Anti-radiation concrete and preparation method thereof

A concrete and anti-radiation technology, which is applied in the field of concrete processing, can solve the problems of reduced mechanical properties of concrete, which is not conducive to the stability of construction projects, etc., and achieve the effect of improving mechanical properties, improving mechanical properties, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

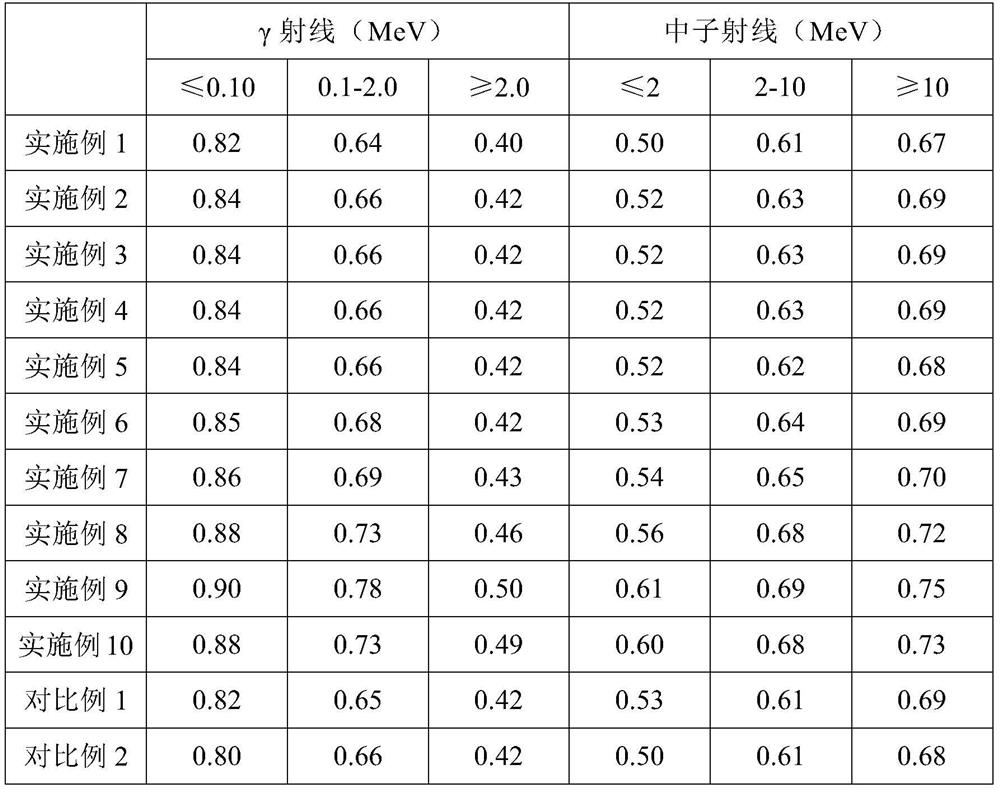

Examples

preparation example 1

[0070] Pretreatment of basalt fiber: put the basalt fiber into an oven, control the temperature at 200°C and heat for 2.5 hours, take it out and cool it, place the cooled basalt fiber in ethyl acetate solution, as long as the basalt fiber is completely submerged, soak 1h, after soaking is completed, take out and wash with water and dry to obtain pretreated basalt fiber;

[0071] Pretreatment basalt modification: using absolute ethanol as a solvent, adding a modifier to the absolute ethanol solvent, the concentration of the added modifier is 1% of the solvent, stirring evenly to obtain a mixture a;

[0072] Add the pretreated basalt fiber into the mixture a, control the bath ratio to 1:3, soak for 1 hour, take out the soaked basalt fiber, dry it, and cool naturally to prepare the modified basalt fiber.

preparation example 2

[0074] Basalt fiber pretreatment: put the basalt fiber into the oven, control the temperature at 230°C and heat for 2 hours, take it out and cool it, put the cooled basalt fiber in ethyl acetate solution, and soak for 1 hour as long as it is completely submerged in the basalt fiber , after soaking, take out and wash with water and dry to prepare pretreated basalt fiber;

[0075] Pretreatment basalt modification: using absolute ethanol as a solvent, adding a modifier to the absolute ethanol solvent, the concentration of the added modifier is 1% of the solvent, and then stirring evenly to obtain a mixture a;

[0076] Add the pretreated basalt fiber into the mixture a, control the bath ratio to 1:4, soak for 1.5h, take out the soaked basalt fiber, dry, and cool naturally to obtain the modified basalt fiber.

preparation example 3

[0078] Basalt fiber pretreatment: put the basalt fiber into the oven, control the temperature at 260°C and heat for 1.5 hours, take it out and cool it, put the cooled basalt fiber in ethyl acetate solution, subject to the fact that the basalt fiber is completely covered, soak 1h, after soaking is completed, take out and wash with water and dry to obtain pretreated basalt fiber;

[0079] Pretreatment basalt modification: using absolute ethanol as a solvent, adding a modifier to the absolute ethanol solvent, the concentration of the added modifier is 1% of the solvent, and then stirring evenly to obtain a mixture a;

[0080] Add the pretreated basalt fiber into the mixture a, control the bath ratio to 1:5, soak for 2 hours, take out the soaked basalt fiber, dry, and cool naturally to obtain the modified basalt fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com