Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Sulphite salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid furtilizer containing humic acid multi nutritive element and mfg. method thereof

InactiveCN1693292ARich in nutritional valueImprove fertilizer efficiencyOrganic fertilisersFertilizer mixturesSulfateHumic acid

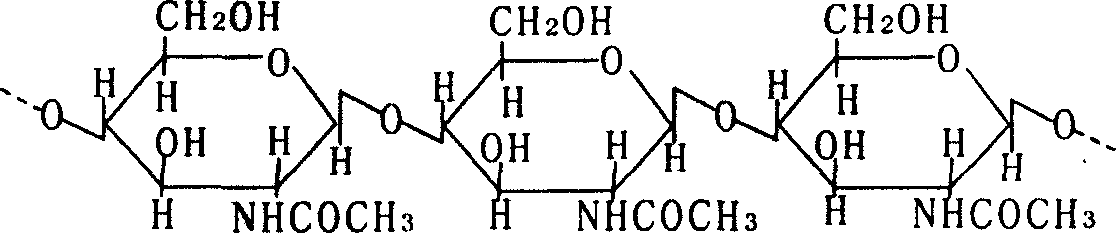

A multi-nutrient liquid fertilizer with high and durably fertility is proportionally prepared from ammonium humate, potassium humate, phosphorus humate, N-P-K humate, trace elements, sulfite as activator (or alkali or alkali-metal carbonate) and chitin solution. Its preparing process is also disclosed.

Owner:马增禄

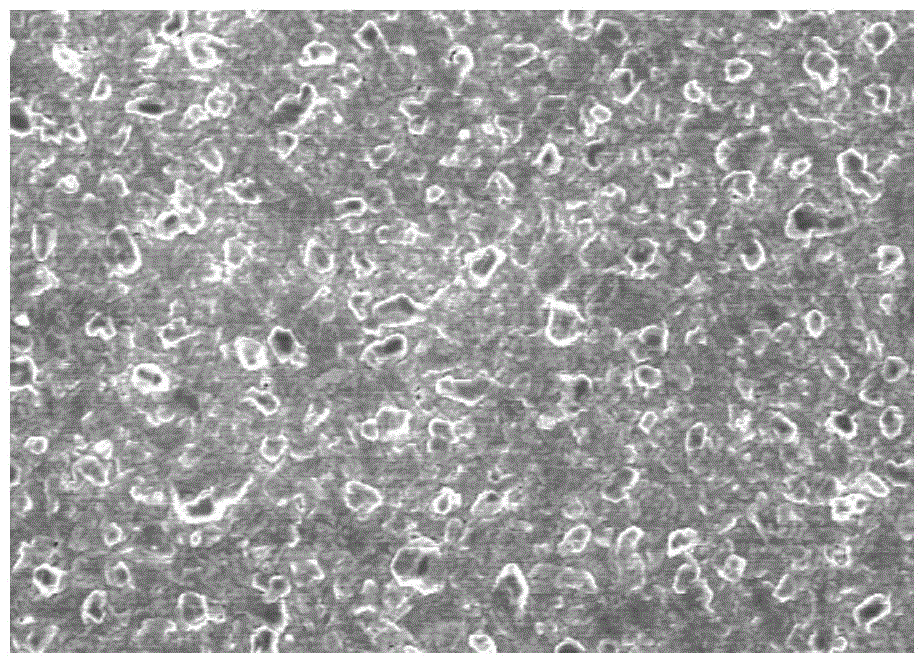

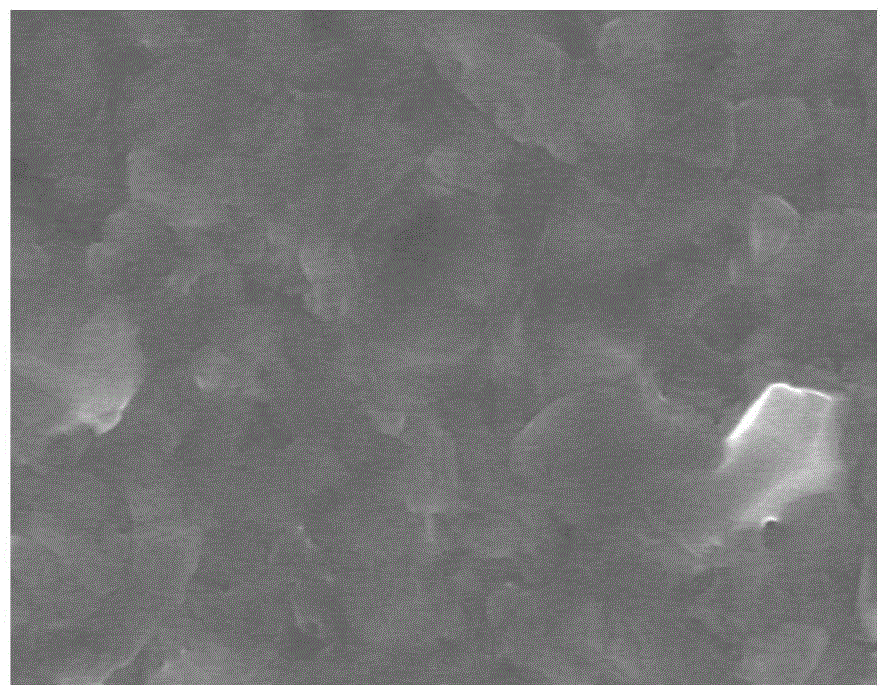

Amorphous alloy metallic phase corrosive agent and metallic phase display method

ActiveCN101576454AEasy to distinguishGood for evaluating qualityPreparing sample for investigationMaterial analysis by optical meansAlloySulphite salt

The invention provides an amorphous alloy metallic phase corrosive agent which comprises nitric acid, hydrochloric acid, lopsided sulphite and water. The metallic phase corrosive agent cannot form a pollution layer on the surface of an amorphous alloy sample and overmuch corrode a crystalline phase in amorphous alloy and is beneficial to observing the crystalline phase of the amorphous alloy so as to evaluate the quality of the amorphous alloy.

Owner:BYD CO LTD

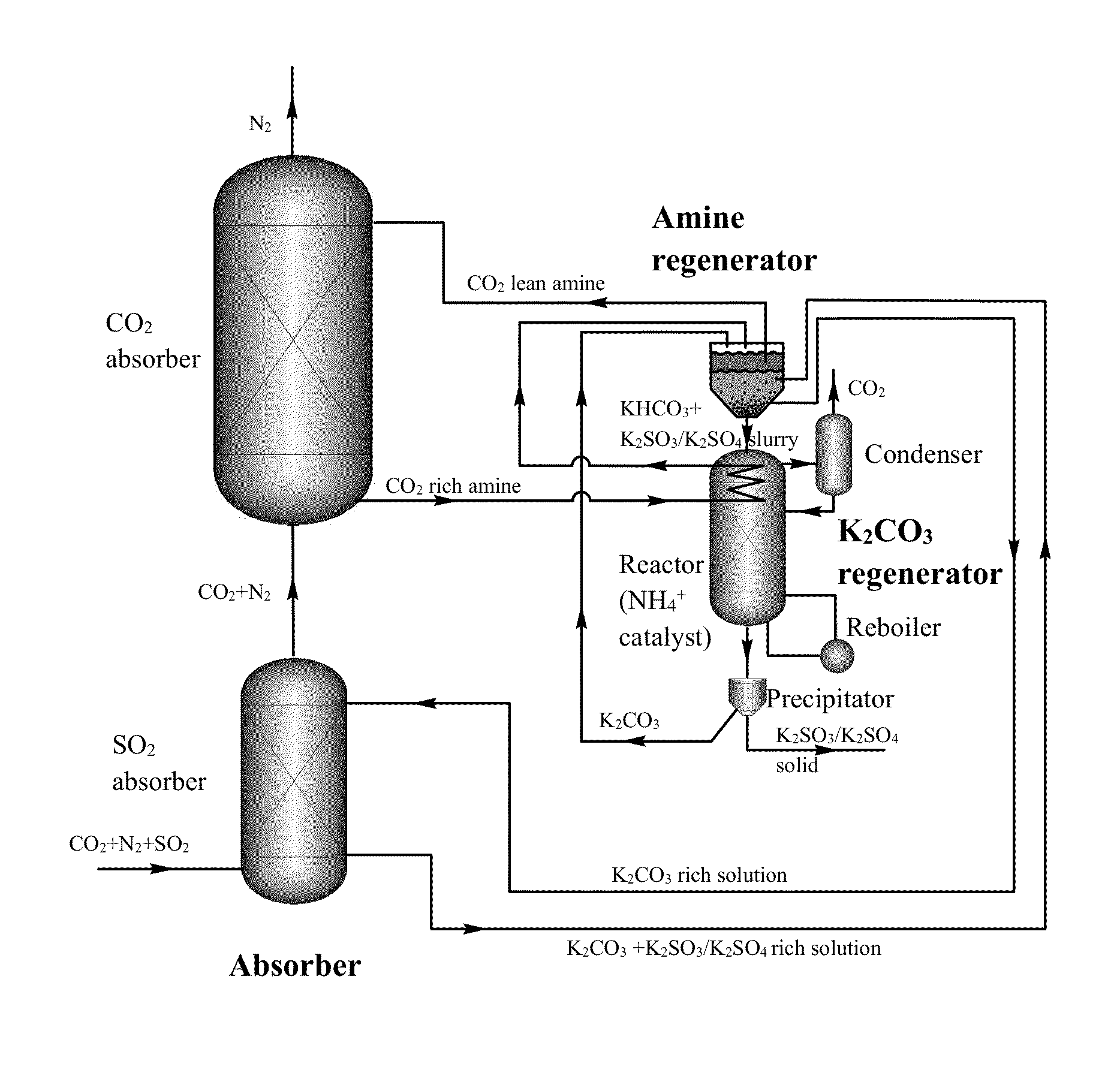

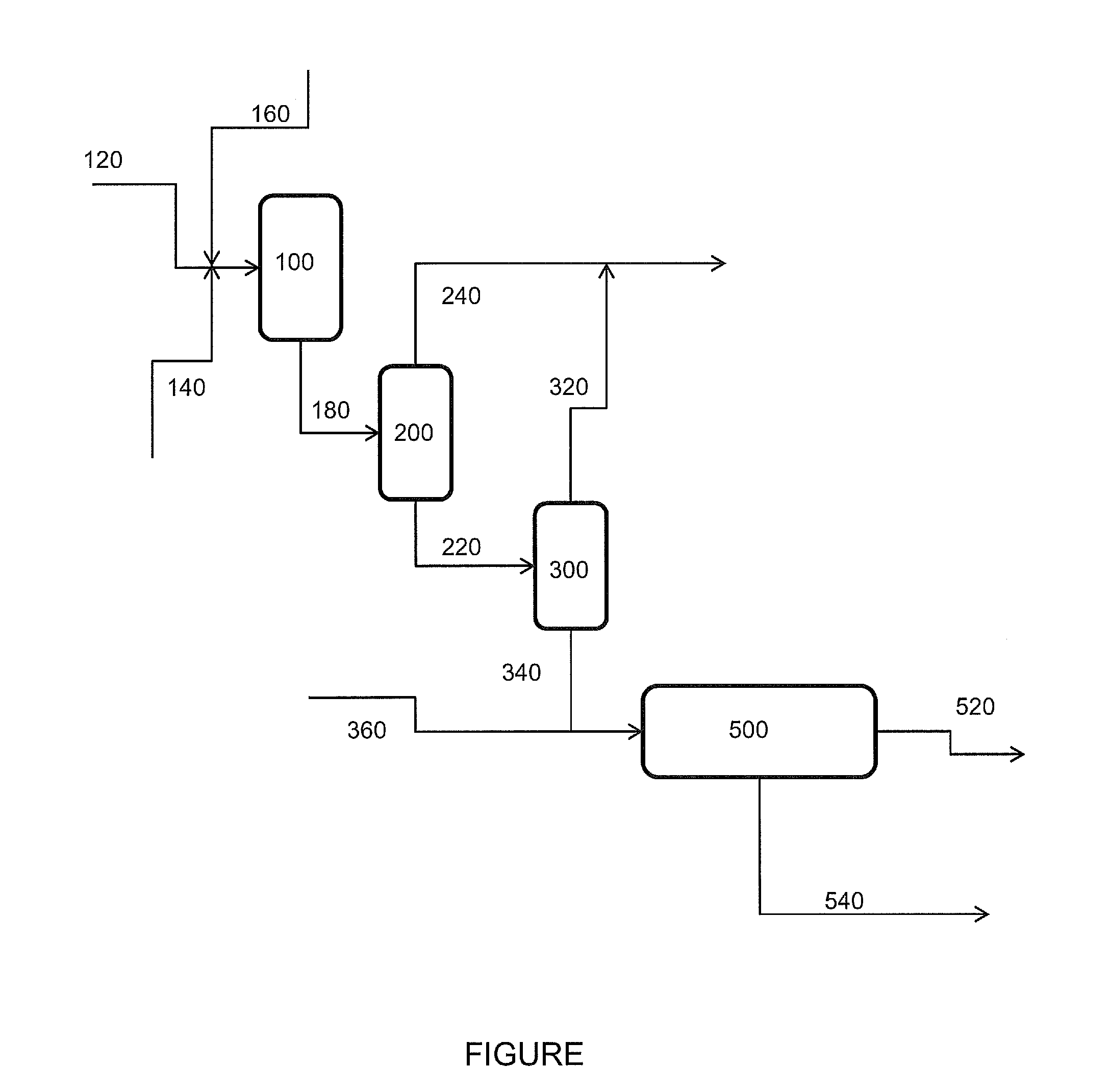

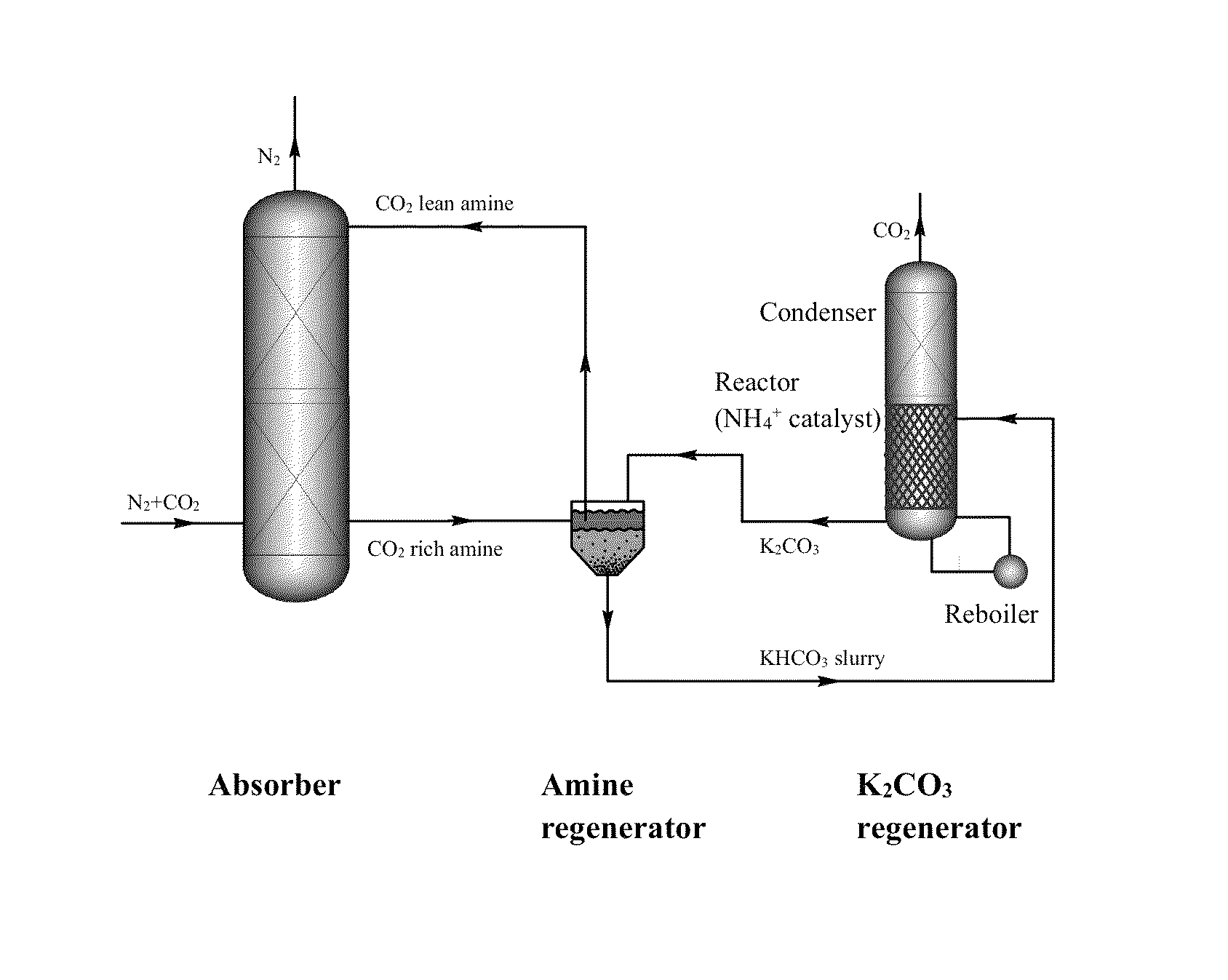

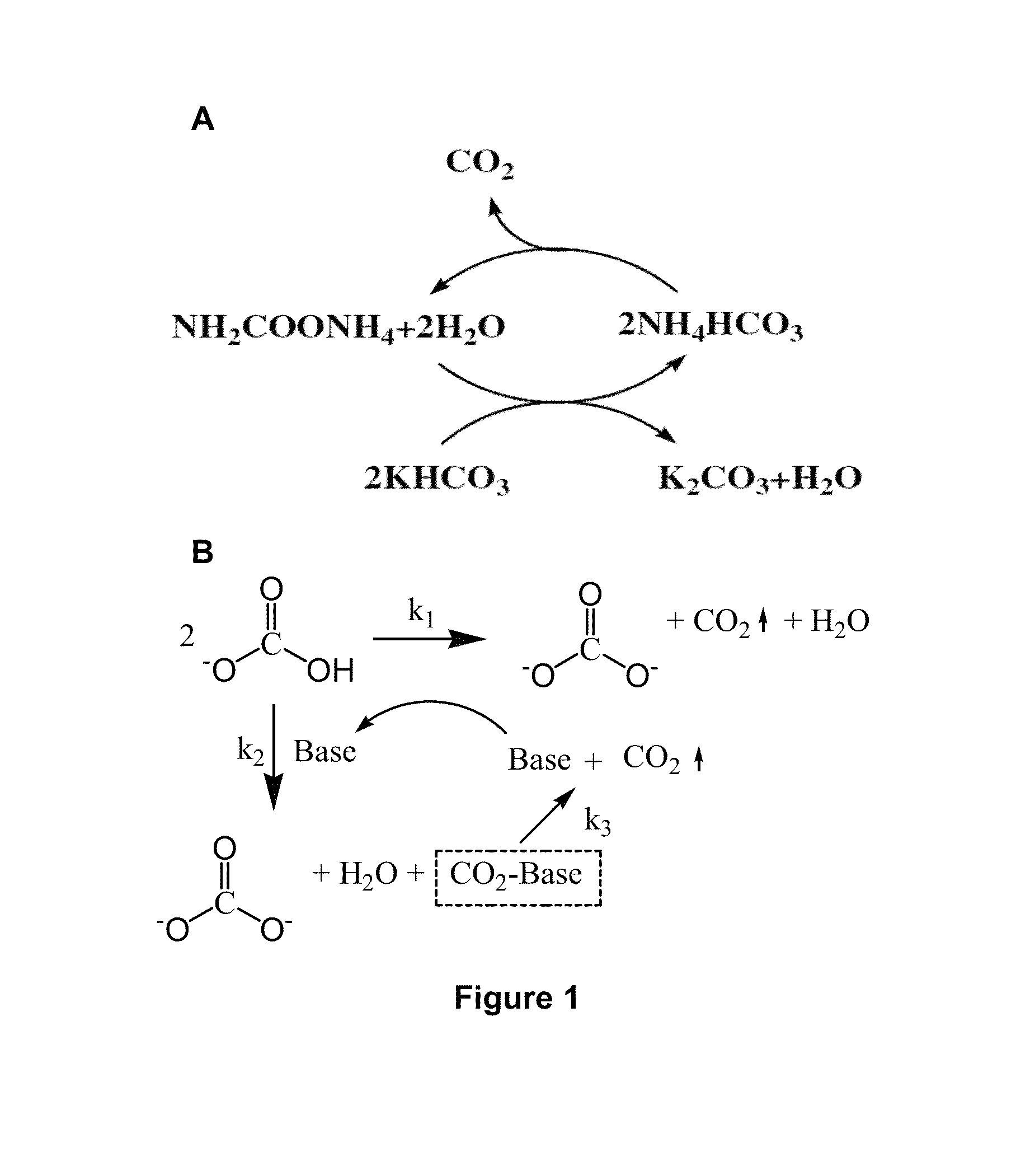

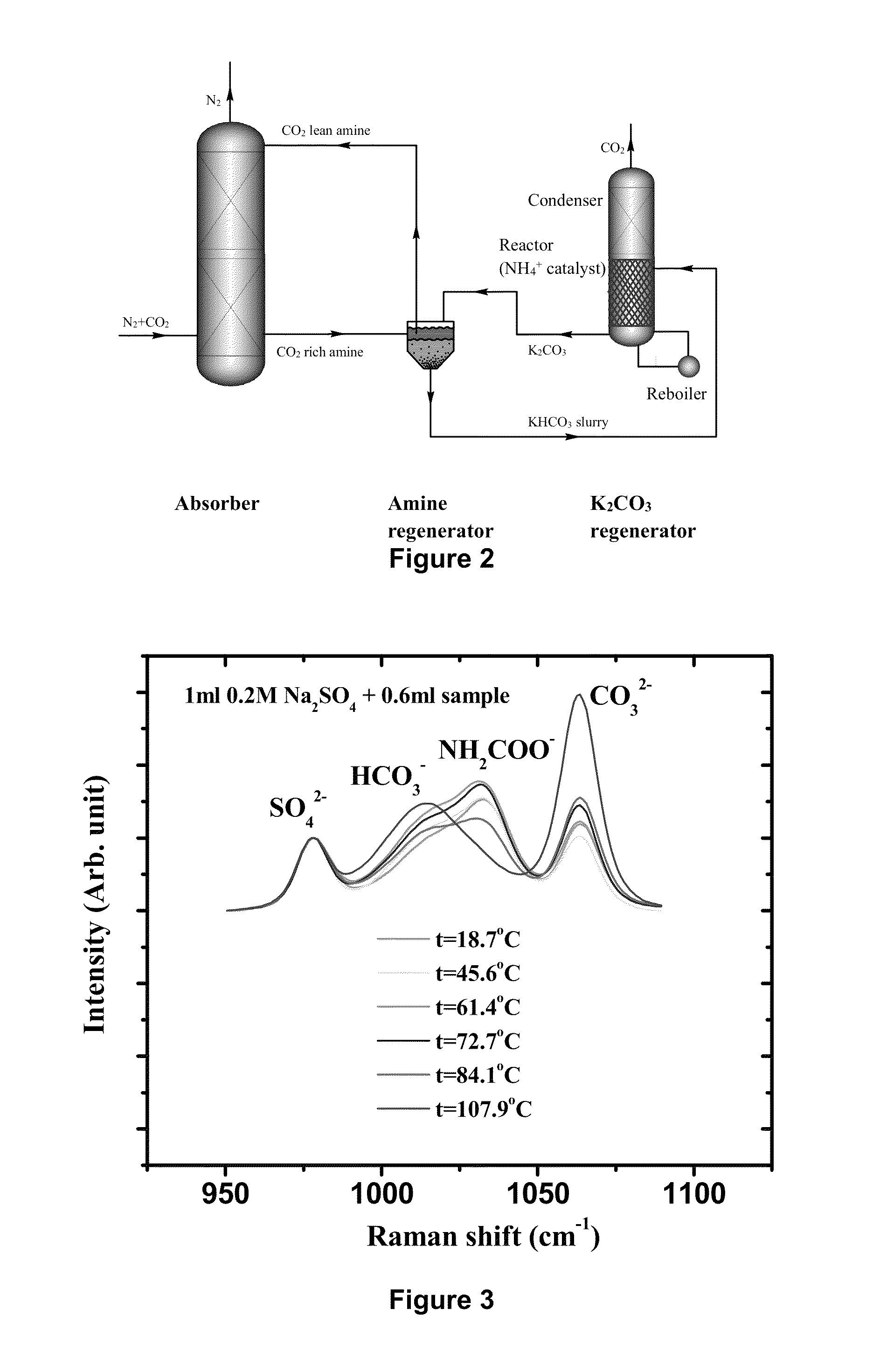

Method and system for capturing carbon dioxide and/or sulfur dioxide from gas stream

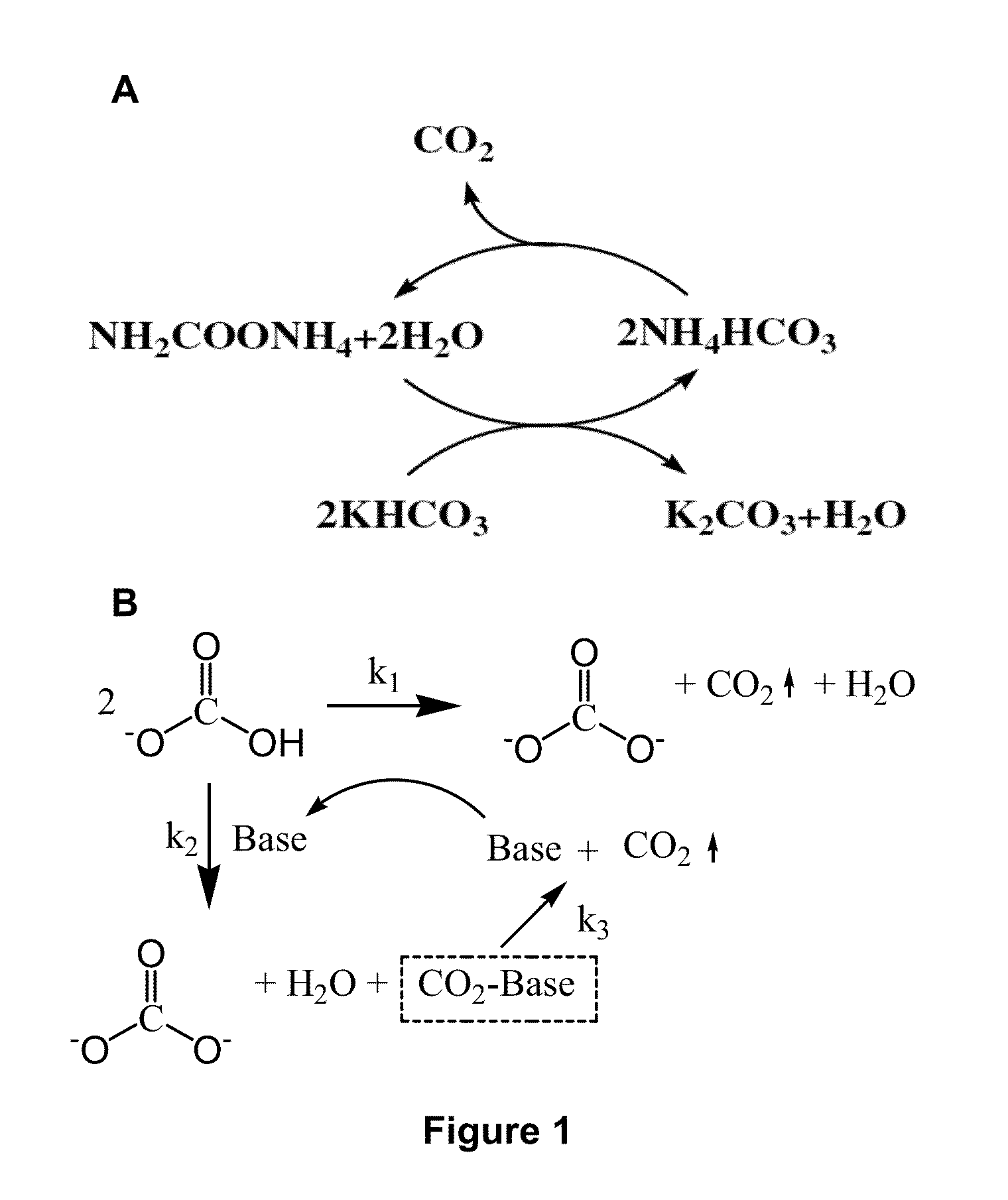

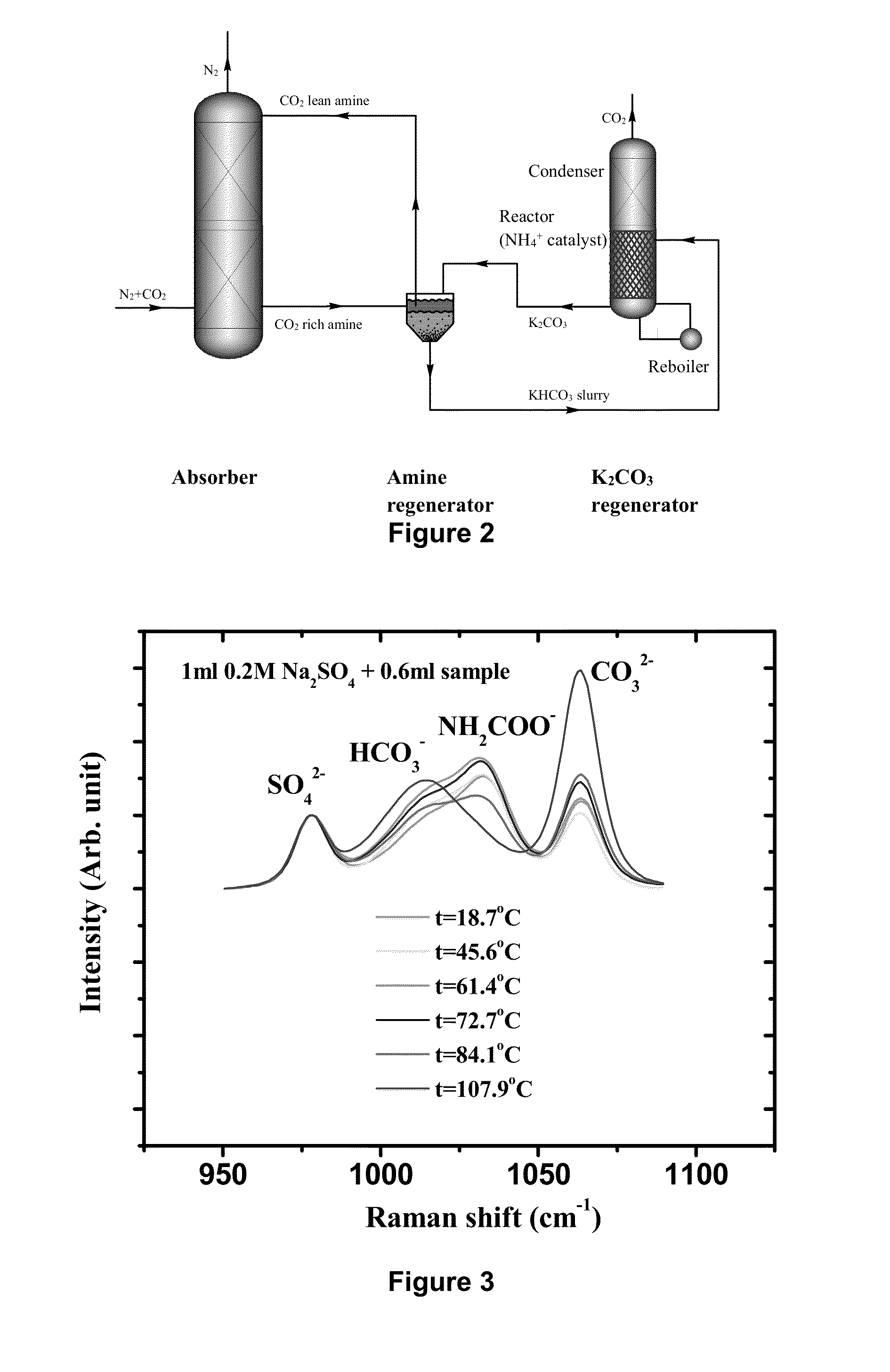

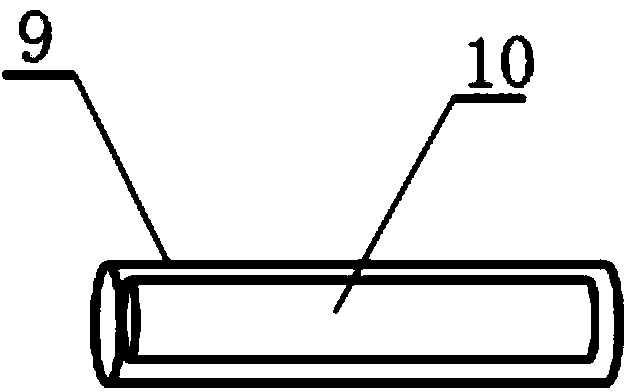

ActiveUS20130139695A1Promote absorptionReduce decreaseGas treatmentUsing liquid separation agentSulfate sulfurProcess engineering

The present invention provides a system for capturing CO2 and / or SO2, comprising: (a) a CO2 and / or SO2 absorber comprising an amine and / or amino acid salt capable of absorbing the CO2 and / or SO2 to produce a CO2- and / or SO2-containing solution; (b) an amine regenerator to regenerate the amine and / or amino acid salt; and, when the system captures CO2, (c) an alkali metal carbonate regenerator comprising an ammonium catalyst capable catalyzing the aqueous alkali metal bicarbonate into the alkali metal carbonate and CO2 gas. The present invention also provides for a system for capturing SO2, comprising: (a) a SO2 absorber comprising aqueous alkali metal carbonate, wherein the alkali metal carbonate is capable of absorbing the SO2 to produce an alkali metal sulfite / sulfate precipitate and CO2.

Owner:RGT UNIV OF CALIFORNIA

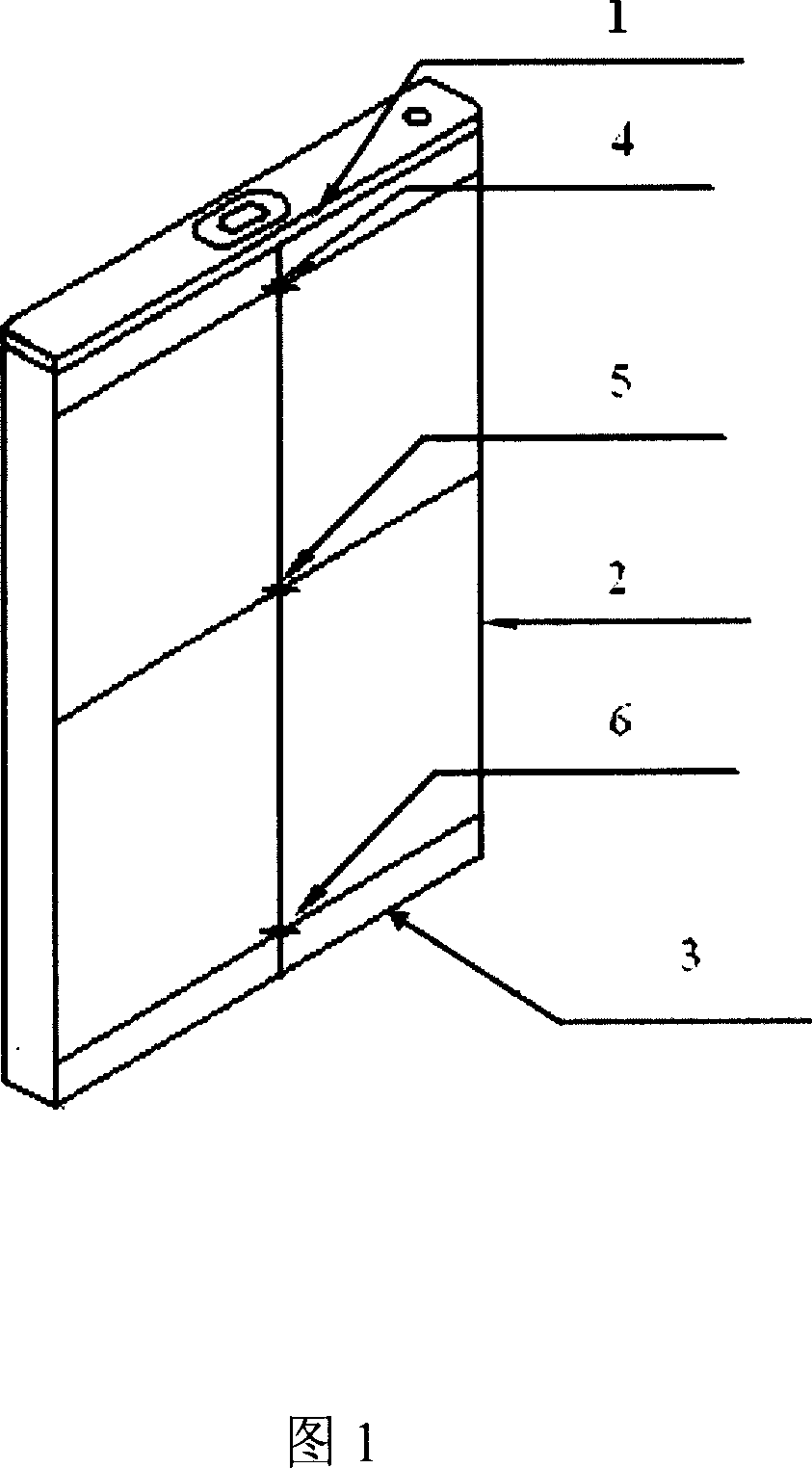

Method and device for oxidizing sulphite grout in wet flue gas desulfurization process

ActiveCN103768902AExtended service lifeAvoid the phenomenon that is easy to be corrodedCalcium/strontium/barium sulfatesDispersed particle separationSlurryOxygen

The invention discloses a method and a device for oxidizing sulphite grout in a wet flue gas desulfurization process. The method comprises the following steps: (1) collecting the sulphite grout generated due to the absorption of alkali liquid at an upper section of a desulfurization tower into a grout tank at a lower section of the same desulfurization tower; (2) introducing oxygen-containing gas into a creeping discharge reactor outside the desulfurization tower, and converting the oxygen-containing gas into active gas containing oxygen active substances; (3) injecting the active gas as an oxidizing agent into the sulphite grout, and oxidizing the sulphite grout to form sulfate grout. According to the device, the creeping discharge reactor is arranged outside the grout tank, so that the oxidation rate is increased, the use amount of the oxygen-containing gas is reduced, meanwhile, phenomena of electrode corrosion and grout backflow are avoided, a wet desulfurization absorption process and an oxidation process are integrated and are finished in the same desulfurization tower, an additional oxidation reactor is omitted, the process is simplified, and the cost is lowered.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL +1

Carbon dioxide solid absorbent capable of effectively inhibiting active components from losing effect

InactiveCN102658023AEasy to getExtended service lifeDispersed particle separationAir quality improvementCo2 absorptionActivated Aluminum Oxide

The invention provides a carbon dioxide solid absorbent capable of effectively inhibiting active components from losing effect. One or more of potassium carbonate, sodium carbonate and alkali metal base carbonates is / are used as the active component, one or more of calcium oxide, magnesium oxide and alkali-earth oxides is / are used as the additive, and active aluminum oxide is used as an absorbent carrier; and a precipitation method, impregnation method, impregnation-precipitation method or impregnation-spray method is used for preparing the carbon dioxide solid absorbent. The absorbent can efficiently and quickly remove carbon dioxide in fume, and can also effectively lower loss of effect of the active component alkali metal base carbonates due to sulfur dioxide and other foreign gases in the fume. The research indicates that the carbon dioxide absorption temperature of the absorbent is 60-80 DEG C, the regeneration temperature is 100-300 DEG C, and calcium oxide, magnesium oxide and other additives react with SO2 in the fume to generate sulfites, thereby effectively lowering the loss of effect of the active components due to SO2 and prolonging the service life of the solid absorbent.

Owner:SOUTHEAST UNIV

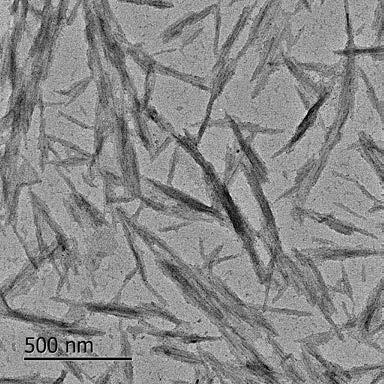

Method for utilizing camellia oleifera abel fruit shells to prepare cellulose nano-crystal whiskers

ActiveCN107419574ALarge specific surface areaStrong Young's modulusPretreatment with alkaline reacting compoundsPulp bleachingCelluloseCamellia oleifera

The invention discloses a method for utilizing camellia oleifera abel fruit shells to prepare cellulose nano-crystal whiskers, and belongs to the technical field of energy chemical materials. According to the method, the camellia oleifera abel fruit shells serve as initial raw materials, and firstly, the fruit shells are subjected to sulphite alkali pretreatment, alkali purification and hydrogen peroxide bleaching to obtain camellia oleifera abel fruit shell cellulose; secondly, the camellia oleifera abel fruit shell cellulose is subjected to acidolysis with organic acid namely oxalic acid, and the camellia oleifera abel fruit shells cellulose can be prepared after centrifugation and ultrasonic dispersion. According to the method, the production process is simple and easy to implement, and not only can the comprehensive utilization value of the camellia oleifera abel fruit shells be well improved, but also the prepared cellulose nano-crystal whiskers have the advantage of being good in mechanical performance, biodegradable, easy to compound and the like and can be widely applied to packaging toughening materials, optoelectronics and semiconductor devices and other industrial fields.

Owner:HUNAN UNIV OF TECH

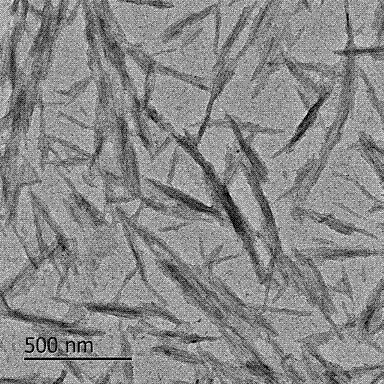

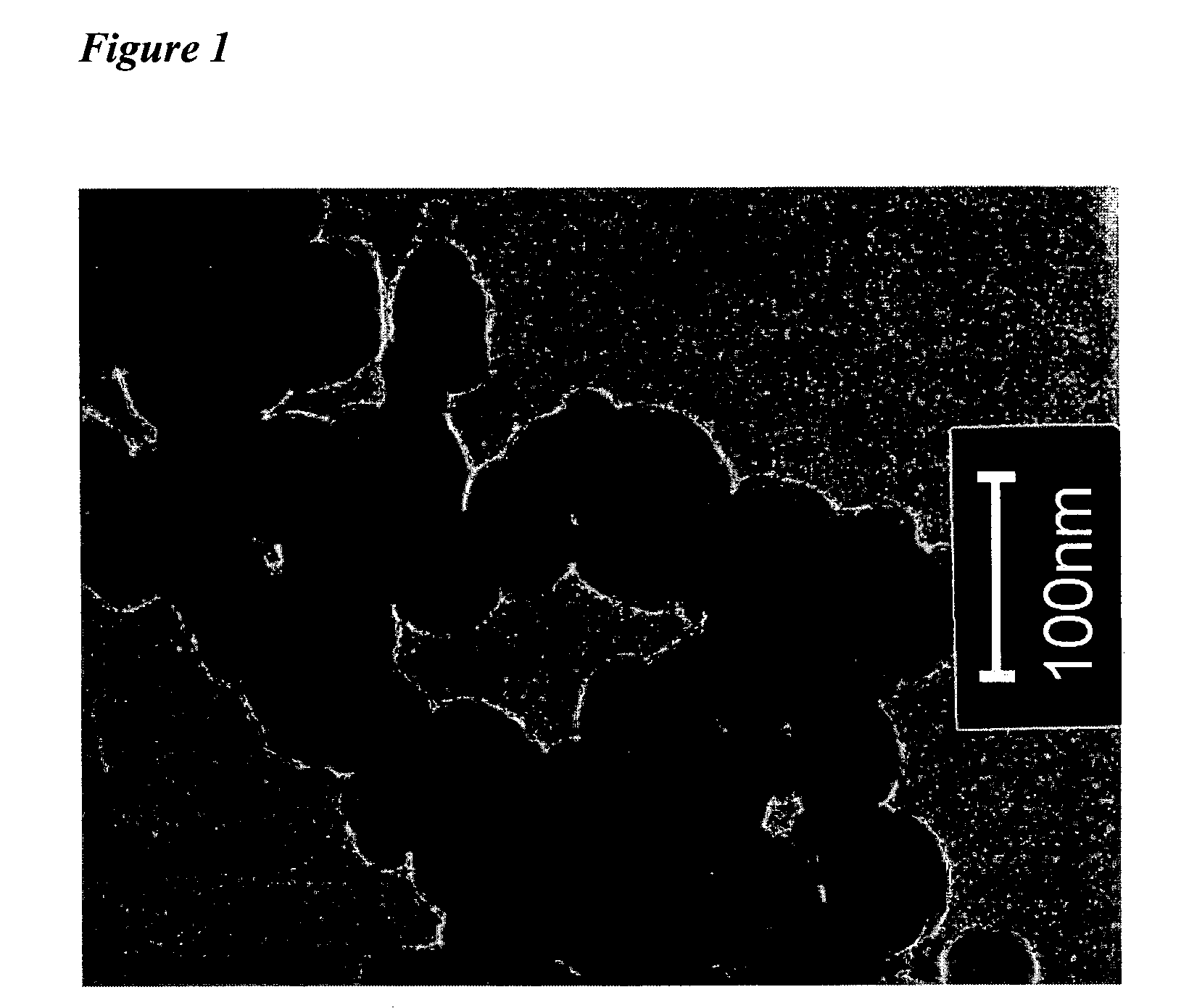

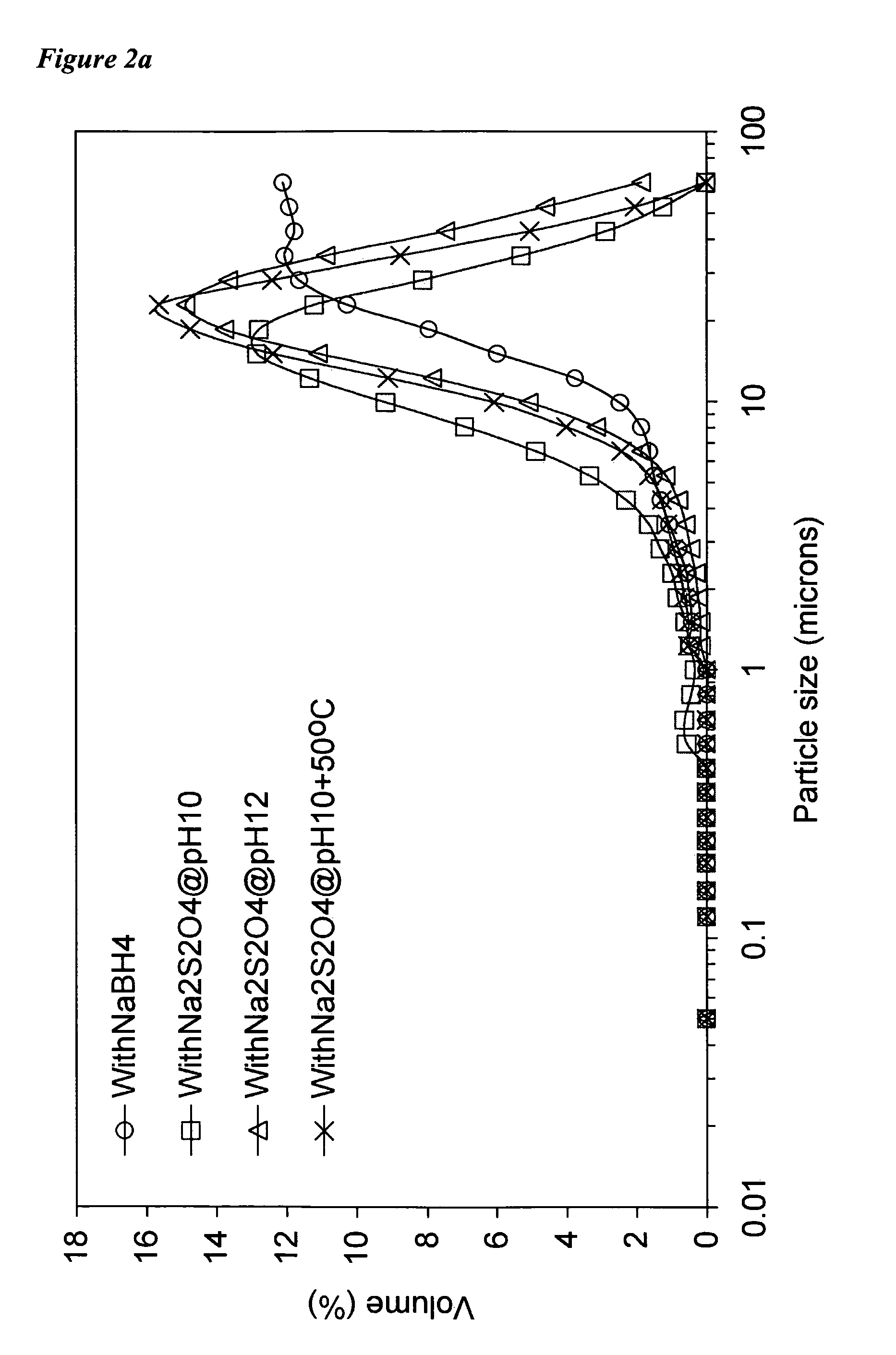

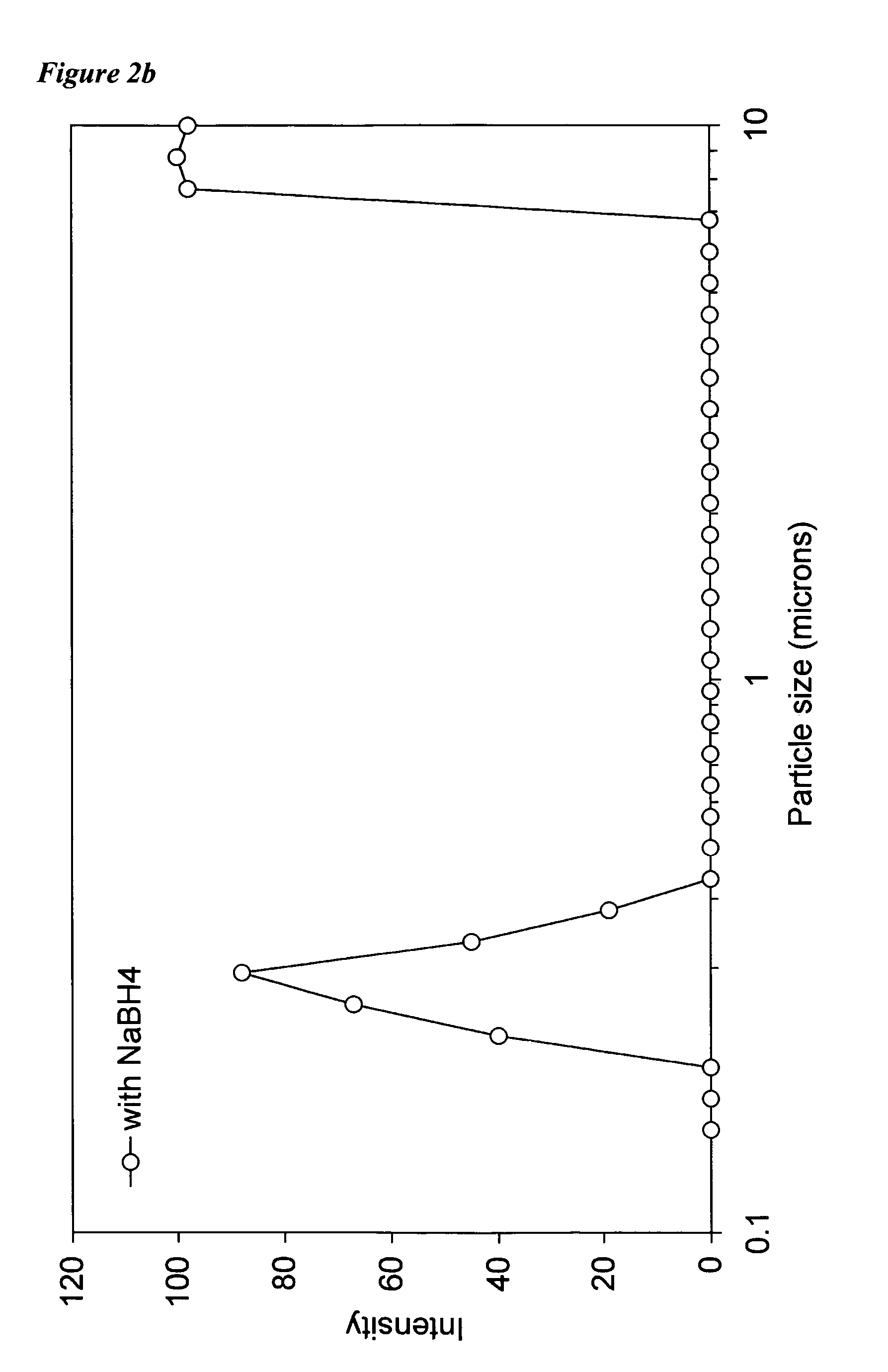

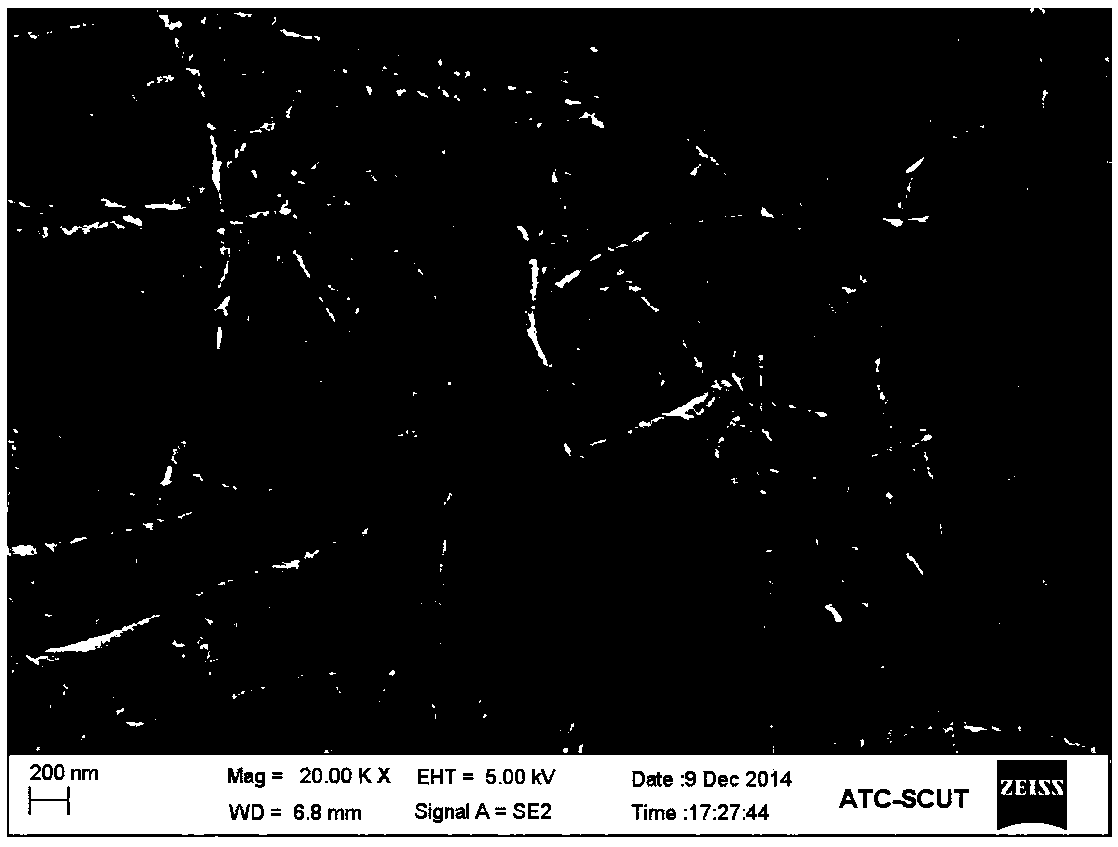

Process for producing a nanoscale zero-valent metal

InactiveUS7674526B2Inhibit productionLiquid surface applicatorsMetal-working apparatusDithionous acidContaminated water

This invention describes a process for producing a nanoscale zero-valent metal, including reduction of a metal ion solution with a dithionite compound, wherein the reduction is carried out under alkaline conditions under substantially an inert atmosphere. A nanoscale zero-valent metal obtainable by this process, and having a new crystalline form, is also described. The nanoscale zero-valent metal produced by the process of the invention is preferably iron, and is advantageously used for the remediation of contaminated water.

Owner:ORICA AUSTRALIA

Bismuth vanadate electrode rich in surface layer oxygen vacancies, and preparation method and application thereof

ActiveCN110791777AHigh majority carrier concentrationImprove separation efficiencyEnergy inputElectrodesSemiconductor electrodeBismuth vanadate

The invention belongs to the technical field of photoelectrochemical cell semiconductor electrodes, and discloses a bismuth vanadate electrode rich in surface layer oxygen vacancies, and a preparationmethod and an application thereof. The electrode comprises a conductive substrate layer and a bismuth vanadate layer, and the bismuth vanadate layer is obtained through photoetching modification. Thepreparation method comprises the steps: firstly, growing bismuth vanadate particles on a conductive substrate by a metal organic matter decomposition method, then immersing the bismuth vanadate particles in an alkaline buffer solution containing sulfite, and simultaneously applying illumination with certain wavelength and certain intensity for certain time to finish the preparation of the whole electrode. The electrode can be assembled into a photoelectrochemical cell for hydrogen production by photolysis of water in the photoelectrochemical cell. The oxygen vacancies are introduced into thesurface layer of the bismuth vanadate electrode, so that the charge separation efficiency of a solid-liquid interface is effectively improved, the photoelectric conversion efficiency of the photoelectrochemical cell is improved, the operation is simple, and the oxygen vacancy introduction efficiency is high; and meanwhile, vacuum equipment is not needed, so that the operation cost is extremely low, and large-scale production is facilitated.

Owner:TIANJIN UNIV

Aluminium alloy complex and preparation method thereof

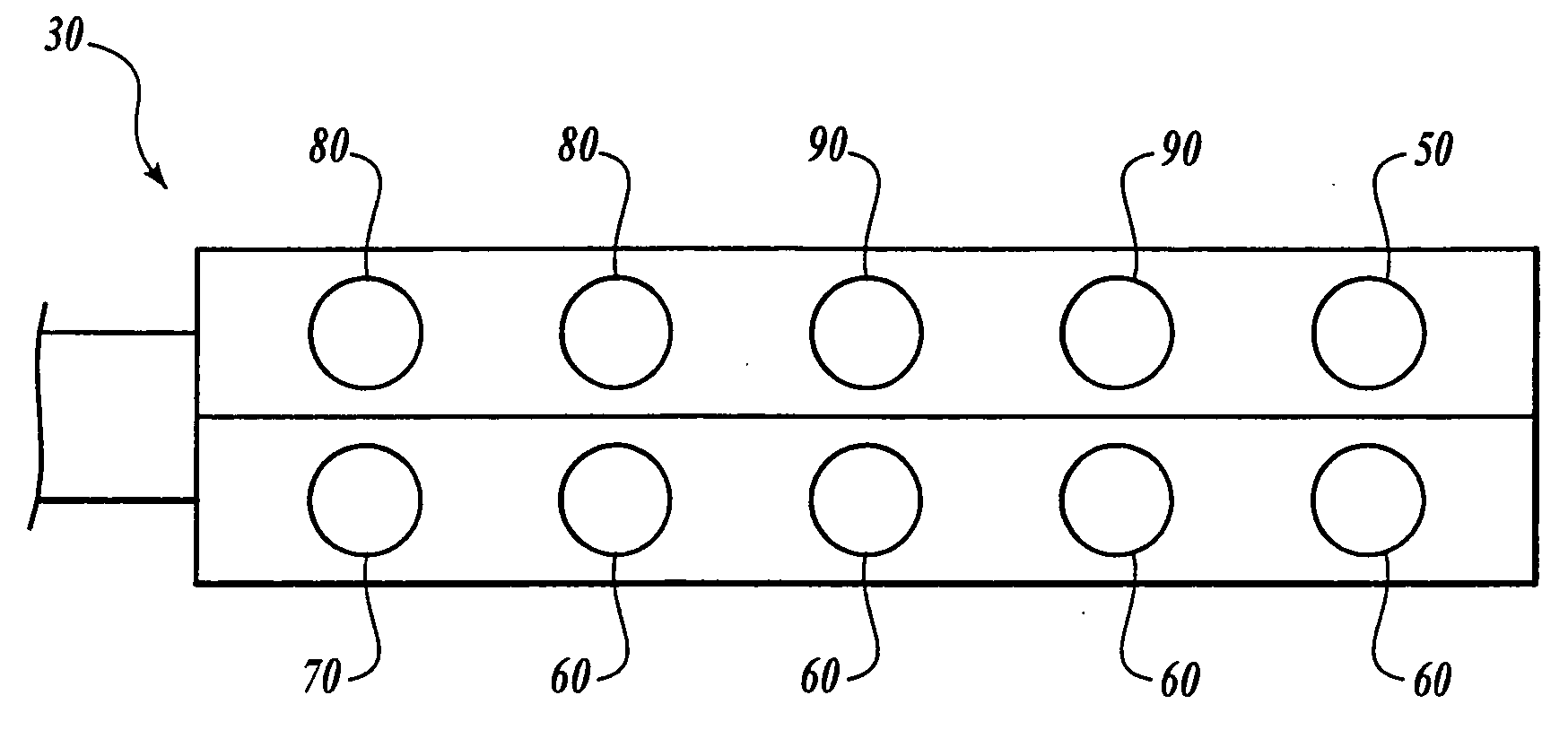

The invention provides a preparation method of an aluminium alloy complex. The method comprises the following steps of: surface treatment: dipping the pretreated aluminium alloy base material into at least one water solution of soluble phosphate, carbonate, acetate and sulphite, and carrying out surface treatment; and molding: after the surface treatment, putting the aluminium alloy base material into a mould, then injecting a resin composition into the mould to be combined with the aluminium alloy base material, and molding to obtain the aluminium alloy complex. The invention also relates to the aluminium alloy complex. According to the method, the soluble phosphate, the carbonate and the acetate are used for treating the aluminium alloy base material, and nanoscale micropores can be obtained; the soluble phosphate, the carbonate and the acetate are free from toxicity and volatility, has no harm to the environment, and has good safety performance; and after the surface treatment, the aluminium alloy base material and a resin layer of the aluminium alloy complex have very good bonding force, so that the aluminium alloy complex is high in tensile strength.

Owner:BYD CO LTD

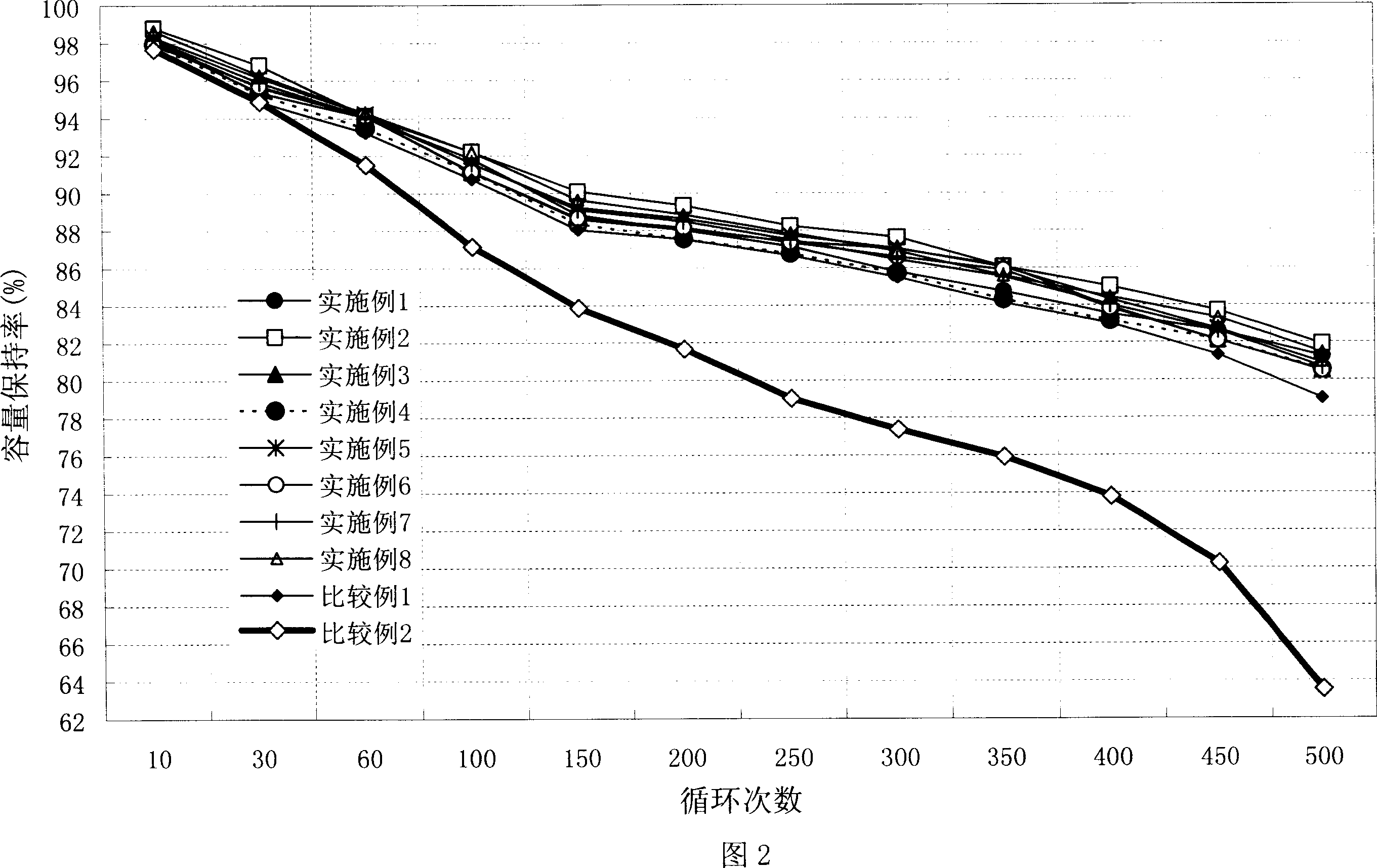

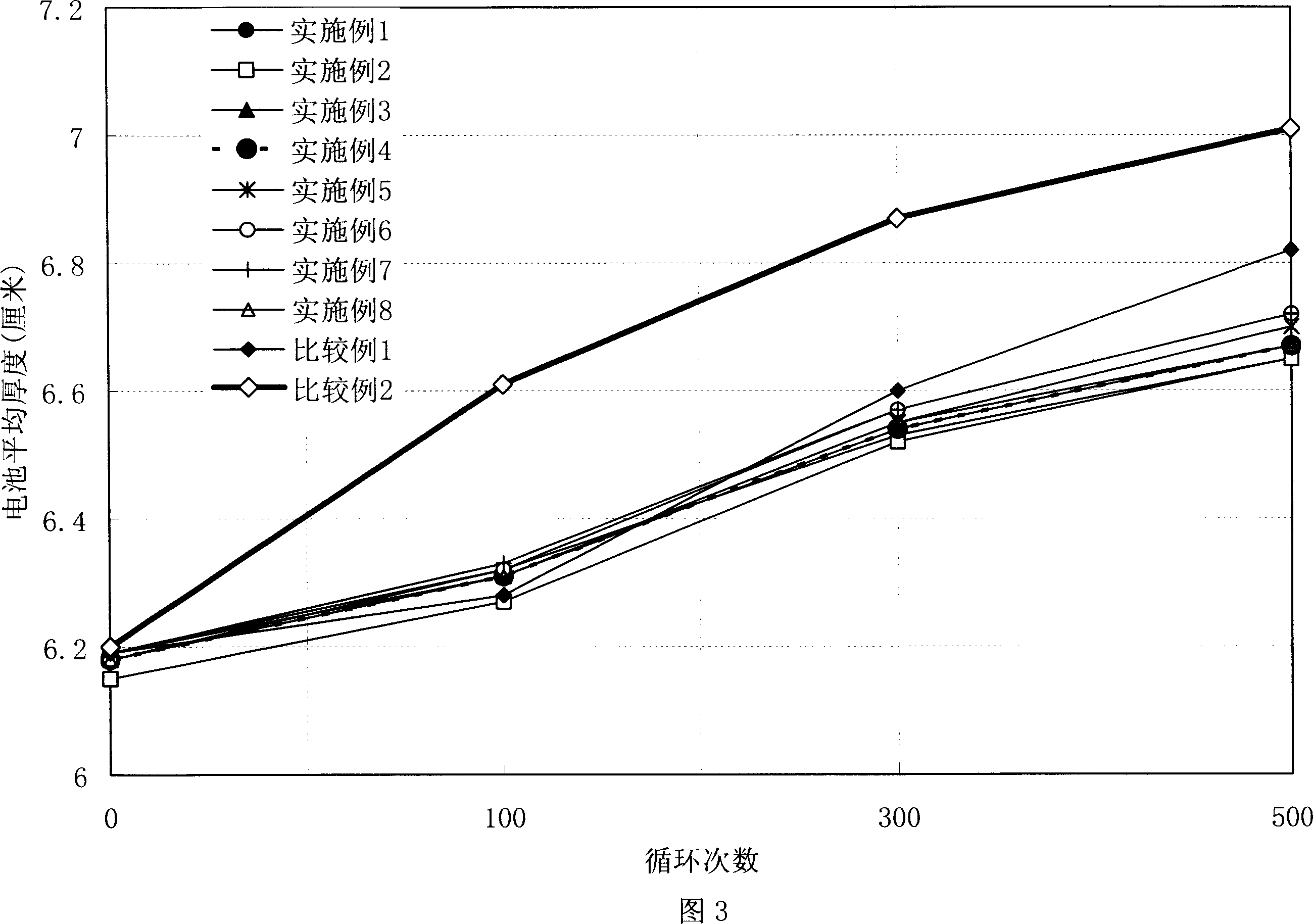

Electrolyte, lithium ion cell containing same and preparing process thereof

ActiveCN1949581AImprove overcharge safety performanceIncrease capacityFinal product manufactureOrganic electrolyte cellsAluminateLithium

The invention is an electrolyte, containing Li salt as electrolyte, organic solvent and additive, where the additive is selected from one or several of Li carbonate, Li sulfate, Li sulfite, Li nitrate, Li nitrite and Li aluminate. Thus, the overcharge safety and low temperature performance of a battery using the electrolyte containing inorganic matter additive are improved and there is no negative effect on the other performances of the battery, even obviously improved. And it not only enhances Li ion battery overcharge safety and improves the low temperature discharging performance, but also increases battery capacity, cycling performance, storage stability and reduces production cost.

Owner:BYD CO LTD

A coated bismuth oxy halide-based pigment

InactiveCN108699351AReduce warpagePromote migrationCosmetic preparationsToilet preparationsPhosphoric Acid EstersAlkaline earth metal

The present invention is directed to a coated bismuth oxy halide-based pigment having a coating comprising an antioxidant, said antioxidant is being a phenol based, a phosphite or phosphonate based, or a thioether based stabilizer, and the coating comprising an inner coating and an outer coating, wherein the outer coating comprises the antioxidant, and wherein the inner coating comprises a first layer consisting of one or more salts, or one or more oxides, heteropolyacids, organic acids, sulphites, sulfides, sulfates, phosphates, pyrophosphates, polyphosphates, hydrates, carbonates, or a combination thereof, selected from the group of alkali-earth metals, metals, non-metals, transition metals or lanthanides. Further, the present invention is directed to a composition comprising a paint, alacquer, an ink, a cosmetic, a resin, a plastisol or a polymer formulation, and such pigment. In addition, the present invention is directed to a method for manufacturing a coated bismuth oxy halide-based pigment, said method comprising the steps of: - providing a dispersion of a bismuth oxy halide-based pigment, adding a dispersion of an antioxidant, mixing and drying.

Owner:FELLOWES INC

Thiourea-and cyanide-free bath and process for electrolytic etching of gold

ActiveUS20050061683A1Little undercuttingWithout producing an undesirable amount of surface roughnessElectrolysis componentsConductive material chemical/electrolytical removalIodideEtching

An aqueous thiourea-free gold etching bath for electrolytically etching gold from a microelectronic workpiece. One embodiment of the aqueous thiourea-free bath contains: (a) about 0.5-1.5 M iodide; (b) about 0.1-0.3 M sulfite; and (c) about 1.0-3.0 g / L wetting agent. The bath is useful in a process for electrolytically etching gold from a microelectronic workpiece. A tool system in which the baths and processes of the present invention may be used is also described.

Owner:APPLIED MATERIALS INC

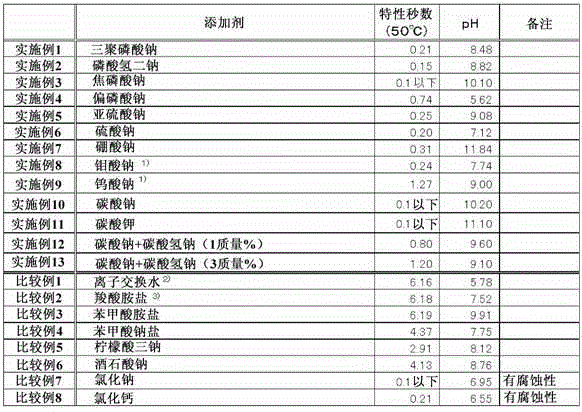

Water-based coolant

InactiveCN104136634AImprove cooling effectNot prone to corrosionHeat-exchange elementsAdditivesPhosphite saltPhosphate

This water-based coolant is characterized by being obtained by mixing at least one of each of the following inorganic acid salts: phosphate, phosphite, sulphate, sulphite, borate, molybdate, tungstate, carbonate, hydrogen carbonate, and sesquicarbonate. This water-based coolant exhibits excellent cooling performance, and excellent anti-corrosion properties towards metal materials to be cooled therewith, and thus is suitable for use as a cutting fluid and a quenching fluid for metal materials.

Owner:IDEMITSU KOSAN CO LTD

Goldplating solution unsubstituted with nickel

The present invention provides a gold-plating solution which can not be substituted by nickel. When the matrix for plating chemical nickel is not powdered with direct current, the matrix can not be substituted in the gold-plating solution to form layer with poor adhesive force, so that it can raise boding force of gold-plated layer on the matrix. Said invention water base gold-plating solution contains potassium dicyanoaurate, EDTA salt, pyrophosphite and thiourea. The use condition of gold-plating solution includes: temp. of plating solution is 55-60 deg.C, pH value is 7.5-10, current intensity is 0.04-0.5 A / sq.dm, and its power supply can be D.C. power supply or pulse square-wave power supply.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Alkaline phenolic resin old sand and regeneration method thereof

ActiveCN104826983AIncreased acid consumptionIncrease acid consumption valueFoundry mouldsFoundry coresUltimate tensile strengthLoss on ignition

The invention relates to a regeneration method of alkaline phenolic resin old sand. The regeneration method comprises the following steps of 1, adding 0.2-2% by mass of powder into alkaline phenolic resin old sand, carrying out mixing to obtain a uniform mixture, heating the mixture to a temperature of 600-800 DEG C, and carrying out hot method regeneration for 30-60min, and 2, screening the regenerative sand subjected to hot method regeneration to remove impurities of the regenerative sand so that the alkaline phenolic resin regenerative sand is obtained. The powder is high-valence carbonate or sulfite. The powder can be easily decomposed at a high temperature and form a corresponding oxide, the oxide is added into the regenerative sand and improves mold core strength and obviously improves regeneration effects, and the treated regenerative sand has obviously reduced acid demand value, pH value and loss on ignition, can replace original sand and can satisfy heating core and cooling core conditions. The regeneration method improves regenerative sand quality, reduces environmental pollution caused by old sand and has an important meaning for saving a casting enterprise molding material cost.

Owner:通辽市仁创铸造材料有限公司

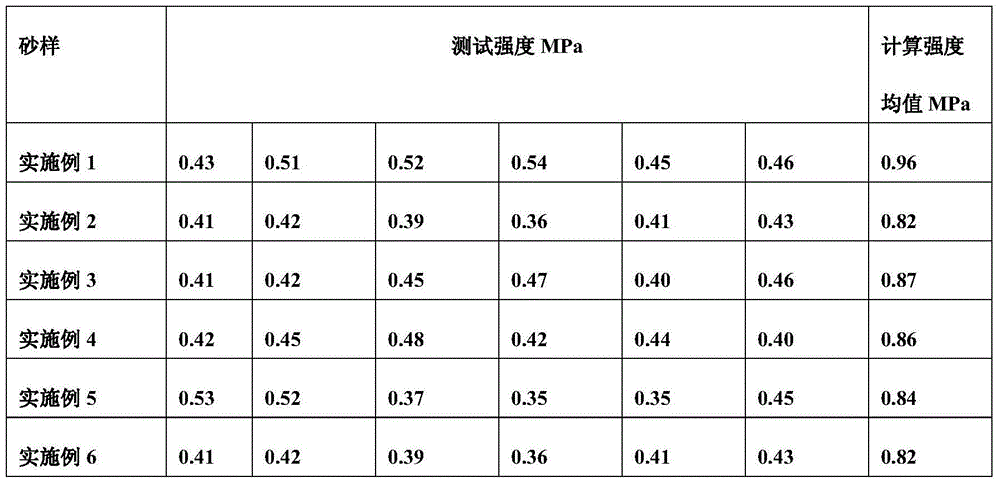

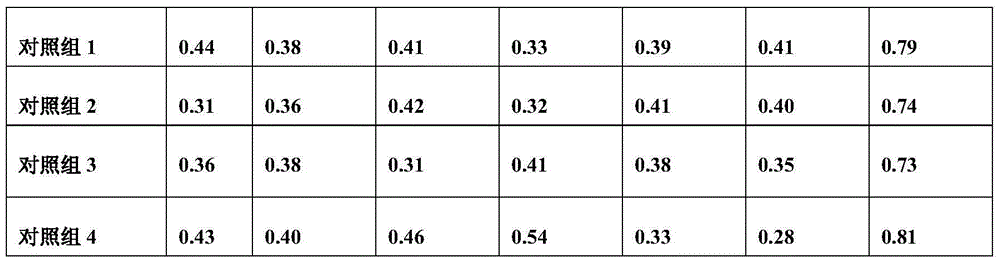

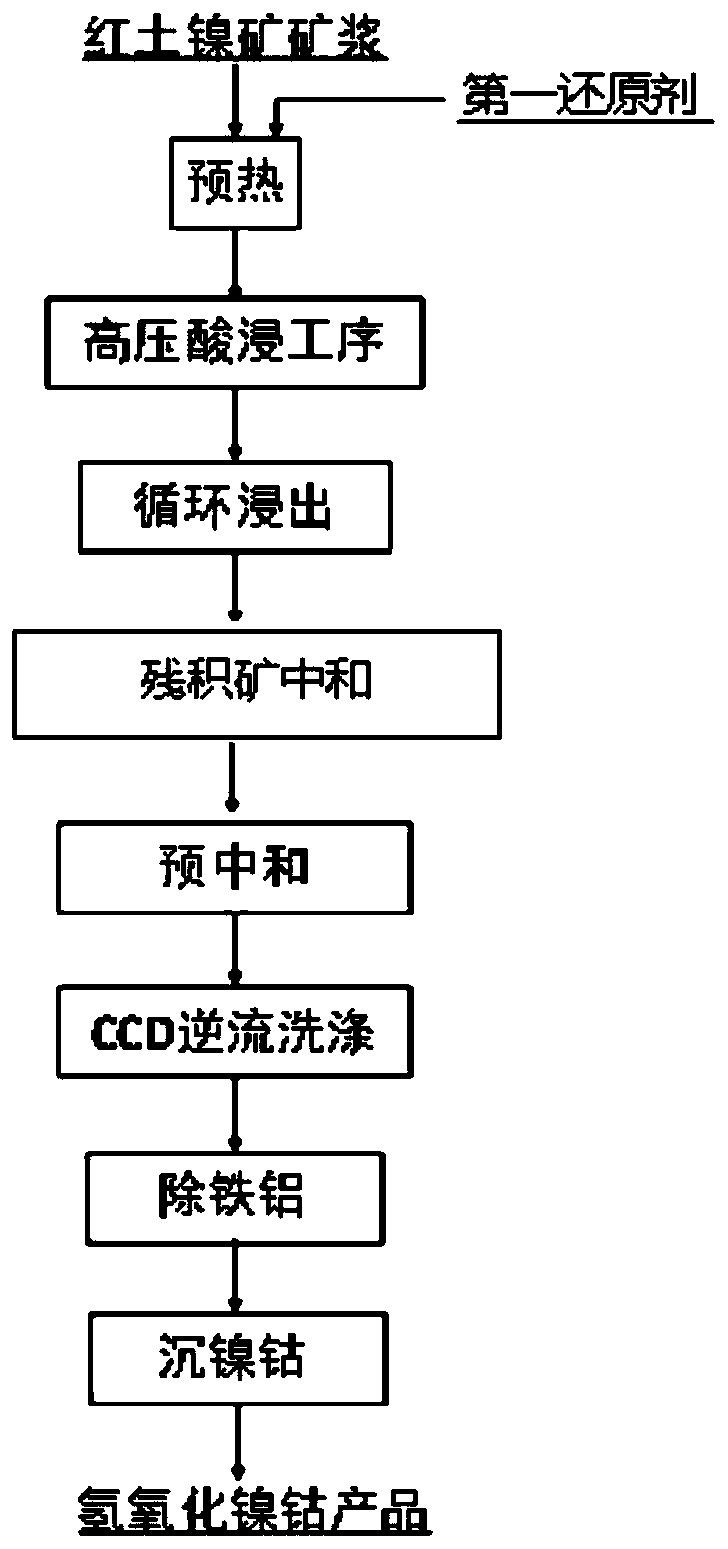

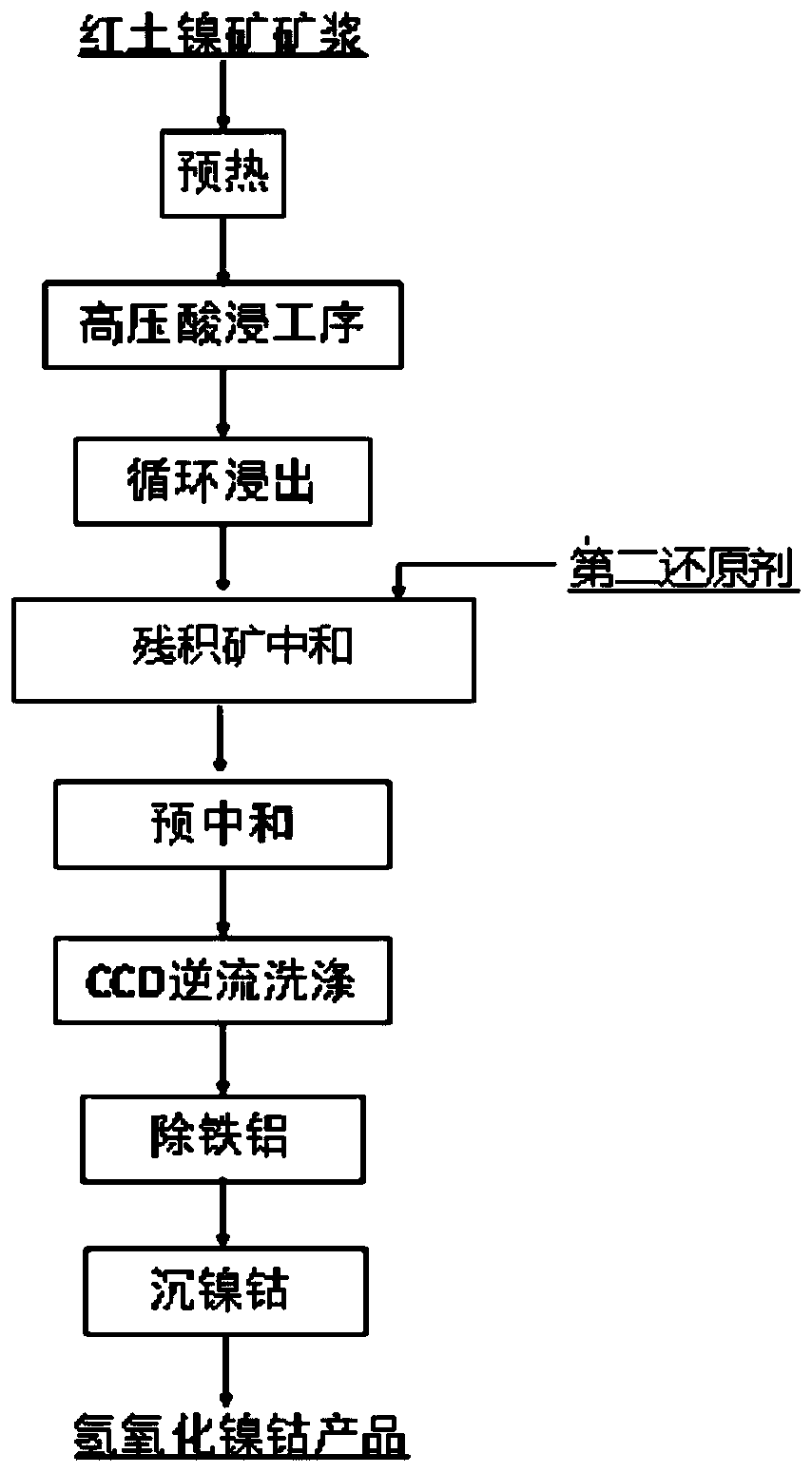

Method for removing hexavalent chromium in process of preparing cobalt nickel hydroxide from laterite-nickel ore

The invention provides a method for removing hexavalent chromium in the process of preparing cobalt nickel hydroxide from laterite-nickel ore. The method comprises the steps that before the high-pressure acid leaching step, laterite-nickel ore pulp is preheated, before the preheating step, a first reducing agent is added into the laterite-nickel ore pulp, and then the laterite-nickel ore pulp added with the first reducing agent is made to enter the high-pressure acid leaching step; wherein the first reducing agent is one or more of pyrite, sulfur and chromite, or organic wastewater; or, a second reducing agent is added into the leachate obtained in the cyclic leaching step, and then the residual ore neutralization step is executed; and the second reducing agent is one or more of sulfite, pyrosulfite, ferrite, thiosulfate, sulfide salt and bisulfite of alkali metal or alkaline-earth metal. By utilizing the method provided by the invention, hexavalent chromium can be removed from the source on the basis of not changing the high-pressure leaching procedure of the laterite-nickel ore, so that the nickel-cobalt hydroxide product is prevented from being carried out, and the original steps are not influenced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Product recovery process in the filtration of polyether polyols

InactiveUS20140303405A1Reduce leachingEther separation/purificationOrganic compound preparationTrans esterificationPtru catalyst

An improved method for recovering a purified polyether polyol comprising the steps of providing an aqueous solution of a polyether polyol containing an alkali metal catalyst residual formed from a transesterification process, contacting the aqueous solution with a stoichiometric excess of magnesium sulfate to form a second aqueous solution, removing water from said second aqueous solution at a temperature above the melt temperature of said polyether polyol to produce a dehydrated slurry containing a molten polyether polyol phase essentially free of residual alkali metal and a precipitated solid phase comprising sulfate and / or sulfite salts of the alkali metal catalyst, magnesium hydroxide, and excess magnesium sulfate and / or sulfide, passing the dehydrated slurry of through a filtration system comprising a filtration press to separate the molten polyether polyol phase from the precipitated solid phase, wherein the filtration press is treated with a filter aid that is essentially free of transition metal oxide content, separating the molten polyether polyol phase substantially free of water, residual alkali metal catalyst and transition metal contaminants from the precipitated solid phase and recovering polyether polyol from the separated polyether polyol phase.

Owner:INVISTA NORTH AMERICA R L

Method and system for capturing carbon dioxide and/or sulfur dioxide from gas stream

ActiveUS8771403B2Promote absorptionReduce energy demandGas treatmentLiquid degasificationSulfate sulfurProcess engineering

The present invention provides a system for capturing CO2 and / or SO2, comprising: (a) a CO2 and / or SO2 absorber comprising an amine and / or amino acid salt capable of absorbing the CO2 and / or SO2 to produce a CO2- and / or SO2-containing solution; (b) an amine regenerator to regenerate the amine and / or amino acid salt; and, when the system captures CO2, (c) an alkali metal carbonate regenerator comprising an ammonium catalyst capable catalyzing the aqueous alkali metal bicarbonate into the alkali metal carbonate and CO2 gas. The present invention also provides for a system for capturing SO2, comprising: (a) a SO2 absorber comprising aqueous alkali metal carbonate, wherein the alkali metal carbonate is capable of absorbing the SO2 to produce an alkali metal sulfite / sulfate precipitate and CO2.

Owner:RGT UNIV OF CALIFORNIA

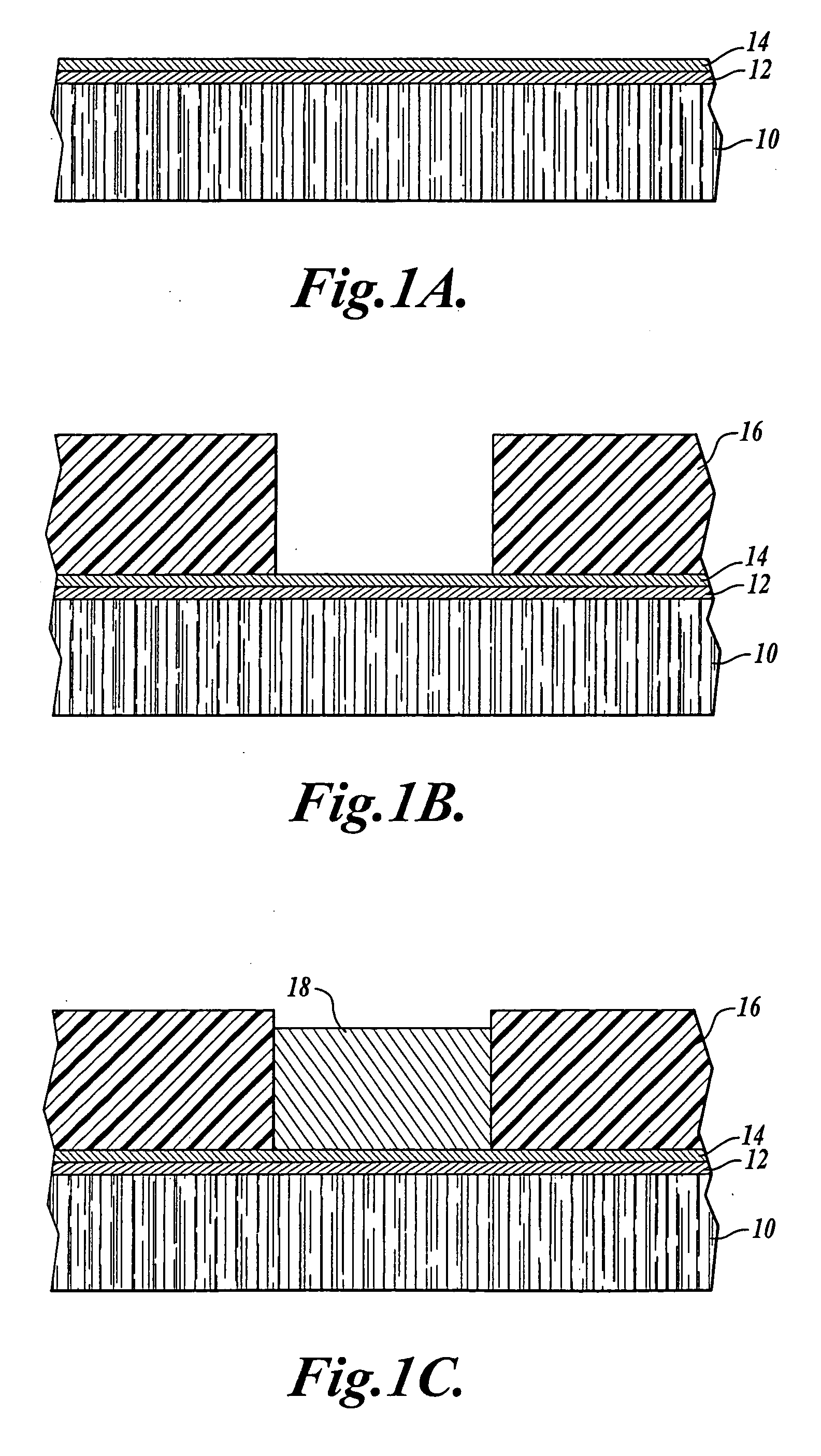

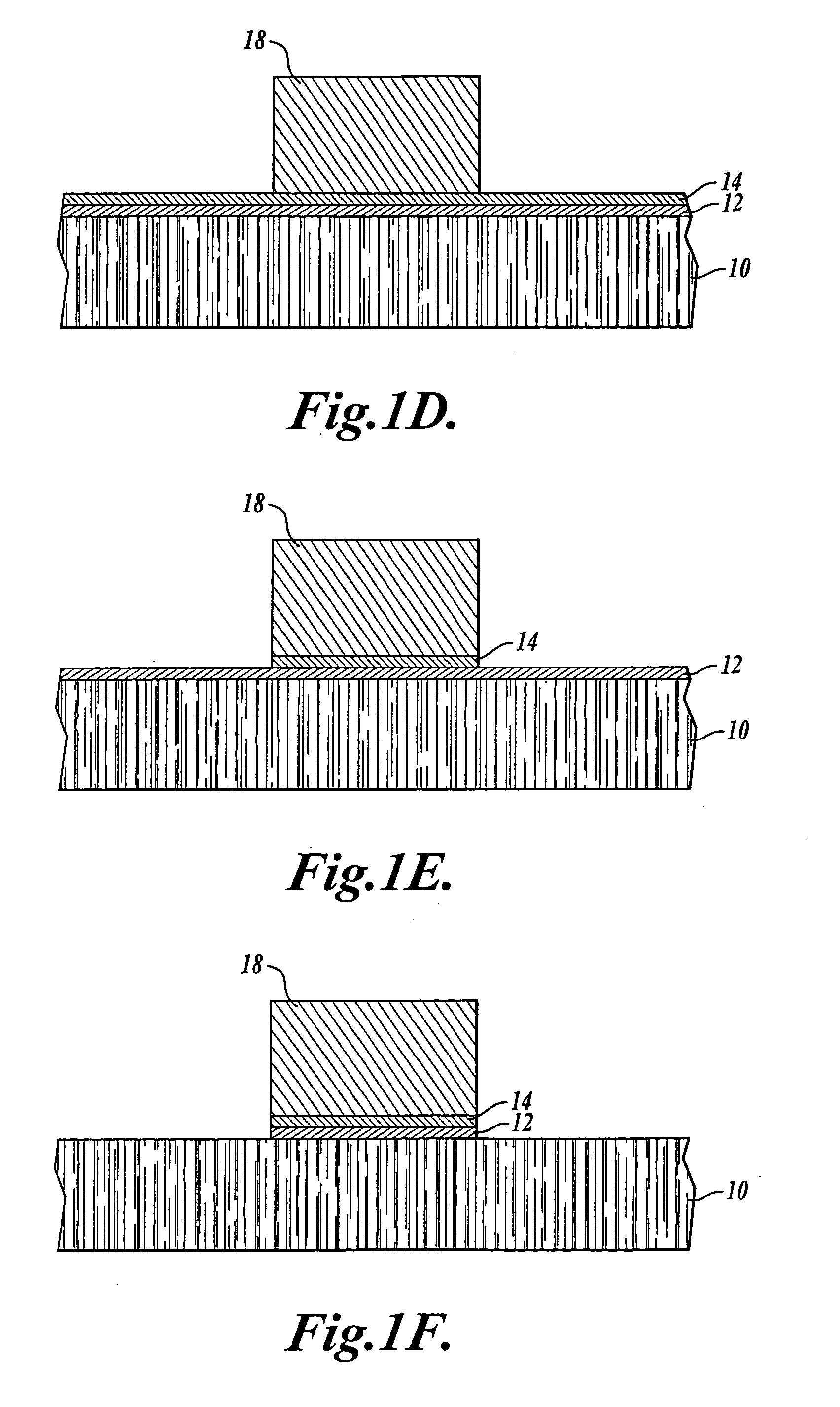

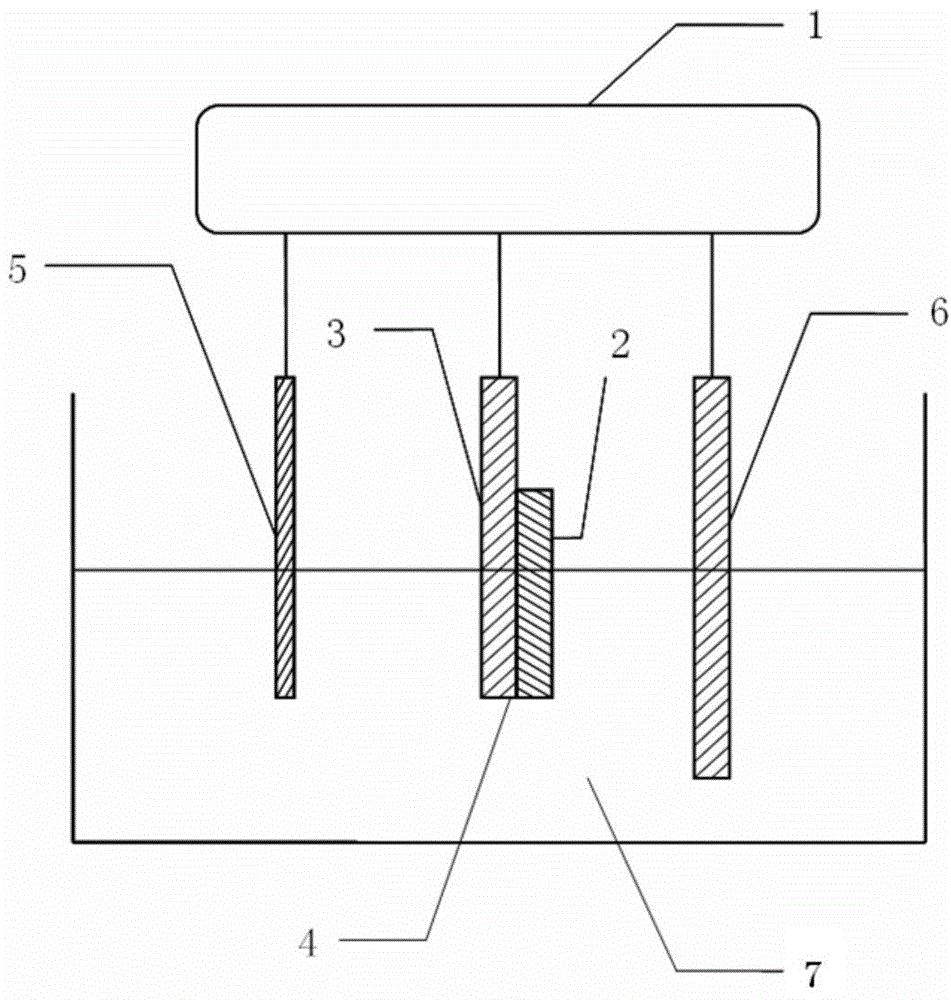

Electrochemical treatment method for surface etching of absorption layer of copper zinc tin sulfide thin film solar cell

ActiveCN105633198AIncrease roughnessEffective dissolutionFinal product manufactureSemiconductor devicesMetallic sulfideNitrogen gas

The invention relates to the technical field of solar cells, and specifically discloses an electrochemical treatment method for surface etching of an absorption layer of a copper zinc tin sulfide thin film solar cell. The method includes the steps of: placing a copper zinc tin sulfide thin film in an electrochemical workstation after selenylation or sulfuration, only connecting a Mo layer with a working electrode, soaking in absolute ethyl alcohol to remove particle impurities; preparing a treatment solution which is a mixed solution of sulfite, metal sulfide and deionized water and whose pH value is 8 to 14; applying an electrical signal, taking the copper zinc tin sulfide thin film out after 1 to 600 seconds, using deionized water to wash the thin film, and drying the thin film with high-purity nitrogen, the electrical signal being any one of a cyclic voltammetry electrical signal, a constant voltage electrical signal, a constant current electrical signal, a pulse voltage electrical signal or a pulse current electrical signal. The method provided by the invention can effectively dissolve a harmful secondary phase protruding from the surface of the thin film, etches defects of the surface of the thin film, reduces the recombination rate of photon-generated carrier pairs at an interface, is environment-friendly, and facilitates industrial popularization.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Desulfurized ash-based cementing material, and preparation method and application thereof

PendingCN112960922AEmission reductionReduce secondary pollutionCement productionStrong acidsPhysical chemistry

The invention discloses a desulfurization ash-based cementing material, and a preparation method and application thereof. The desulfurization ash-based cementing material is mainly prepared by doping a certain amount of an H4000 surfactant into industrial waste residues such as desulfurization ash, S95-grade mineral powder, boiler ash, fly ash and the like at normal temperature and normal pressure. The preparation method solves the limitation of the existence of unstable sulfite in the desulfurized fly ash components on the materialization application of the desulfurized fly ash components, and has the advantages of simple process, wide raw material source, no addition of strong acid, strong alkali and other easily-corrosive reagents, low energy consumption and small secondary pollution. In addition, the desulfurized ash-based cementing material has the characteristics of high early strength, large softening coefficient, continuously increased later strength and the like, can be applied as a wall material and a road roadbed material, and has a wide prospect.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY +1

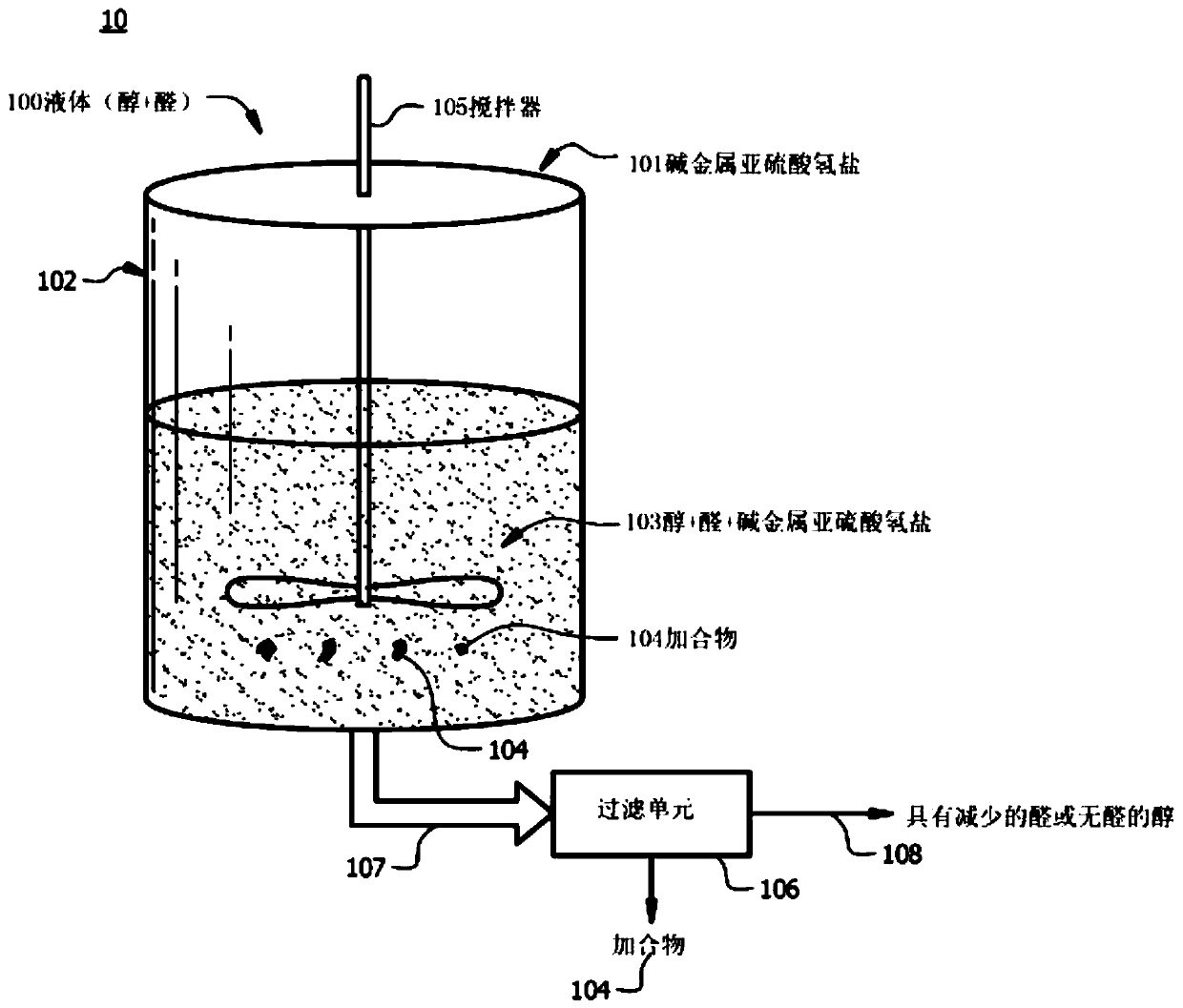

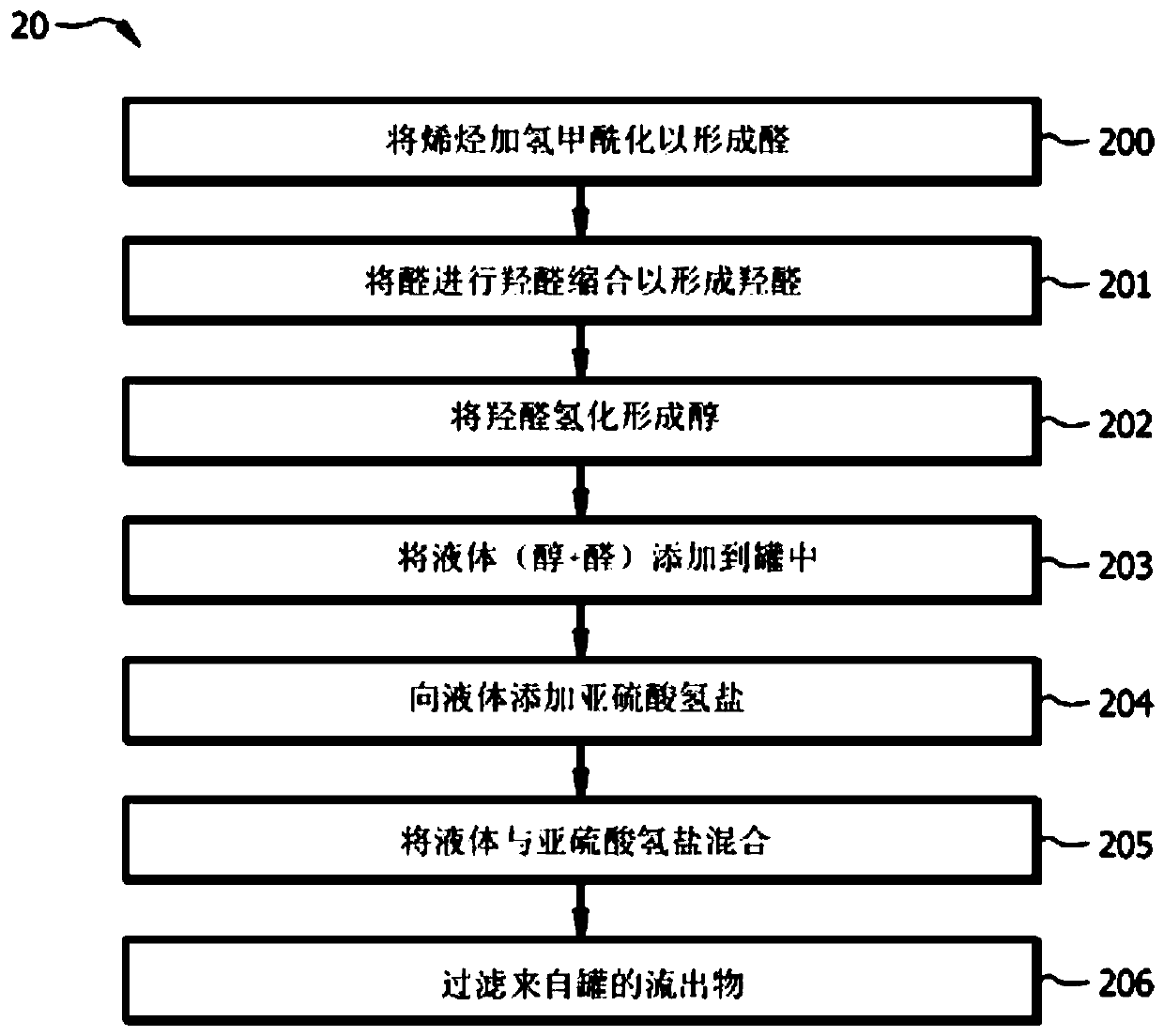

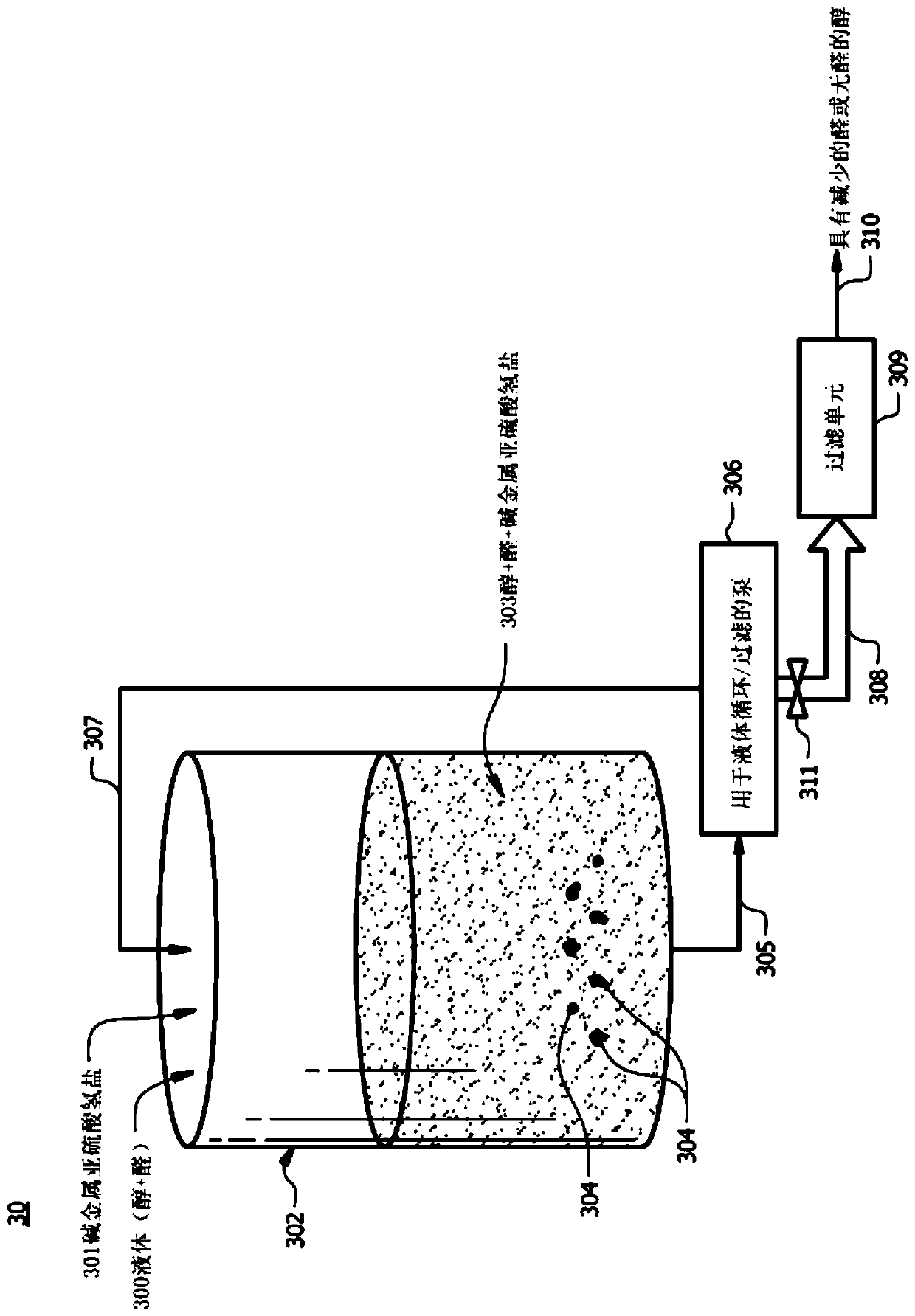

Process for aldehyde removal from alcohols by treatment with bisulphite

ActiveCN111164065AOrganic compound preparationHydroxy compound separation/purificationBisulphite saltAlcohol

A process of purifying alcohol produced in a process that includes the Oxo process is disclosed. Aldehyde from the Oxo process that remains with the alcohol is removed by a reaction with an alkali sulphite to produce an insoluble adduct and alcohol having a reduced amount of aldehyde mixed with it. The adduct is removed from the alcohol by filtration.

Owner:SABIC GLOBAL TECH BV

High alkaline cleaners, cleaning systems and methods of use for cleaning zero trans fat soils

ActiveUS11118137B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentEnvironmental engineering

The present disclosure relates to high alkaline cleaners, cleaning systems and methods for removing polymerized zero trans fat soils. The high alkaline cleaner of the present invention generally includes one or more alkaline wetting and saponifying agent(s), a chelating / sequestering system and a surface modifying-threshold agent system. In various embodiments, the cleaners may include, at least one cleaning agent comprising a surfactant or surfactant system and / or a solvent or solvent system and / or a cleaning booster such as a peroxide or sulfite type additive. The cleaners may also include one or more components to modify the composition form and / or the application method in some embodiments. All components described above may also be optimized optionally, to provide emulsification of a composition (both as a usable product or a concentrate that can be diluted to form a usable product). The use of the high alkaline cleaner of the present invention has demonstrated enhanced cleaning characteristics especially at higher temperatures (100° F. to about 300° F.) but also shows enhanced cleaning at ambient temperatures.

Owner:ECOLAB USA INC

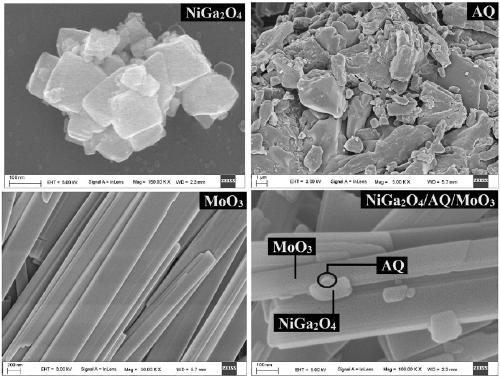

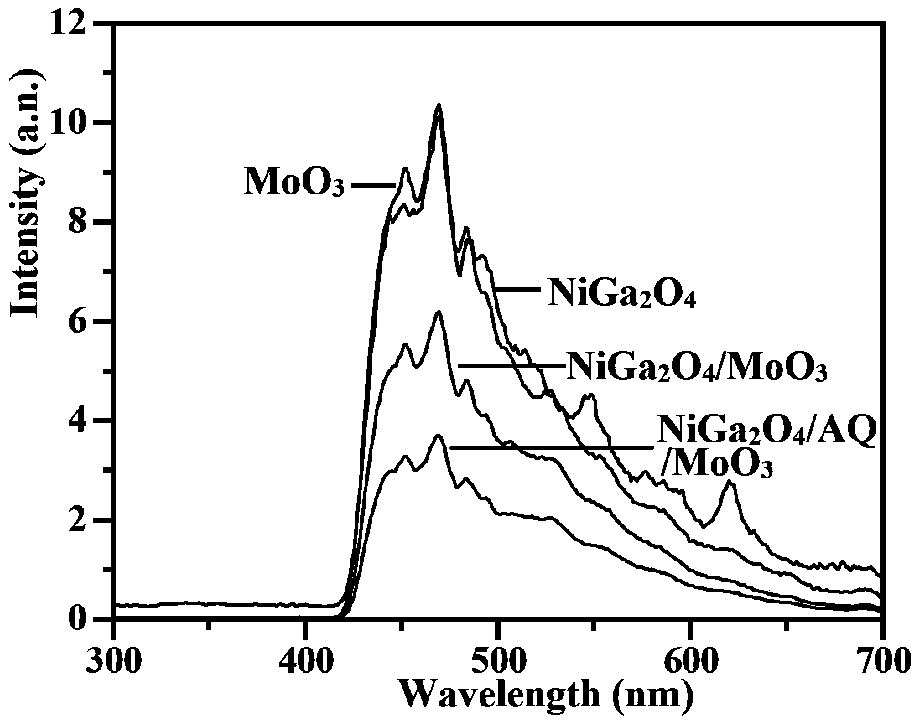

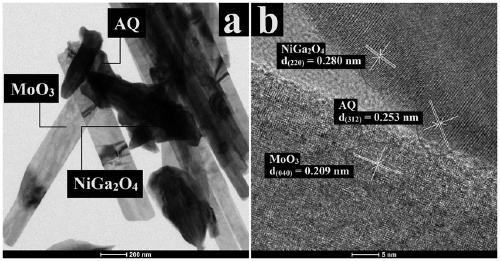

Novel photocatalyst NiGa2O4/AQ/MoO3 as well as preparation method and application thereof

ActiveCN109433273AStable in natureImprove efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsNanotechnologyNitriteAlcohol

The invention relates to a novel photocatalyst NiGa2O4 / AQ / MoO3 as well as a preparation method and application thereof, and belongs to the technical field of a photocatalyst. A hydrothermal method isused for preparing NiGa2O4 / AQ / MoO3; nanometer NiGa2O4 / AQ and nanometer MoO3 are added into absolute ethyl alcohol; after ultrasonic dispersion, obtained suspension liquid is heated and boiled to the boiling state, and is then subjected to constant temperature treatment for 30 min; after the filtering, obtained filtered materials are dried for 8.0 h to obtain powder; the powder is ground to obtainNiGa2O4 / AQ / MoO3. The prepared NiGa2O4 / AQ / MoO3 composite material shows efficient and stable photocatalysis activity in the nitrite and sulphite conversion process; wide application prospects are realized in nitrite and sulphite waste water treatment.

Owner:LIAONING UNIVERSITY

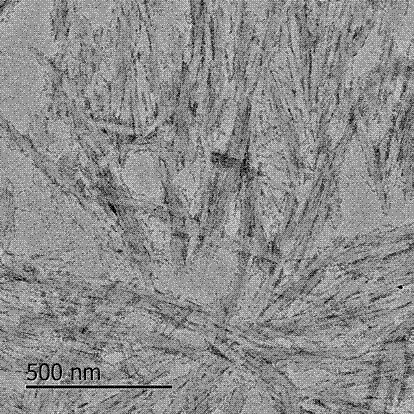

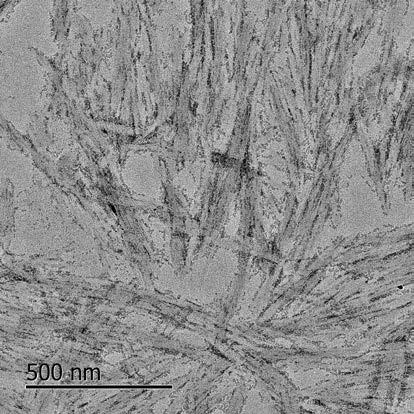

A method for preparing nanofibril cellulose with high aspect ratio by using camellia oleifera husk

ActiveCN107190546BHigh reactivityLarge specific surface areaPulp bleachingPulping with inorganic basesCelluloseCamellia oleifera

The invention relates to a method for preparing nano-filament cellulose with a high length-diameter ratio by using camellia oleifera shells, belonging to the technical field of nano structure materials. The method comprises the steps of pretreating the camellia oleifera shells serving as an initial raw material by using a sulfite alkaline method, carrying out alkali purification, bleaching by using hydrogen peroxide to obtain camellia oleifera shell cellulose; after that, using a TEMPO / NaClO / NaBr medium oxidation system to treat a great deal of carboxyl groups introduced to fibers of the camellia oleifera shell cellulose, and then further carrying out high-pressure homogenization treatment so as to finally obtain the nano-filament cellulose with the high length-diameter ratio. The method is simple in production technology and easy to implement, and not only well improves the comprehensive utilization value of the camellia oleifera shells and meets the requirements of the sustainable development strategy of China, but also can be used for preparing the nano-filament cellulose which has the high length-diameter ratio and the characteristics of being good in mechanical properties, biodegradable, easy to compound, and the like, thus being widely applied to the industrial fields such as optics, electrics and semiconductor devices.

Owner:HUNAN UNIV OF TECH

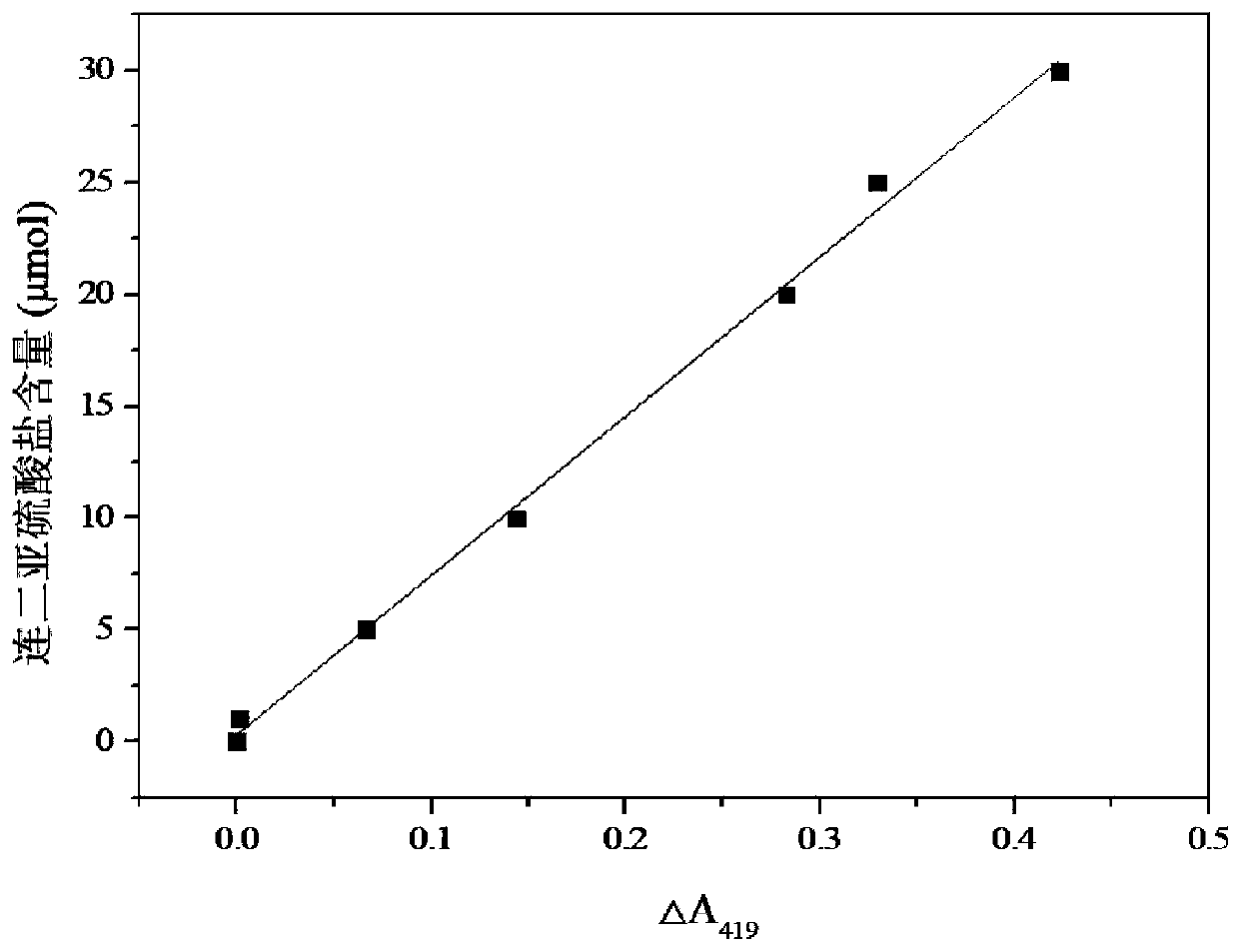

Method for measuring dithionite by potassium ferricyanide differential spectrophotometry

InactiveCN110793925AImprove accuracyReduce mistakesColor/spectral properties measurementsDithionous acidPotassium cyanide

The invention discloses a method for measuring dithionite by potassium ferricyanide differential spectrophotometry, which aims at the problems that in the prior art, when the content of dithionite ismeasured by use of a potassium ferricyanide differential titration method, the detection limit is high, and the detection requirement of low-concentration dithionite cannot be met. The method comprises the following steps: (1) adding an alkaline substance to enable a reaction to occur under an alkaline condition; (2) sequentially adding a potassium ferricyanide solution and a dithionite sample tobe measured into the alkaline substance, oscillating and shaking to enable the substances to react fully; and (3) detecting a difference value between absorbance values before and after the sample tobe measured is added through spectrophotometry, substituting the difference value into a standard curve equation, and calculating to obtain the content of the dithionite in the sample to be measured.According to the method of the invention, the content of the sample to be measured is reflected through the absorbance change of the potassium ferricyanide after being reduced and consumed by the dithionite under alkaline conditions, thus the method has accurate measurement result, wide detection range and small instrument limiting factor, and is convenient for conventional laboratories to use.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Solution for direct chemical copper plating of aluminum substrate and application method thereof

ActiveCN112593219ANot easy to attackNo obvious damageLiquid/solution decomposition chemical coatingActive agentSurface-active agents

The invention discloses a solution for direct chemical copper plating of an aluminum substrate and an application method thereof. The solution comprises the following components of, in percentage by mass, 5-15 g / L of copper salt, 20-60 g / L of sulfite, 10-50 g / L of complexing agent, 10-30 g / L of reducing agent, 10-50 g / L of buffering agent, 0.05-0.5 g / L of corrosion inhibitor, 0.05-0.1 g / L of surfactant and the balance water, and the copper plating solution is formed by uniformly mixing the components according to the proportion and adjusting the pH value to 7.0-8.0 by using a buffer agent. Thesolution for direct chemical copper plating of the aluminum substrate solves the problem that traditional copper plating corrodes aluminum and the problem that a plating solution attacks photoresist,in the field of wafer-level packaging, vacuum copper plating can be completely replaced, the cost is reduced, and the productivity is improved.

Owner:江苏矽智半导体科技有限公司

A kind of method utilizing camellia oleifera husk to prepare cellulose nano-whiskers

ActiveCN107419574BLarge specific surface areaStrong Young's modulusPretreatment with alkaline reacting compoundsPulp bleachingCelluloseOXALIC ACID DIHYDRATE

The invention discloses a method for utilizing camellia oleifera abel fruit shells to prepare cellulose nano-crystal whiskers, and belongs to the technical field of energy chemical materials. According to the method, the camellia oleifera abel fruit shells serve as initial raw materials, and firstly, the fruit shells are subjected to sulphite alkali pretreatment, alkali purification and hydrogen peroxide bleaching to obtain camellia oleifera abel fruit shell cellulose; secondly, the camellia oleifera abel fruit shell cellulose is subjected to acidolysis with organic acid namely oxalic acid, and the camellia oleifera abel fruit shells cellulose can be prepared after centrifugation and ultrasonic dispersion. According to the method, the production process is simple and easy to implement, and not only can the comprehensive utilization value of the camellia oleifera abel fruit shells be well improved, but also the prepared cellulose nano-crystal whiskers have the advantage of being good in mechanical performance, biodegradable, easy to compound and the like and can be widely applied to packaging toughening materials, optoelectronics and semiconductor devices and other industrial fields.

Owner:HUNAN UNIV OF TECH

A kind of cyanide-free sulfite gold plating solution and its application

The invention relates to the field of gold plating, and discloses a cyanide-free sulfite gold plating solution and an application thereof. The cyanide-free sulfite gold plating solution contains gold sulfite, alkali metal sulfite, and 3-nitrobenzenesulfonic acid Salts, organic polyamines, organic phosphonates, polyol compounds, high molecular polymers containing imines, and thiourea compounds. The cyanide-free sulfite gold plating solution provided by the present invention contains a current efficiency stabilizer with excellent properties, which participates in the reduction process of the cathode during the gold plating process, and prevents the occurrence of chemical side reactions, thereby improving the current efficiency, which is obviously beneficial Improve the throwing ability of the plating solution. And it improves a series of problems such as the inaccurate prediction of the amount of gold plating caused by the low current and unstable current efficiency, the relatively poor dispersion ability of the plating solution and the low current density.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

Carbon steel corrosion inhibitor used in oxygen-containing brine and preparation method thereof

PendingCN110952103AGood corrosion inhibitionSolve the requirements of corrosion resistanceSulfatePhysical chemistry

The invention relates to a carbon steel corrosion inhibitor used in oxygen-containing brine and a preparation method thereof. The corrosion inhibitor includes 1-10 wt% of shrimp shell powder, 10-30 wt% of alkali metal sulfite, 5-25wt% of alkali metal silicate, 5-15 wt% of higher fatty acid glyceride and the balance water. The prepared corrosion inhibitor is added into the oxygen-containing brine according to a certain proportion, after verification, the corrosion rate of carbon steel is lower than 0.1 mm / a, the carbon steel corrosion inhibitor can serve as the corrosion inhibitor for the carbon steel in the oxygen-containing brine, and the characteristics that cost is low, the effect is good, and environment protecting is achieved are achieved.

Owner:WANHUA CHEM GRP CO LTD

Cyanide-free sulfite system electrogilding solution and application thereof

PendingCN113862736AImprove stabilityQuality improvementProcess efficiency improvementGold contentCerium

The invention discloses a cyanide-free sulfite system electrogilding solution and application thereof. The cyanide-free sulfite system electrogilding solution comprises the following raw materials: 10 g / L-30 g / L of gold sulfite (in terms of gold element), 50 g / L-250 g / L of alkali metal sulfite, 130 g / L-280 g / L of an auxiliary complexing agent, 50 g / -120 g / L of conductive salt and 0.08 g / L-1 g / L of a composite additive. The composite additive comprises an organic additive and an inorganic additive, the organic additive at least contains an alcohol additive, and the inorganic additive at least contains any one of antimony, cerium, copper, tellurium and bismuth ions. The cyanide-free sulfite system electrogilding solution researched and developed is high in gold content, simple in component, stable in property, wide in pH value range, good in deep plating capacity, relatively high in cathode current density and high in current efficiency, and can be applied to preparation of a thick gold layer.

Owner:深圳市潮尊珠宝首饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com