Gas diffusion layer and preparation method thereof

A gas diffusion layer and surface coating technology, which is applied in the field of gas diffusion layer and its preparation, can solve the problems of high contact surface resistance, poor conduction effect of titanium fiber felt plate, and low contact efficiency, so as to reduce the contact surface resistance, Effects of improving electrolysis efficiency and improving contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

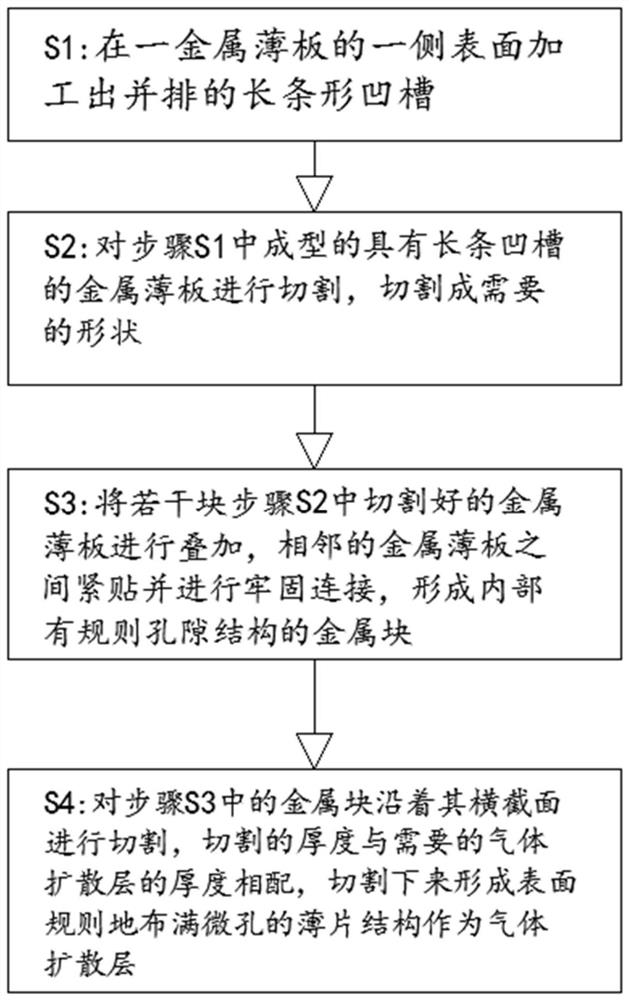

[0031] Such as figure 1 As shown, a kind of preparation method of gas diffusion layer is provided, comprising the following steps:

[0032] Step S1, process side-by-side strip-shaped grooves on one side of the metal sheet, and the strip-shaped grooves are used to form micropores on the gas diffusion layer. An important indicator of the gas diffusion layer is the porosity, which is the micropores. The ratio of the area of the hole to the area of the gas diffusion layer, and the size of the strip groove and the thickness of the metal sheet will affect the porosity of the gas diffusion layer. Let the depth of the strip groove be a, and the depth of the strip groove The width of the groove is b, the distance between adjacent strip-shaped grooves is c, and the total thickness of the metal sheet is d. By setting the ratio of these four parameters, a gas diffusion layer with a certain porosity can be obtained, such as a:b:c:d=1:1:1:2, the final porosity of the gas diffusion laye...

Embodiment 2

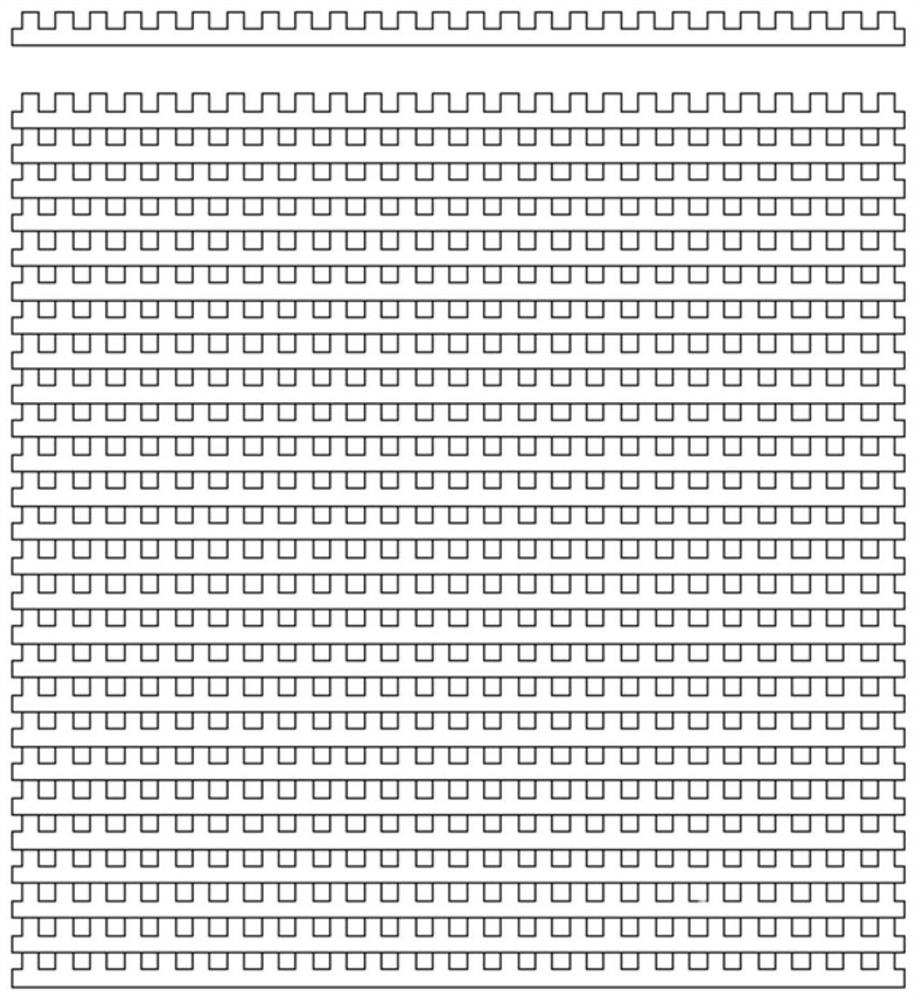

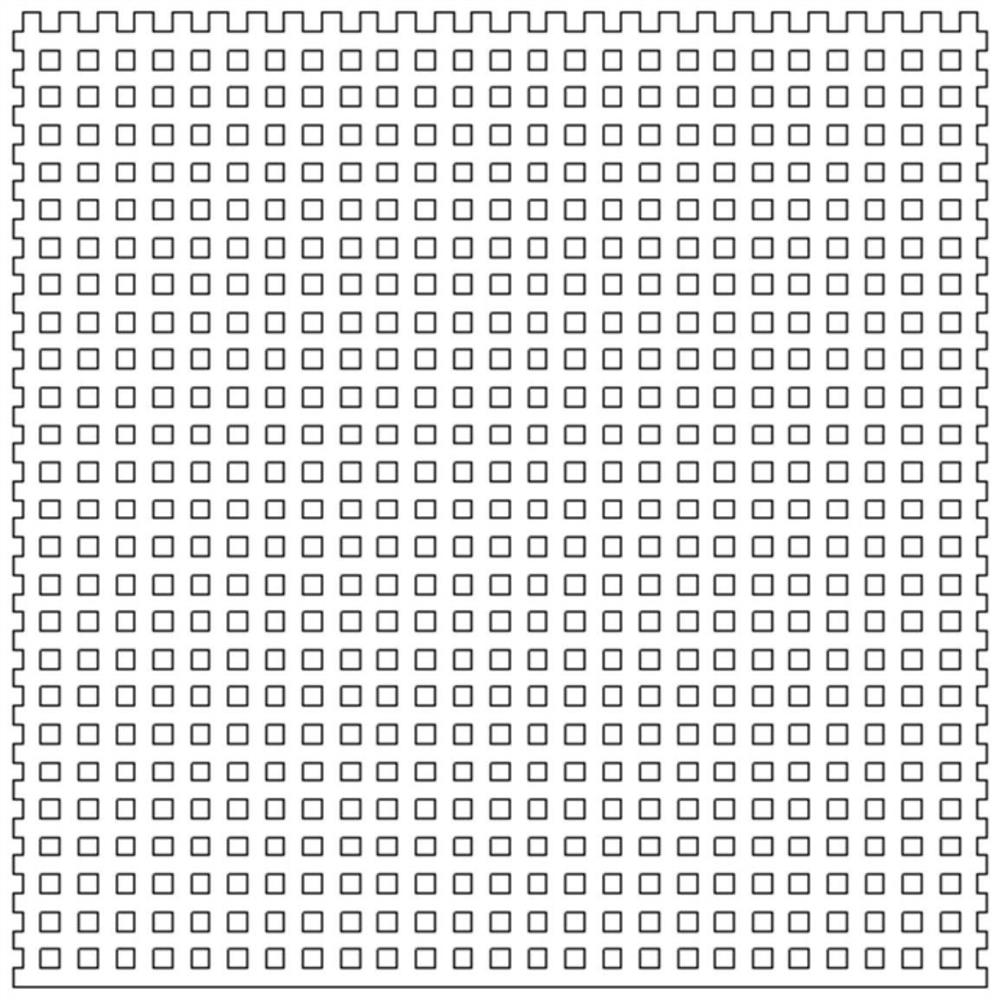

[0043] In the embodiment of the application, the application provides a gas diffusion layer, such as Figure 4 As shown, the gas diffusion layer is prepared by the preparation method described in Example 1. The specific structure includes a thin plate main body, and the thin plate main body is regularly arranged with several micropores penetrating the thin plate main body. The thickness of the thin plate main body is preferably 200-800 microns, such as Figure 4 As shown, the microwells are arranged in a rectangular array, and it can also be shown as Figure 5 As shown, the microholes are arranged in several rows, and the microholes in adjacent rows are arranged in a dislocation manner, which can make the microholes more uniform, and can improve the utilization of the area for the main body of the special-shaped thin plate.

[0044]This application adopts a brand-new preparation method, which has high efficiency and can prepare a gas diffusion layer with a smooth surface and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com