Nano magnetofluid fracturing fluid imbibition oil-increasing method for tight reservoir and modified nano magnetic particles

A nano-magnetic fluid, tight reservoir technology, applied in the fields of fluid production, chemical instruments and methods, earth-moving drilling, etc., can solve the problems of damage to the reservoir, inconvenience, and high cost, so as to increase crude oil production and reduce water production. The effect of improving the diversion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

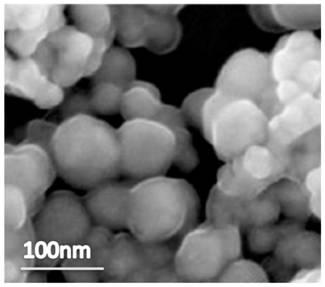

[0056] Modified nano-magnetic particles, which are surface-modified nano-Fe 3 o 4 Granules, the surface modifier is sodium oleate. The particle size range is 60nm~70nm, the temperature resistance range is less than or equal to 225°C, and the molar magnetic susceptibility is 480~510cm 3 / mol.

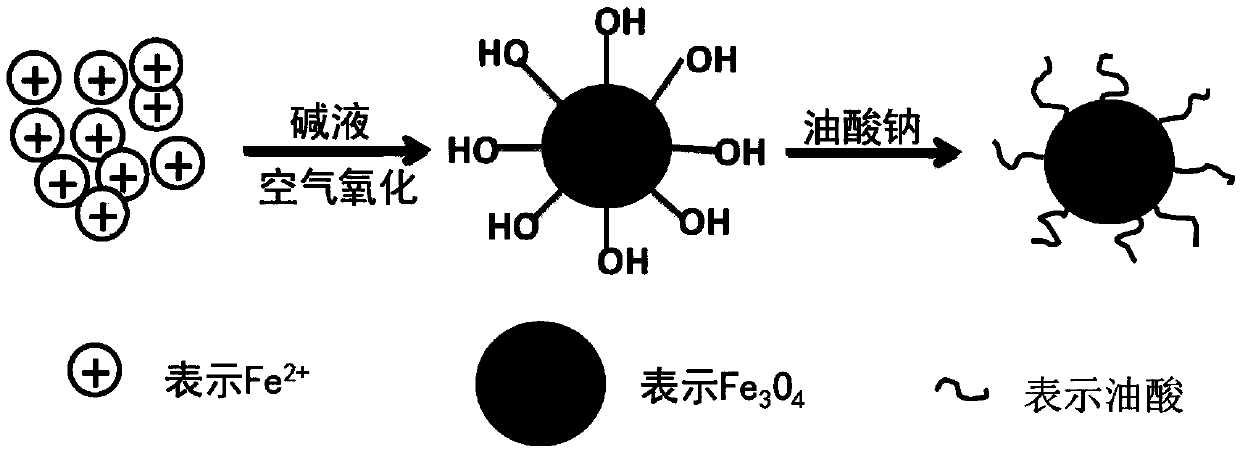

[0057] Preparation of modified magnetic nanoparticles (such as figure 1 shown):

[0058] a. At a stirring speed of 500r / min, mix NaOH and NH with a molar ratio of 1:1 3 ·H 2 O mixed solution was slowly added to 100 mL of FeCl with a solubility of 0.5 mol / L 2 In the solution, adjust to pH = 10, and continue to stir for 30 minutes to complete the reaction.

[0059] b. Add 3.05g sodium oleate (C 17 h 33 CO 2 Na), then continue to stir for 60min, making C 17 h 33 COO- fully adsorbs on Fe 3 o 4 surface.

[0060] c. After stopping the stirring, let it stand still and use a strong magnet to separate Fe 3 o 4 particles, and then alternately washed with distilled water and absolu...

Embodiment 2

[0067] The preparation of the modified nano-magnetic particles is the same as in Example 1.

[0068] The method for imbibing and increasing oil by nano-magnetic fluid fracturing fluid in tight reservoirs includes the following steps:

[0069] (1) Add modified nano-magnetic particles into the fracturing fluid base fluid and mix evenly to obtain a magnetic fracturing pre-fluid. The mass ratio of the fracturing fluid base fluid to the modified nano-magnetic particles is 6:4; The magnetic fracturing pre-fluid is injected to form fractures in the formation, the width of the fractures is 0.1-1.5cm, and the length of the single wing of the fracture is 10-200m;

[0070] (2) Connect a plurality of coil-wrapped electromagnets at the tail of the downhole tubing. The electromagnets are connected to the ground power supply through cables, and the magnetic field of the electromagnets is controlled by applying current through the ground power supply. The power supply is applied so that the m...

experiment example

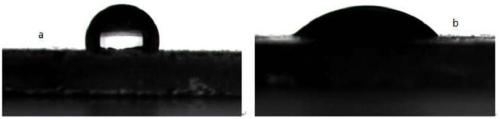

[0074] Experimental verification of strong lipophilic and hydrophobic properties of modified nano-magnetic particles:

[0075] Apply the modified nanoparticles on the surface of the quartz plate and flatten it, then drop water and crude oil on the surface, and test the contact angle between water and modified nanoparticles and the contact angle between crude oil and modified nanoparticles through a contact angle meter Angle, to verify that the modified nano-magnetic particles have strong lipophilic and hydrophobic properties, the results are as follows image 3 shown by image 3 It can be seen that the contact angle between water and modified nanoparticles is 105.36°, which has strong hydrophobicity, and the contact angle between crude oil and modified nanoparticles is 31.83°, which has strong lipophilicity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com