Preparation method of titanium fiber porous material

A porous material and titanium fiber technology, applied in the field of metal porous materials, can solve the problems of unresolved pore structure uniformity, affecting material physical and chemical properties, and weakness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

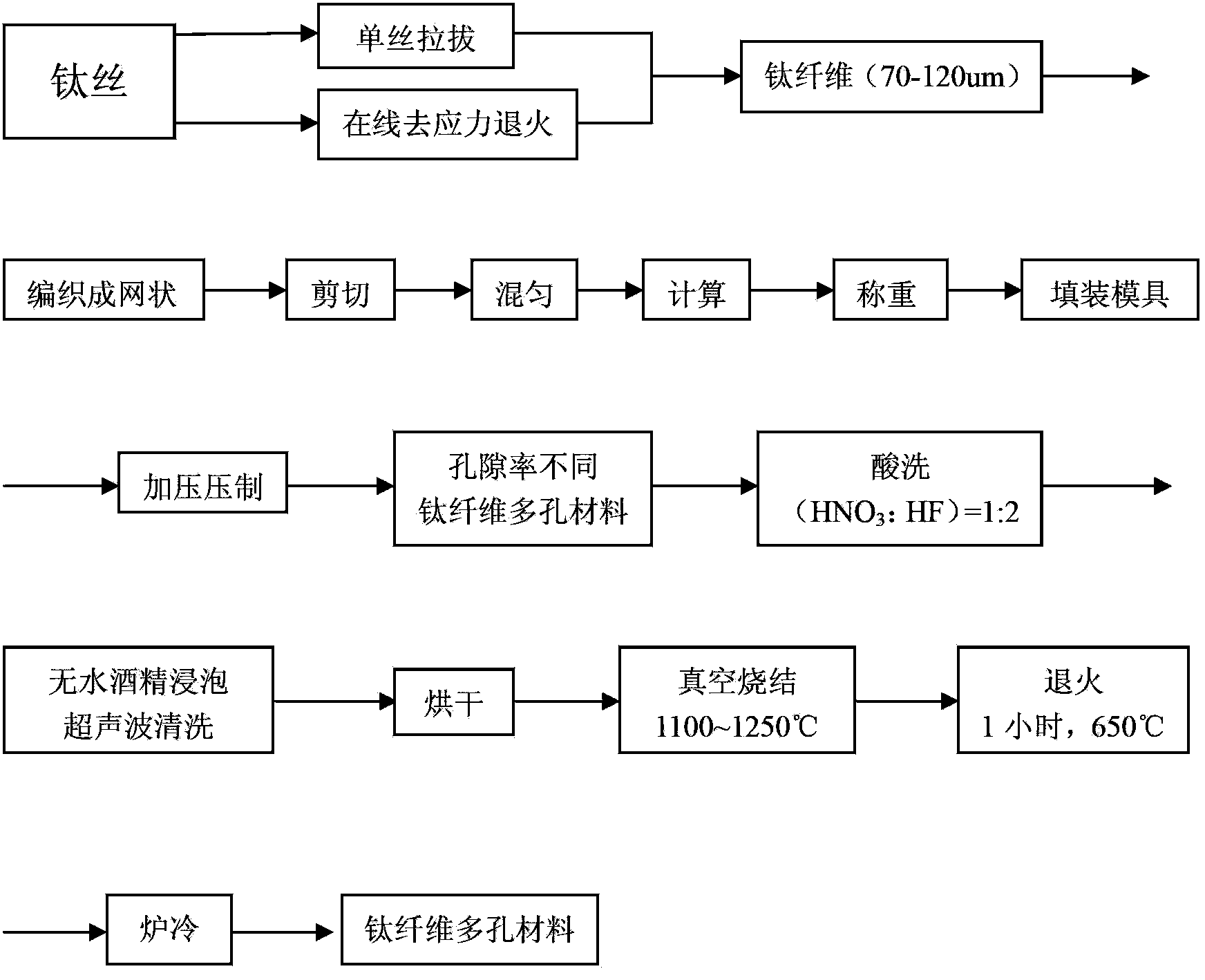

[0034] see figure 1 , the preparation method of titanium fiber porous material of the present invention, the method comprises the following steps:

[0035] (a) The titanium wire is drawn by a single wire of the water tank wire drawing machine, and the titanium wire is subjected to stress annealing twice, so that the titanium wire is drawn into a 120-70 μm fiber shape.

[0036] (b) Weave the titanium wire drawn into a fibrous shape into a titanium fiber mesh according to the wire weaving method, wherein the metal wire weaving method includes plain weave method, twill weave method, plain weave Dutch weave method, twill weave Dutch weave method or reverse To the Dutch weaving method.

[0037] (c) Cut the titanium fiber mesh into titanium fiber mesh blocks of different sizes, and mix the titanium fiber mesh blocks of different sizes evenly. The relationship, that is, P=1-m / Vρ s (1)

[0038] In the formula (1), P is the porosity of the porous material, m is the mass of the ...

Embodiment 1

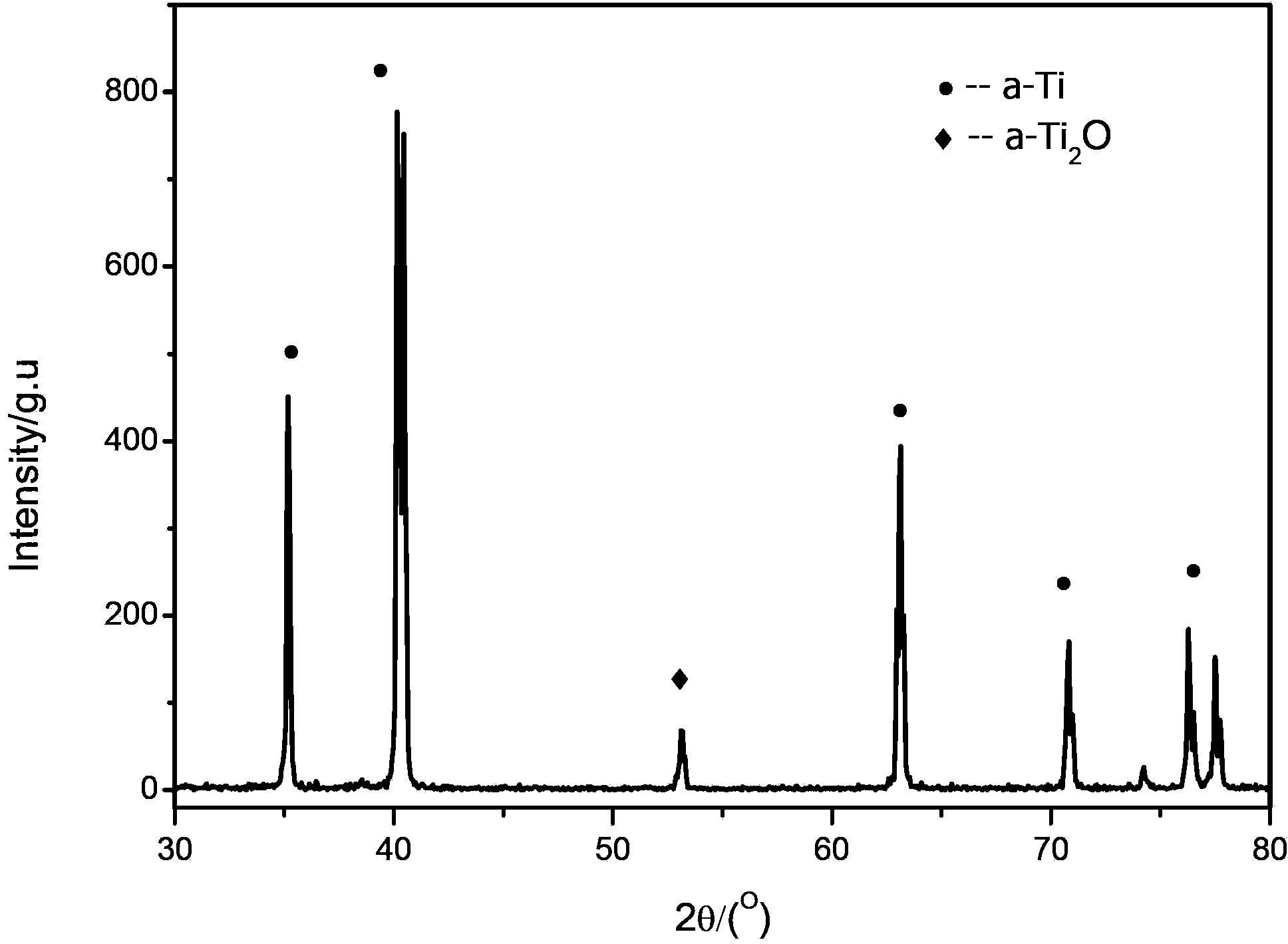

[0049] Before and after the sintering of the titanium fiber porous material, the chemical analysis of the oxygen content was carried out with a sample oxygen and nitrogen measuring instrument. The oxygen content on the surface of the titanium fiber before sintering was measured to be 120ppm, and the surface oxygen content was measured to be 130ppm after sintering at 1250°C. The oxygen content did not increase significantly before and after sintering. After sintering at 1250°C, the phase composition of the titanium fiber porous material was analyzed by XRD, and the spectrum is as follows figure 2 shown. The calibration results of the diffraction peaks show that the sintered structure is mainly composed of ɑ-Ti, and there is a small amount of titanium oxide Ti2O, and no diffraction peak of TiO2 is found in the diffraction spectrum. It shows that before and after sintering at 1250°C, the material substance remains consistent and similar to the prepared similar material, and the ...

Embodiment 2

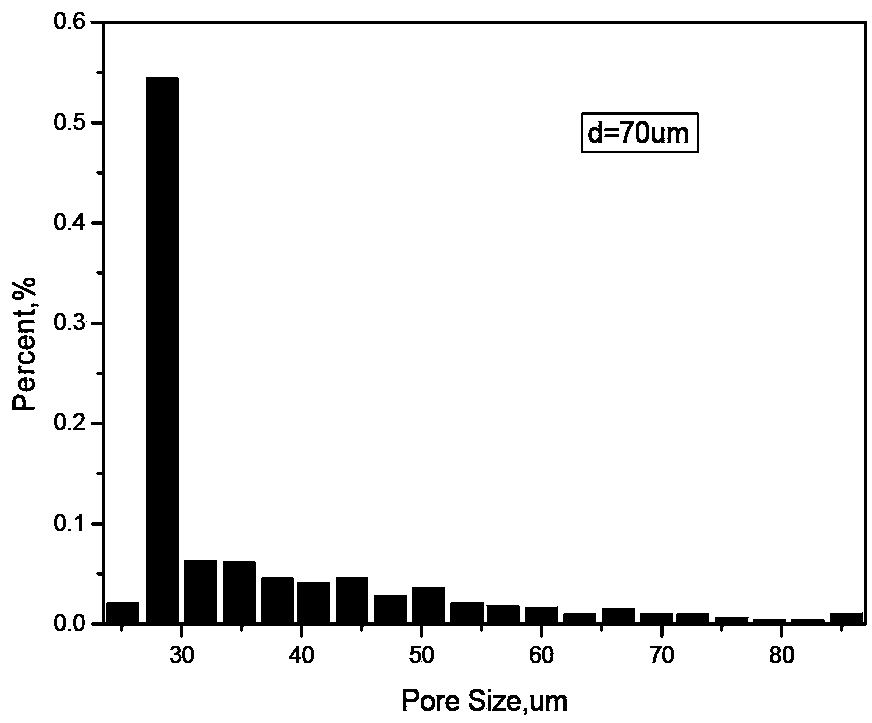

[0051] It can be seen that the pore size distribution diagram of the titanium fiber with a diameter of 70 μm in Figure 3 (a) has a high concentration of pore size distribution, and the pore size of 30 μm accounts for about 55%, indicating that the pore size of the material is relatively consistent and the pore structure is relatively neat. Comparing Figure 3(b) with a fiber diameter of 100 μm and Figure 3(c) with a fiber diameter of 120 μm, Figure 3(c) has a larger pore size and a more dispersed pore structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com