Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "Titanium fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-radiation concrete and preparation method thereof

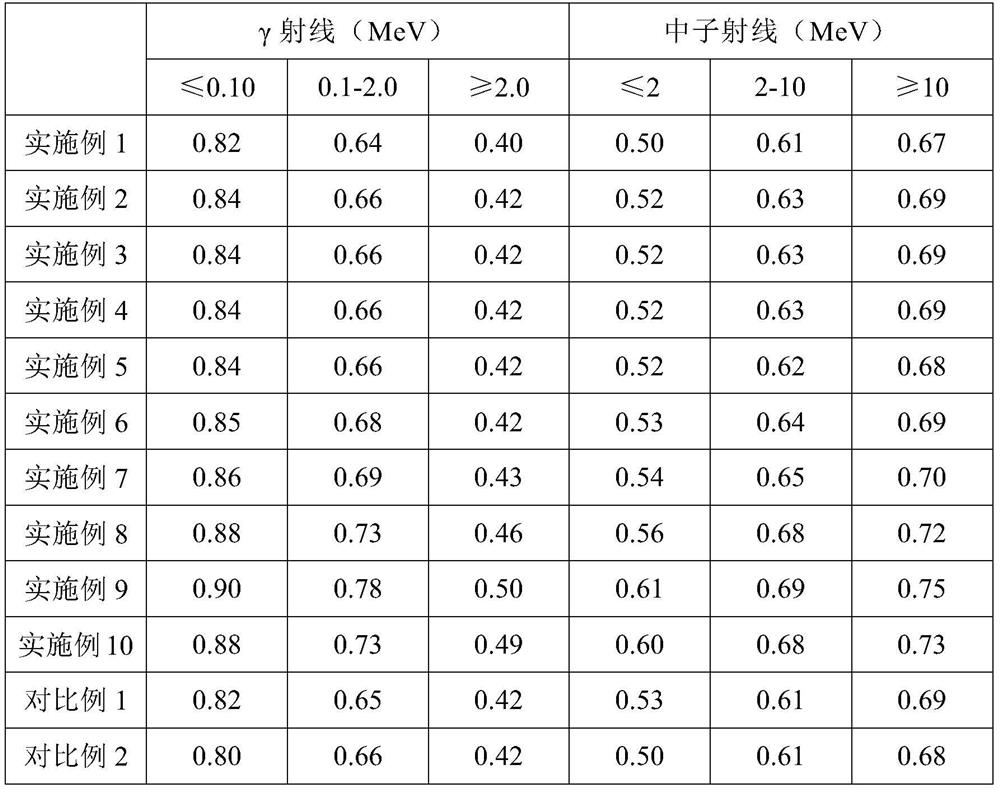

The invention discloses anti-radiation concrete and a preparation method thereof. The anti-radiation concrete is prepared from the following raw materials in parts by weight: 220-280 parts of cement;30-50 parts of mineral powder; 40-80 parts of fly ash; 1350-1400 parts of a heavy aggregate; 525-575 parts of a lightweight aggregate; 30-40 parts of a fiber additive; 25-35 parts of an expanding agent; 5-8 parts of a water reducing agent; 150-200 parts of water. The heavy aggregate is barite and heavy crystal sand, the light aggregate is basalt, the fiber additive comprises basalt fibers and titanium fibers, and the ratio of the basalt fibers to the titanium fibers is 1:(1-1.5). The anti-radiation concrete has the advantages that the volume weight is reduced, the mechanical property and the construction property are improved and the cost is reduced under the condition that the anti-radiation effect is guaranteed; in addition, the invention further provides a preparation method of the anti-radiation concrete, and the prepared concrete has excellent comprehensive performance.

Owner:北京怀建混凝土有限责任公司

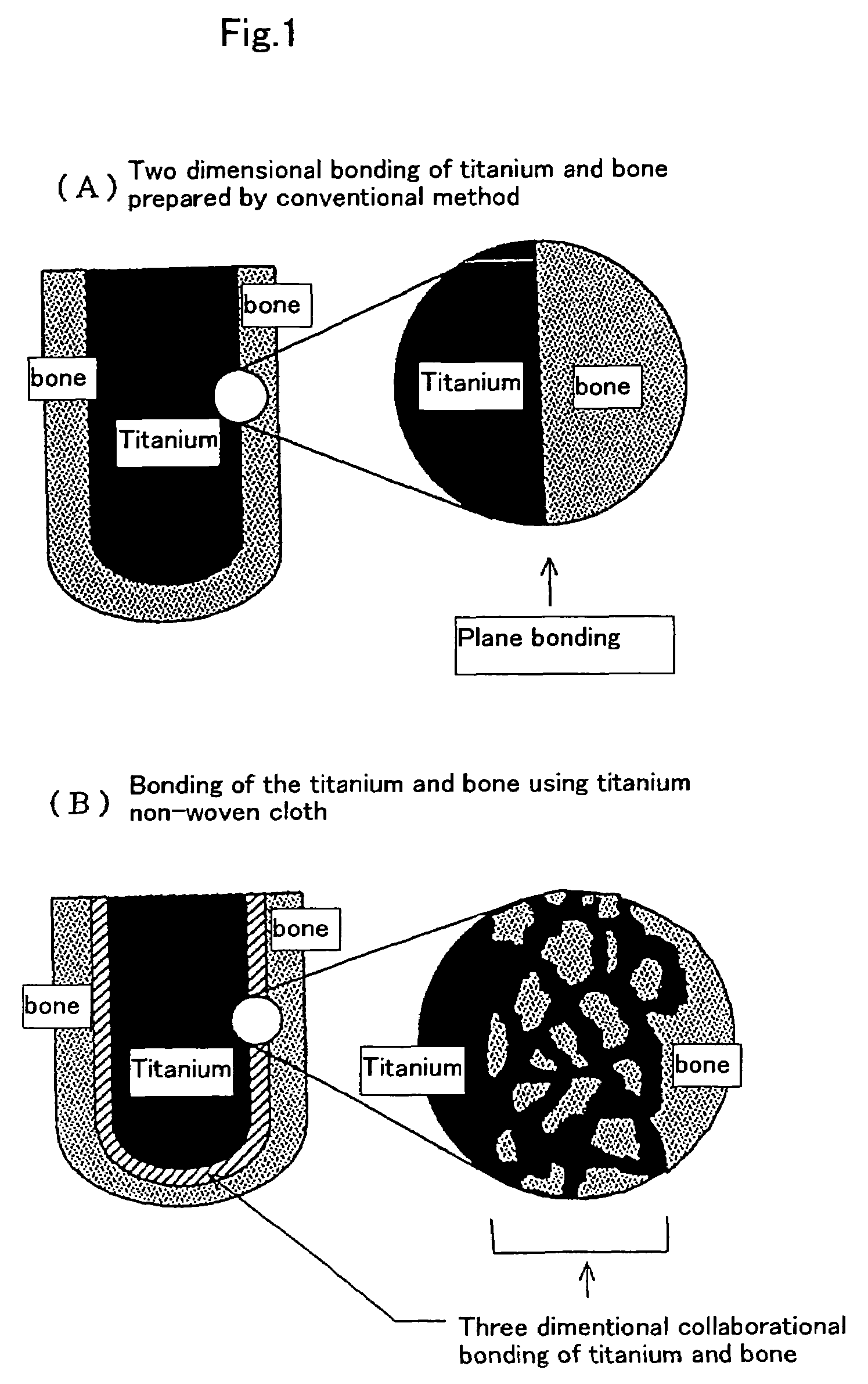

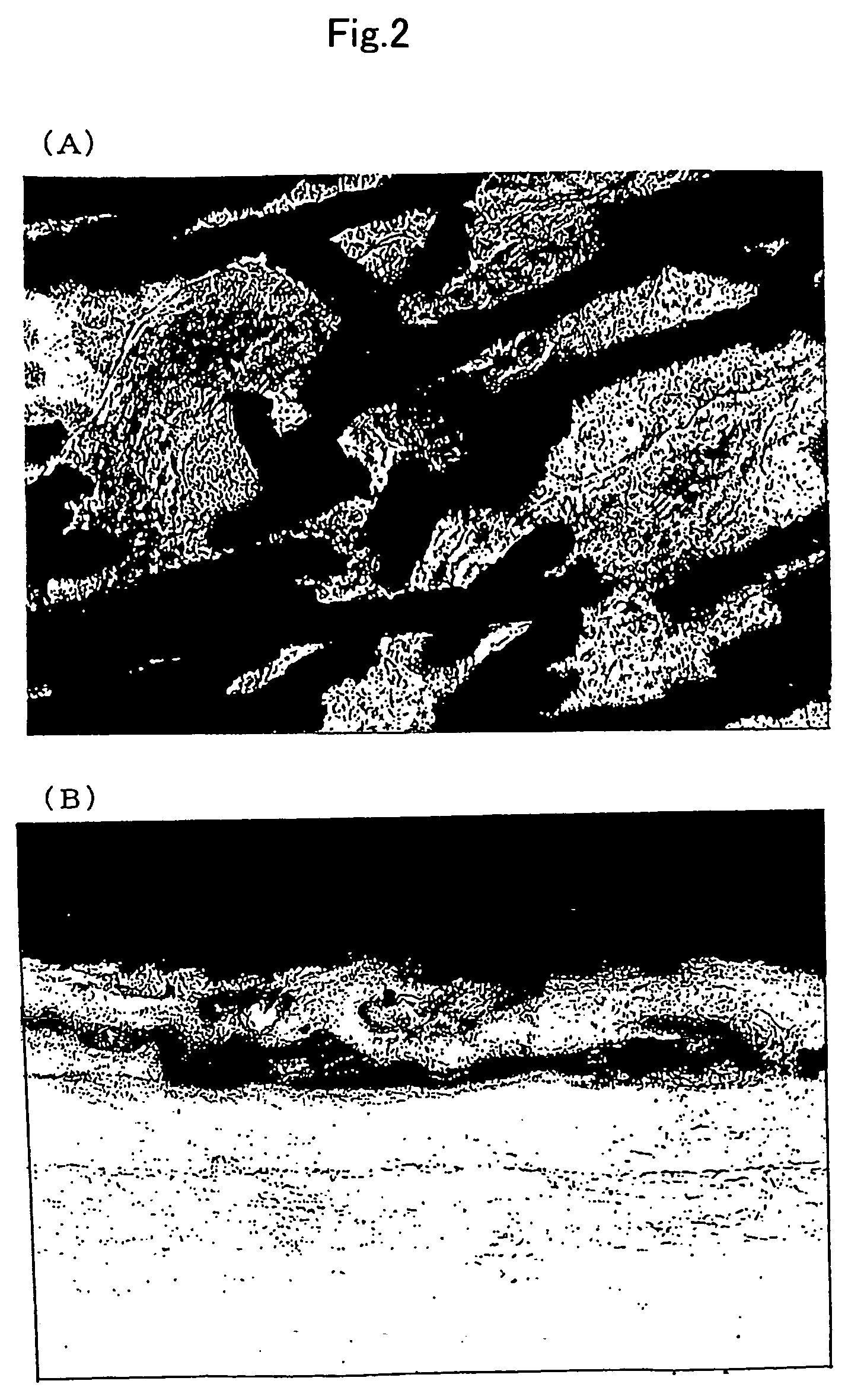

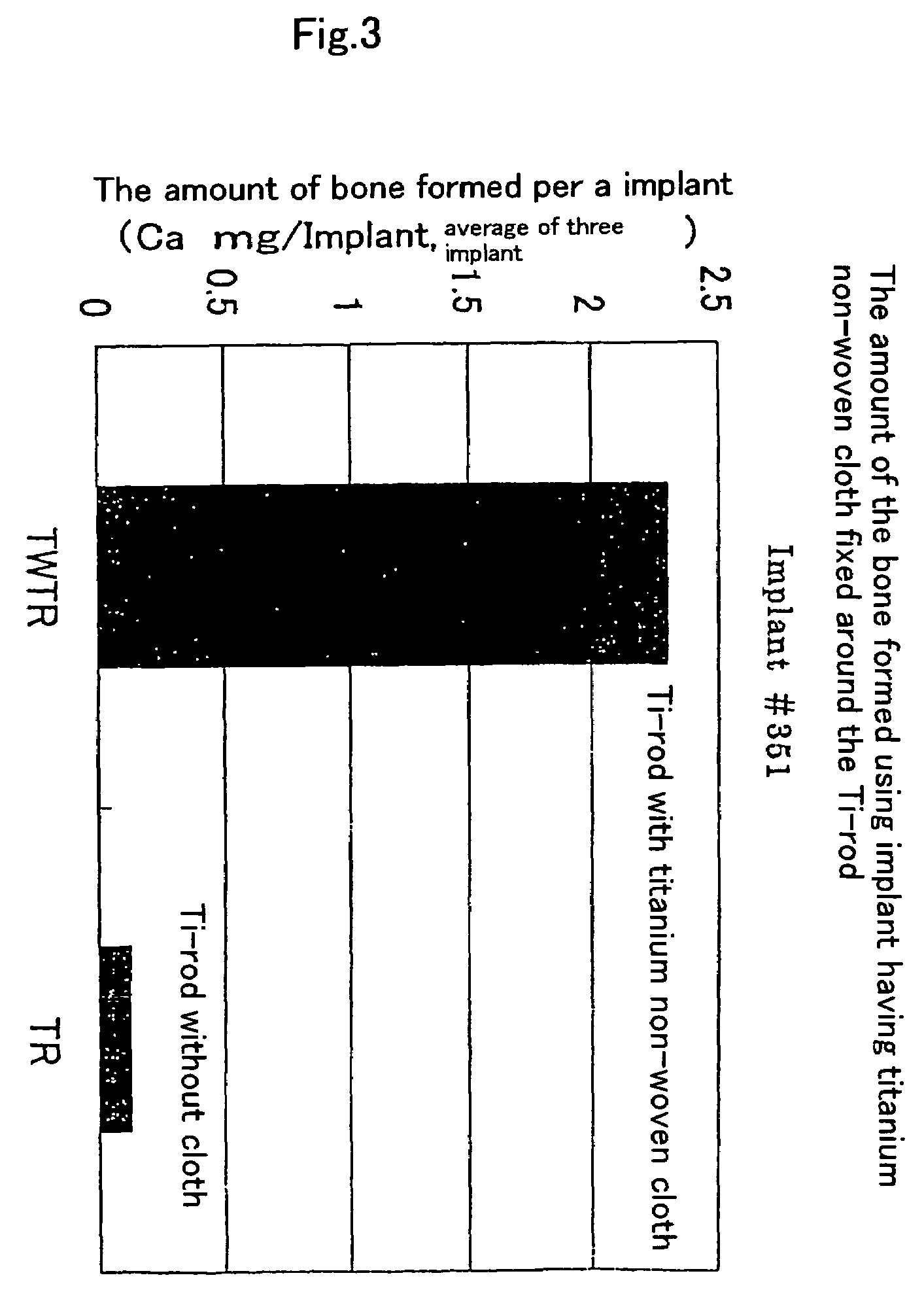

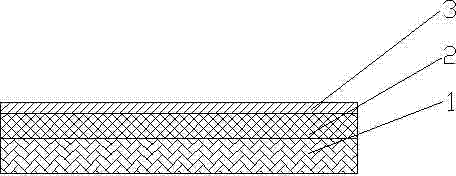

Medical material made of titianium fiber

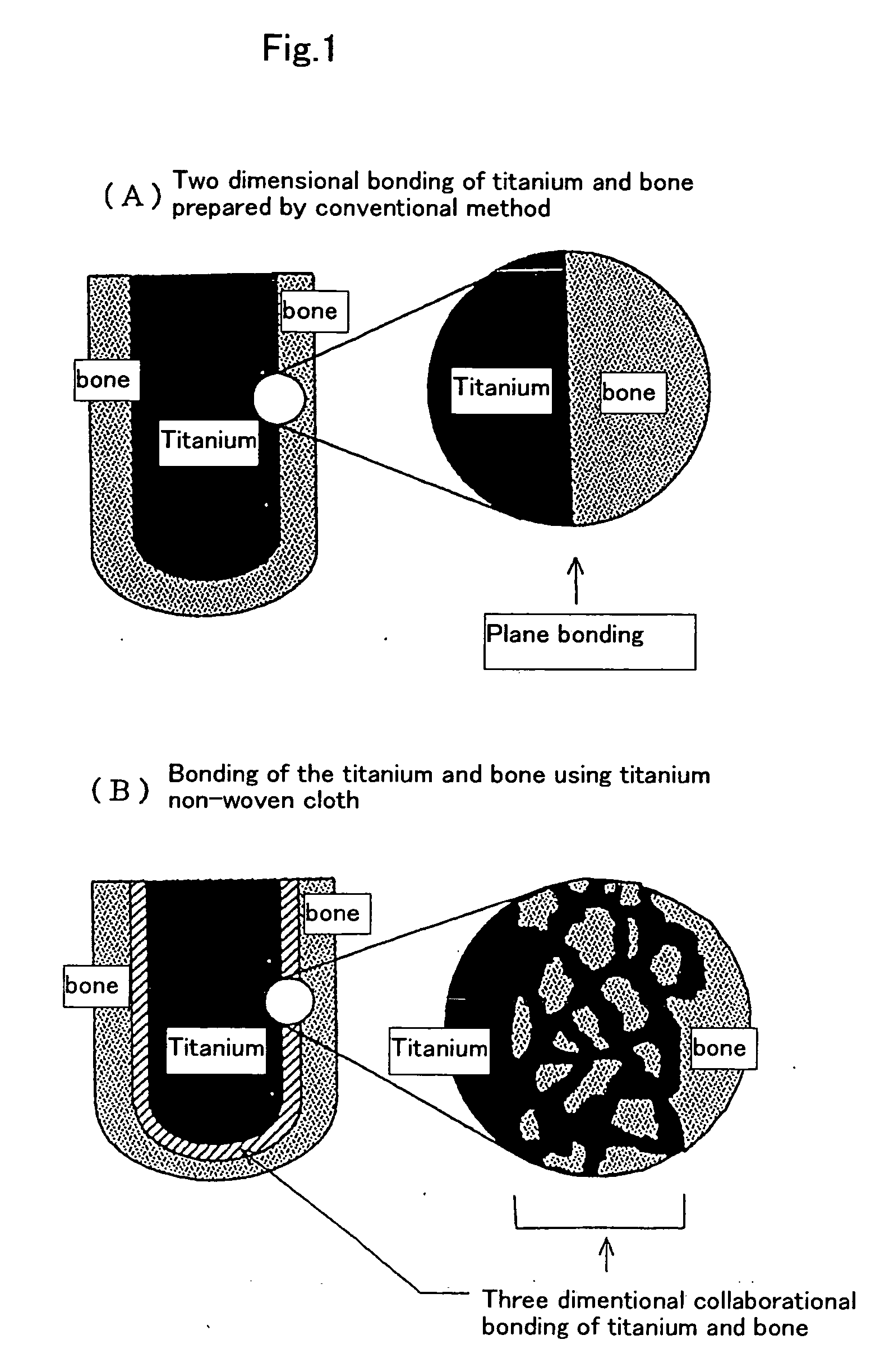

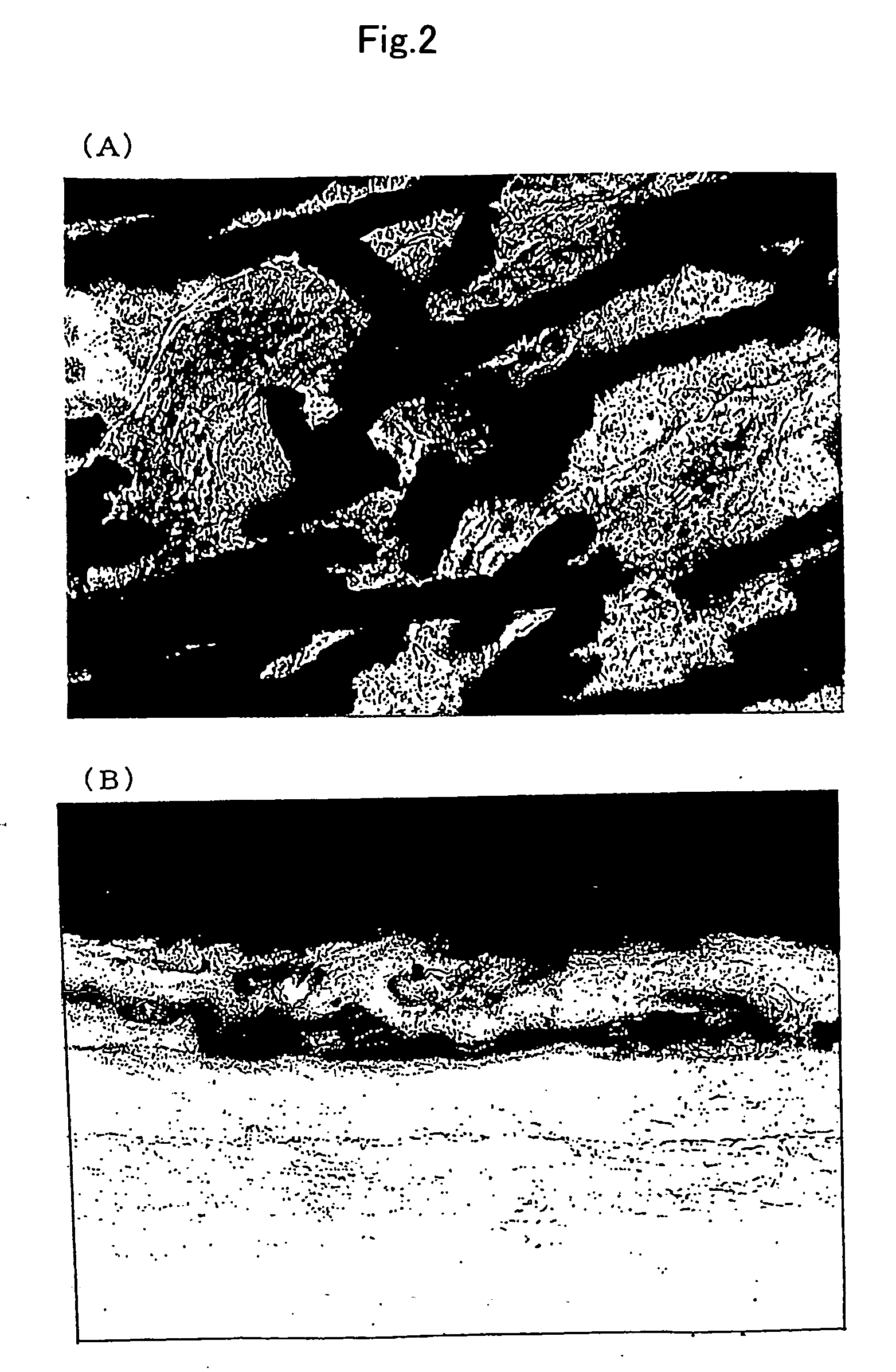

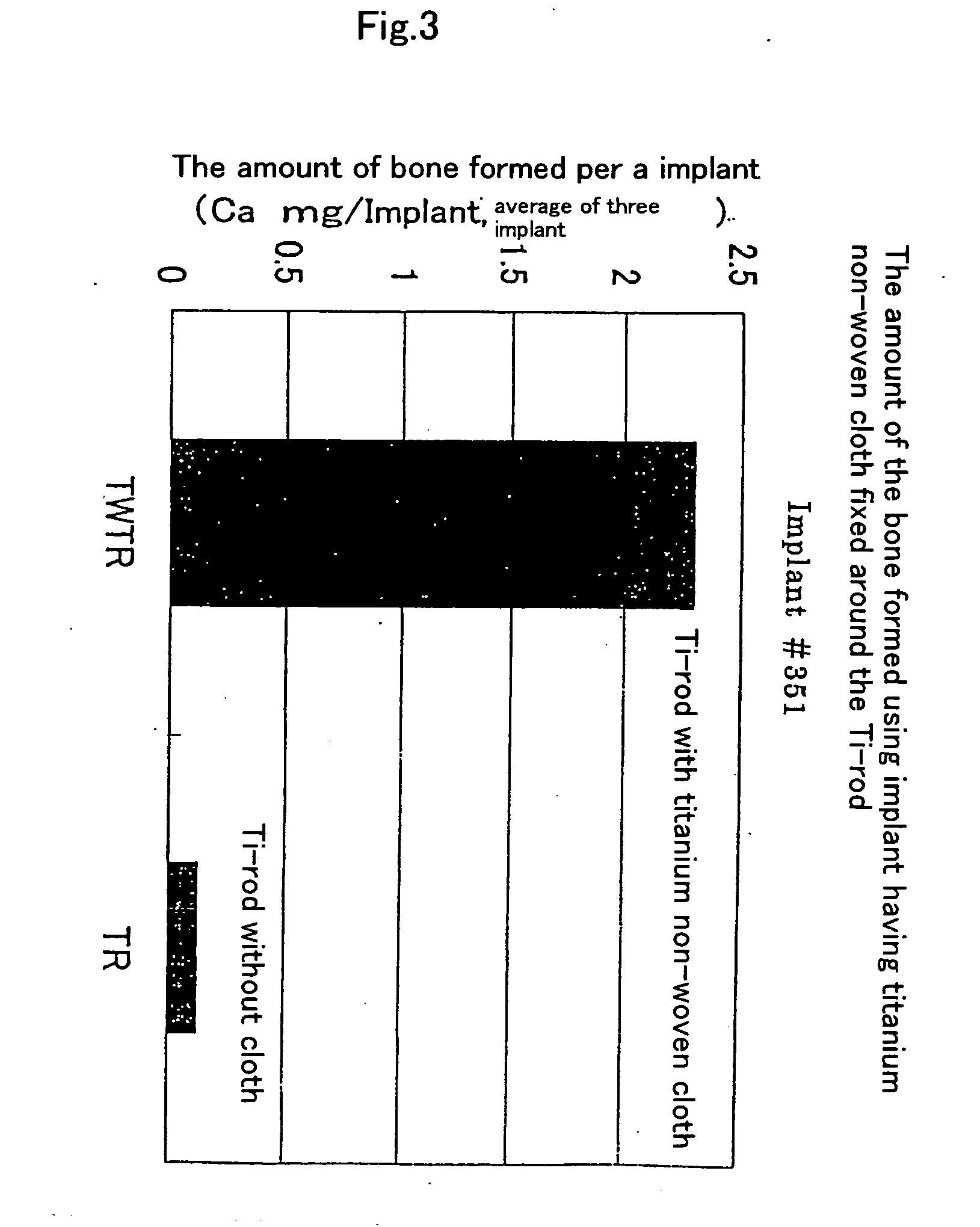

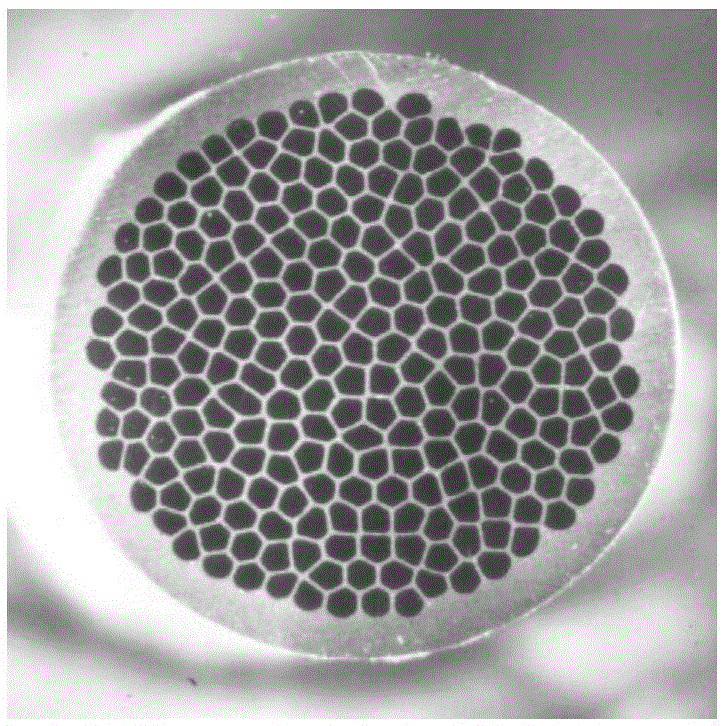

It is intended to provide a scaffold whereby a bone and a metallic material can three dimensionally form together a stereoscopic binding layer. Thus, a geometric space sufficient for cell actions is provided. As a result, the time required for the formation of a stereoscopic bond can be shortened and, moreover, a bond can be self-repaired owning to cell actions even in the case where a pair of the bond is injured by a wound, etc. As a material for designing a scaffold, titanium fibers of less than 100 μm in size and having an aspect ratio of 20 or more are selected. Then these fibers are entangled together to form a layer which is integrally fixed by vacuum sintering to a periphery surface of the various implant bodies, and coated with apatite. The fact that the layer contains spaces of an excellent ability to induce a biological hard tissue and fix the same is proved by the material, in which the layer is fixed to the periphery of an implant.

Owner:KUBOKI YOSHINORI

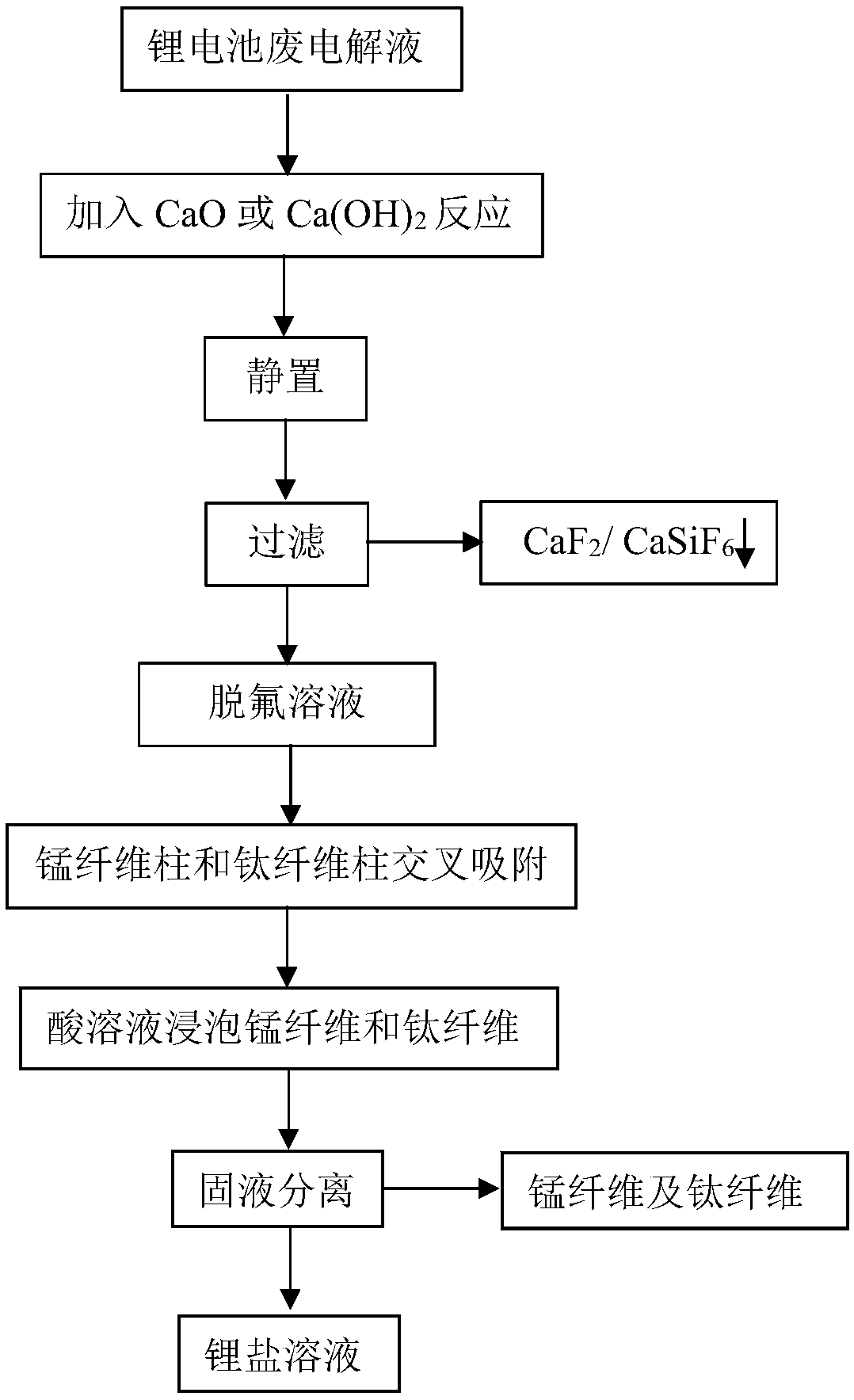

Method for recycling fluorine and lithium from waste electrolyte of lithium battery

ActiveCN108666644AReduce pollutionEasy to separateWaste accumulators reclaimingBattery recyclingManganesePhysical chemistry

The invention discloses a method for recycling fluorine and lithium from waste electrolyte of a lithium battery. The method comprises the following steps: (1) putting CaO or Ca(OH)2 into waste lithiumbattery electrolyte, enabling Ca<2+> to react with fluorine ions in the electrolyte to generate CaF2 precipitate, leaving to stand and layer, and further carrying out solid-liquid separation so as toobtain CaF2 and a defluorination solution; (2) introducing the defluorination solution into an adsorption device with a manganese fiber and a titanium fiber, carrying out adsorption treatment, and enriching lithium ions in the defluorination solution through the manganese fiber and the titanium fiber; (3) soaking the manganese fiber and the titanium fiber into an acid solution, so as to obtain alithium salt solution. By adopting the method, CaO or Ca(OH) 2 is enabled to react with the waste lithium battery electrolyte firstly, Ca<2+> is enabled to react with the fluorine ions in the electrolyte to generate CaF2, later physical oriented adsorption on lithium ions is carried out by using a multi-stage manganese fiber adsorption column and a titanium fiber adsorption column, then fluorine and lithium in the electrolyte can be recycled, and both the fluorine and the lithium are recycled and environment pollution can be reduced.

Owner:东莞市坤乾新能源科技有限公司

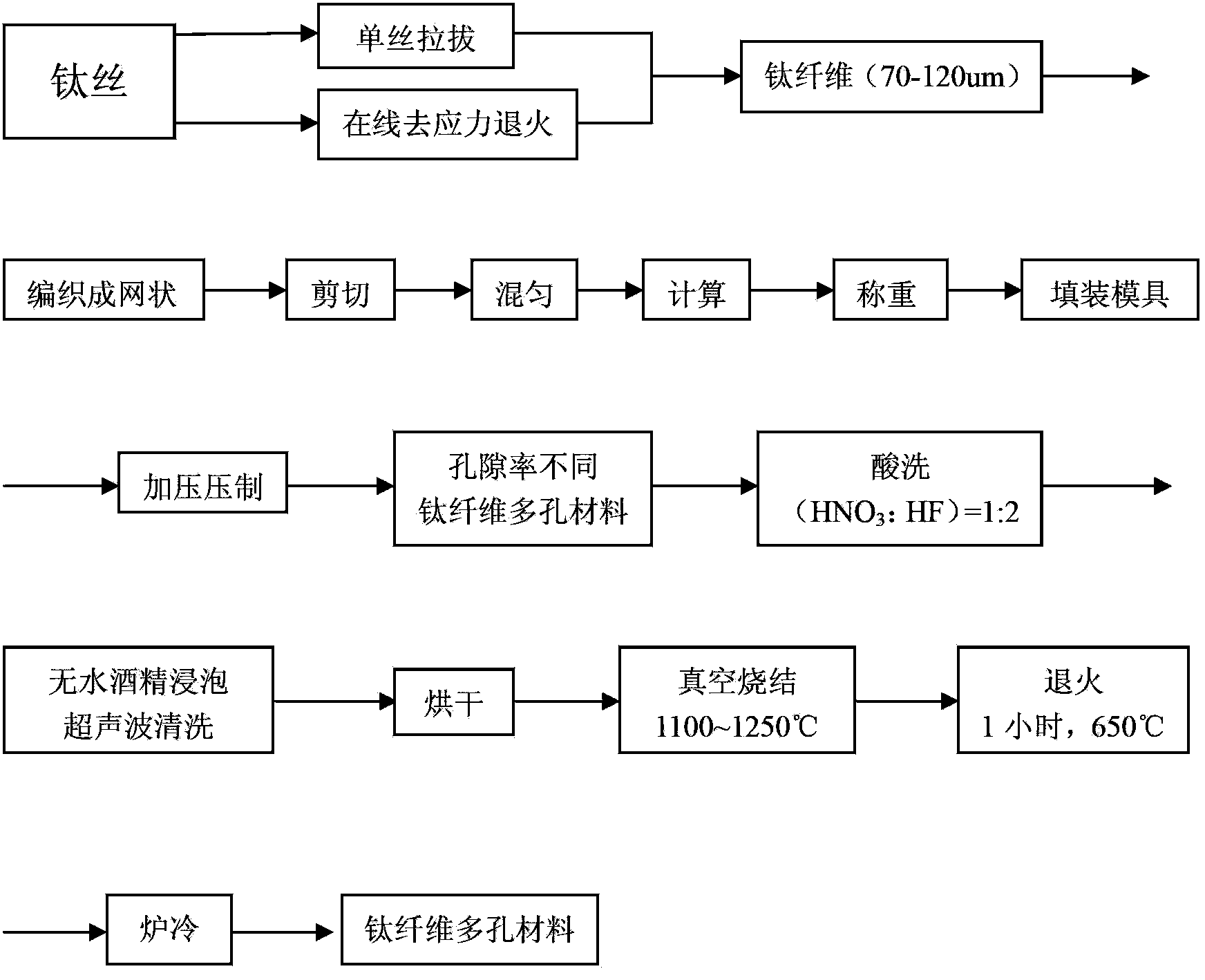

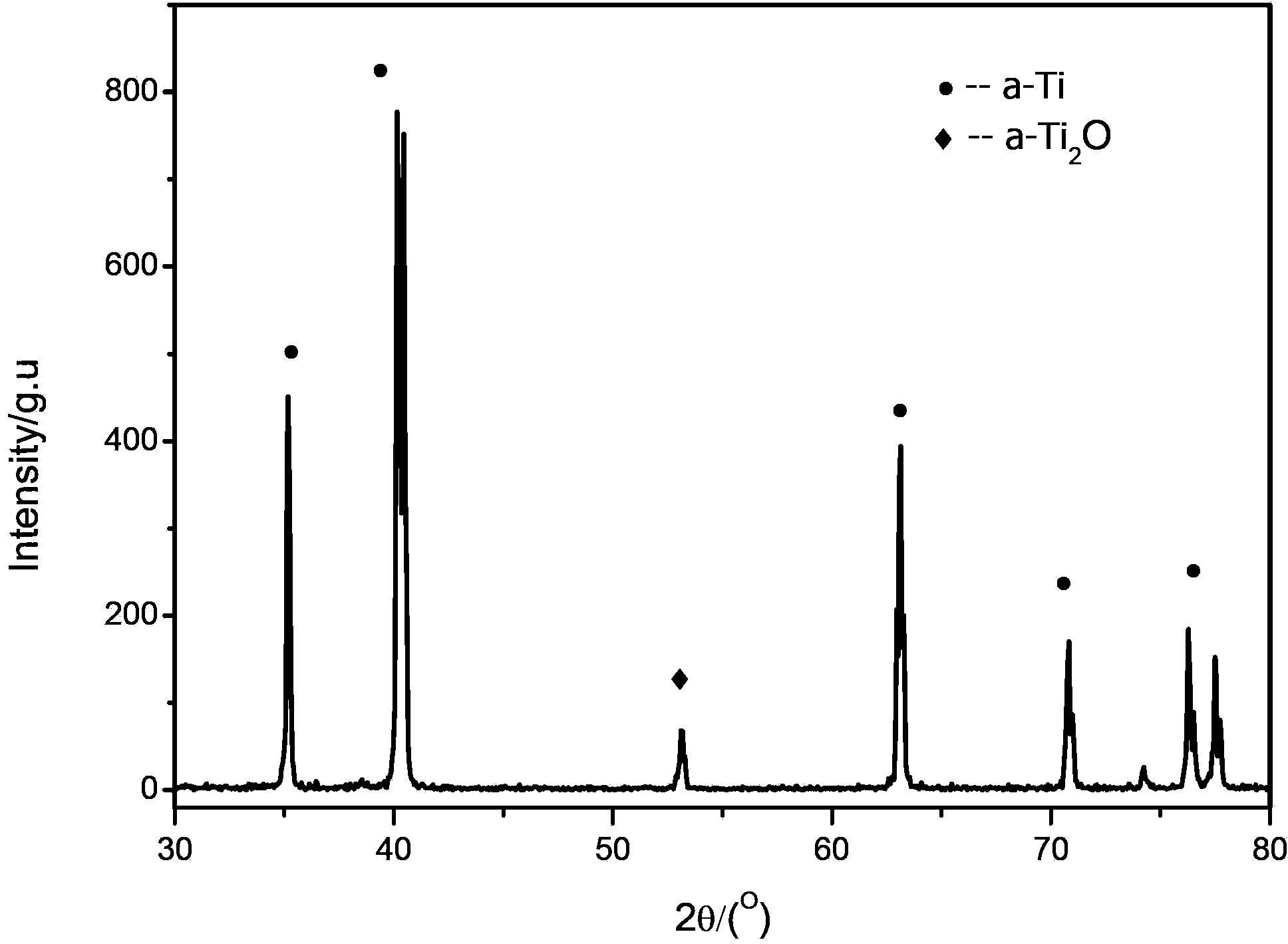

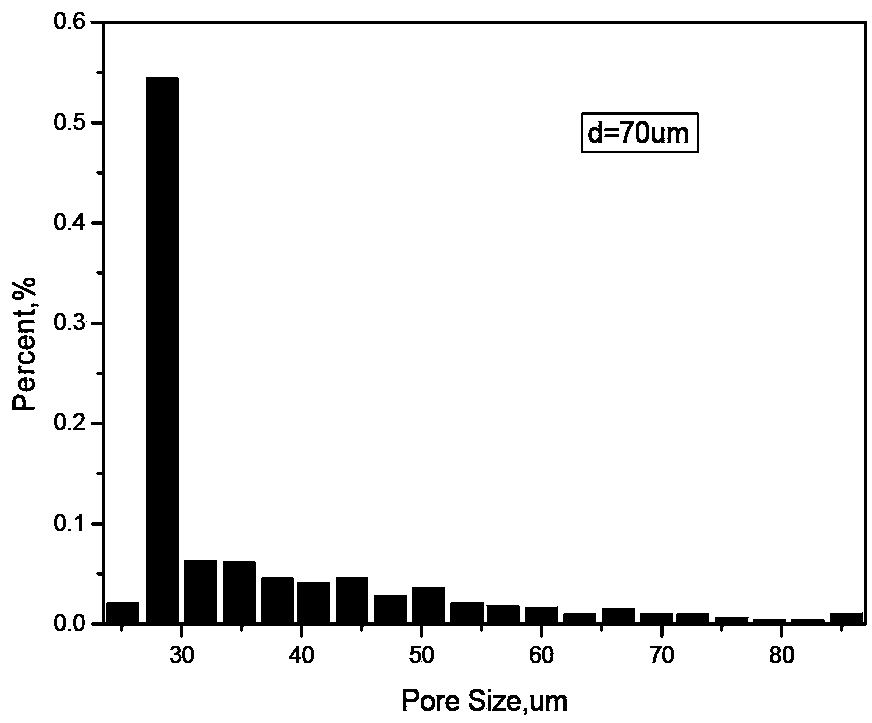

Preparation method of titanium fiber porous material

The invention provides a preparation method of a titanium fiber porous material, which has controllable fiber diameter and porosity. The material is prepared by: drawing a titanium wire into a fibrous state, and then carrying out weaving and compression molding. After the material is prepared, pickling is conducted to remove of the oxide on the surface of the titanium fiber porous material, and then the material is subjected to high temperature sintering by a vacuum sintering furnace. By means of the method provided in the invention, a sintered titanium fiber porous material can be obtained, and all properties of the titanium fiber porous material are greatly improved. Thus, the method provides an important basis for realization of product industrialization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

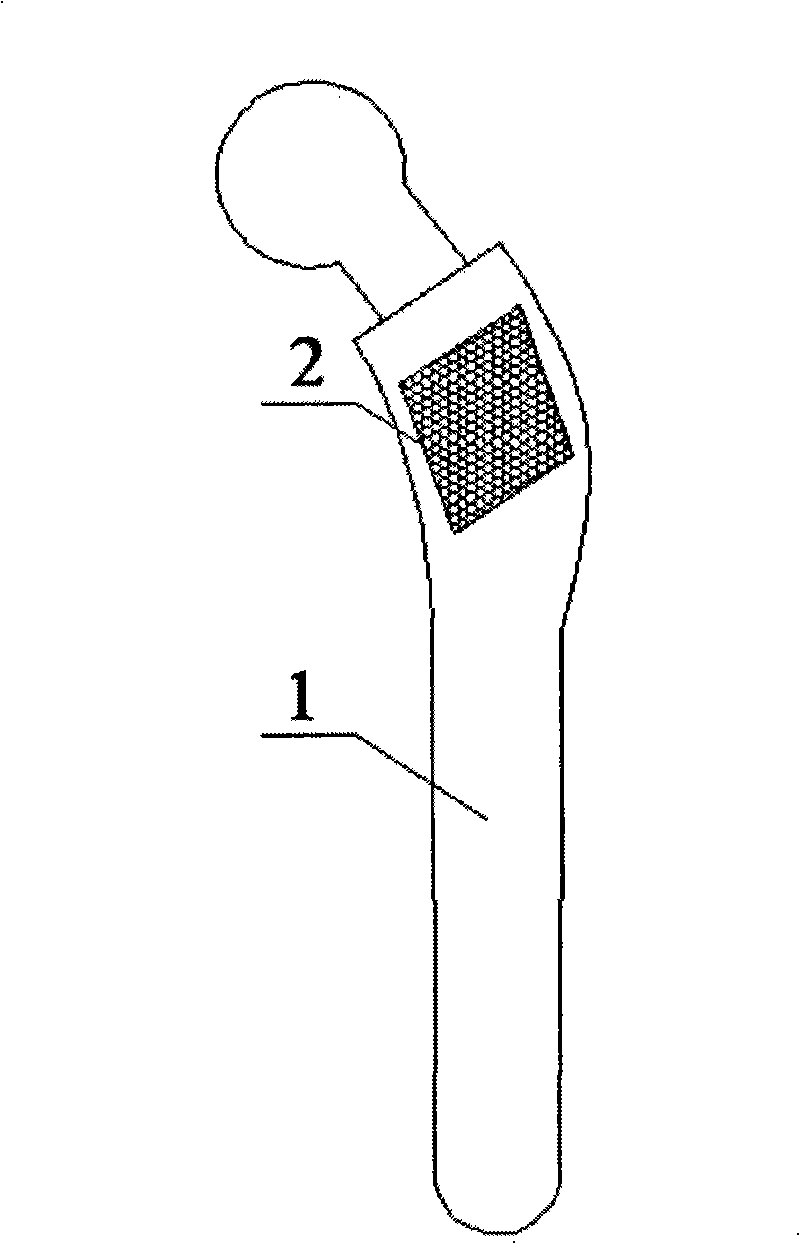

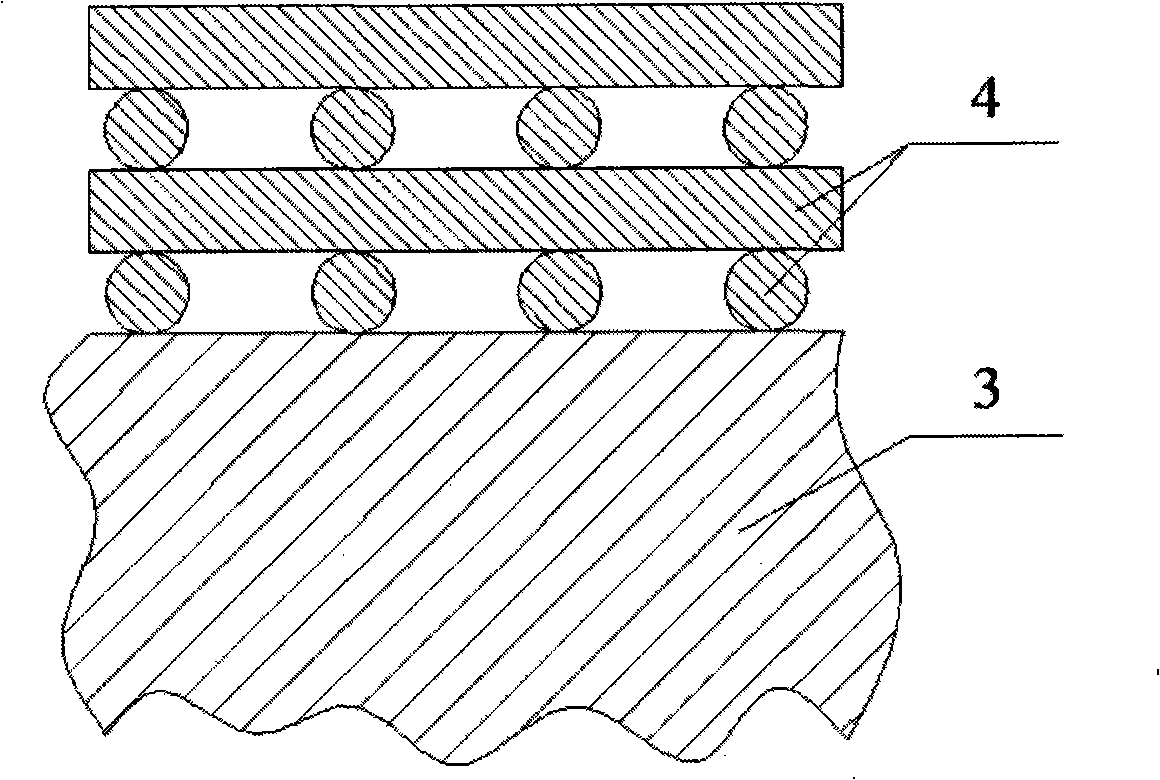

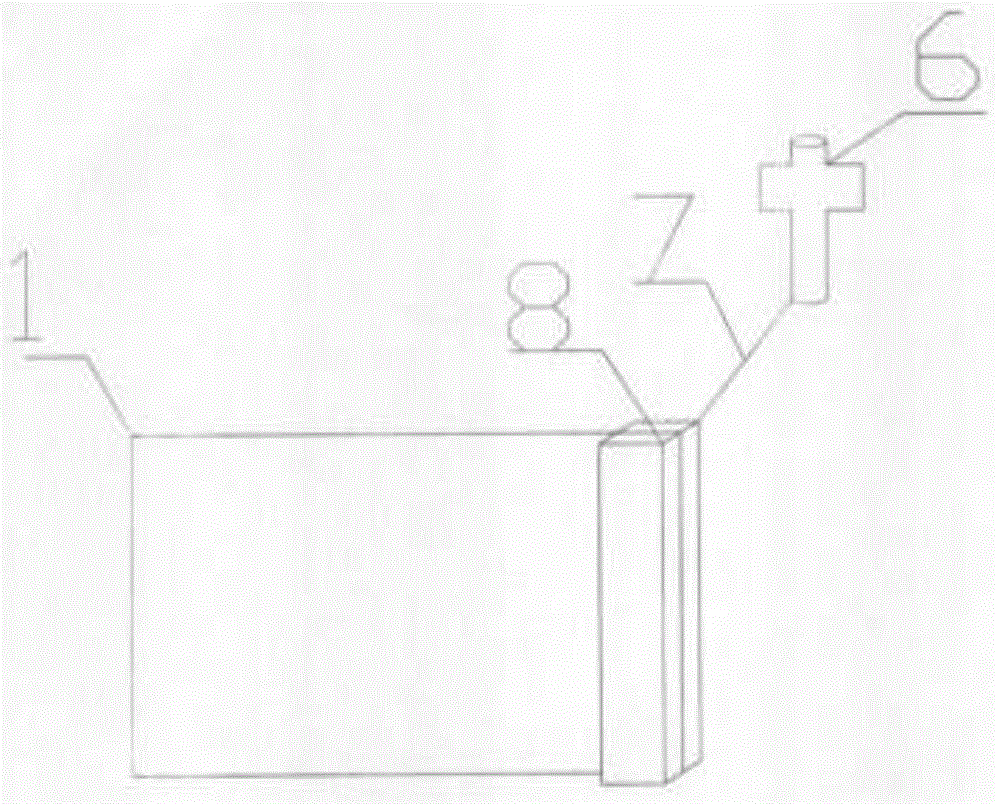

Local spatial grid structure artificial joint prosthesis and preparation method thereof

InactiveCN101283936AAchieve biofixationProtect high-strength mechanical propertiesJoint implantsPorosityMechanical property

The invention relates to an artificial joint prosthesis with a local grid structure and the manufacturing method thereof, which belongs to the field of biomedicine engineering. The prosthesis comprises a prosthesis handle and a grid structure body, wherein the grid structure comprises a titanium plate and titanium fibers; and the titanium fibers are braided in cross, quadrangular or star shape and sintered on the titanium plate to form the 3D grid structure body with a pore size of 200 to 1,200 mum and a porosity of 30 to 60%. The manufacturing method comprises following steps: braiding and sintering the titanium fibers on the titanium plate to obtain the grid structure body, and welding on the predetermined portion of the joint prosthesis. The method can prevent the prosthesis handle from being subjected to high-temperature thermal processing, maintain good high-strength mechanical property and acquire proper grid structure, thus providing space for the growth of cells and tissue, promoting ankylosing of new-born bone tissue and host bone and achieving bio-fixation of prosthesis. The artificial joint prosthesis can be used for repairing injured joints clinically.

Owner:SHANGHAI JIAO TONG UNIV

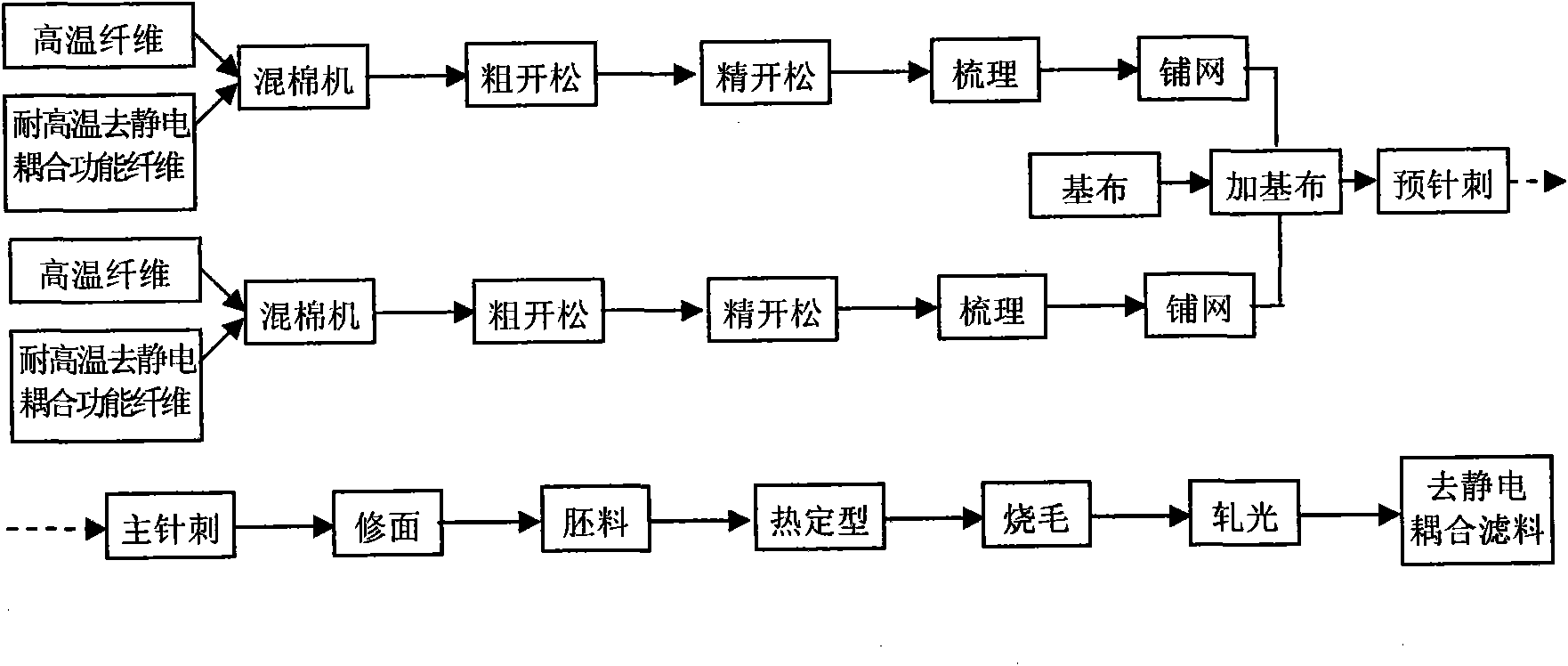

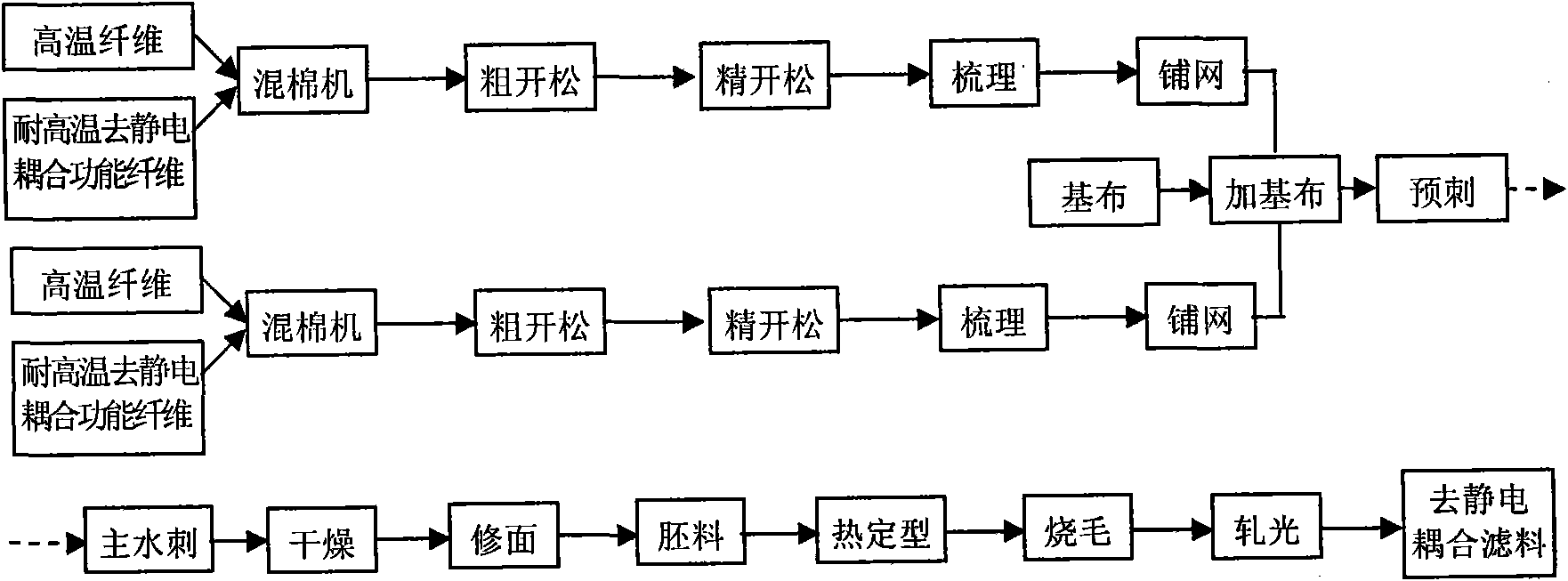

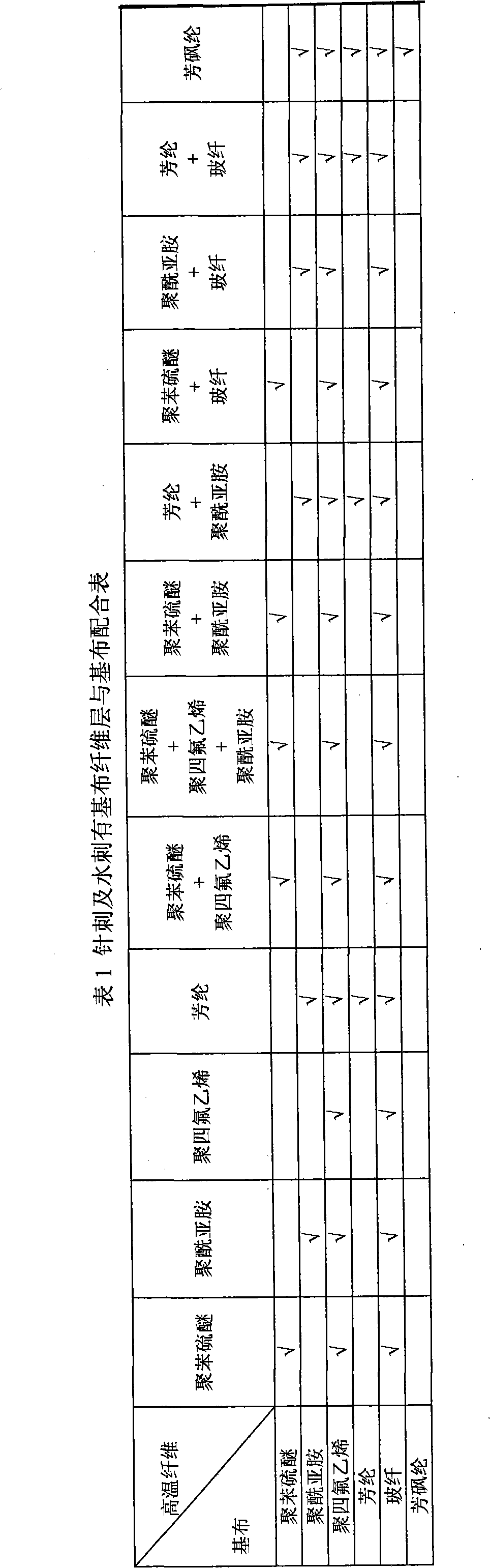

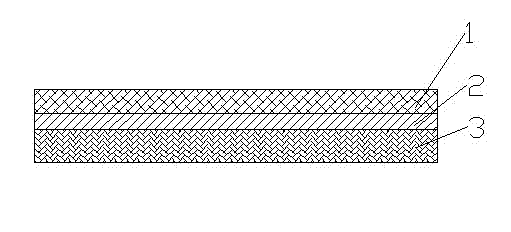

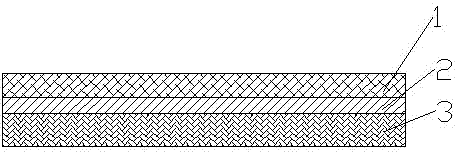

High-temperature filter material with function of removing electrostatic coupling by using base fabric for electric-bag composite dust-collector and production method thereof

InactiveCN101850202AImprove production efficiencyReduce manufacturing costCombination devicesLayered productsYarnPunching

The invention discloses a high-temperature filter material with the function of removing electrostatic coupling by using base fabric for an electric-bag composite dust-collector and a production method thereof, belonging to the technical field of high-temperature filter materials. The filter material for the electric-bag composite dust-collector is formed by clamping the base fabric between two fiber layers; the fiber layers consist of fibers with the functions of resisting high temperature and removing electrostatic coupling and high-temperature fibers; the base fabric has a mesh structure formed high-temperature yarns; and stainless steel fiber yarns, carbon fiber yarns or titanium fiber yarns are decided to be spaced according to the demand of the function of removing electrostatic coupling. The high-temperature filter material can be obtained by using a needle punching method and a hydroentangling method. The invention has the advantages that the filter material can remove the electrostatic coupling by combining the functional fibers and the high-temperature fibers and prevent the soot in a filter bag of the electric-bag composite dust-collector from leaking due to discharge damage and the dust collector from losing efficiency. Meanwhile, the filter material has high production efficiency and low production cost.

Owner:孙熙

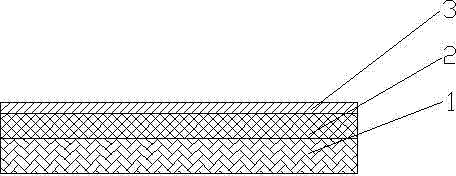

Apocynum titanium sub-fabric

InactiveCN102501455AWith far infrared functionImprove immunityWoven fabricsMetal layered productsYarnCarbon fibers

The invention discloses an apocynum titanium sub-fabric. The apocynum titanium sub-fabric comprises a titanium fiber layer, a glue layer and an apocynum fiber layer which are sequentially arranged from top to bottom, wherein the titanium fiber layer is a blended fabric layer formed by titanium fiber yarns and cotton fibers; the apocynum fiber layer is a blended fabric layer formed by apocynum fibers and other fibers; and the other fibers are one or two of cotton fibers, wool fibers, tencel fibers and bamboo carbon fibers. Due to the ways, the apocynum titanium sub-fabric disclosed by the invention has a far-infrared function, can enhance human immunity, relieve fatigue, help sleep, absorb moisture, ventilate and remove bromidrosis, and is comfortable to wear without being adhered to skin.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

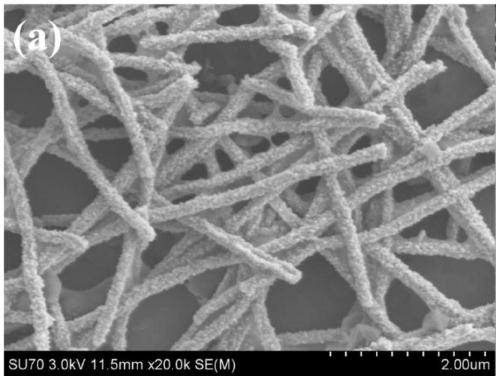

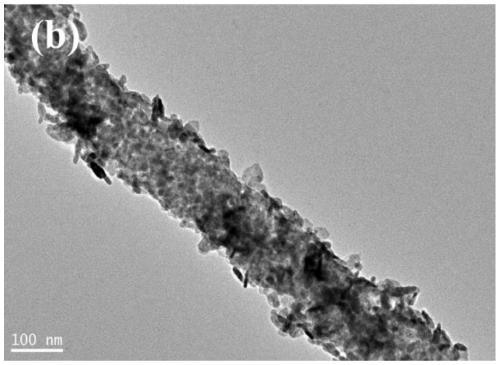

Preparation method of surface-dispersed nanometer bismuth molybdate composite photocatalytic material

ActiveCN111215119AIn situ growthHelp recyclingWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionSemiconductor materials

The invention relates to a semiconductor material technology, and aims to provide a preparation method of a surface-dispersed nanometer bismuth molybdate composite photocatalytic material. The preparation method comprises the following steps: preparing a titanium-containing precursor solution from a polyacrylonitrile-containing mixture, preparing titanium-containing fibers by using an electrostatic spinning device, drying, and calcining in a muffle furnace to obtain titanium dioxide nanofibers with rough surface morphology; dispersing the titanium dioxide nanofibers in ethylene glycol of sodium molybdate dihydrate and bismuth nitrate pentahydrate and absolute ethyl alcohol, and carrying out a hydrothermal reaction; and after the reaction is finished, centrifuging, collecting, washing the obtained precipitate, and drying the precipitate to obtain the product. A surface-dispersed nanometer heterojunction is beneficial to the simultaneous utilization of visible light by titanium dioxide and bismuth molybdate to form a two-photon excited catalytic system. Bismuth molybdate nanoparticles grow on the surface of the titanium dioxide coarse fibers in a dispersed mode to form a three-dimensional hierarchical structure, light can be fully utilized by inducing multiple reflections of visible light, meanwhile, the high specific surface area is kept, active sites are increased, and adsorption and photochemical reactions are promoted.

Owner:ZHEJIANG UNIV

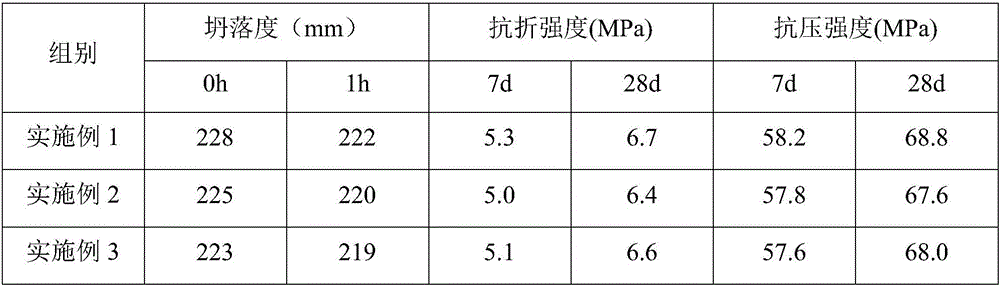

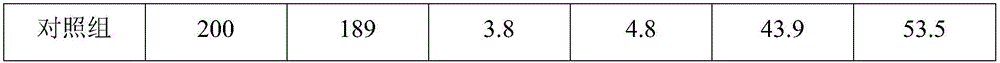

Green high-performance concrete

The invention discloses green high-performance concrete. The green high-performance concrete comprises water, cement, aggregates, water reducers, nucleating agents, gelatinization assistants, coal ash, water-quenched manganese residues, sulfonated lignin, calcium chloride, lignin, titanium fibers, hemicellulose, pectin, anhydrite and swelling agents. A preparation method of the gelatinization assistants specifically includes mixing beta-cyclodextrin with silicon dioxide and water, drying off moisture after soaking, adding expanded perlite, and evenly mixing to obtain the gelatinization assistants. A preparation method of the nucleating agents includes grinding stone and the anhydrite into powder with the grain diameter of 0.075-1.25mm, and adding ferric chloride and copper sulfate before even mixing. The green high-performance concrete has the advantages of capability of extending concrete pumping distance, high initial slump, low slump loss, high compressive strength, high breaking strength and capability of saving energy sources.

Owner:GUANGXI SHENGTIAN CEMENT PROD CO LTD

Medical implant having a layer of titanium or titanium alloy fibers

ActiveUS7419679B2Easy to migrateHigh correlationDental implantsImpression capsApatiteMetallic materials

Owner:KUBOKI YOSHINORI

Abrasion-resistant healthy fabric

InactiveCN102501517AImprove tensile strengthHigh tear strengthFibre treatmentSynthetic resin layered productsJoint arthralgiaEngineering

The invention discloses an abrasion-resistant healthy fabric, which comprises base cloth formed by interweaving warp yarns and weft yarns, wherein the warp yarns are Tencel fibers; the weft yarns comprise polyester fibers and cotton fibers; the upper surface of the base cloth is provided with a titanium fiber fabric layer; the titanium fiber fabric layer is blended cloth made of titanium fibers and polyamide fibers; the base cloth accounts for 65-75 percent of the total weight of the fabric; and the titanium fiber fabric layer accounts for 25-35 percent of the total weight of the fabric. Through the manner, the abrasion-resistant healthy fabric disclosed by the invention is capable of strengthening the immune system of human, improving headache, podalgia, backache and arthralgia and promoting blood circulation. The abrasion-resistant healthy fabric disclosed by the invention has a simple process, and the tensile strength, the tearing strength and the abrasion resistance of the fabric are effectively improved, the wearing comfort of the fabric is enhanced and the service life of the fabric is prolonged.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

High-performance concrete for building and preparation method thereof

The invention discloses high-performance concrete for building. The concrete is prepared from the following raw materials in parts by weight: 32 to 36 parts of Portland cement, 28 to 30 parts of quartz sand, 24 to 26 parts of fly ash, 22 to 24 parts of superfine mineral powder, 18 to 22 parts of bechilite powder, 14 to 16 parts of polyethylene glycol oxide, 3 to 5 parts of titanium fiber, 4 to 8 parts of fatty alcohol-polyoxyethylene ether, 8 to 10 parts of thermal stabilizers, 3 to 4 parts of anti-aging agents, 1 to 2 parts of water-reducing agents, 2 to 3 parts of waterproof agents and 20 to22 parts of water. The high-performance concrete for building has the advantages that the concrete has excellent intensity and durability; meanwhile, the raw material ingredients are safe and non-toxic and achieve the environment-friendly effects; high practical values and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Silk scarf fabric with health care functions

A silk scarf fabric with health care functions comprises bio-magnetic fibers, bamboo carbon functional fibers, far infrared functional fibers, silk, titanium fibers, silver fibers, long stapled cotton, combed cotton and anion fibers. The fabric made by the formula is dry, clean and air-permeable, has multiple health care functions such as sterilization, anti-inflammation, pain relief, constriction and hemostasis, is soft and free of deformation, does not generate static electricity, and has high warmth keeping performance and high wet permeability. The fabric can promote cell metabolism of a human body, strengthen and improve immunity functions, relieve fatigue, promote physical strength recovery, eliminate insomnia and delay aging, etc.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

Water-proof healthcare shell fabric

The invention discloses a water-proof healthcare shell fabric comprising an internal layer, an external layer and an intermediate layer provided between the internal layer and the external layer. The external layer is woven by combed pure cotton yarn and the external surface thereof is applied with a water-proof coating layer. A breathable membrane layer is provided between the water-proof coating layer and the external surface of the external layer. The intermediate layer is woven by blended polyester yarn and titanium fiber yarn. The internal layer is an infrared yarn mesh fabric woven by blended polyester / cotton. Through the above pattern, the titanium fiber yarn of the shell fabric can continuously release anions to promote the blood circulation in order to relieve muscle soreness, anxiety, chronic insomnia, poor sleep quality and so on caused by excessive kations in the body. The water-proof healthcare shell fabric is ultra-light, ultra-strong and will not cause allergy, has soft texture, good washable performance, good water-proof and breathable properties and good heat retention. Since far infrared is the functional healthcare fiber, the shell fabric has unique healthcare function when being worn next to the skin.

Owner:江苏红运果服饰有限公司

Method for preparing high strength concrete by using pebbles

The invention discloses a method for preparing high strength concrete by using pebbles. The method comprises the following steps: selecting the following raw materials, by weight, 207 parts of cement, 99 parts of water, 87 parts of pebble powder, 3 parts of a water reducer, 37 parts of zeolite powder, 13 parts of carbon nanotubes, 20 parts of fly ash hollow microspheres, 7 parts of fly ash, 27 parts of ore powder, 13 parts of tourmalinite powder, 47 parts of quartz sand, 2 parts of an antifoaming agent, 3 parts of an expanding agent, 19 parts of steel fibers and 3 parts of titanium fibers; mixing, and homogenizing; and carrying out high temperature and high pressure curing. The method enhances the compactness of concrete, and greatly enhances the compressive and flexural strength of the concrete.

Owner:CHINA ROAD & BRIDGE

Supercapacitor battery

ActiveCN103985567AStrongly corrosiveReduced service lifeHybrid capacitor separatorsHybrid capacitor electrodesConductive materialsSulfide

The invention discloses a supercapacitor battery. The supercapacitor battery is mainly composed of electrodes, an electrolyte, a membrane, end plates, a lead and a packaging material. The main conductive material of the electrodes is silicon carbide. The electrode lead is directly connected with the battery end plates in a welding mode through a multi-strand sterepsinema with the diameter ranging from 1 mm to 4 mm, and the multi-strand sterepsinema is made of metallic titanium fibers or titanium alloy fibers. The NMP ultrahigh viscosity solution of methylamino butyric acid lithium, polysulfide lithium, lithium perchlorate and lithium phosphate serves as the electrolyte. A polyphenylene sulfide thin film serves as the membrane. The end plates are made of metallic titanium or titanium alloy. The packaging material is formed by welding an ultra-thick polyphenylene sulfide injection molding part and a thin film in a laser mode. One electrode, one end plate, the electrolyte, the membrane, the electrolyte, the other end plate and the other electrode are overlapped in sequence or wound into the 88-188 layers of the supercapacitor battery. The supercapacitor battery has the advantages of being high in temperature resistance, low in temperature resistance, corrosion resistant, short in charging time, large in number of circulation times and long in service life, and can be widely applied to places with the very hostile environmental conditions.

Owner:扬州荣可然科技有限公司

Cement mortar for decoration engineering construction and preparation method thereof

The invention discloses cement mortar for decoration engineering construction and belongs to the technical field of cement mortar. The cement mortar comprises, by weight, 180 to 200 parts of cement, 300 to 320 parts of fine sand, 40 to 50 parts of steel fibers, 20 to 30 parts of titanium fibers, 35 to 40 parts of polyethylene terephthalate fibers, 10 to 14 parts of silicon carbide, 15 to 20 parts of calcium carbonate, 60 to 70 parts of fly ash, 3 to 5 parts of hydroxypropyl methyl cellulose, 8 to 10 parts of redispersible latex powder, 2 to 4 parts of an early strength agent, 1 to 3 parts of a retarder, 2 to 3 parts of a defoamer, 1 to 2 parts of a rust inhibitor, 2 to 4 parts of a silicone waterproofing agent, 1 to 2 parts of an aluminum-magnesium silicate thixotropic lubricant and 130 to 150 parts of water. The invention also discloses a preparation method of the decoration engineering construction. The cement mortar has high strength, fire and high temperature resistance, long use time and good waterproof effects.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

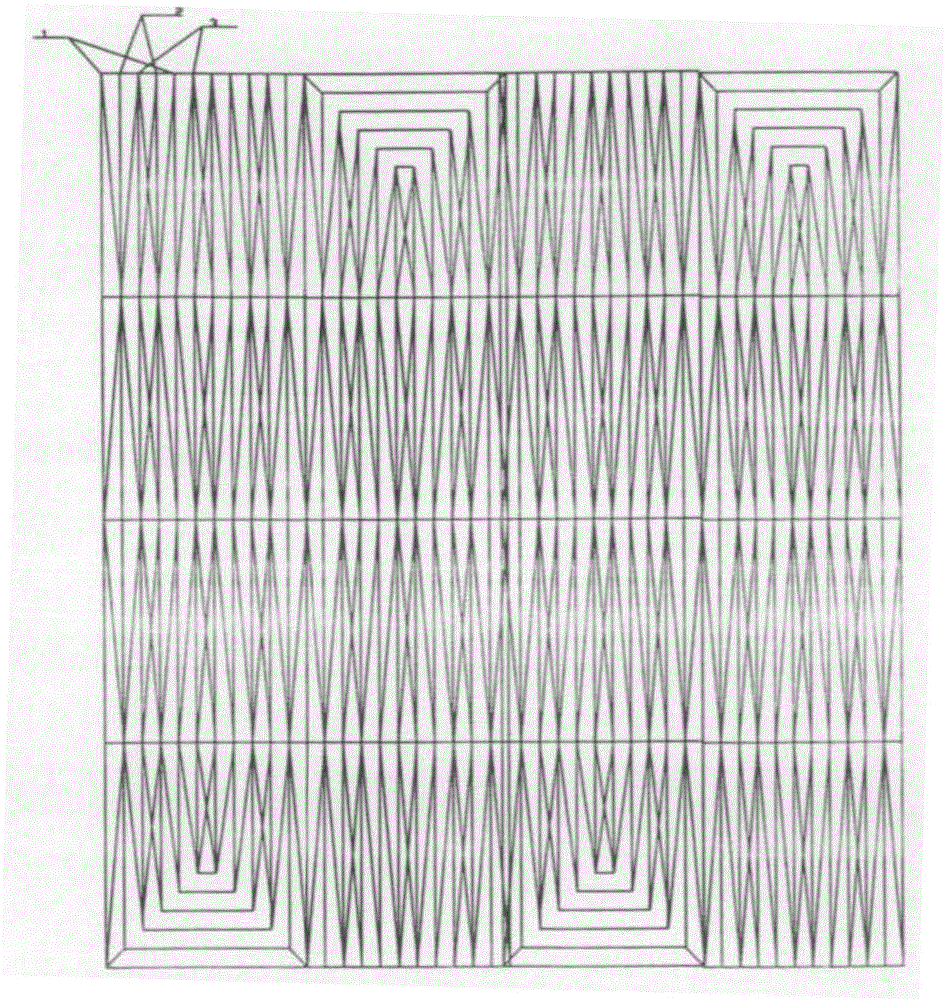

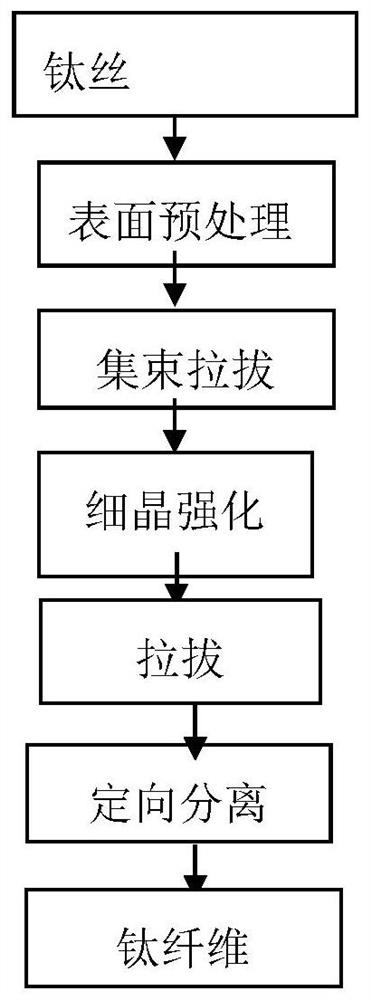

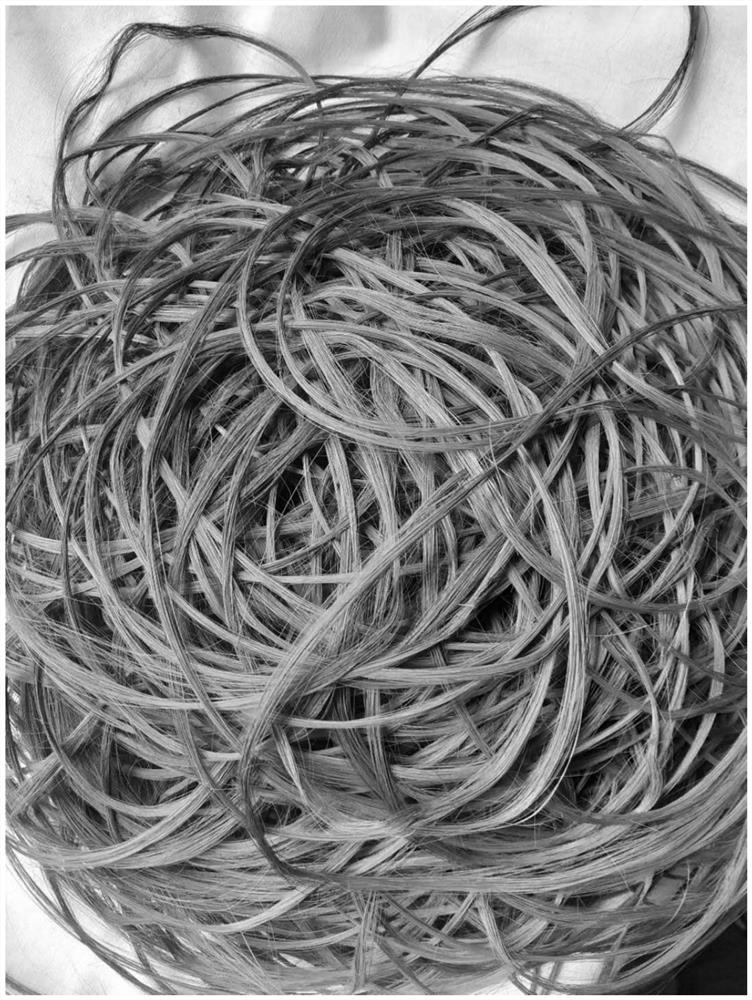

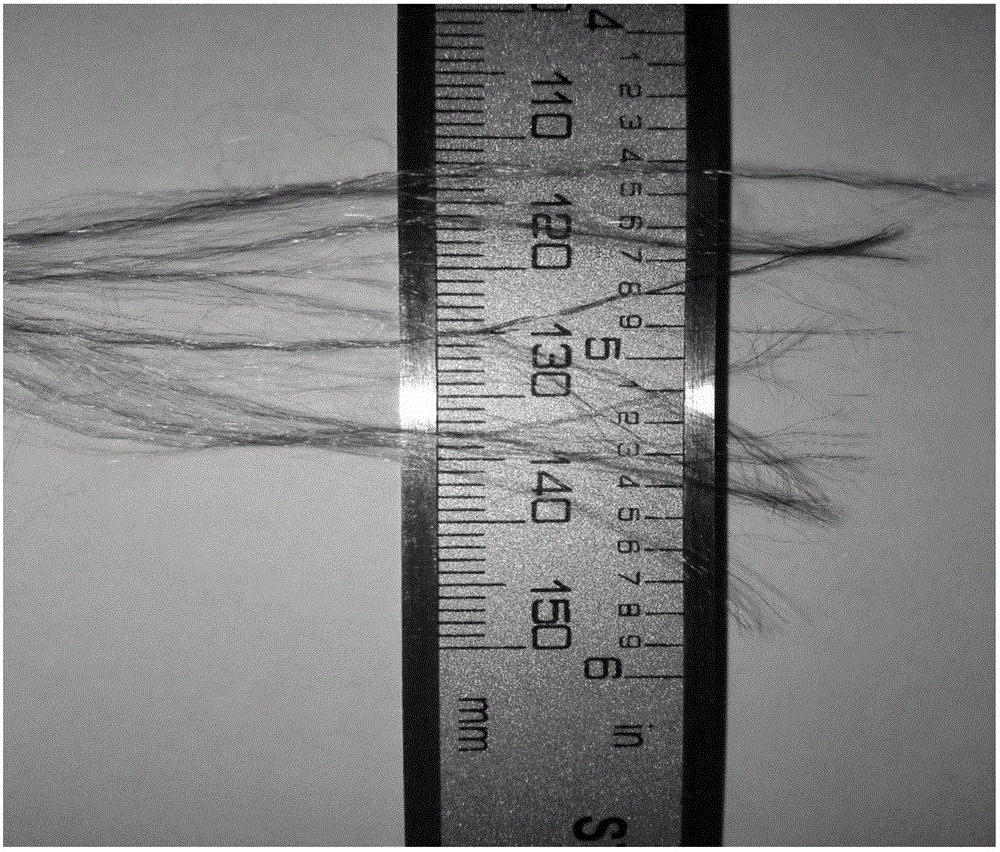

Titanium fiber production process

The invention belongs to the technical field of non-ferrous metal processing, and relates to titanium and titanium alloy wire processing, in particular to a production process for preparing a titaniumfiber bundle smaller than 22 microns through rolling drawing. The production process comprises the following steps: S1, copper coating of a titanium wire: carrying out pretreatment, nickel pre-plating and copper plating on the titanium wire to realize copper coating; S2, bundling: using a copper pipe as a sleeve, bundling the titanium wire coated with the copper, and obtaining a composite wire; S3, drawing: continuously drawing the composite wire into a finished composite wire with the needed diameter through a multi-pass rolling die; S4, fine grain strengthening: performing annealing heat treatment on the composite wire in the drawing process; and S5, directional separation: removing a coated copper layer from the finished composite wire, and then cleaning and drying to obtain a titaniumfiber tow with the diameter of less than 22 microns. According to the preparation process, the titanium metal fiber with the diameter smaller than 22 microns is prepared, so that titanium metal serving as a new metal fiber material has spinnability and has a larger application prospect.

Owner:湖南汇博金属材料有限责任公司

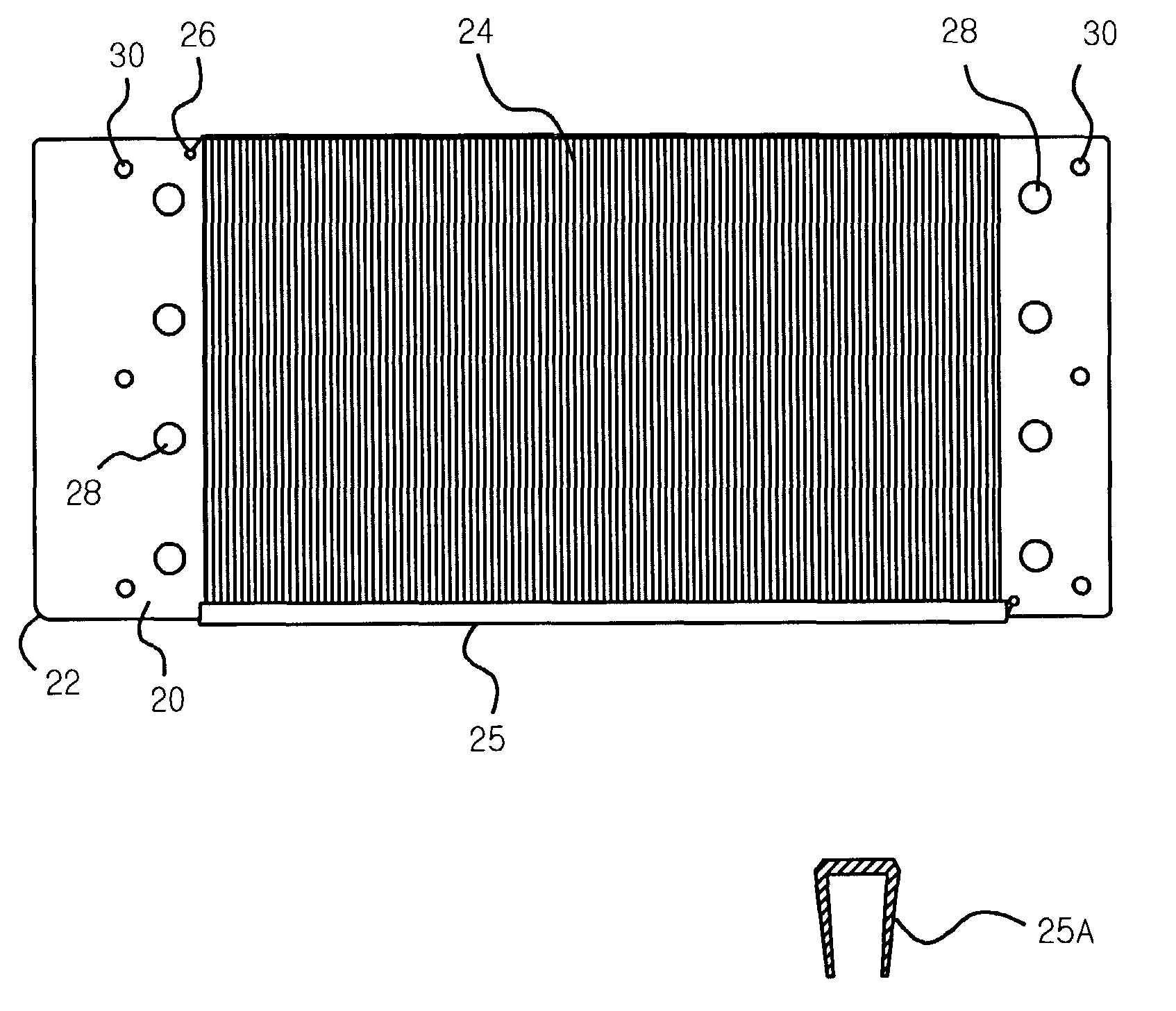

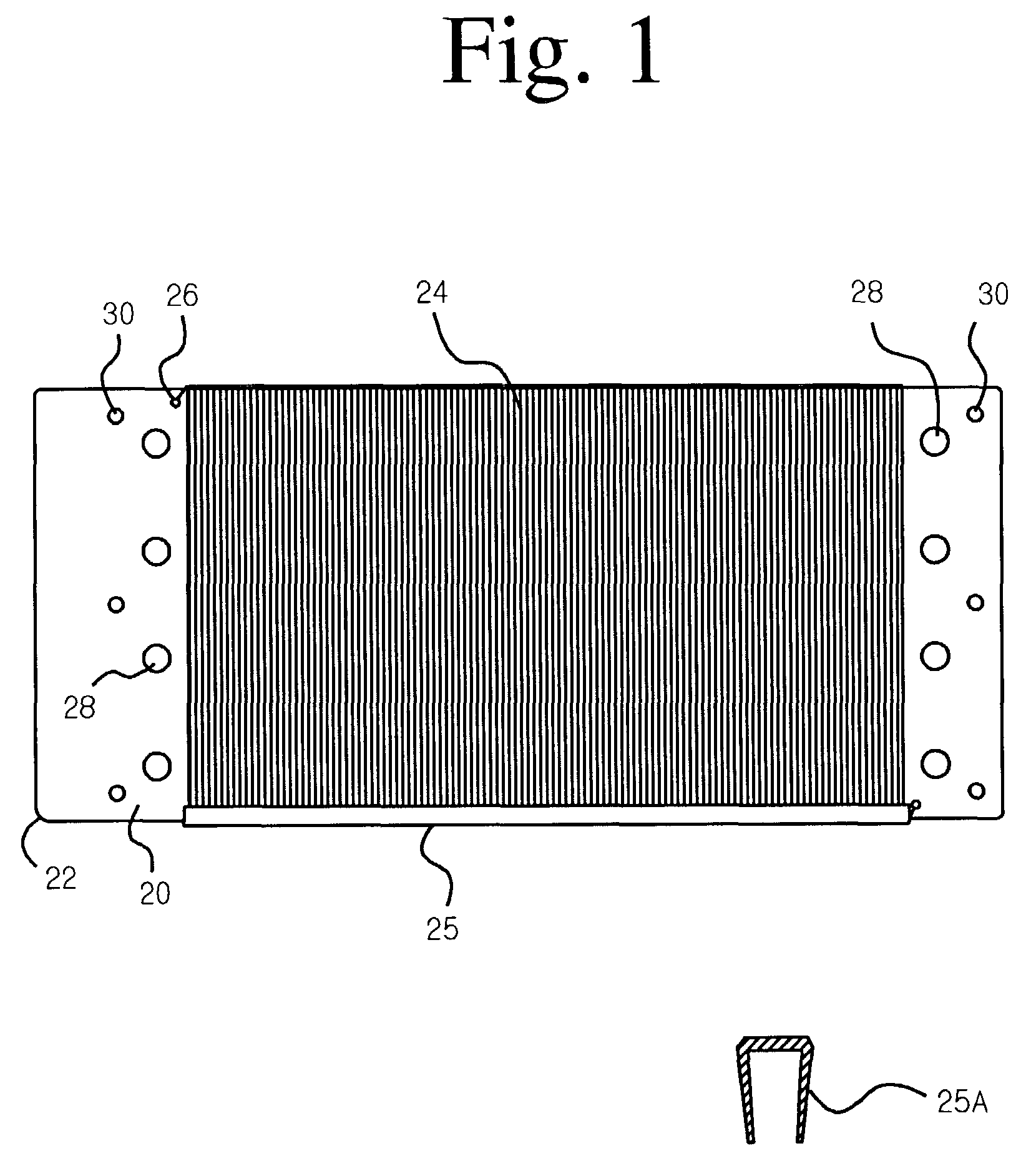

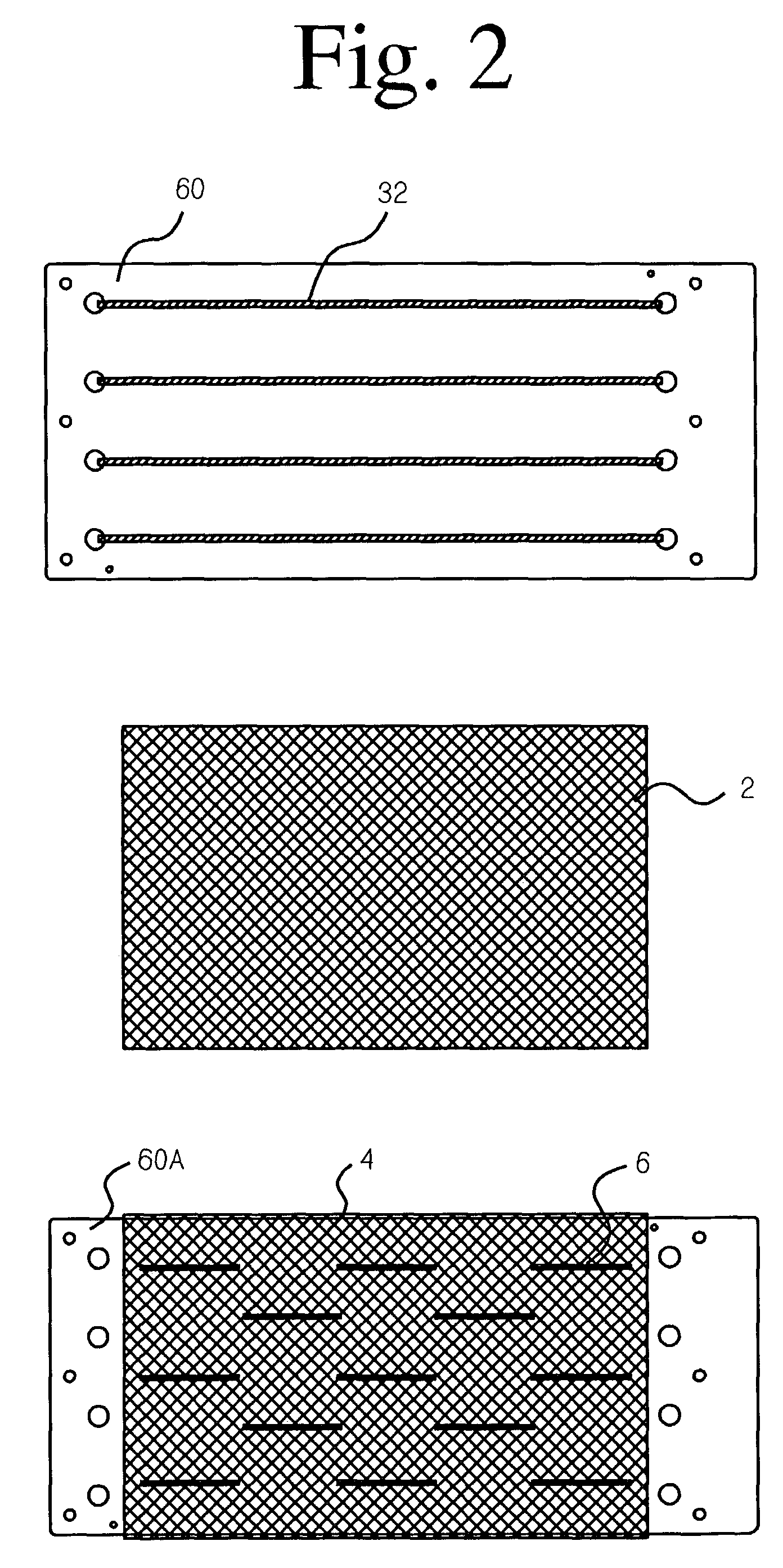

Large surface area electrode and method to produce same

InactiveUS7077937B2Increase contactImprove isolationMachining electrodesMultiple component coatingsMetal fibersHydroxyl radical

A large surface area electrode well-suited to electrochemical applications is produced by winding many turns of a metallic fiber tow on to a sheet metal rectangle. In the preferred embodiment, an anode that can be used to purify water by electrochemical production of hydroxyl free radical is made by winding titanium fiber tow on to a rectangular substrate made of titanium sheet, and applying a suitable multilayered electrocatalytic coating. Made of other metals, an electrode of this description can also serve as the cathode of an electrochemical cell, or as a battery plaque.

Owner:WERES OLEH

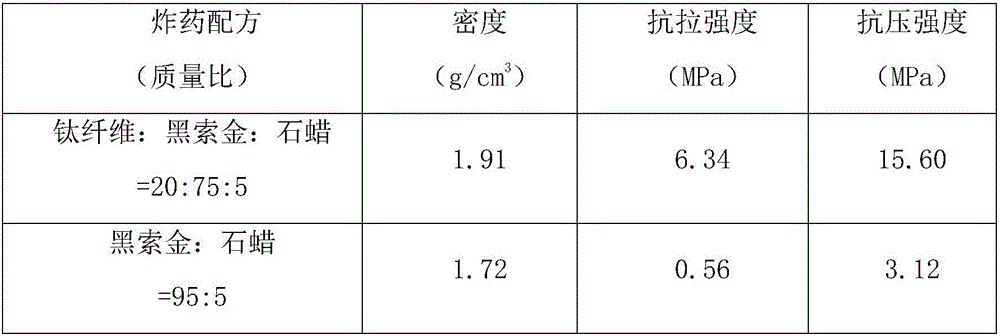

High-strength titanium-based fiber explosive

ActiveCN106045799AImprove tensile propertiesVolume energy increaseExplosivesSingle substanceHigh intensity

The invention discloses a high-strength titanium-based fiber explosive. The high-strength titanium-based fiber explosive is characterized in that titanium fibers or titanium alloy fibers are added to a single substance explosive or a mixed explosive as a metal additive, wherein the fibers can be titanium fibers, and also can be titanium alloy fibers or a titanium fiber and titanium alloy fiber mixture. The high strength characteristic of the titanium fibers and the titanium alloy fibers are fully used to improve the mechanical performances of the titanium-based fiber explosive, so the safety of the explosive in the production, storage and transportation process is greatly enhanced, and the volume energy density of the explosive is obviously improved.

Owner:UNIV OF SCI & TECH OF CHINA

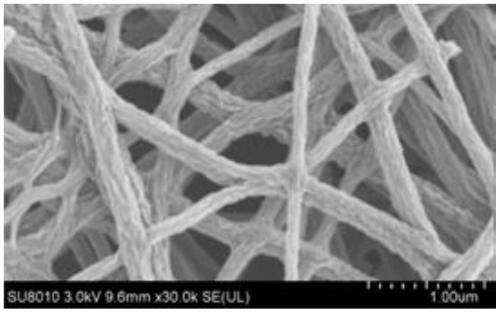

Preparation method of titanium fiber

ActiveCN105598199AGuaranteed performance and stabilityIncrease productivityCopper platingTitanium nitride

The invention discloses a preparation method of titanium fiber. The preparation method comprises following steps: titanium wires are subjected to acid pickling, nickel preplating, and surface copper plating so as to obtain copper-plated titanium wires; the copper-plated titanium wires are dried, are subjected to bundling compounding and vacuum annealing, and then are subjected to bundling drawing so as to obtain a complex; and the complex is subjected to acid pickling, water washing, and drying so as to obtain a finished product. The preparation method is used for replacing monofilament drawing in titanium fiber production, so that production efficiency is increased greatly, production cost is reduced, performance stability of batched produced titanium fiber is ensured, product quality is improved, a problem that titanium fiber with a diameter smaller than 0.1mm is difficult to process is solved, and multicore titanium fiber with a smallest diameter of 25<mu>m is prepared.

Owner:西安菲尔特金属过滤材料股份有限公司

Quantum titanium fiber plate and preparation method thereof

InactiveCN108034160AImprove adhesionReduce interfacial energyWood veneer joiningDomestic articlesFoaming agentMixed materials

Owner:湖北名望世家装饰材料股份有限公司

Fine grain titanium fiber pumice magnesium alloy composite material and preparation method thereof

The invention provides a lightweight fine grain titanium fiber pumice magnesium alloy composite material and a preparation method thereof. The composite material has high strength and excellent damping performance. The method has simple process and low production cost and is suitable for industrial production. The composite material takes magnesium alloy as a substrate on which fine grain titanium fibers and pumice particles are distributed, the size of grains of the fine grain titanium fibers is 1-10 mu m, the fine grain titanium fibers and the pumice particles account for 45-55% of the composite material by volume, and the weight ratio of the fine grain titanium fibers to the pumice particles is 1:1. The magnesium alloy substrate comprises the following chemical components in percentage by weight: 4%-8% of Al, 0.01%-0.05% of Gd, 0.01%-0.05% of Gr, 0.001%-0.005% of Mo, 0.03%-0.09% of Si, 0.003%-0.009% of V, 0.003%-0.09% of Sn and the balance Mg.

Owner:淮安市清河区科技转化服务中心

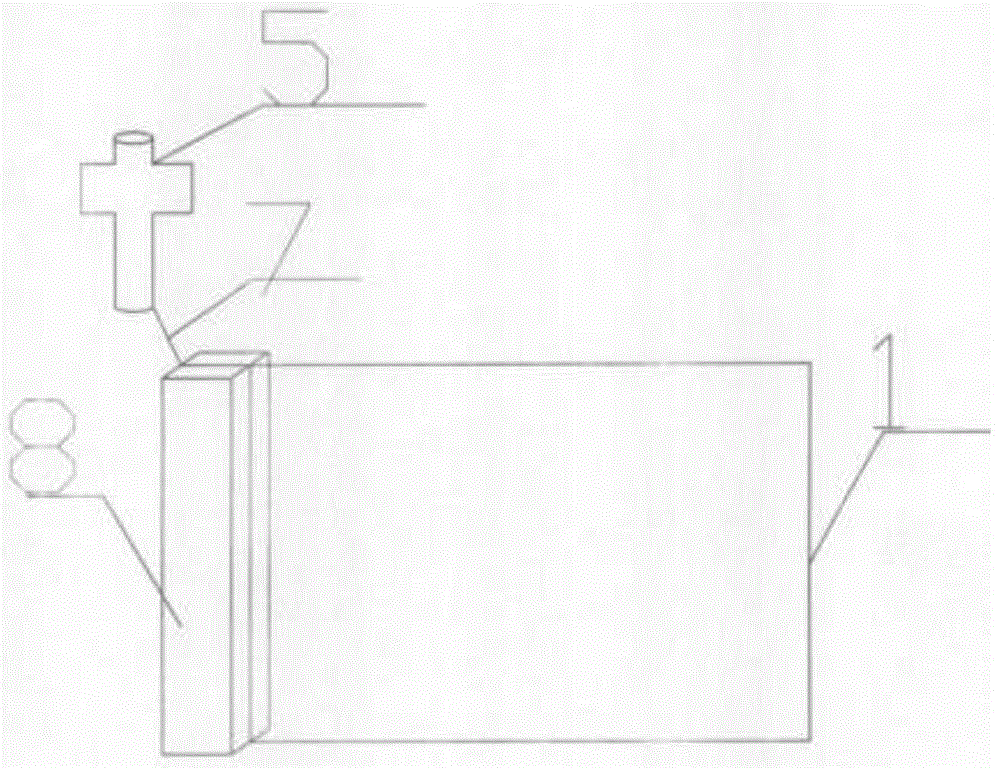

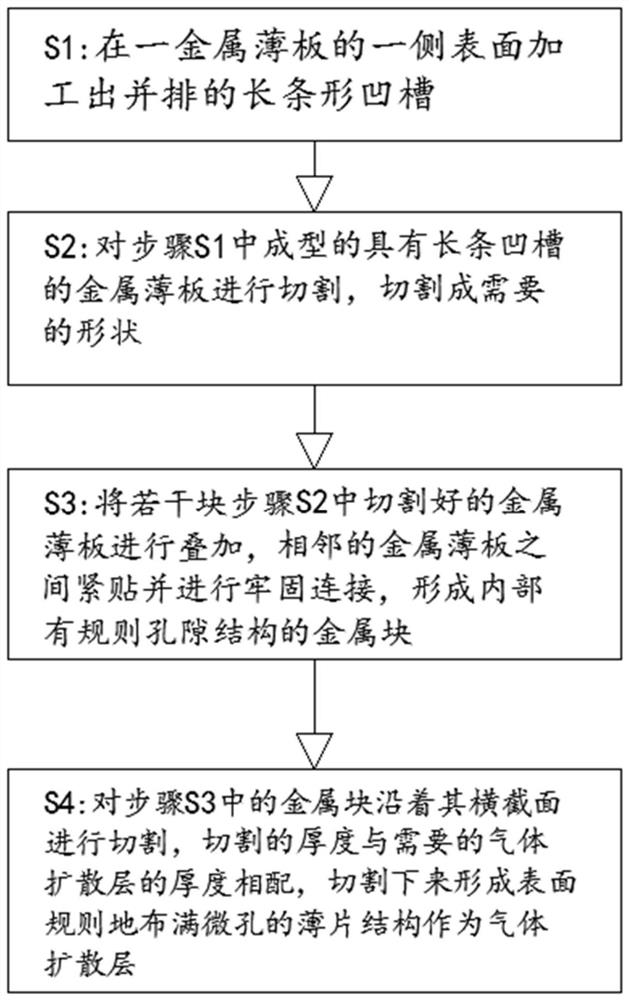

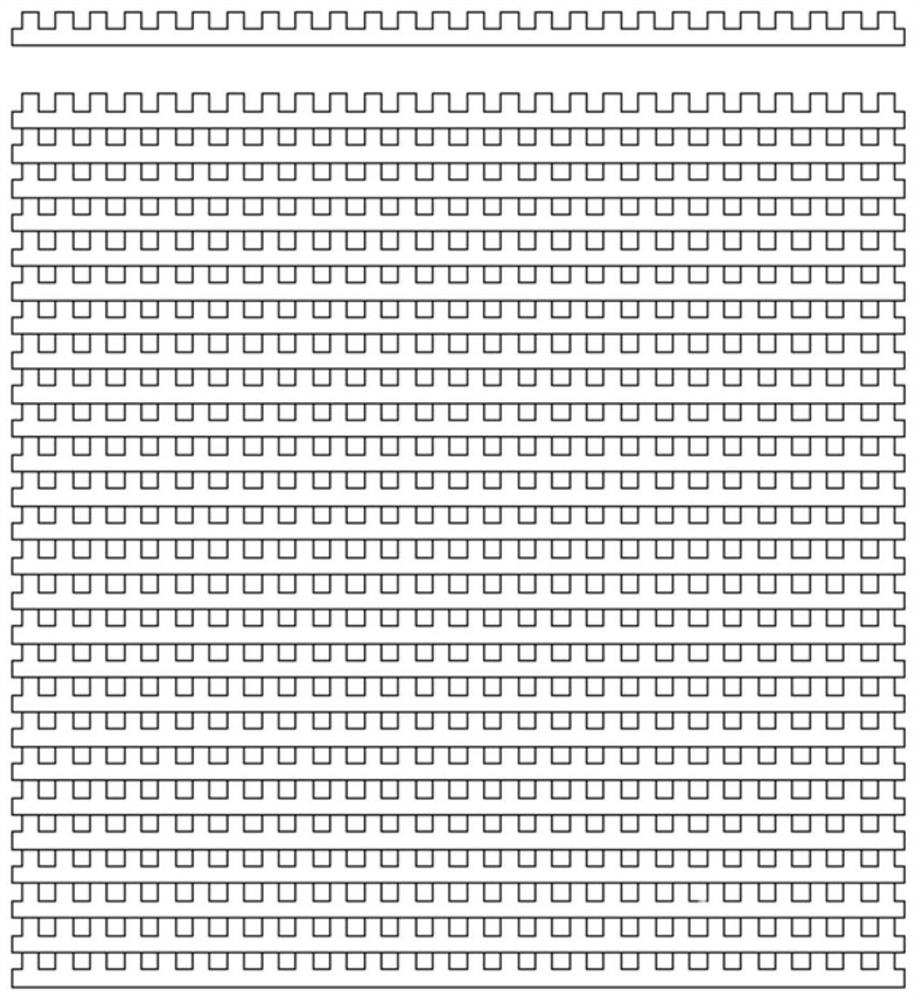

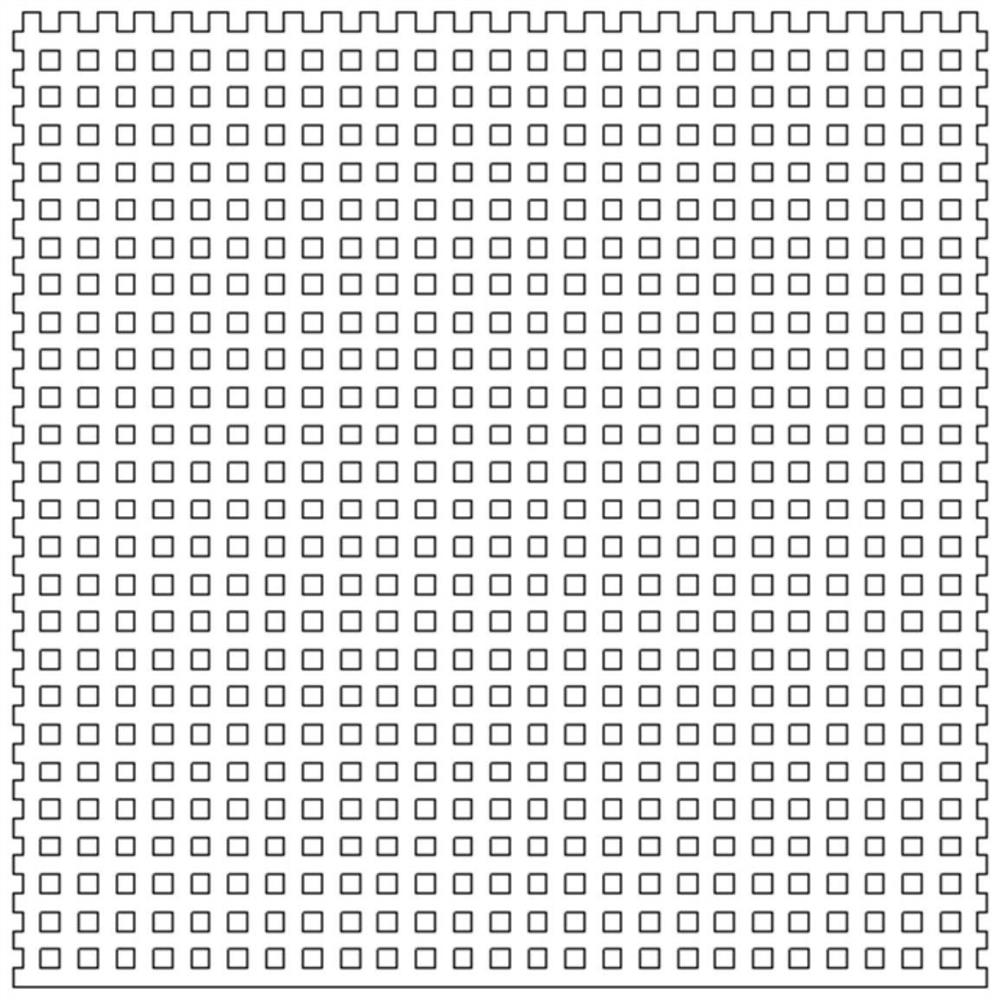

Gas diffusion layer and preparation method thereof

PendingCN113789537AImprove diversion capacityImprove diversion efficiencyCellsElectrodesStructural engineeringMetal sheet

The invention discloses an air diffusion layer and a preparation method thereof. The preparation method comprises the following steps: S1, side-by-side strip-shaped grooves are processed in the surface of one side of a metal sheet; S2, the metal sheet with the long-strip-shaped groove is cut into a needed shape; s3, the multiple cut metal sheets are stacked, the adjacent metal sheets are tightly attached and firmly connected, and a metal block with a regular pore structure inside is formed; and S4, the metal block is cut along the cross section of the metal block, the cutting thickness is matched with the thickness of the needed gas diffusion layer, and a sheet structure with micropores regularly distributed in the surface is formed through cutting and serves as the gas diffusion layer. The gas diffusion layer can solve the problems that an existing titanium fiber felt plate is poor in flow guide effect, low in contact efficiency and large in contact surface resistance.

Owner:QINGKE NEW ENERGY TECH (SHANGHAI) CO LTD

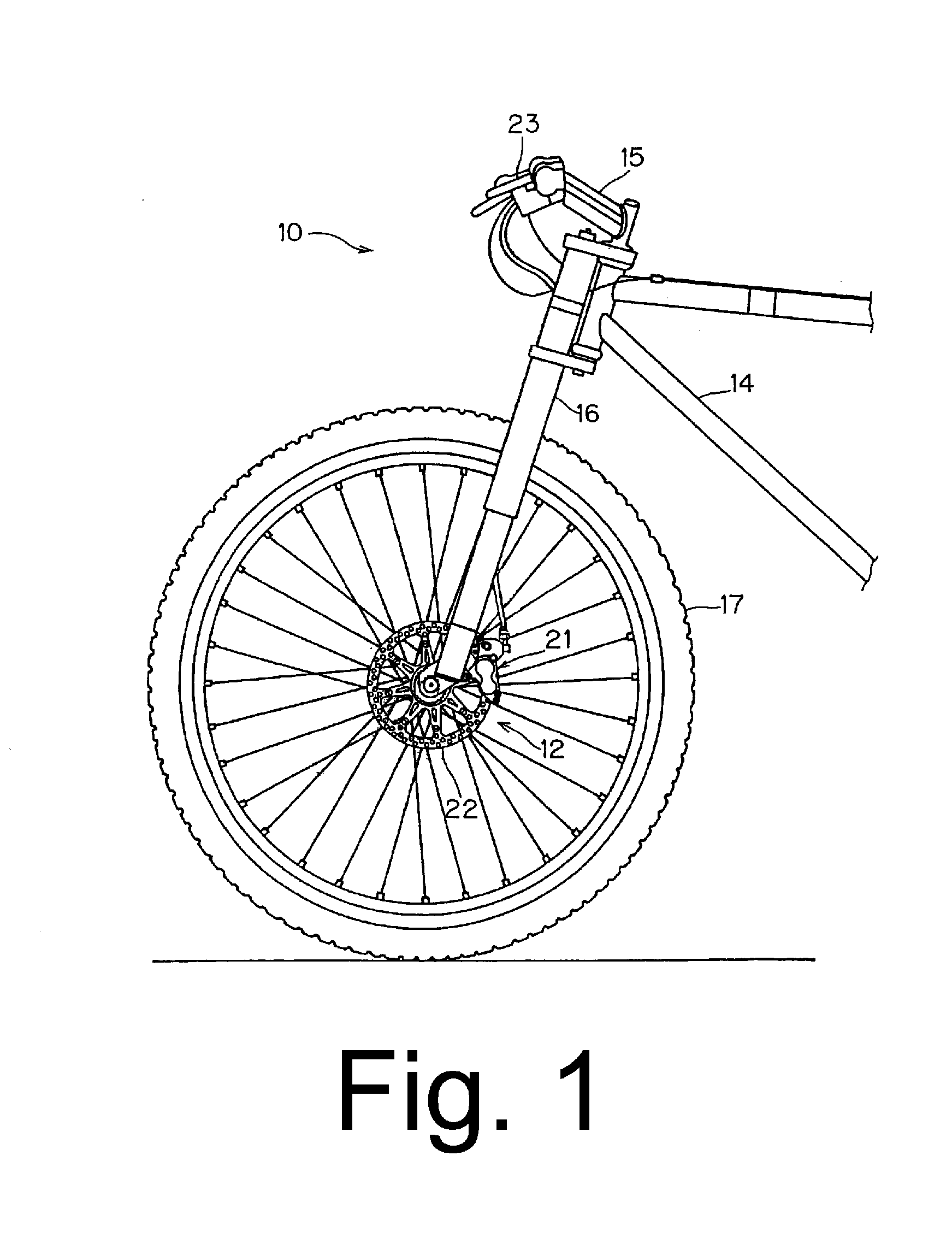

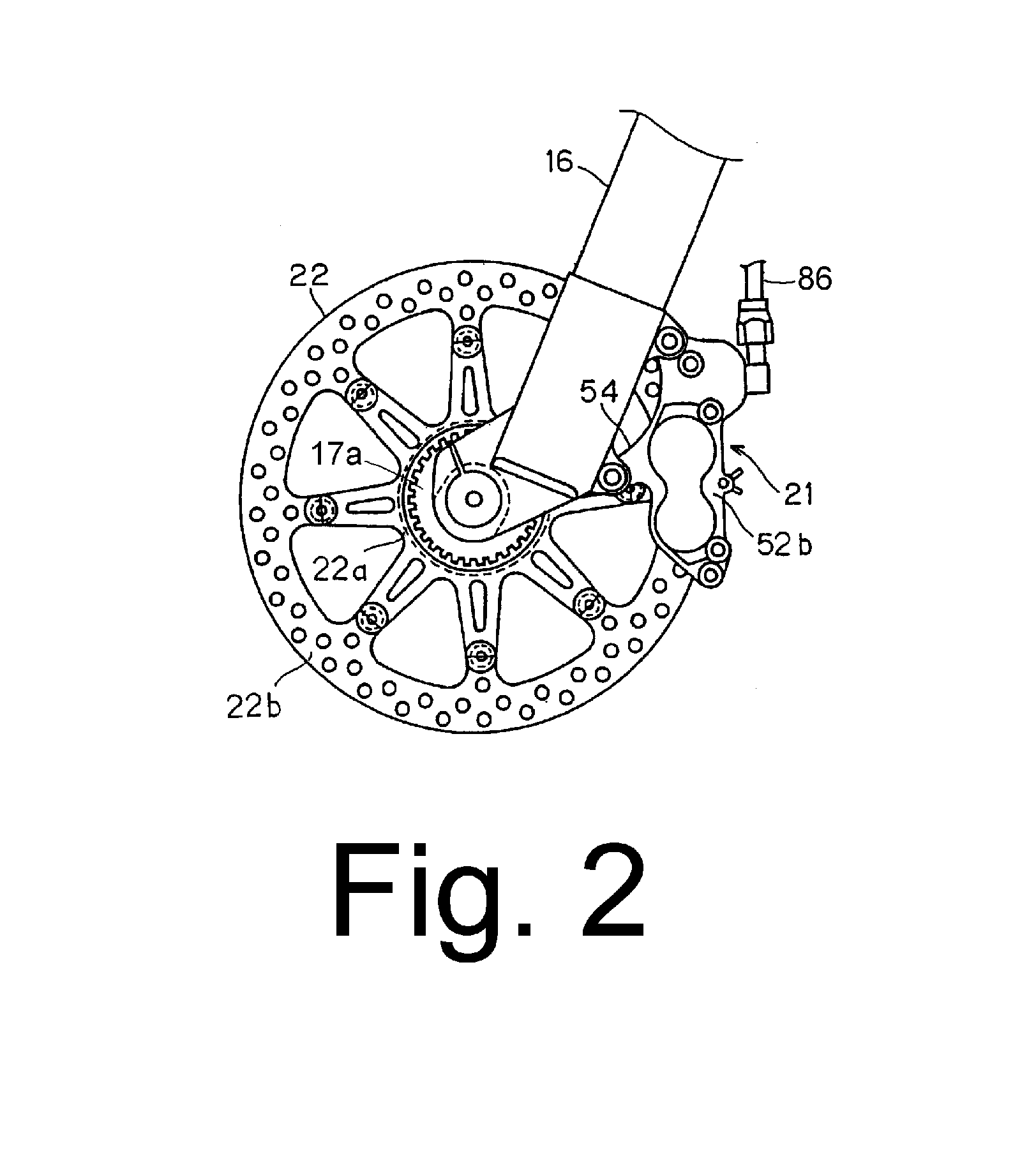

Bicycle disk brake pad with titanium fiber friction material

Owner:SHIMANO INC

Quantum titanium fiber material

InactiveCN110016731AGuaranteed softness and comfortVersatilityElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsUltravioletPolymer

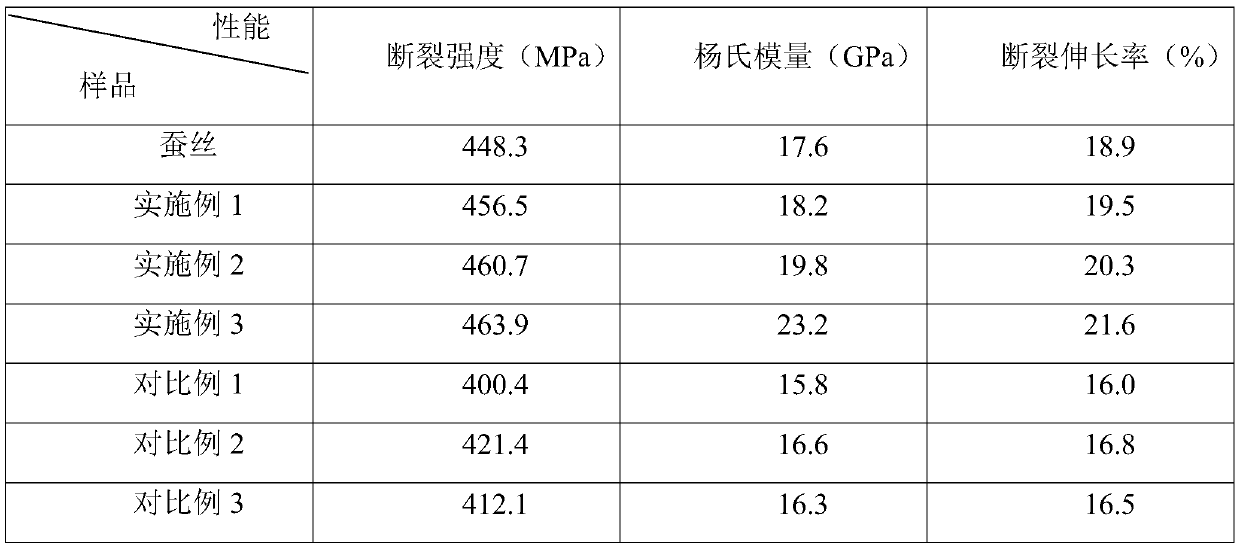

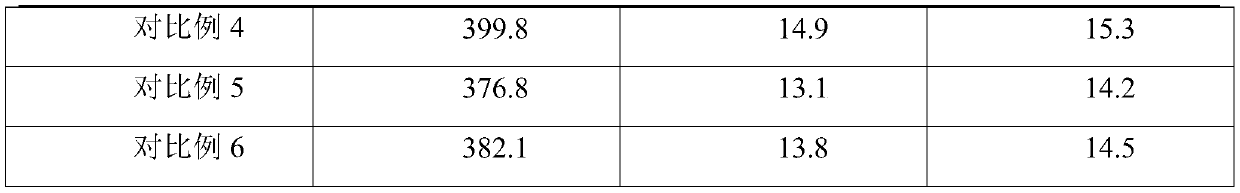

The invention discloses a quantum titanium fiber material. The quantum titanium fiber material is prepared from a hybrid material of quantum dots, silk fibroins and polymer materials through the spinning technology. Besides the soft and comfortable properties of silk fiber, the quantum titanium fiber material has excellent air permeability, antimicrobial property, anti-ultraviolet-ray property, anti-static property, durability and health-care functions, the UPF of the woven fabric is far greater than 30, the T (UVA) is far less than 5%, and the anti-bacterial rate is more than 90%. The material solves the problems that a current silk fabric is monotonous in function and poor in durability, and the material can be used for textile fabrics and meets the needs of people for multi-functionalclothing.

Owner:张慧

Zinc alloys, sepiolite-ferric oxide and vermiculite-barium ferrate composite material and preparation method thereof

The invention provides a zinc alloys, sepiolite-ferric oxide and vermiculite-barium ferrate composite material and a preparation method thereof. The composite material has high absorbing property and excellent damping property. The preparation method is simple in process, low in production cost and suitable for industrialized production. The composite material takes the zinc alloys as the matrices and the sepiolite-ferric oxide and vermiculite-barium ferrate compounds and titanium fibers are distributed on the matrices. The zinc alloys, the sepiolite-ferric oxide and the vermiculite-barium ferrate account for 40-50% of the composite material by volume. The titanium fibers comprise the following components in percentage by weight: 0.2-0.4% of V, 0.003-0.09% of Pr and the balance Ti. The zinc alloy matrices comprise the following chemical components in percentage by weight: 13-18% of Al, 0.05-0.1% of Te, 0.05-0.1% of Co, 0.005-0.01% of Pr and the balance Zn.

Owner:高满华

A kind of diamond scribing knife for dividing ceramic substrate and preparation method thereof

The invention discloses a diamond scribing knife for ceramic substrate segmentation as well as a preparation method thereof. The preparation method comprises the following steps: enabling a mixture ofdiamond, epoxy resin powder, silicon carbide, aluminum oxide, titanium oxide fiber and 4-methylbenzyl alcohol to pass through a 300-mesh sieve to obtain a molding material; hot-pressing the molding material to obtain a hot-pressed green body; curing the hot-pressed green body to obtain a molding body; and processing the molding body to obtain the diamond scribing knife for ceramic substrate segmentation. The diamond scribing knife disclosed by the invention can be applied to ceramic substrate segmentation, has the size precision only being 4 mum, has the sharp generality of a resin binding agent diamond scribing knife, also has the characteristics of high processing precision, small processing edge breakage, avoidance of microcrack and the like, and effectively solves the technical problem of ceramic substrate high-precision segmentation.

Owner:苏州赛尔科技有限公司

Production technology for Good-Fortune titanium fiber Raschel blanket

ActiveCN106377126AAntibacterial and deodorantSelf-cleaningElectroconductive/antistatic filament manufactureBlanketYarnWork in process

The invention relates to the field of blanket preparation and discloses a production technology for a Good-Fortune titanium Raschel blanket. The production method comprises steps of 1) weaving, 2) pre-preparing, 3) dyeing and finishing, 4) post-preparing and 5) inspecting finished products and packing and storing. In the first step, plush yarns and ground yarns are warped, weaved and cutting to achieve a Good-Fortune titanium fiber Raschel blanket semi-finished product; in the second step, a fabric is fixed, brushed, burn-polished and rolled; in the third step, the fabric is dyed, then cleaned, an at last is neutralized via acetum solution, washed, dried, aged and color-fixed, processed to achieve flexibility and smoothness, and dried again; and in the fourth step, the fabric is dried and fixed, burn-polished and brushed on the front surface, then burned and sheared on the front surface, and fluffed on the back surface, brushed, burn-polished, sheared on the back surface, then re-fixed, burn-sheared on the front surface, burn-sheared on the back surface, and cut into strips and sewed. The Good-Fortune titanium fiber Raschel blanket is characterized by smooth and upright villus, great elasticity, cloth skin-closeness, moisture absorbing and releasing performance and good ventilating property, and being antibacterial, health-caring, and green and environment-protective.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Health functional fabric for embroidery

InactiveCN107604547AImprove wrinkle resistanceImprove actual functionsEmbroidering machines apparatusApocynum venetumMaterials science

The invention discloses a health functional fabric for embroidery. The health functional fabric for embroidery comprises the following components in parts by weight: 2-7 parts of penthorum chinense stem fibers, 11-16 parts of spun silk fibers, 3-8 parts of titanium fibers, 12-17 parts of silver fibers, 4-9 parts of penthorum chinense leaf fibers, 13-18 parts of apocynum venetum fibers, 0.5-0.9 part of cashmere fibers, 0.3-0.8 part of silk fibers and 1-5 parts of aloe fibers. According to the manner, the health functional fabric for embroidery provided by the invention has the effects of beingexcellent in wrinkle resistance, comfortable, close-fitting to skin and capable of effectively enhancing the human body function.

Owner:SUZHOU YEXIU CRAFTS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com