Quantum titanium fiber plate and preparation method thereof

A titanium fiber and sheet technology, applied in the field of quantum titanium fiber sheet and its preparation, can solve the problems of inability to achieve firm bonding of nano-photocatalyst materials, unfavorable material extrusion, etc., to improve melt flow rate, improve surface bonding performance, improve The effect of using the expiration date

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A quantum titanium fiber plate, the raw material composition and parts by weight are: resin powder 33-58, wood powder 20-35, photocatalyst nano-titanium material 3-8, foaming agent 0.5-2, coupling agent 0.5-1, Active light calcium 10-20, and the preparation method of the plate includes the step of mixing and modifying the photocatalyst nano-titanium material and coupling agent.

[0028] The wood powder is mixed with bamboo powder, crop straw powder and poplar wood powder with a particle size of 80-120 mesh and an aspect ratio of 1:2-4, and the bamboo powder, crop straw and poplar wood powder The ratio of parts by weight is 1:2-3:2-3.

[0029] The photocatalyst nano-titanium material is at least one of nano-titanium dioxide and nano-titanium phosphate.

[0030] The raw material composition of the plate also includes toughening agent with 1-1.5 parts by weight, stabilizer with 1-5 parts by weight and regulator with 3-6 parts by weight.

[0031] The foaming agent is comp...

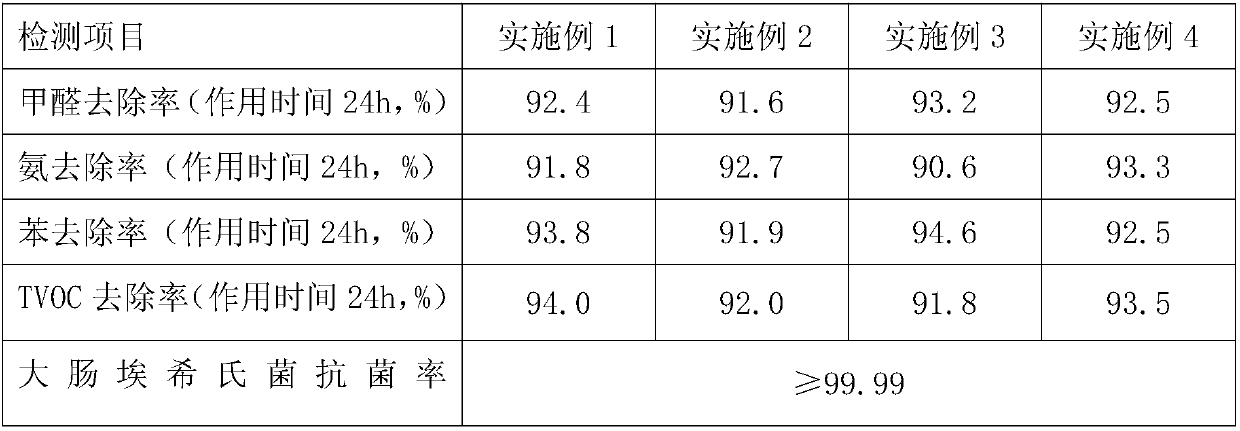

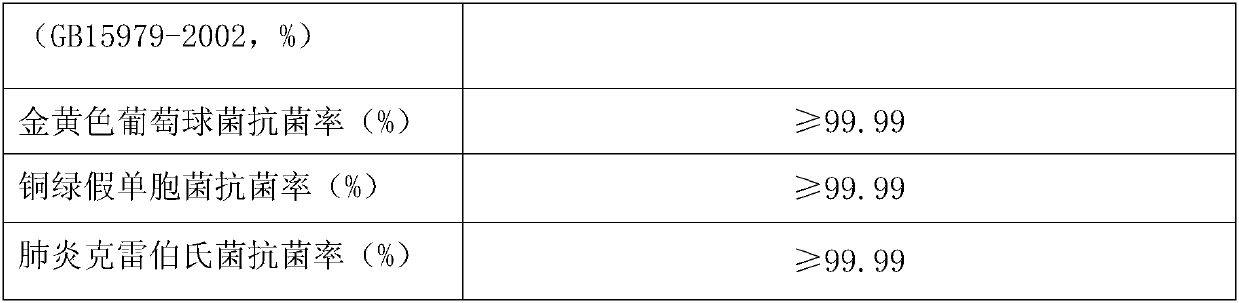

Embodiment 1

[0050] A fiber-integrated board, its raw material composition and parts by weight are: polyvinyl chloride resin powder 30, chlorinated polyethylene resin 3, wood powder 25, photocatalyst nano-titanium material 5, foaming agent 1, coupling agent 1, active Light calcium 20, toughening agent 1, stabilizer 3, and regulator 2, wherein the wood powder is composed of bamboo powder and crop straw powder with a particle size of 80-120 mesh and an aspect ratio of 1:2-4 and poplar wood powder, and the ratio of weight and number of bamboo powder, crop stalks, poplar wood powder is 1:3:3, the photocatalyst nano-titanium material is nano-titanium dioxide, and the foaming agent is composed of AC and BHK- 1, the toughening agent is PA-48, the coupling agent is KH-570, the stabilizer is an organotin stabilizer, and the regulator is HL-100A.

[0051] The above-mentioned fiber-integrated board is prepared according to the following steps:

[0052] Pretreatment: first dry the wood powder, then m...

Embodiment 2

[0057] The difference with Example 1 is:

[0058] The raw material composition and parts by weight of the board are: polyvinyl chloride resin powder 50, chlorinated polyethylene resin 8, wood powder 20, photocatalyst nano-titanium material 8, foaming agent 2, coupling agent 1, active light calcium 15 , toughening agent 1.5, stabilizer 4, regulator 3, wherein, the ratio of parts by weight of the bamboo powder, crop straw, poplar wood powder is 1:2.5:2.5.

[0059] In the pretreatment step, the temperature of mixing modification is 110°C;

[0060] In the mixing step, the stirring temperature is 110°C.

[0061] In the wrapping step, the decorative film is a PVC film with a thickness of 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com