Safety-type large-power, large-current and high-voltage-resistant composite electrical connector

An electrical connector, high-power technology, applied in the direction of connection, electrical components, connection insulation, etc., can solve the problems of high resistivity, small extrusion deformation, small cross section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

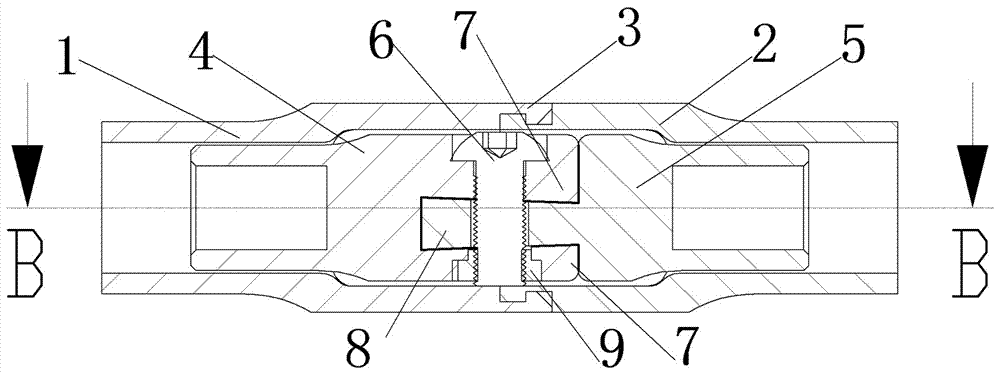

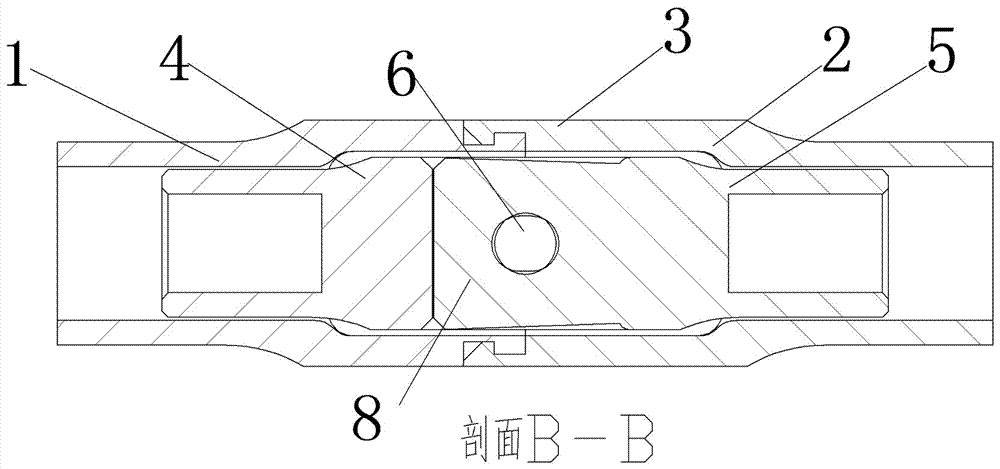

[0033] Example: see Figure 1-8 , a safe high-power, high-current, and high-voltage-resistant composite electrical connector in the figure is characterized by: including a conductive connection component and an insulating protective sleeve, the conductive connection component includes a conductive connection male head, a conductive connection female head, and a locking Bolt; one end of the conductive connection male head is a cylindrical welding cup, which is used for cable welding, and the other end is a trapezoidal chuck extending in the longitudinal section along the axial direction. The upper and lower surfaces of the chuck have an included angle with the central axis; The thickness of the outer end of the head is greater than the thickness of the root. One end of the conductive connection female head is a cylindrical welding cup, which is used for cable welding, and the other end is two clamps protruding axially and located on both sides of the axis. The shape of the area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com