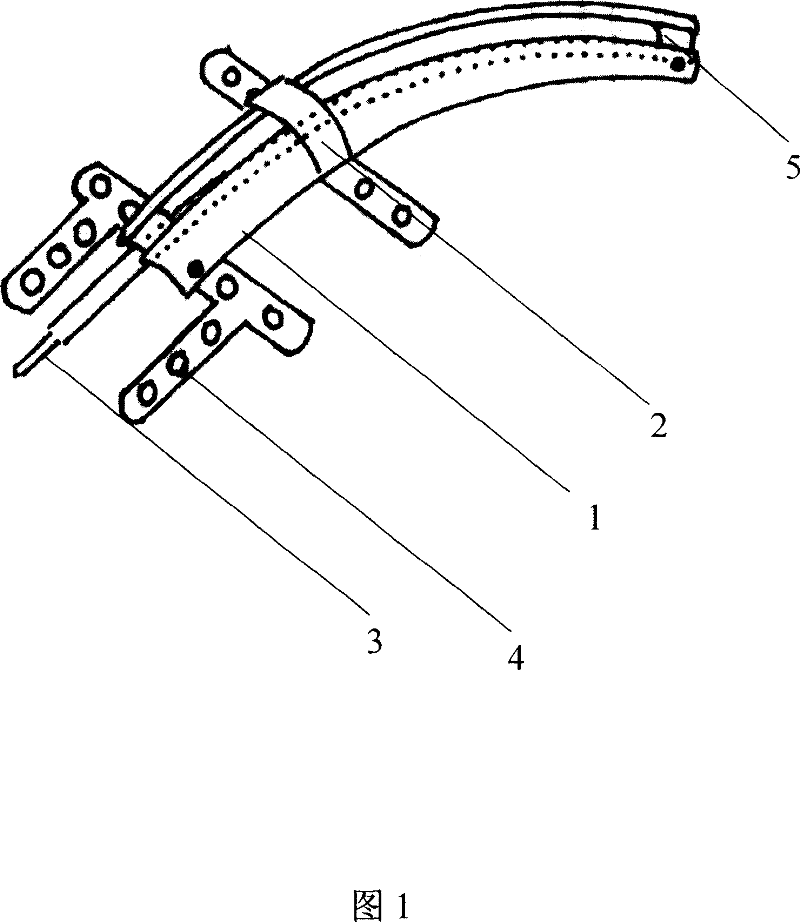

Zygoma internal arced distractor

InactiveCN101040793AHigh strengthHigh strength, good biocompatibilityExternal osteosynthesisEngineeringFace shape

A malar bone internal arch bone drawer is characterized in that it is formed by an arch track, a block, a flexible central screw, a fixing plate and a positioning sheath. The flexible central screw is made from ultra-flexible titanium nickel alloy, arranged at the center of the arch track, through the center of the block and fixed by the positioning sheath at two ends, to force via a special forcing rod in drawing process. The flexible central screw can rotate along with the arc shape of the arch track, to move the block in arc movement along the arch track. When upper jaw hurts most, patient face is significant concave, without bone support, which is hard to rebuild chewing ability. And the invention can tension internal arc into bones to repair part of upper jaw to rebuild bone support at hurt part, to realize ability rebuilding. The invention can better compatibility, small volume, simple design, and easy operation.

Owner:牛学刚

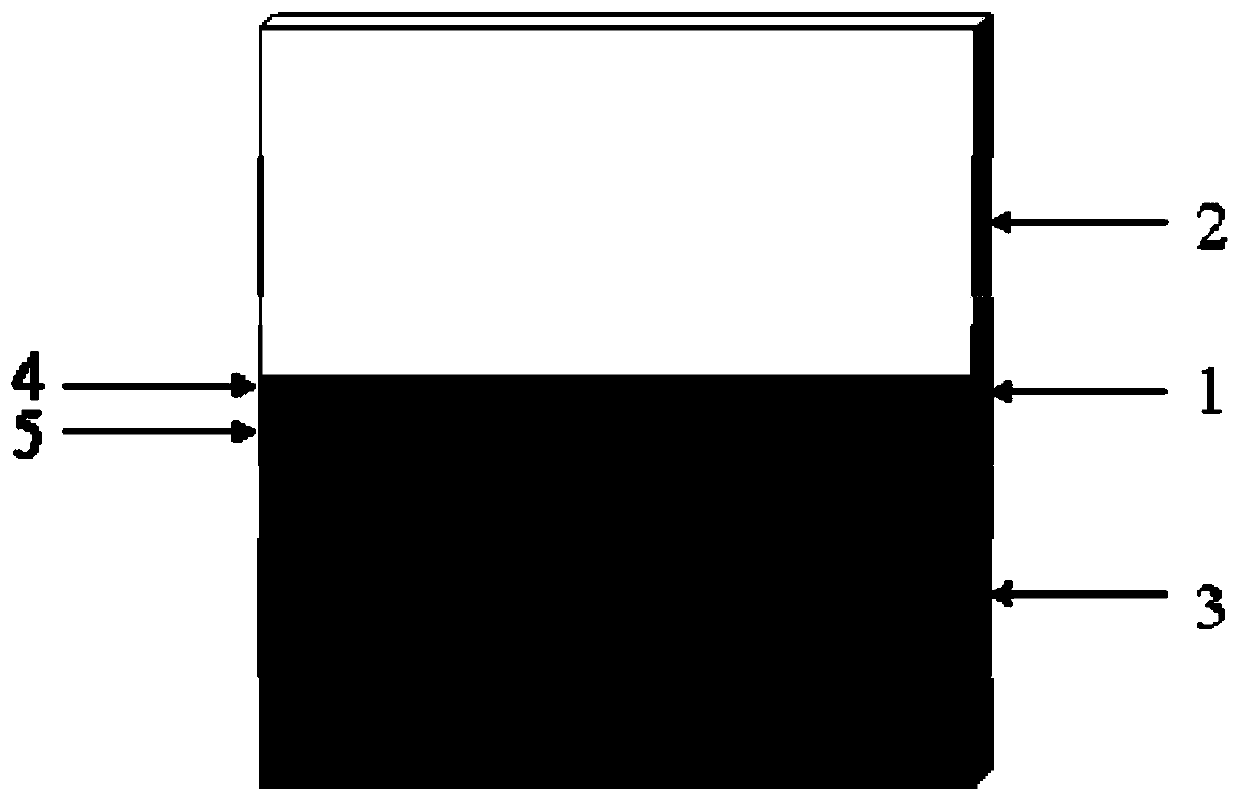

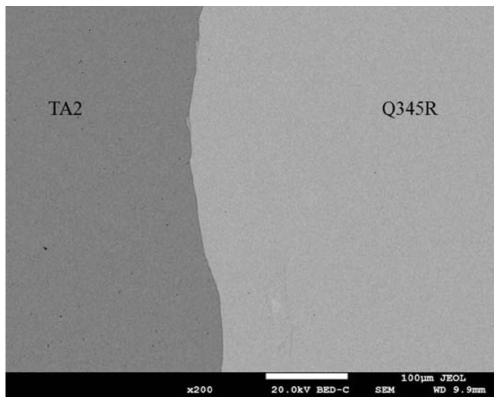

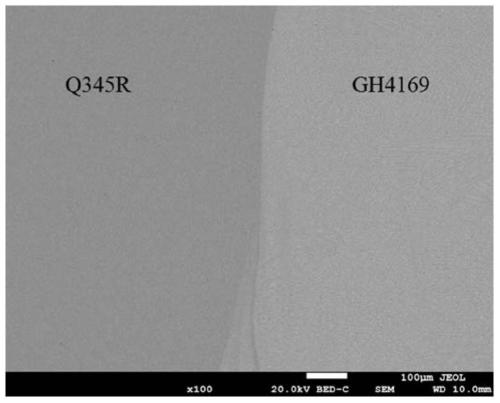

Titanium/nickel alloy component based on explosion welding and laser additive manufacturing and preparation method

ActiveCN111215855AOvercoming the problem of interface crackingFast formingAdditive manufacturing apparatusGrinding machinesNickel alloyTitanium

The invention discloses a titanium / nickel alloy component based on explosion welding and laser additive manufacturing and a preparation method, and belongs to the technical field of connection of thermometal components. The titanium / nickel alloy component comprises an explosion welding component and a laser additive manufacturing component which are connected. The explosion welding component is atitanium / steel composite plate or titanium / nickel composite plate, and the laser additive manufacturing component is made from a titanium alloy or a nickel-based alloy. According to the titanium / nickel alloy component based on explosion welding and laser additive manufacturing, a middle transition layer is connected through an explosion welding method, and the problem that due to the fact that a titanium / nickel alloy is in direct contact with a generated brittle intermetallic compound, an interface cracks is solved; and the titanium / nickel alloy component is prepared based on the explosion welding component through a laser additive manufacturing process, the forming speed is high, the flexibility is good, and the efficiency is high.

Owner:有研金属复材技术有限公司

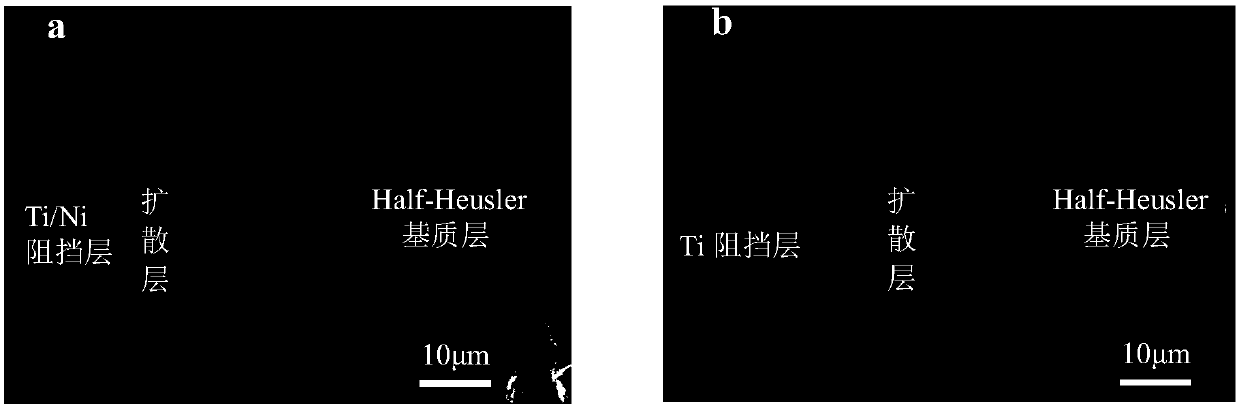

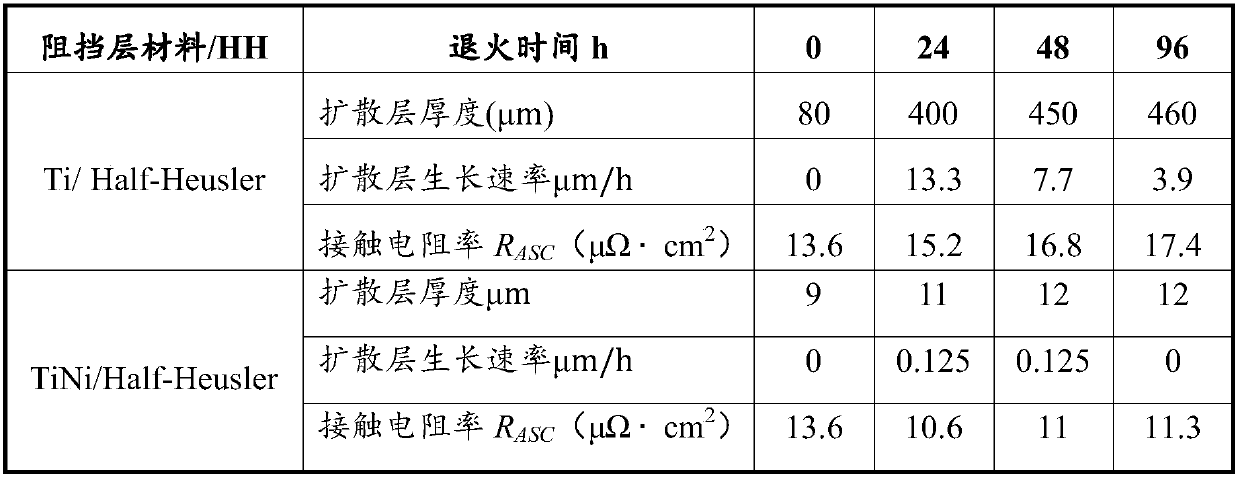

Thermoelectric device and electrode thereof, and method for preparing electrode

InactiveCN107665943AWell matched thermal expansionImprove structural stabilityThermoelectric device manufacture/treatmentThermoelectric device detailsNickel alloyThermal expansion

The invention discloses a thermoelectric device and an electrode thereof, and a method for preparing an electrode. The electrode of the thermoelectric device comprises a half-Heusler matrix layer, a solder layer and an electrode layer which are laminated and combined and laminated in a manner. A barrier layer is arranged between the half-Heusler matrix layer and the solder layer in a laminated andcombined manner, wherein the barrier layer is a titanium-nickel alloy layer. According to the electrode, on the basis of the the titanium-nickel alloy layer structure, good thermal expansion matchingbetween the electrode layer and the contact interface of the half-Heusler matrix layer is realized; a diffusion layer formed between the interface has low thickness and the interface contact resistance is low; the thickness of the diffusion layer is stable with extension of service time, so that the interface stability is improved and thus the high thermoelectric conversion efficiency of the thermoelectric device is realized. Besides, because of the preparation method, stability of performances of the thermoelectric device electrode is guaranteed and the production efficiency is high.

Owner:SHENZHEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com