Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "Not prone to corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

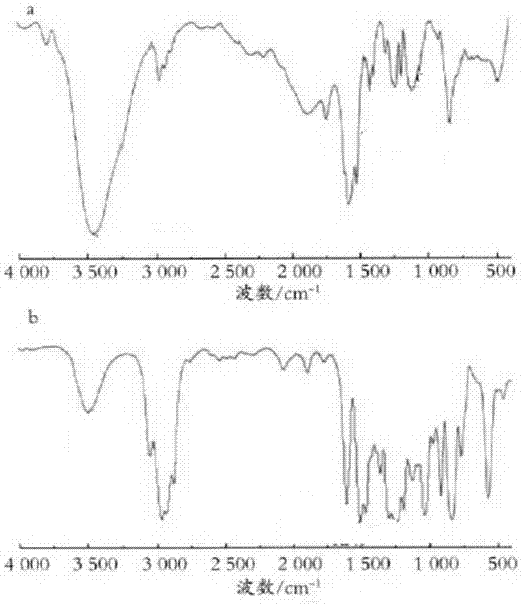

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

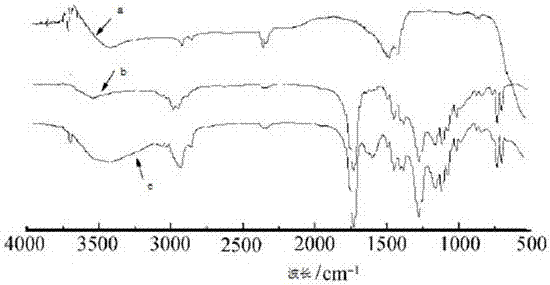

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

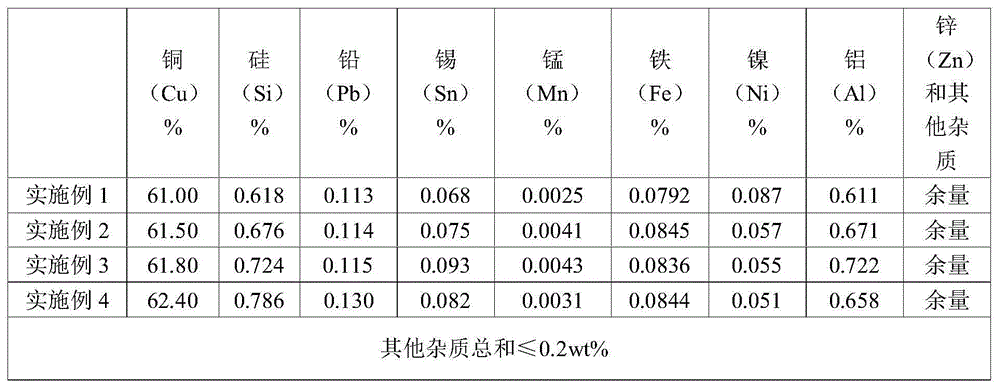

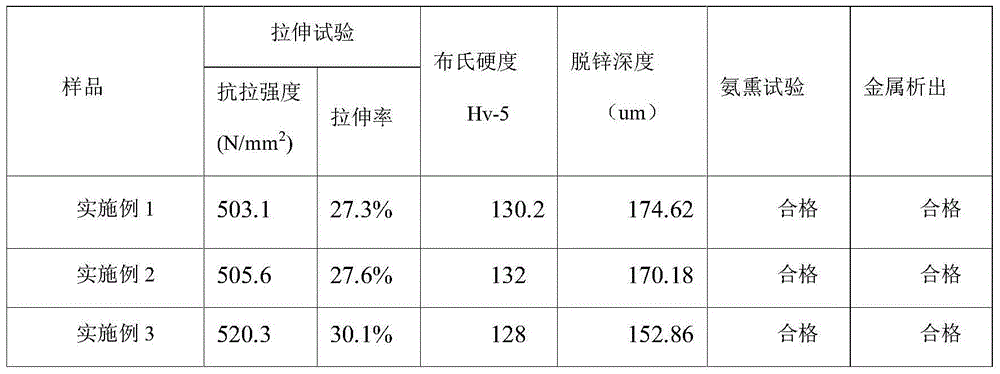

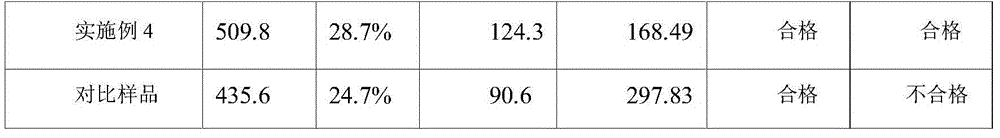

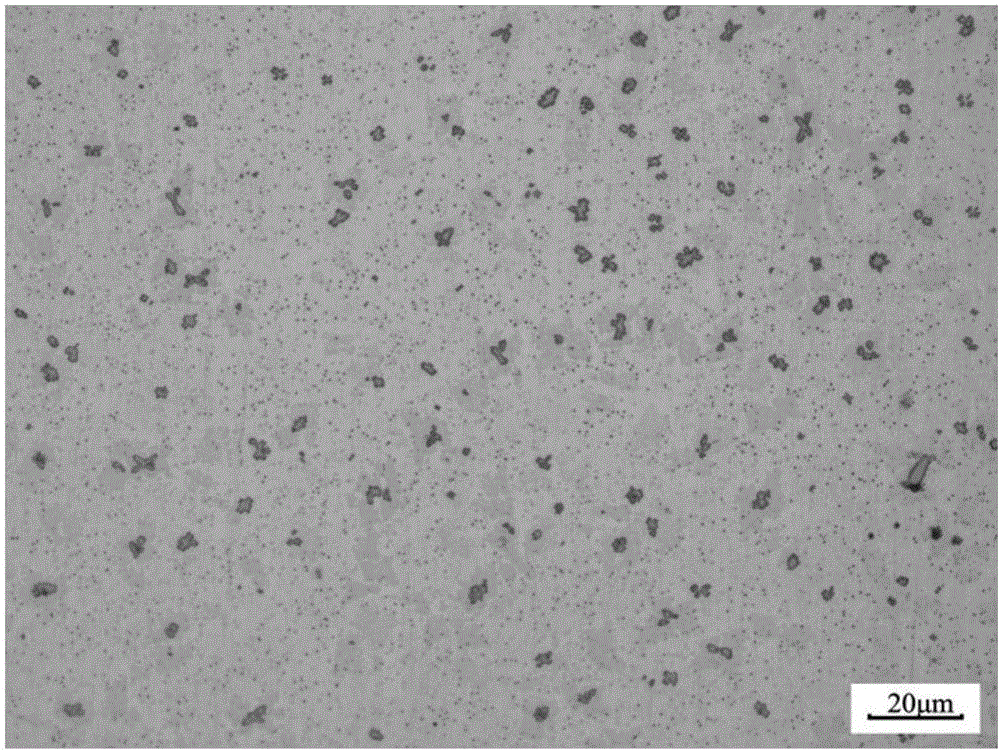

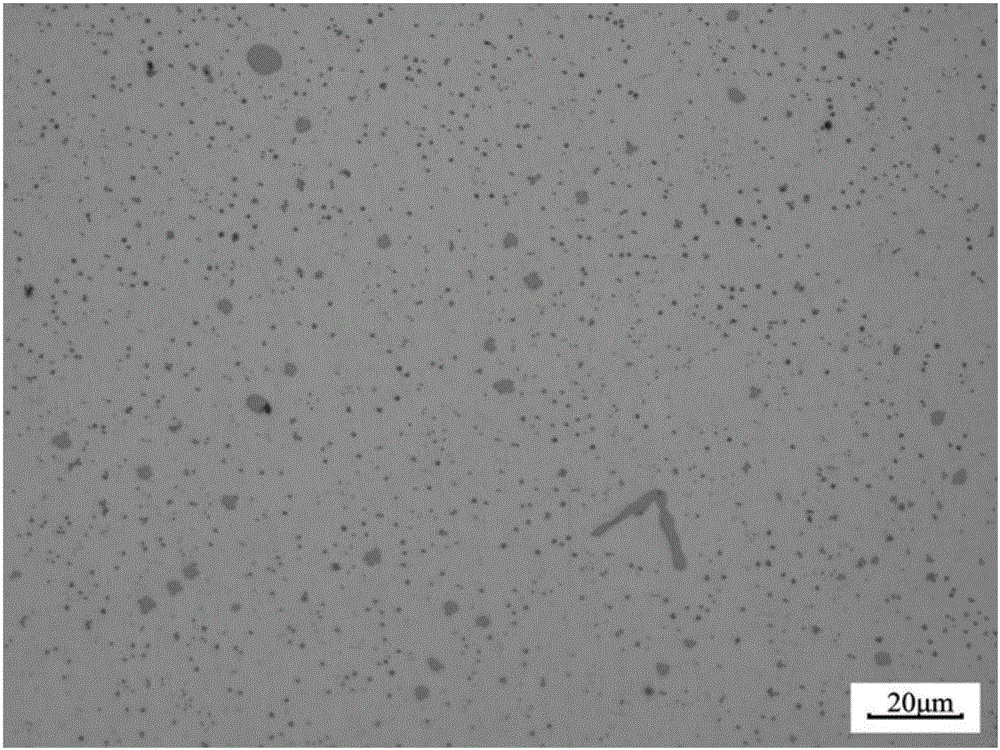

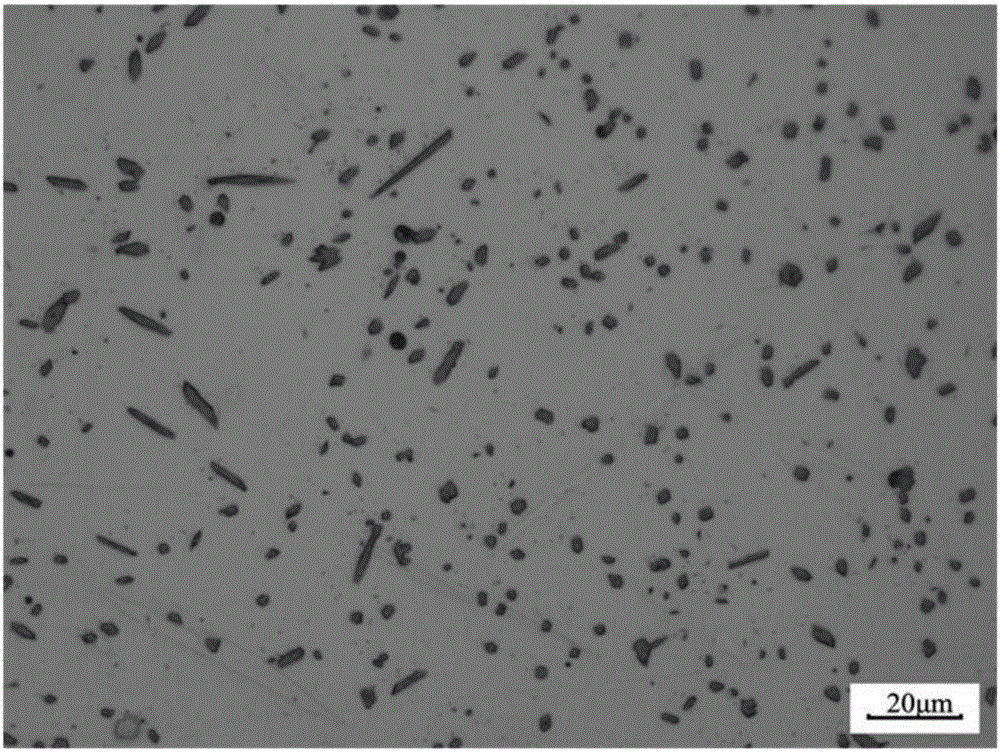

Easily processed silicon brass alloy and preparation method thereof

The invention discloses an easily processed silicon brass alloy. The alloy comprises the following components in percentage by weight: 60-63% of copper (Cu), 0.50-0.90% of silicon (Si), 0.50-0.80% of aluminum (Al), 0.10-0.20% of lead (Pb), less than 0.3% of other elements, and the balance of zinc (Zn) and inevitable impurities, wherein the sum of copper, silicon, aluminum and zinc is more than 99.60%, and other elements are a combination of tin (Sn), manganese (Mn), ferrum (Fe) and nickel (Ni). The invention further comprises a preparation method of the silicon brass alloy. The prepared silicon brass alloy is obviously higher than common lead brass in the performances of tensile strength, elongation rate, hardness and anti-zinc removal, the casting processability is good, practical production and application demands can be met, the precipitation of metals can meet the standard requirements, and the easily processed silicon brass alloy can be widely applied to water heating, valves and other various industries having limit on the precipitation of metal pollutants.

Owner:JOMOO KITCHEN & BATHROOM

Fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing as well as preparation method thereof

The invention belongs to the technical field of metal processing and particularly relates to fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing as well as a preparation method thereof. The fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing comprises the following components in parts by weight: 5 to 25 parts of carboxylic acid ammonium salt composite antirust agent, 5 to 30 parts of sulfonated castor oil, 2 to 15 parts of water-soluble lubricating agent, 1 to 6 parts of monoacid, 0.5 to 2 parts of mildew-proof fungicide,0.02 to 1 part of defoaming agent and 20 to 55 parts of water. According to the fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing, which is provided by the invention, through compounding of the sulfonated castor oil and the water-soluble lubricating agent, high lubricating property is provided, and the fully-synthesized environmentally-friendly cutting liquidfor aluminum alloy processing serves as a cutting liquid product not containing oil and can replace semi-synthesized cutting liquid with low oil content under the same condition; in addition, throughcompounding of castor oil acid, organic acid and special alcohol amine, the protective effect that aluminum alloy is not liable to change color is achieved, and high lubricating requirement in the processing process of the aluminum alloy is met.

Owner:GUANGZHOU LANDNOK CHEM TECH

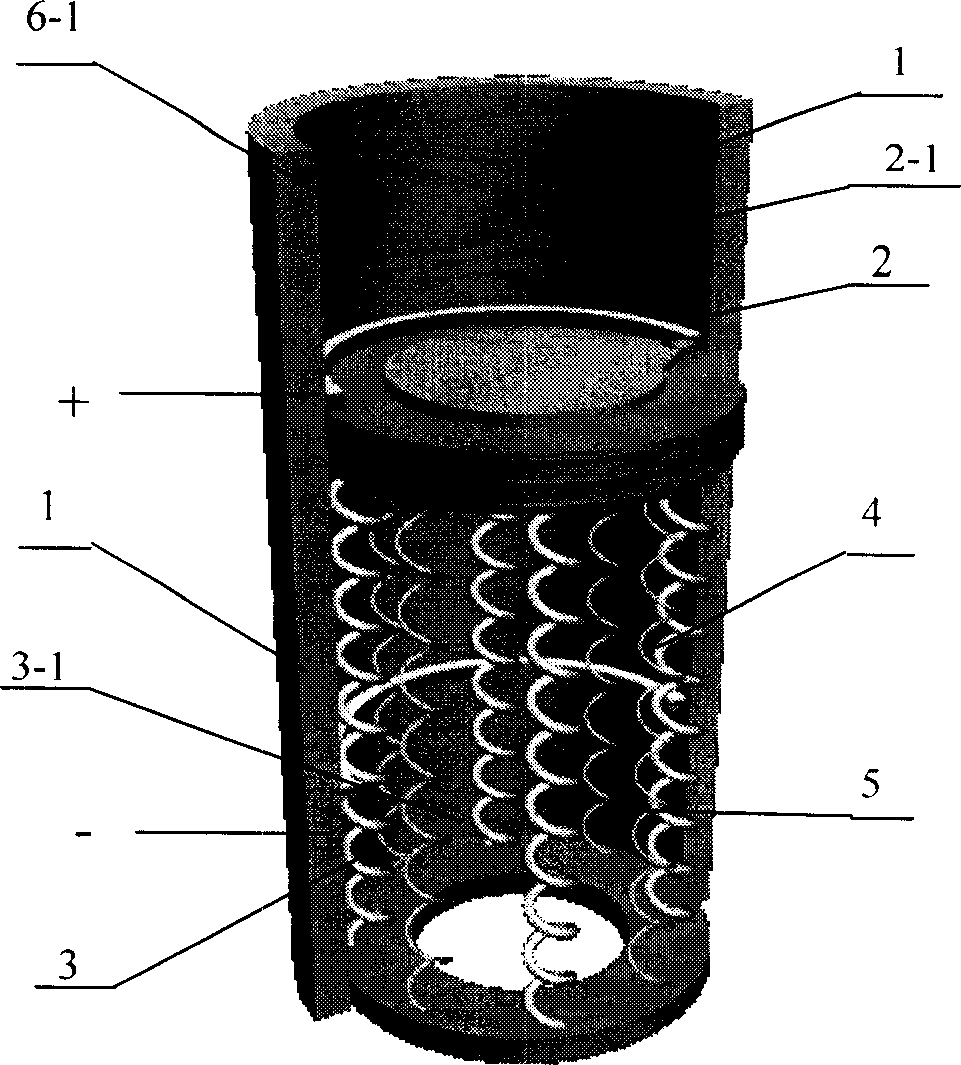

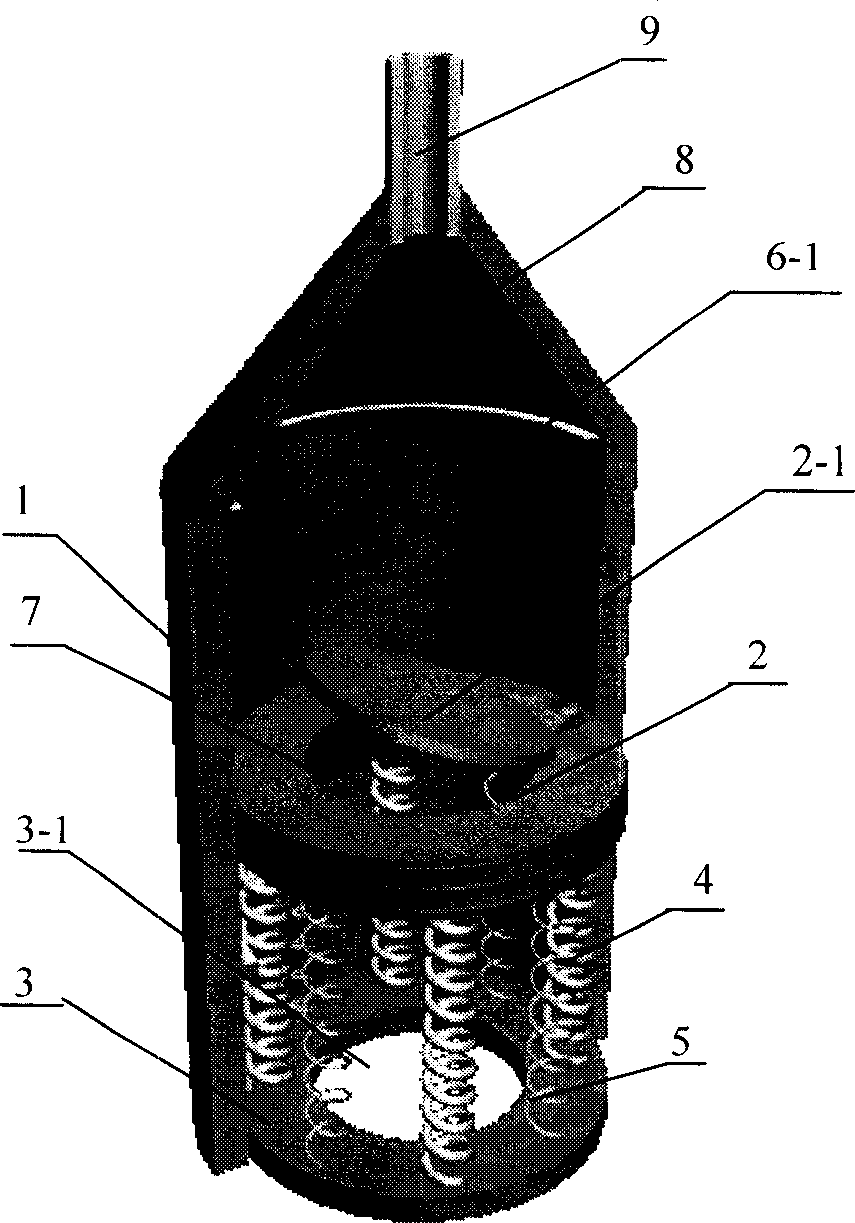

Piston type liquid spraying device driven by marmen

InactiveCN1718289ASimple structureReduce volumeMachines/enginesLiquid spraying apparatusCoil springShape-memory alloy

A pi ston-type liquid spraying apparatus driven by marmem driver has a cylinder with annular bottom plate, a piston with check valve, and marmem drive between said bottom plate and piston. It features simple structure and low cost and noise.

Owner:HARBIN INST OF TECH

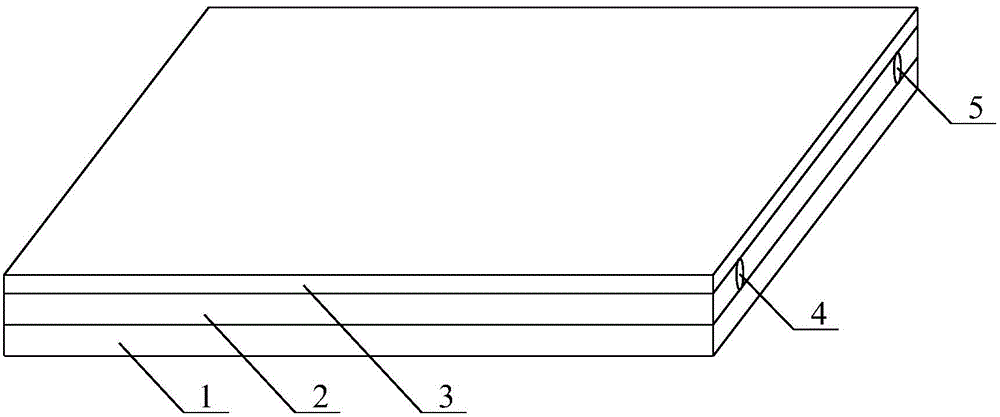

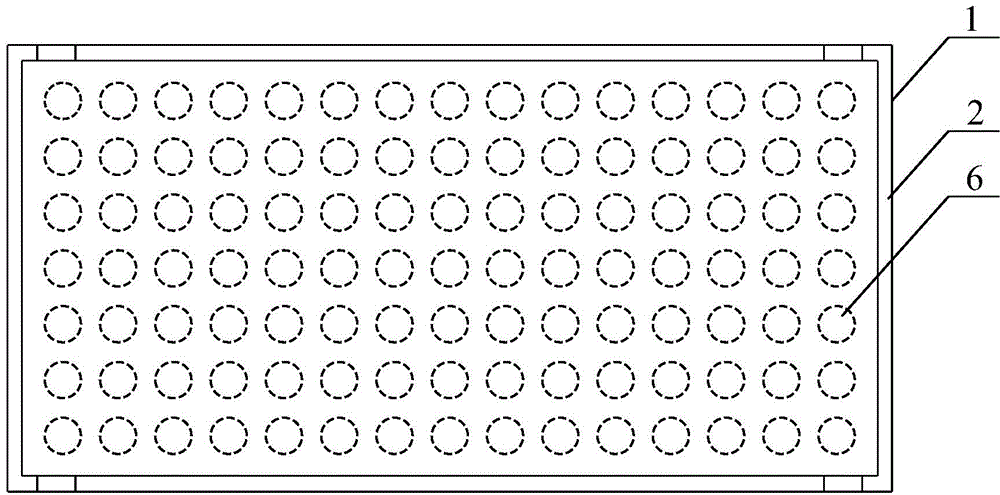

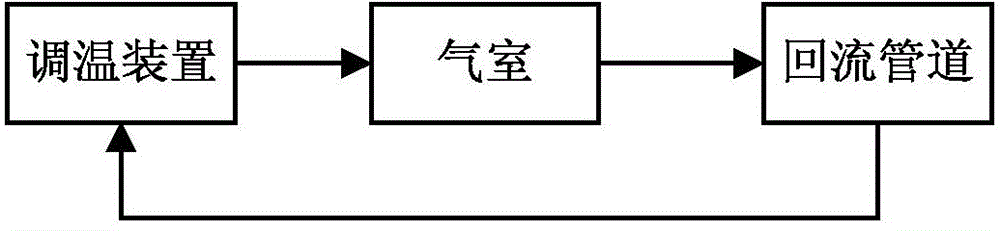

Contact type temperature control device for regulating temperature by gas

InactiveCN104664910ASimple structureGood thermoregulation effectGarment special featuresBlanketTemperature senseEngineering

The invention discloses a contact type temperature control device for regulating the temperature by gas and relates to the field of gas temperature regulation. The contact type temperature control device comprises a bottom layer and a temperature sensing layer which are sequentially arranged from bottom to top, wherein a supporting outer frame is arranged between the bottom layer and the temperature sensing layer; a gas chamber is formed by spaces inside the bottom layer, the supporting outer frame and the temperature sensing layer; at least forty support members are arranged inside the gas chamber; all the support members are distributed at the top of the bottom layer in a disperse way; the sum of cross section areas of all the support members is 50-70 percent that of the gas chamber; the height of each support member is identical with the thickness of the supporting outer frame; at least one gas inlet and at least one gas outlet are formed in the wall of the supporting outer frame; a temperature regulating device is arranged in the at least one gas inlet and is provided with a fan for introducing gas. The contact type temperature control device disclosed by the invention has the advantages of better temperature regulating effect, convenience for use of people, safety and environment friendliness for use and wide application range.

Owner:胡斌

Aluminum alloy

The invention discloses aluminum alloy, which comprises the following components in percentage by weight: 0.40 to 0.44 percent of Si, 0.56 to 0.61 percent of Mg, 0.05 percent of Cu, 0.15 percent of Fe, 0.05 percent of other inevitable trace elements and the balance of Al. An aluminum product produced from the aluminum alloy is free of obvious surface recess and wider in hardness range, and has a smooth surface.

Owner:江苏礼德铝业有限公司

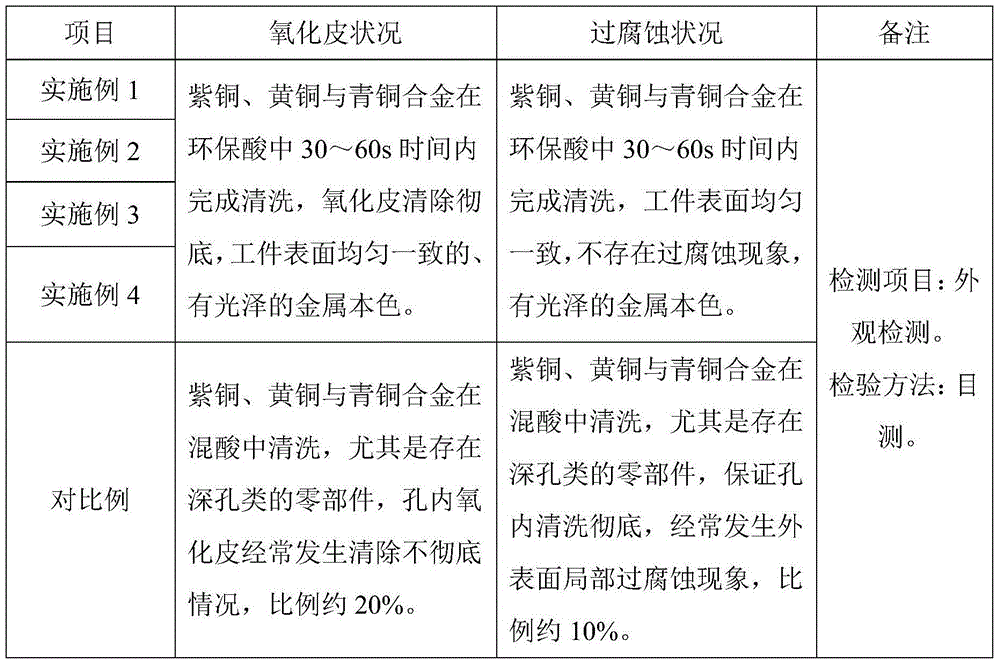

Environment-friendly copper and copper alloy pickling agent and copper and copper alloy silver-plating pretreatment method

The invention discloses an environment-friendly copper and copper alloy pickling agent and a copper and copper alloy silver-plating pretreatment method. The pickling agent is prepared from the following ingredients in percentage by mass: 21.5-44.0% of sulfuric acid, 2.5-15.5% of phytic acid, 2.5-10% of sodium nitrate, 0.5-2.0% of dispersing agent and the balance of water. The environment-friendly pickling agent is clean and environment-friendly, has no solvent volatilization, cannot generate acid mist during cleaning, has low pollution, can create a clean environment for pretreatment process, has high copper and copper alloy cleaning quality, and can prevent parts from being over-etched, realizes cleaning of silver-plating pretreatment of copper, copper-like and copper alloy used for high-voltage switches, can improve the operation environment, can protect the health of staffs, can be used repeatedly during cleaning, has the using period which is more 2-3 times than that of the traditional pickling acid, can greatly reduce the cleaning cost, has remarkable comprehensive benefit and is suitable for popularization and application.

Owner:HENAN PINGGAO ELECTRIC +2

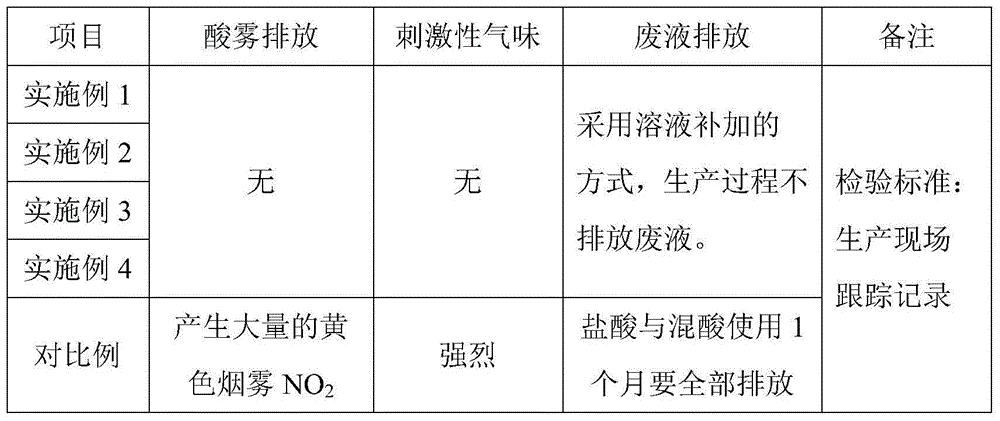

Water-based coolant

InactiveCN104136634AImprove cooling effectNot prone to corrosionHeat-exchange elementsAdditivesPhosphite saltPhosphate

This water-based coolant is characterized by being obtained by mixing at least one of each of the following inorganic acid salts: phosphate, phosphite, sulphate, sulphite, borate, molybdate, tungstate, carbonate, hydrogen carbonate, and sesquicarbonate. This water-based coolant exhibits excellent cooling performance, and excellent anti-corrosion properties towards metal materials to be cooled therewith, and thus is suitable for use as a cutting fluid and a quenching fluid for metal materials.

Owner:IDEMITSU KOSAN CO LTD

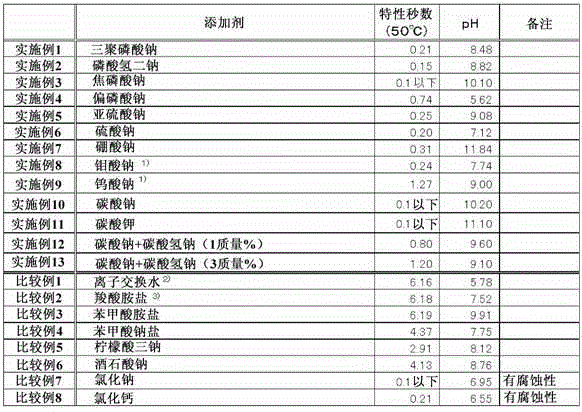

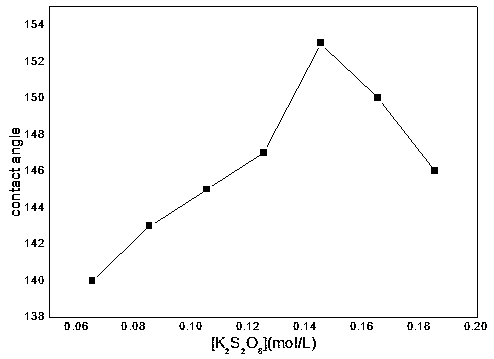

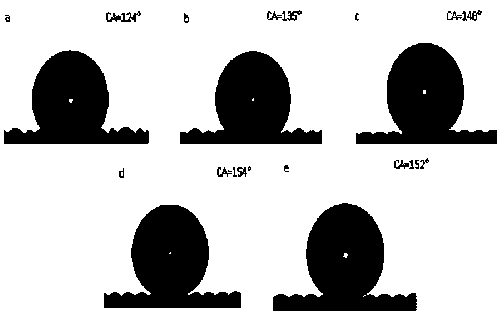

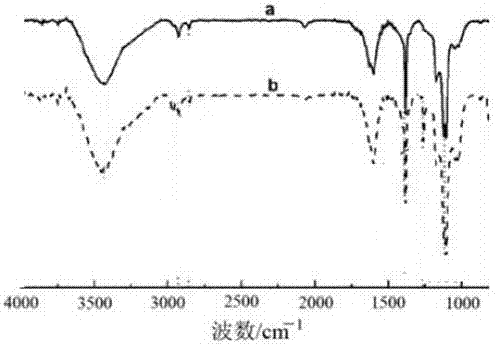

Preparation method for improving metal hydrophobicity based on vapor deposition method

InactiveCN109207979ANo change in appearanceImprove surface hydrophobicityVacuum evaporation coatingSputtering coatingElectricityHexamethyldisilane

The invention discloses a preparation method for improving metal hydrophobicity based on a vapor deposition method. The method comprises the steps that 1, the surface oxidation control method is utilized for generating an oxidation metal film on the metal surface; and 2, hexamethyldisilane modifies oxidation metal through the vapor deposition method. By using the manufacturing method of super-hydrophobic metal, surface hydrophobicity of the metal is improved correspondingly, the hexamethyldisilane is cheap and low in toxicity compared with chlorine and fluorine containing reagent, and is friendly to environment, thus the metal does not corrode easily in the humid environment, or does not frost or freeze easily at the low temperature, thus heat conduction to the metal is avoided, the influence on electricity conducting performance is avoided, the stability of metal products and devices is improved directly and substantially, and the property of people and social safety are guaranteed.

Owner:XUCHANG UNIV

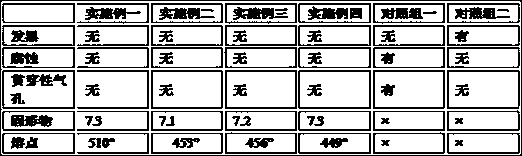

A halogen-free pickling flux and its preparation method are disclosed

ActiveCN108890172AHigh activityLow melting pointWelding/cutting media/materialsSoldering mediaPorosityHalogen

The invention discloses a halogen-free pickling flux, which comprises the following components in parts by weight: trimethyl borate 50 60 part, methanol 30 parts 40 part, water 10 part 20 part, sodium tetraborate 1 5 part, boric acid 1 3 copies. In the halogen-free pickling flux of the invention, the addition of trimethyl borate protects the workpiece from oxidation, the trimethyl borate is hydrolyzed to generate boric acid through the addition of water, the generated boric acid and sodium tetraborate form a traditional eutectic compound combination of the flux, the melting point is further reduced by the addition of sodium tetraborate, and the activity of the flux is improved. Especially, the addition of halogen is insulated, so that the surface of the brazed workpiece will not be oxidized and blackened, and corrosion and penetrating porosity are not easy to occur, and the brazing activity is high, so that the brazing efficiency is higher.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

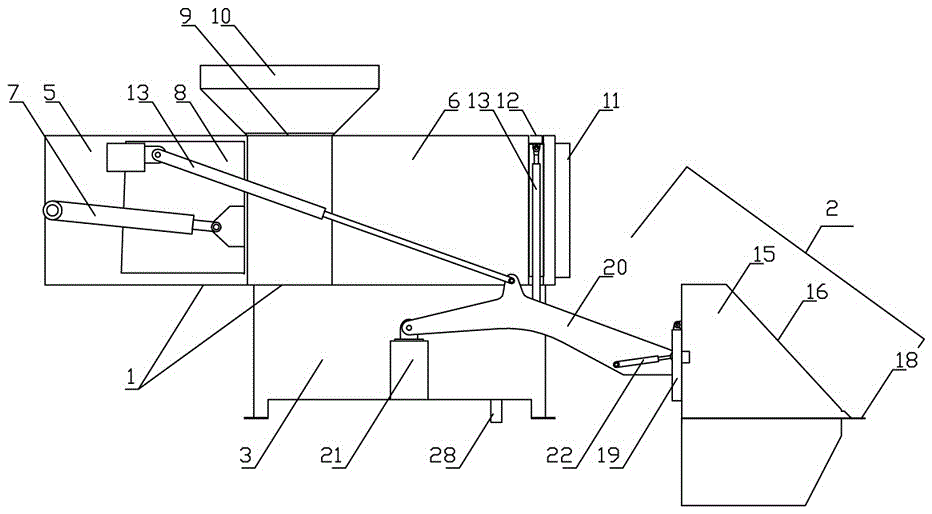

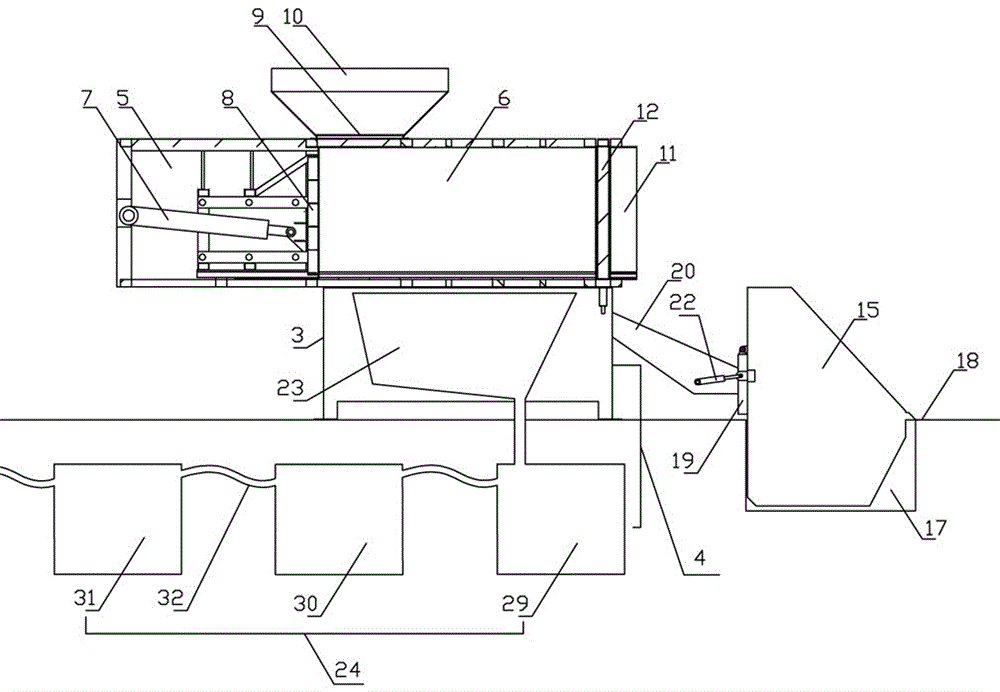

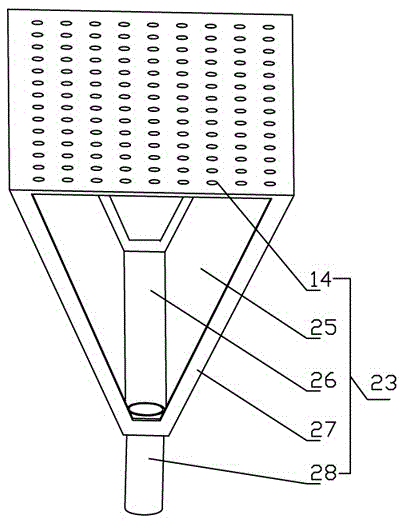

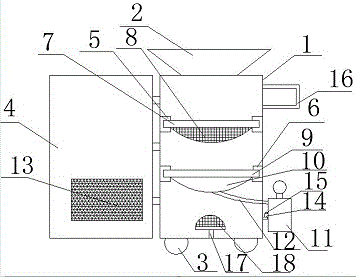

Environment-friendly ground horizontal type waste compacting transfer station

ActiveCN106429110ASave spaceReduced overall structureRefuse receptaclesRefuse transferringEngineeringSewage

The invention relates to the field of waste recovery equipment, in particular to an environment-friendly ground horizontal type waste compacting transfer station which is provided with a compacting box body. A feeding device is hinged to one end of the compacting box body. A supporting box body is welded to the bottom of the compacting box body. A sewage drainage device is installed in the supporting box body. An oil cylinder cavity and a compacting cavity are sequentially arranged in the compacting box body. A hydraulic push cylinder is installed in the oil cylinder cavity. The end of the hydraulic push cylinder is connected with a compacting push plate. A feed inlet is formed in the top of one end of the compacting cavity. The other end of the compacting cavity is provided with a discharge outlet. A gate capable of being perpendicularly opened is arranged between the compacting cavity and the discharge outlet. According to the environment-friendly ground horizontal type waste compacting transfer station, a ground vertical type vertical compacting and leveling device is omitted, the total structure is simplified, a high and large building does not need to be built, the material space is saved, the manufacturing cost is reduced, meanwhile, an installation site is convenient and fast to wash due to the fact that no large pit needs to be built, secondary environmental pollution is avoided, and the popularization prospect is quite good.

Owner:湖北骏马环保科技有限公司

High-temperature fuel cell bipolar plate anti-oxidation plating layer

InactiveCN111933965AReduce contact resistanceImprove bindingVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceFuel cells

The invention provides a high-temperature fuel cell bipolar plate anti-oxidation plating layer, and relates to the technical field of fuel cells. The high-temperature fuel cell bipolar plate anti-oxidation plating layer comprises a composite plating layer, wherein the composite plating layer is composed of a CrN film layer, a silver plating layer and a gold plating layer. The preparation method ofthe anti-oxidation plating layer comprises the steps of 1) selecting a stainless steel plate as a bipolar plate material, and pretreating the stainless steel plate; 2) generating a film and depositing the film on the surface of the stainless steel plate to obtain a CrN film layer; 3) plating a silver plating layer on the CrN film layer; and 4) plating a gold plating layer on the silver plating layer. According to the invention, the contact resistance of the bipolar plate can be reduced, the contact resistance value of the stainless steel plate can be further reduced after silver plating due to good conductivity of silver, and meanwhile, the binding force of the plating layer is very good; and a small amount of thin gold is electroplated or sputtered on the silver layer, so that the problem of infirm combination of a gold-plated plating layer can be well solved, and good conductivity and relatively small contact resistance are obtained.

Owner:苏州敦胜新能源科技有限公司

An electrolytic polishing method for complex brass

An electrolytic polishing method for complex brass is disclosed. The method includes (1) grinding complex brass and then preforming mechanical polishing, (2) performing electrolytic polishing, with the complex brass after mechanical polishing being adopted as an anode, a lead block being adopted as a cathode, an electrolytic polishing direct voltage being 1-4 V, a current being 0.1-4 A, an electrolytic polishing temperature being room temperature, and electrolytic polishing time being 5-30 s, and (3) taking the complex brass out after electrolytic polishing, washing with absolute ethanol and then drying the complex brass to obtain a product, wherein an electrolytic polishing liquid comprises H3PO4, gelatin and oxalic acid, 2-4 g of the gelatin and 2-4 g of the oxalic acid are added for each 30-70 mL of the H3PO4 and the H3PO4 concentration is not less than 85%. According to the method, requirements on previous mechanical polishing quality before the electrolytic polishing are low, the electrolytic polishing can be operated at room temperature, and the electrolytic polishing liquid is simple in formula, nontoxic, nonirritant and nonvolatile, and can be stored for a long term and repeatedly used.

Owner:HEBEI UNIV OF TECH

Coated piece and manufacturing method thereof

InactiveCN102465251AImprove corrosion resistanceCorrosion current reductionVacuum evaporation coatingSputtering coatingAlloy substrateSilicon

The invention provides a coated piece which comprises an aluminum or aluminum alloy substrate, an amorphous alloy layer and a colored layer with an anti-corrosion function, wherein the amorphous alloy layer and the colored layer are formed on the aluminum or aluminum alloy substrate in turn; the amorphous alloy layer is Fe70Cr10B13X7; and X is any one selected from phosphorus, carbon and silicon. The coated piece has excellent corrosion resistance and decorative appearance. The invention also provides a manufacturing method for the coated piece.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

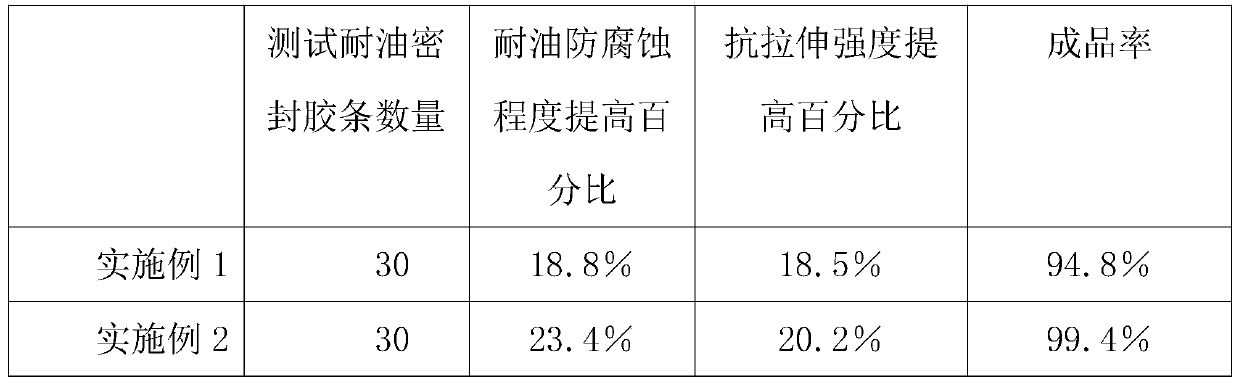

Preparation process of rubber composite material for oil-resistant sealing rubber strip

InactiveCN110483858AImprove corrosion resistanceImprove aging resistancePolymer scienceVulcanization

The invention discloses a preparation process of a rubber composite material for an oil-resistant sealing rubber strip. The invention relates to the field of sealing rubber strips. The main materialscomprise the following components in parts by weight:90-110 parts of NBR, 3.5-4.5 parts of an active agent, 0.38-0.42 part of stearic acid SA, 56-64 parts of a filler, 0.48-0.52 part of sulfur, 0.7-0.9 part of an accelerant, 5-7 parts of a cold-resistant plasticizer DOA, 4-5 parts of an anti-aging agent and 2.3-2.7 parts of a vulcanizing agent DCP. The preparation method comprises the following specific preparation steps: S1, mixing; s2, vulcanization sample preparation. According to the invention, by means of the NBR, active agent, stearic acid SA, filling material, sulfur, promoter, cold-resistant plasticizer DOA, anti-aging agent and vulcanizing agent DCP, a mixing process is adopted, optimal processing parameters can be obtained through vulcanization sample preparation, the prepared sealing rubber strip has the characteristics of excellent corrosion resistance, aging resistance, cold resistance, oil corrosion resistance and the like, the sealing rubber strip is also suitable for mass production, and the product quality and the yield can be well guaranteed.

Owner:衡水华瑞工程橡胶有限责任公司

Preparation method of anti-corrosion and anti-fatigue damping spring

InactiveCN110527944AHigh strengthImprove corrosion resistanceSolid state diffusion coatingFurnace typesMechanical componentsUltimate tensile strength

The invention mainly relates to the technical field of machining of mechanical parts, and discloses a preparation method of an anti-corrosion and anti-fatigue damping spring, which comprises the following steps: cleaning, polishing, carburizing, primary quenching, nitriding, secondary quenching, tempering and post-treatment. According to the preparation method of the anti-corrosion and anti-fatigue damping spring, the prepared spring is high in strength, high in anti-corrosion capacity, not prone to corrosion when exposed to air, high in deformation capacity and anti-fatigue performance and capable of still having a good damping effect after being used for a period of time, and the driving comfort can be improved.

Owner:MAANSHAN SANCHUAN MACHINERY MFG CO LTD

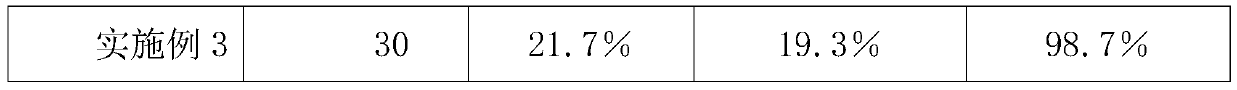

Sulfuric acid evaporator for refined acid producing apparatus

InactiveCN106166395AEasy on-site inspectionApplicable concentration is wideSulfur compoundsEvaporator regulation/controlWeld seamCondensed water

The invention discloses a sulfuric acid evaporator for a refined acid producing apparatus. The sulfuric acid evaporator is provided with a nicotinic acid tank and a water vapor tank, wherein the bottom portion of the nicotinic acid tank is provided with a nicotinic acid inlet, the top portion of the nicotinic acid tank is provided with a SO3 gas outlet, both side walls on the middle portion of the nicotinic acid tank are respectively provided with a nicotinic acid outlet, the top portion of the water vapor tank is provided with a steam inlet, the bottom portion of the water vapor tank is provided with a condensed water outlet, a U-shaped tube bundle is arranged inside the nicotinic acid tank, the inlet of the U-shaped tube bundle is positioned inside the water vapor tank and is communicated to the steam inlet, the outlet of the U-shaped tube bundle is positioned inside the water vapor tank and is communicated to the condensed water outlet, both sides on the middle portion inside the nicotinic acid tank are respectively provided with an overflow groove, and the bottom portion of the overflow groove is communicated to the nicotinic acid outlet. According to the present invention, the sulfuric acid evaporator is changed into the horizontal evaporator, the U-shaped tube bundle is used, the medium inside the tube bundle is the steam, the nicotinic acid is arranged outside the tube bundle, the actual pressure component of the equipment is reduced, the tube bundle welding seam on the tube nest contacts the steam, no corrosion is generated, and the acid inflow structure and the acid outflow structure of the evaporator consider the uniform flowing so as to ensure the uniform evaporation.

Owner:上海京藤化工有限公司

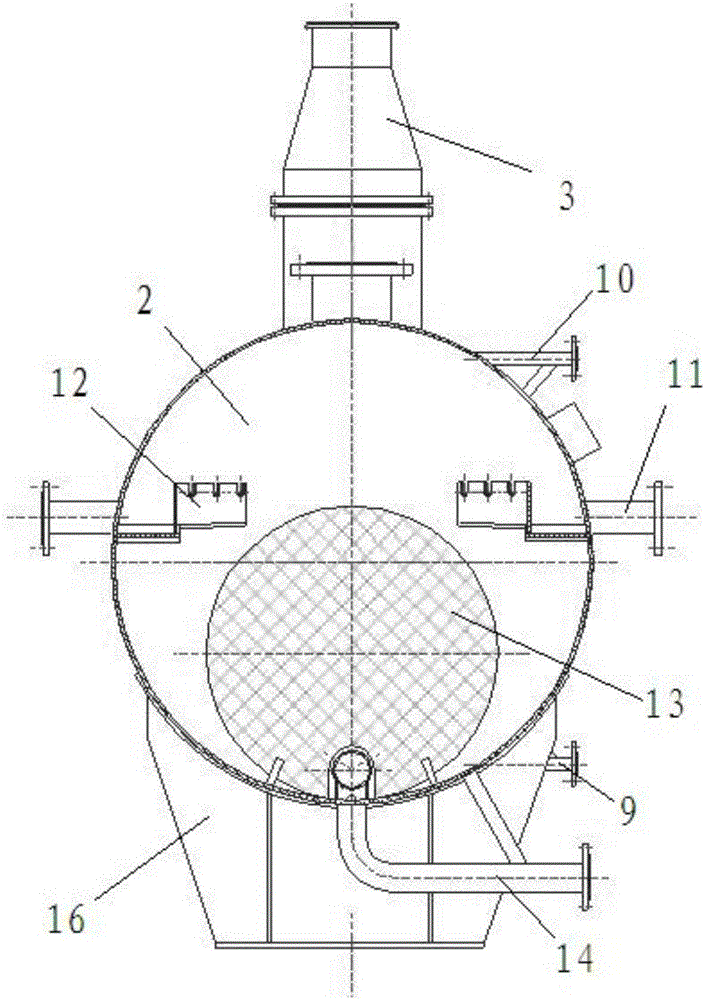

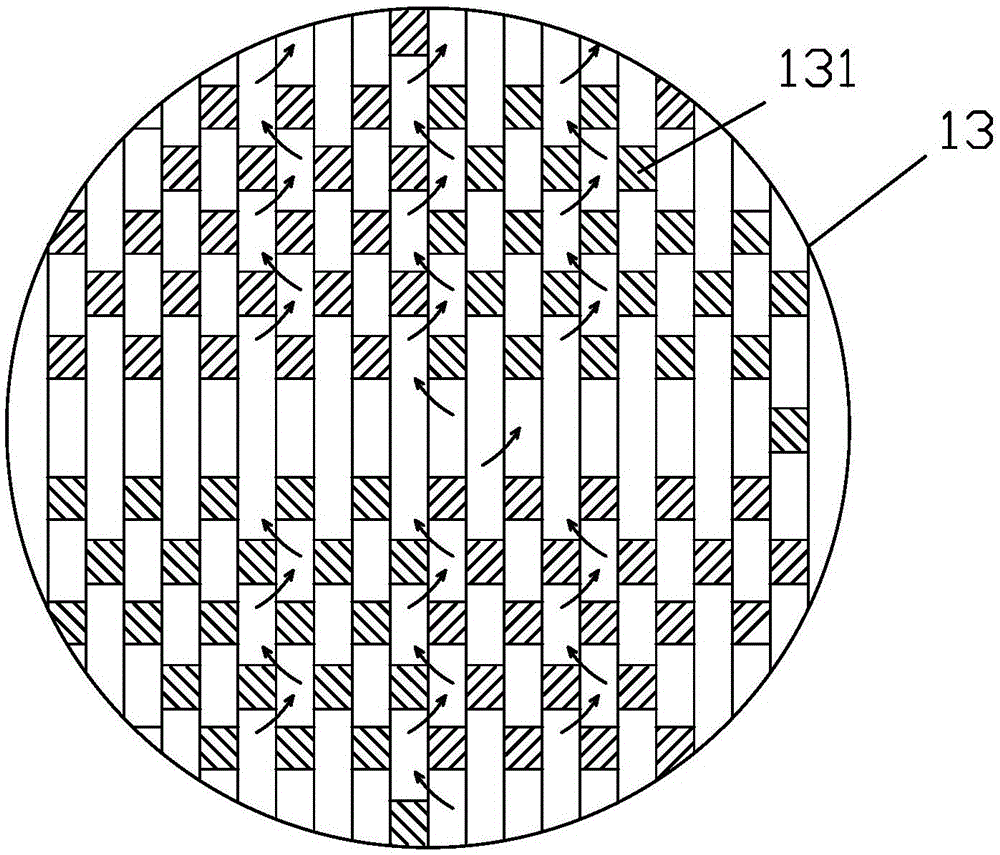

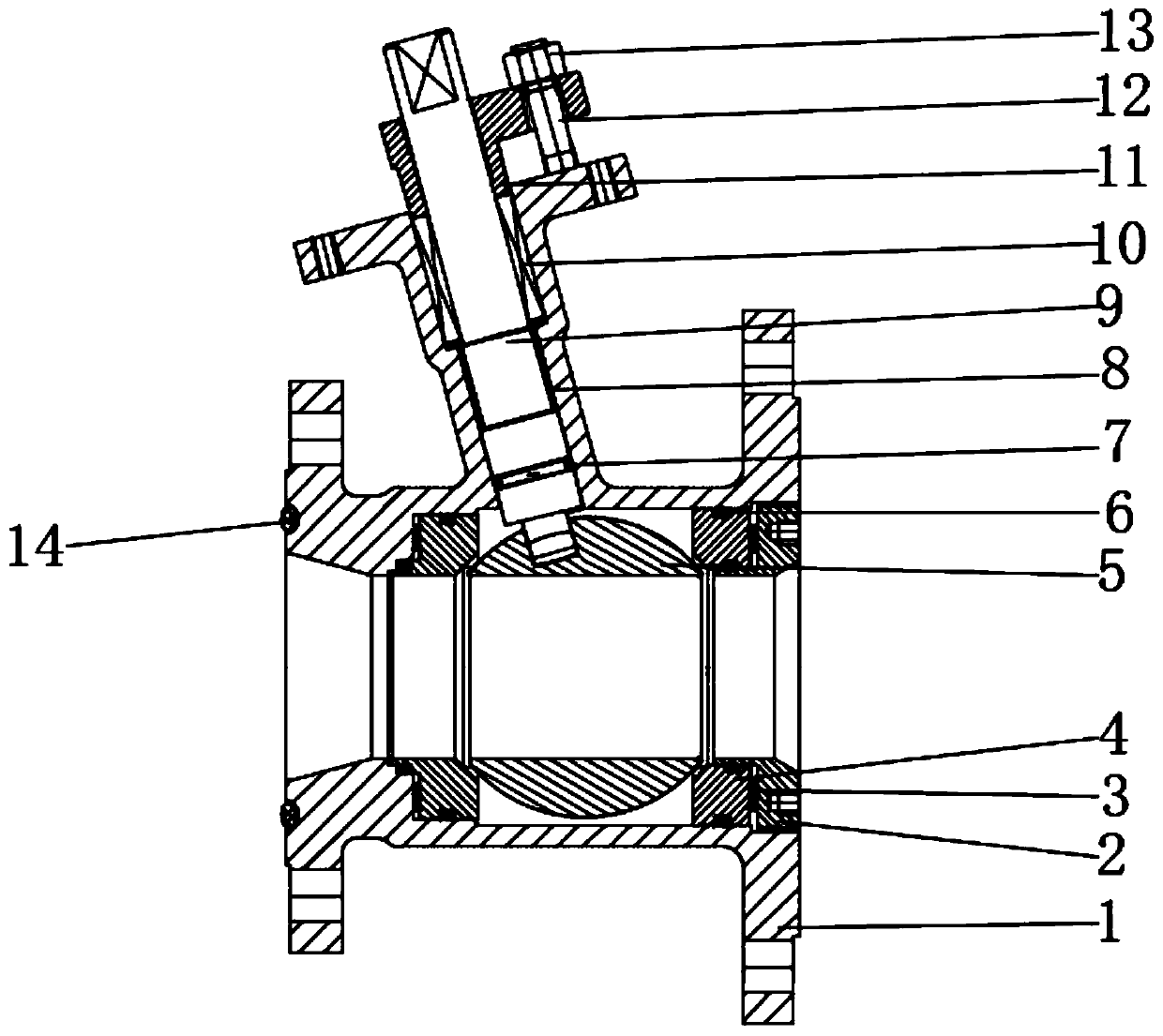

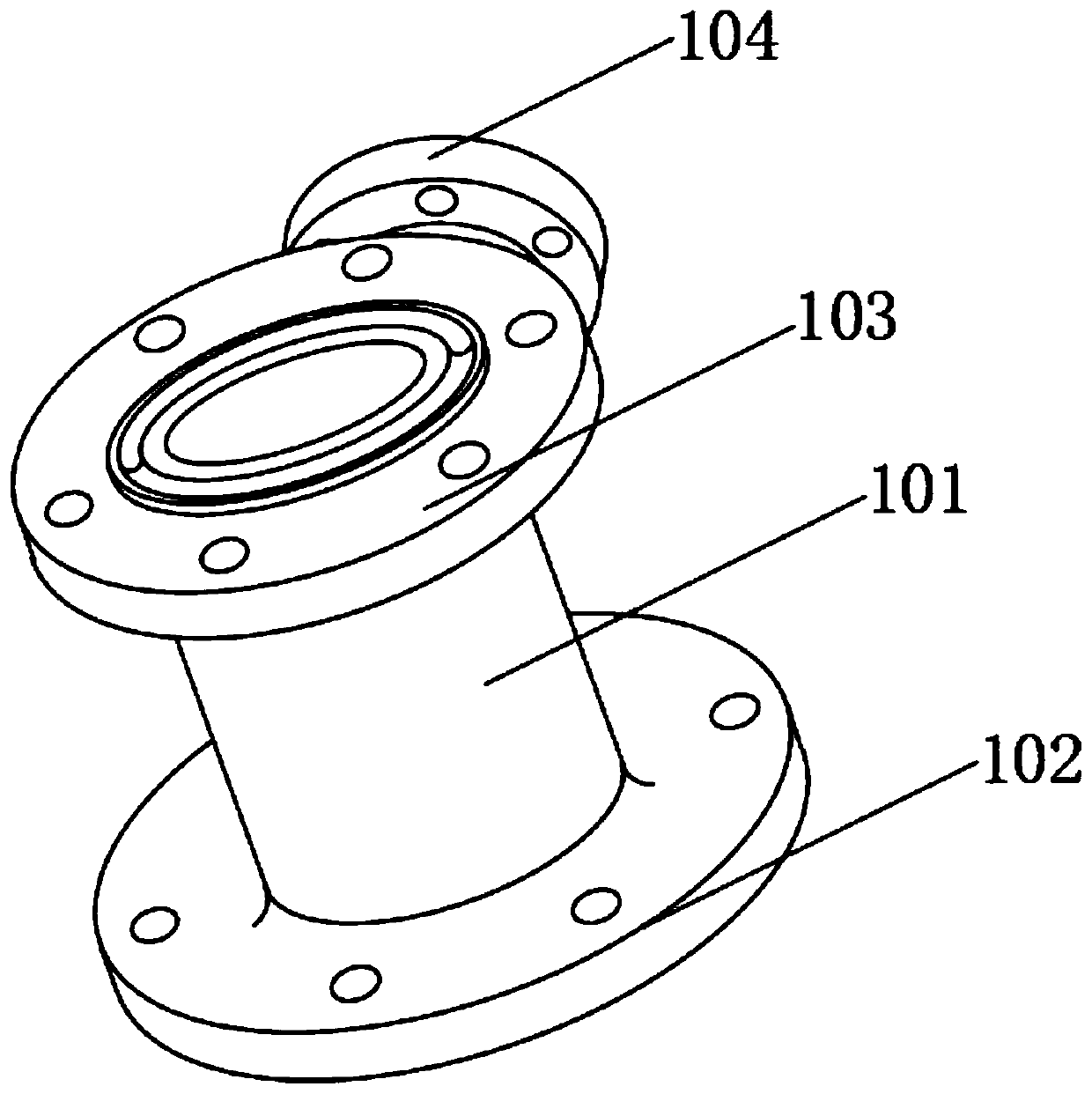

Slash kettle bottom discharging valve

PendingCN109973679AReduce rotational frictionEasy to useSpindle sealingsPlug valvesEngineeringValve seat

The invention discloses a slash kettle bottom discharging valve. The slash kettle bottom discharging valve comprises a discharging valve body, a valve body cap is arranged at one end of the discharging valve body, a discharging valve seat is embedded in the inner side, corresponding to the valve body cap, of an inner cavity of the discharging valve body, a valve body plate spring is arranged between the discharging valve seat and the valve body cap, a sphere valve element is movably embedded in an inner cavity of the discharging valve seat, the inner wall, corresponding to the discharging valve body, of the outer surface of the discharging valve seat is nested with a valve seat O-shaped ring, a discharging valve rod is embedded in the side face of the sphere valve element, the position, close to the sphere valve element, of the side face of the discharging valve rod is nested with a valve rod O-shaped ring, and the middle of the side face of the discharging valve rod is nested with a valve rod shaft sleeve. According to the slash kettle bottom discharging valve, the problem that during rotating of the sphere valve element, rotating is excessive, thus a gap is produced between the sphere valve element and the discharging valve body, and then leakage is caused can be solved, rotary frictional force of the discharging valve rod can be lowered through the valve rod shaft sleeve, thus the discharging valve rod is convenient to use, and the use time of the valve rod shaft sleeve is prolonged.

Owner:浙江天天阀门有限公司

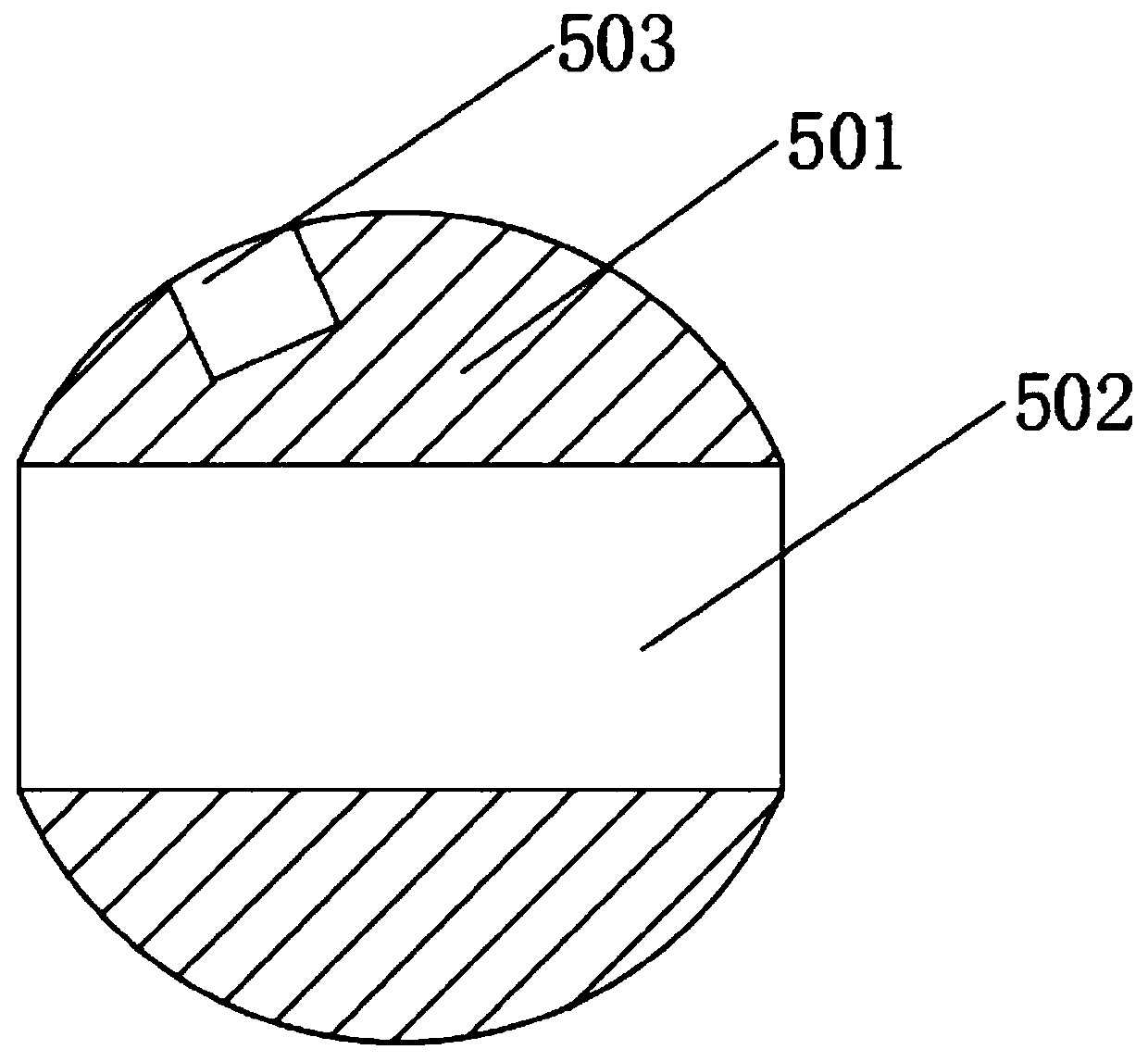

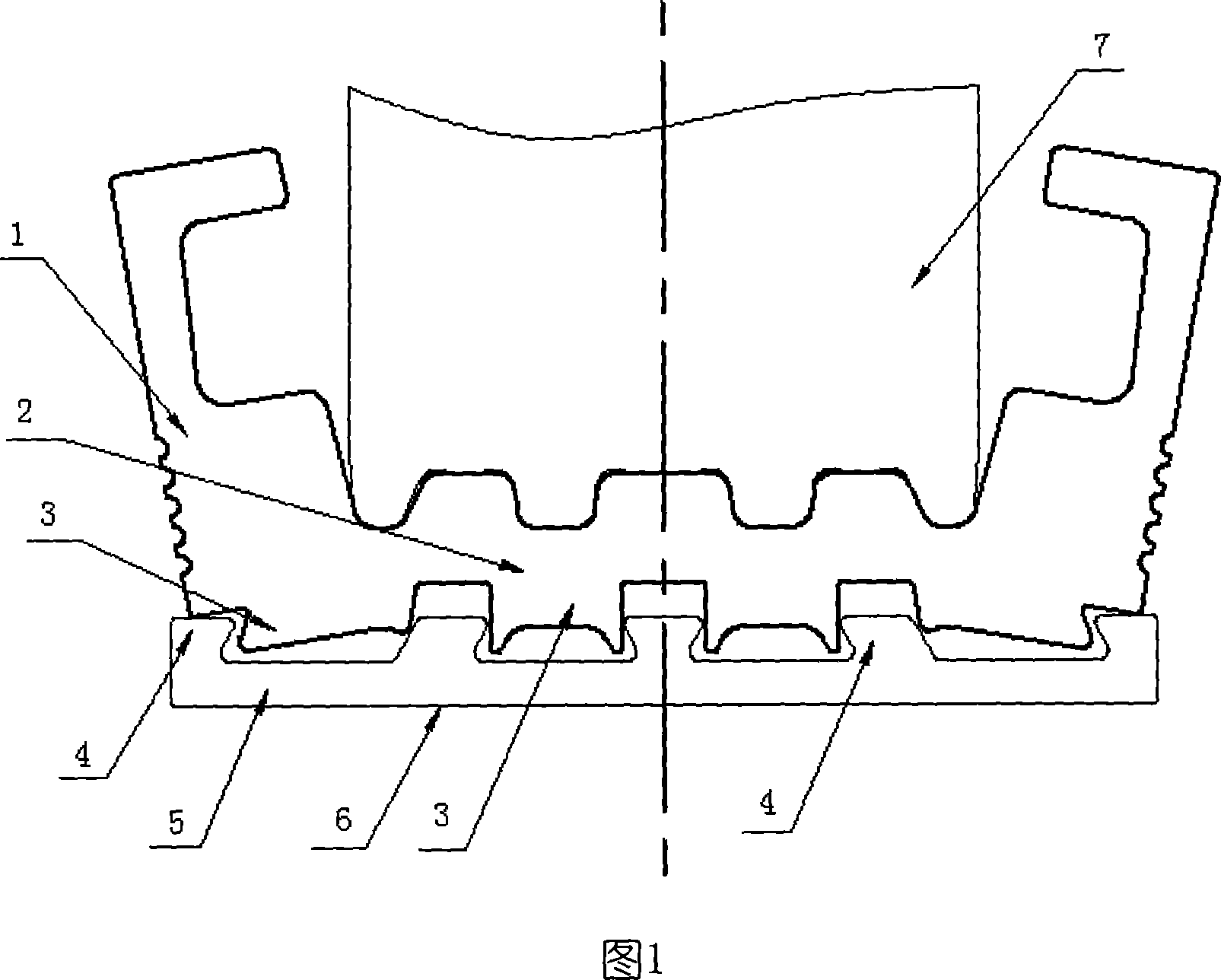

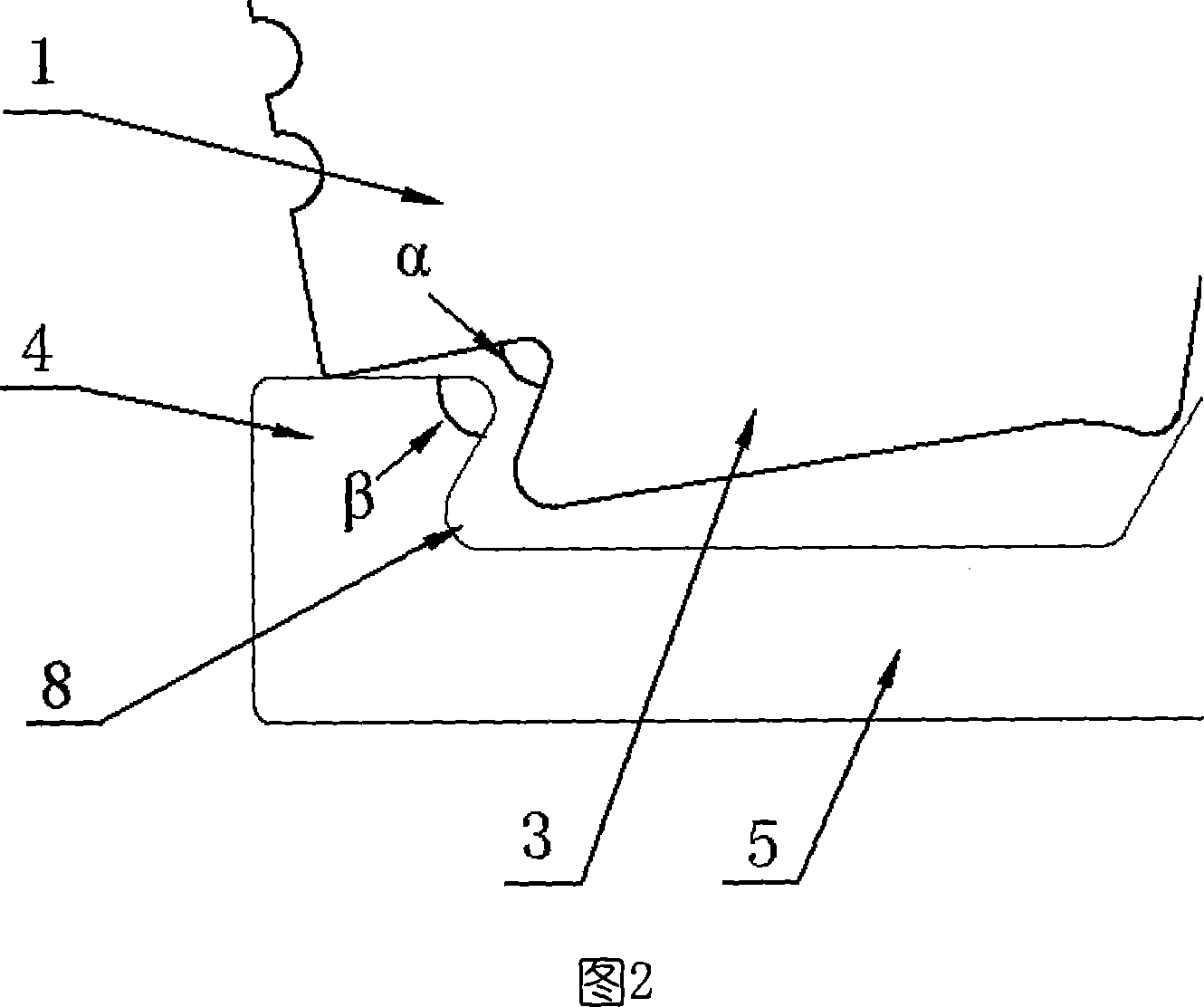

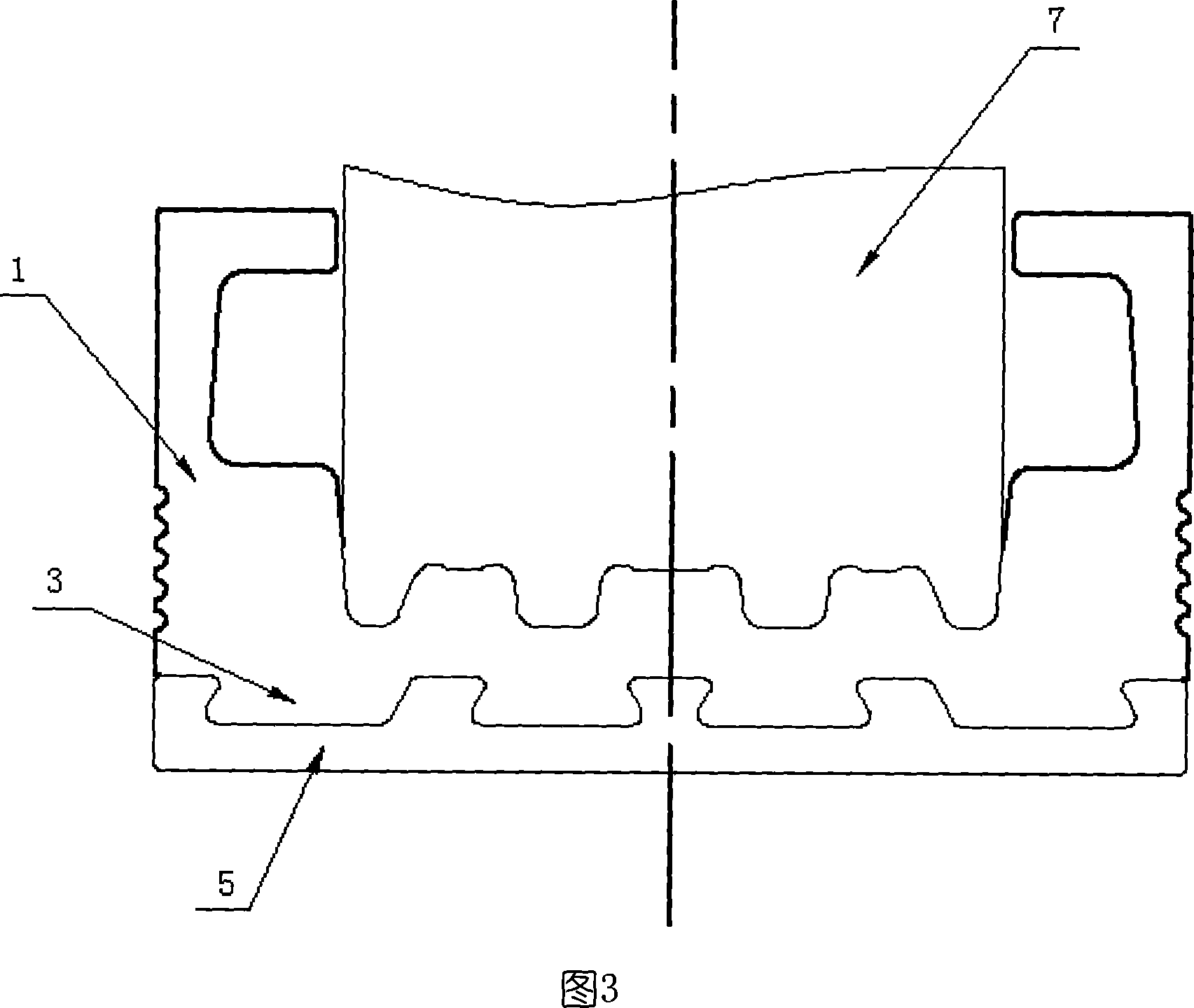

Conductor rail and manufacturing method thereof

The invention relates to a conductive rail that comprises the base and abrasion resistant material made electric brush surface with protruding batten embedded inside the base, at least one batten and electric brush surface and the back formed into pits, which is stuffed with base material. It features in partial bending of the assembly part of the front base, through at least one time deformation assembly to straighten it up and stuffing it between the battens. It is close in adhesion, firm, convenient in base and electric brush assembly, low in production cost.

Owner:HUNAN HUAPIN RAIL TRANSIT CO LTD

Expanded-base type pre-stressed composite anchor cable uplift pile and preparation method thereof

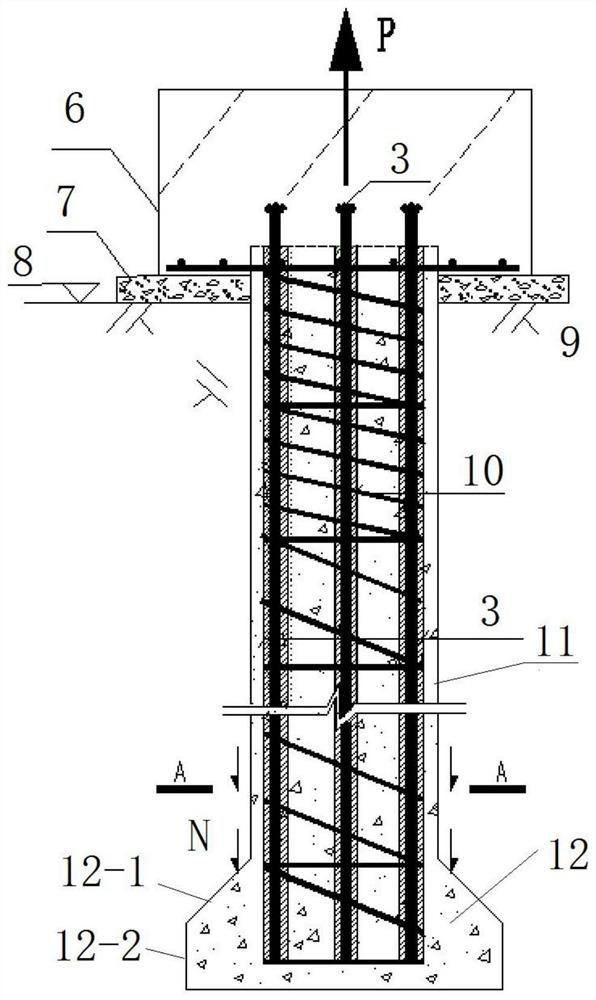

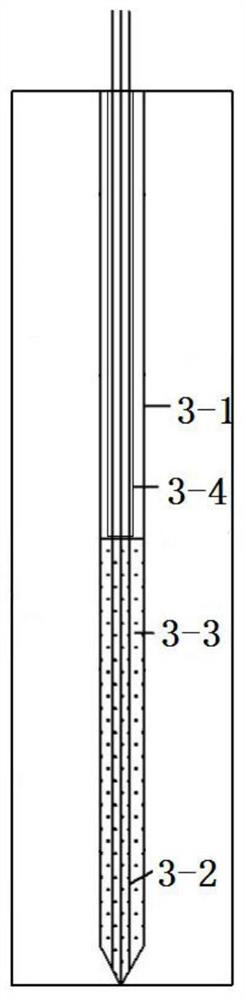

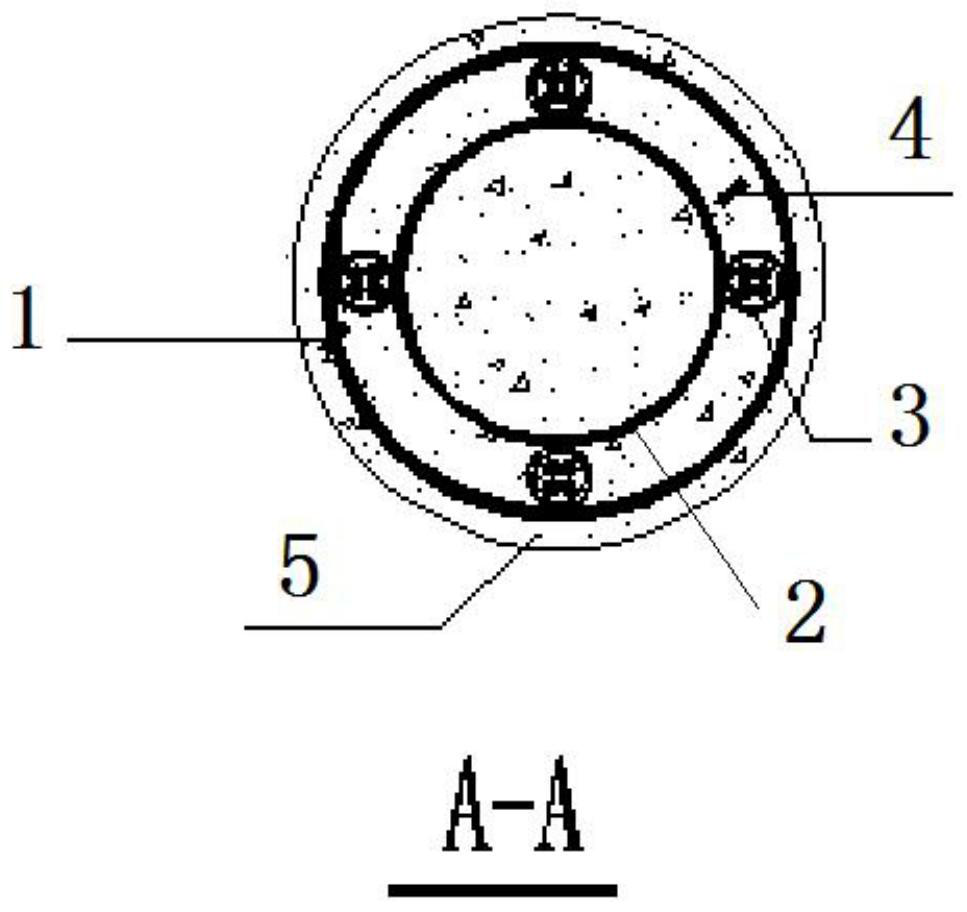

InactiveCN112049158AImprove bearing capacityGood value for moneyProtective foundationBulkheads/pilesPre stressDrill hole

The invention belongs to the field of underground construction, and particularly relates to an expanded-base type pre-stressed composite anchor cable uplift pile. The expanded-base type pre-stressed composite anchor cable uplift pile is characterized by comprising an uplift pile composite reinforcement cage, a composite anchor cable, a head expanding part and a filler, wherein the uplift pile composite reinforcement cage comprises an uplift pile cage outer wall and an uplift pile cage inner wall; the composite anchor cable is arranged between the uplift pile cage outer wall and the uplift pilecage inner wall, the composite anchor cable is composed of an isolation body and an uplift anchor cable body arranged in the isolation body, and the isolation body separates the corrosives from the uplift anchor cable body; the head expanding part is arranged at the drilling bottom; and the bottom anchoring end of the uplift pile composite reinforcement cage is arranged in the head expanding part. The expanded-base type pre-stressed composite anchor cable uplift pile is easy to drill, easy to construct, resistant to corrosion, good in supporting performance of the overall pile cage, high in uplift bearing performance of the bottom of the pile body and not prone to breaking of the pile top.

Owner:北京京投交通枢纽投资有限公司 +1

Novel ink stone

ActiveCN107128110ANot prone to corrosionHigh strengthCoatingsInk standsEngineeringCorrosion resistant

The invention provides a novel ink stone. The novel ink stone comprises an ink stone parent body, a corrosion-resistant layer located in an ink grinding area, and a light absorption layer located on the side wall of the ink stone parent body. According to the novel ink stone, a corrosion phenomenon is not prone to occurring; the strength is high; the ink retaining performance cannot be reduced; and in addition, ink can be prevented from being solidified through the novel ink stone.

Owner:HUANGSHAN GUCHENG SHEZHOU INKSTONE CO LTD

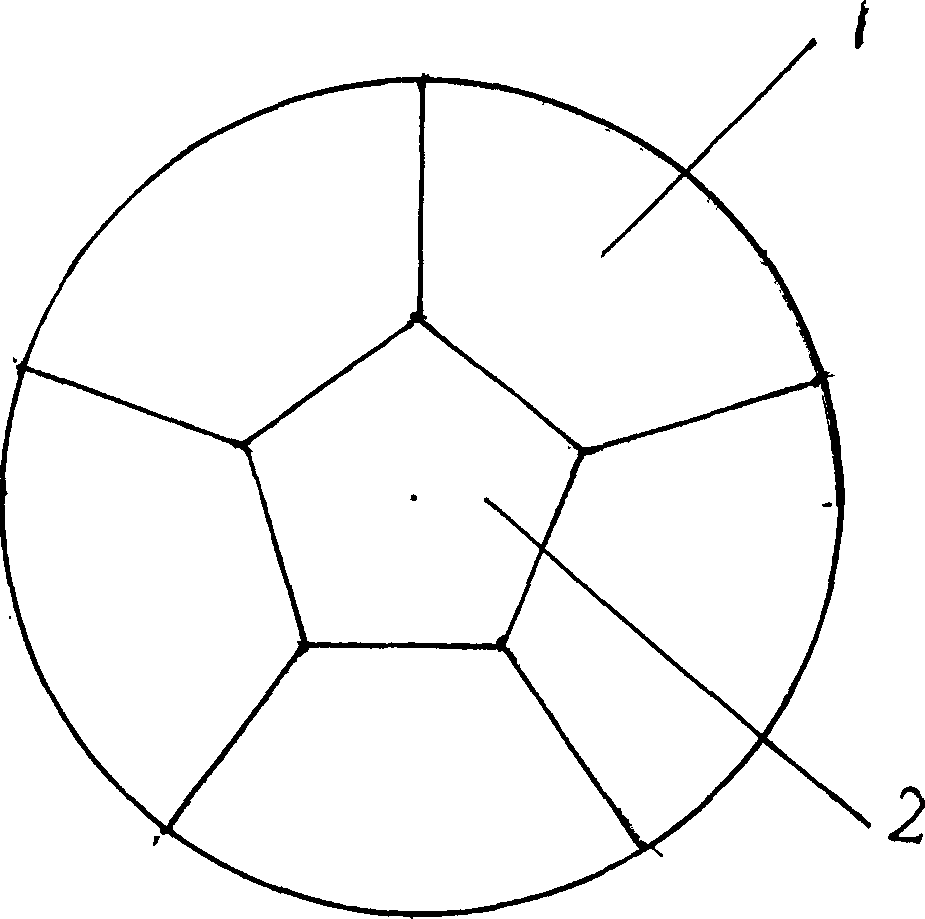

Processing method of multiple bamboo sheet sandwiching solid stick

The present invention relates to bamboo and timber product making technology, and is polyhedral sandwiched solid bamboo rod making process. The making process includes the following steps: cutting bamboo stem section into sector strips, adhering the sector strips around core strip with plant glue and bundling, extruding in a hot press to form, polishing and painting to obtain the product. Thus made polyhedral sandwiched solid bamboo rod has smooth and beautiful surface, less mildew and rot, high strength, less breaking, less deformation and stable verticality. The making process has high efficiency, and raised bamboo material utilization. The said method may be also used in making hollow rod.

Owner:胡煜亿

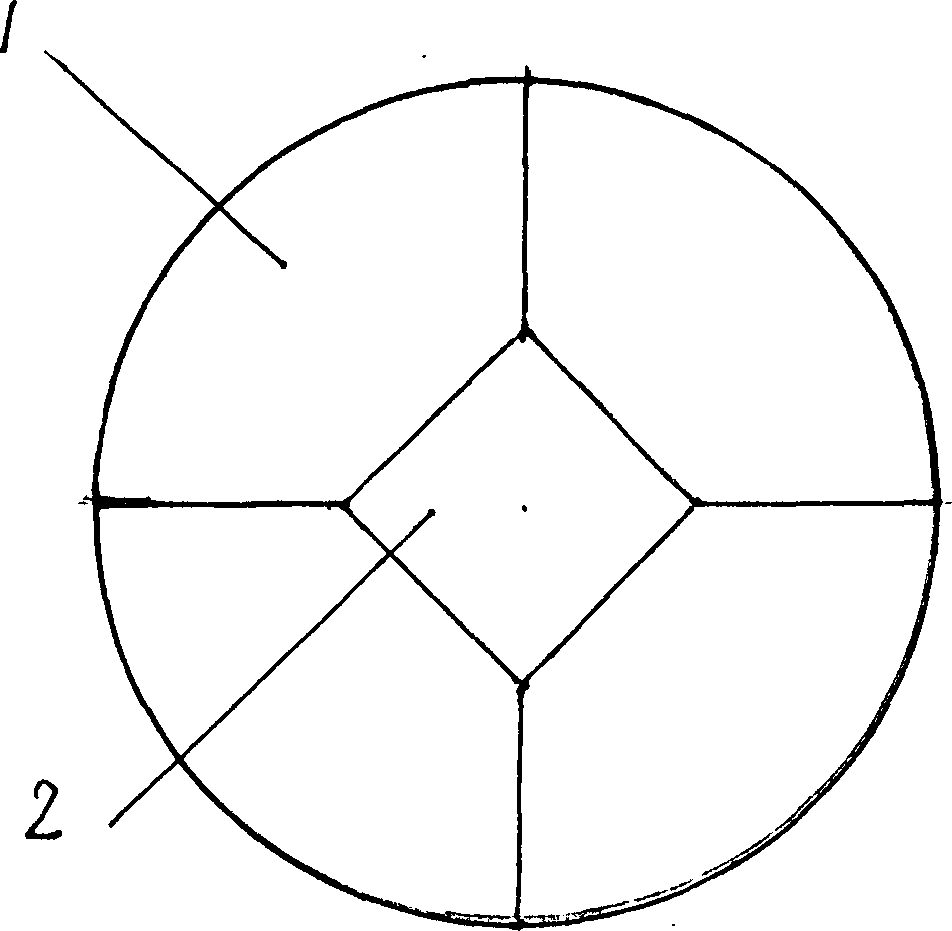

Crucible cover plate for polycrystalline silicon ingot casting

ActiveCN106048717AImprove thermal shock resistanceExtended service lifePolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

The invention discloses a crucible cover plate for polycrystalline silicon ingot casting. The crucible cover plate comprises a cover plate body; first transitional arc surfaces are formed between the side surfaces of the cover plate body and the upper surface of the cover plate body; second transitional arc surfaces are formed between the side surfaces of the cover plate body and the lower surface of the cover plate body. The crucible cover plate has the advantages of simple structure, high thermal shock resistance, long service life, and high product quality.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Absorbent and method for removing acidic gases in waste gas

InactiveCN104437045AImprove absorption efficiencyGood oxygen resistanceDispersed particle separationEpoxyEthylene oxide

The invention discloses an absorbent and a method for removing acidic gas in waste gas. The absorbent is an organic amine salt aqueous solution added with an additive, and the additive is isopropanol strontium. The absorbent is prepared according to the following steps: step 1. heating in the presence of active aluminum oxide as the catalyst at the temperature of 350-400 DEG C; then cooling to 120-130 DEG C, and reacting by adding epoxy ethane in mixing state; step 2. reacting the reactant obtained from step 1 and vanadic acid to obtain an organic amine salt; and step 3.dissolving the organic amine salt obtained from step 2 in water, then uniformly mixing after isopropanol strontium is added to prepare the organic amine salt aqueous solution which is the absorbent. According to the method for removing acidic gas in waste gas, the absorbent thoroughly, reversely contacts waste gas in an absorption tower to obtain the saturated absorbent; then the saturated absorbent is subjected to distilling or extraction to recover the useful components in the absorbent, the residual solution after recovery is used as an absorbent solution for reuse, so that the absorbent is recyclable.

Owner:WUXI EPIC TECH

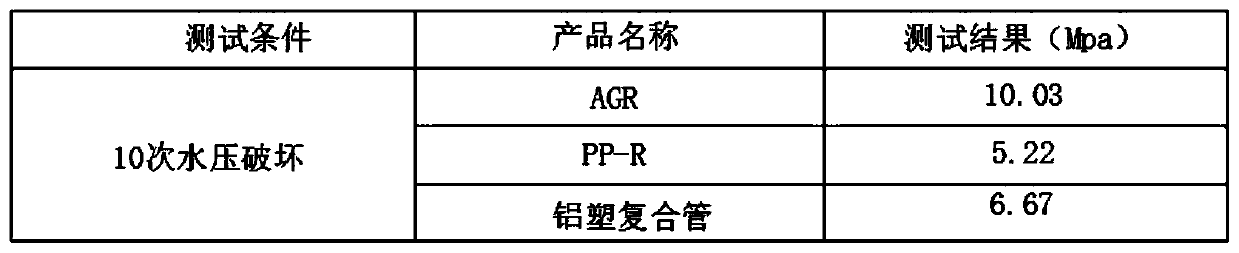

Acrylic acid copolymerized polyvinyl chloride pipe for water supply and preparation method thereof

The invention discloses an acrylic acid copolymerized polyvinyl chloride pipe for water supply and a preparation method thereof. The preparation method comprises the following steps that acrylic resinand polyvinyl chloride are placed in a polymerization kettle, the acrylic resin and the polyvinyl chloride are mixed and placed in a pre-polymerization kettle, the pre-polymerization kettle is a vertical stainless steel polymerization kettle, a turbo-type flat paddle stirrer is arranged in the pre-polymerization kettle, and the; wherein the stirring speed is controlled to be 50-250 rpm, then themixed material is placed from the pre-polymerization kettle into a post-polymerization kettle, the post-polymerization kettle is a horizontal kettle and is internally provided with a stirrer which isformed by combining three helical ribbons and is used for stirring at a low speed, and the rotating speed of the horizontal kettle is 6-7 rpm; the AGR pipe manufactured through the method is simple and convenient in process, complex process steps are reduced, meanwhile, the product quality is improved, the occurrence frequency of defective products is reduced, installation and construction are convenient, the AGR pipe does not need to consider the influence of thermal expansion and cold contraction on the pipe, and construction can be conducted all the year round, in a high-temperature area and in a cold area.

Owner:CHENGDU CHUANXING TECH PLASTICS INDUSRTY CO LTD

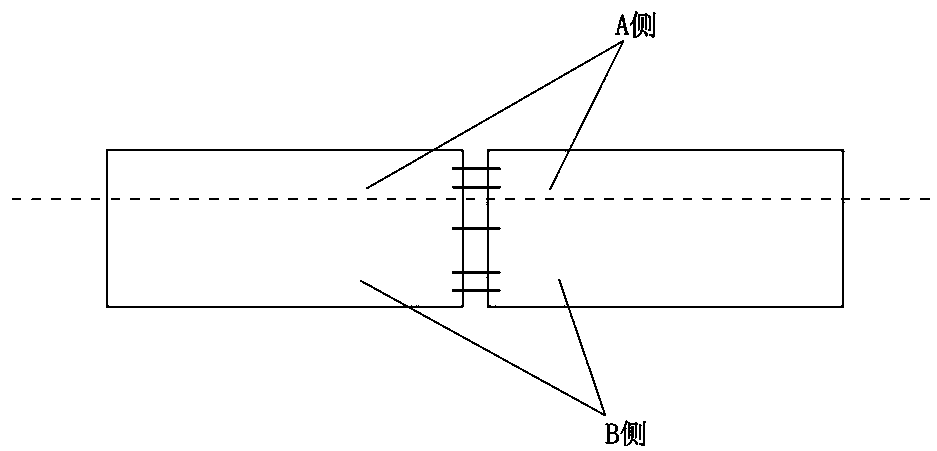

Light beam-electron beam composite brazing method for high-nitrogen steel

ActiveCN109128417AHigh strengthNo damageWelding/cutting media/materialsSoldering mediaOptical radiationHeat-affected zone

The invention discloses a light beam-electron beam composite brazing method for high-nitrogen steel. The method comprises the following steps that firstly, solder paste is prepared and applied to a to-be-welded surface of a welded part; secondly, the two ends and the center of the welded surface are subjected to optical radiation heating welding through xenon arc lamp light beam welding; thirdly,a side A of the to-be-welded surface is brazed through electron beam defocusing welding, and the welding parameters are set as follows: the vacuum degree is (2.5-5) x 10-8MPa, the electron beam current is 25-45mA, the partial beam amount of the electron beam current is 1.2-3.6mm, the welding speed is 8.5-11.5dm / min, the acceleration voltage is 45-65kV, and the focusing current is 2350-2760mA; andfourthly, a side B of the to-be-welded surface is brazed through electron beam focusing welding, and the welding parameters are set as follows: the electron beam current is 25-33mA, the partial beam amount of the electron beam current is 0.01-0.55mm, the welding speed is 3.5-7.5dm / min, the acceleration voltage is 45-65kV, and the focusing current is 2180-2250mA. During welding, high-nitrogen steelbase metal is not melted, nitrogen elements are not lost, pores are not prone to being formed, the welding heat affected zone and residual stress are reduced, and the mechanical properties of a brazed connector are enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

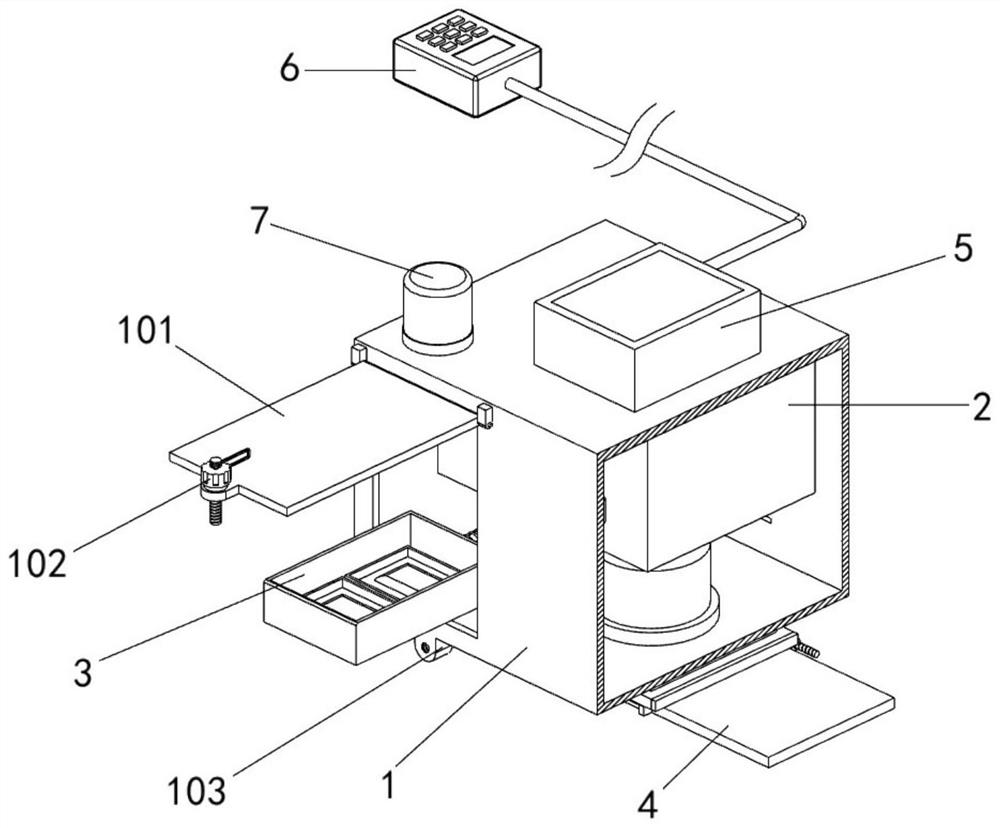

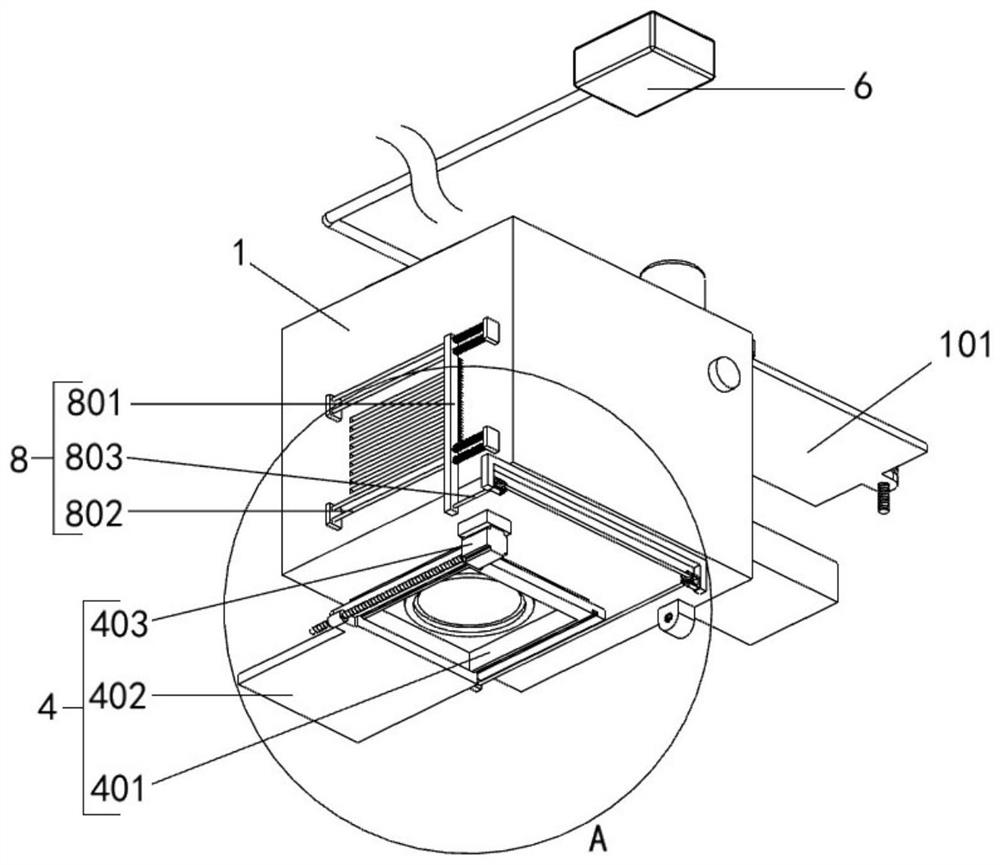

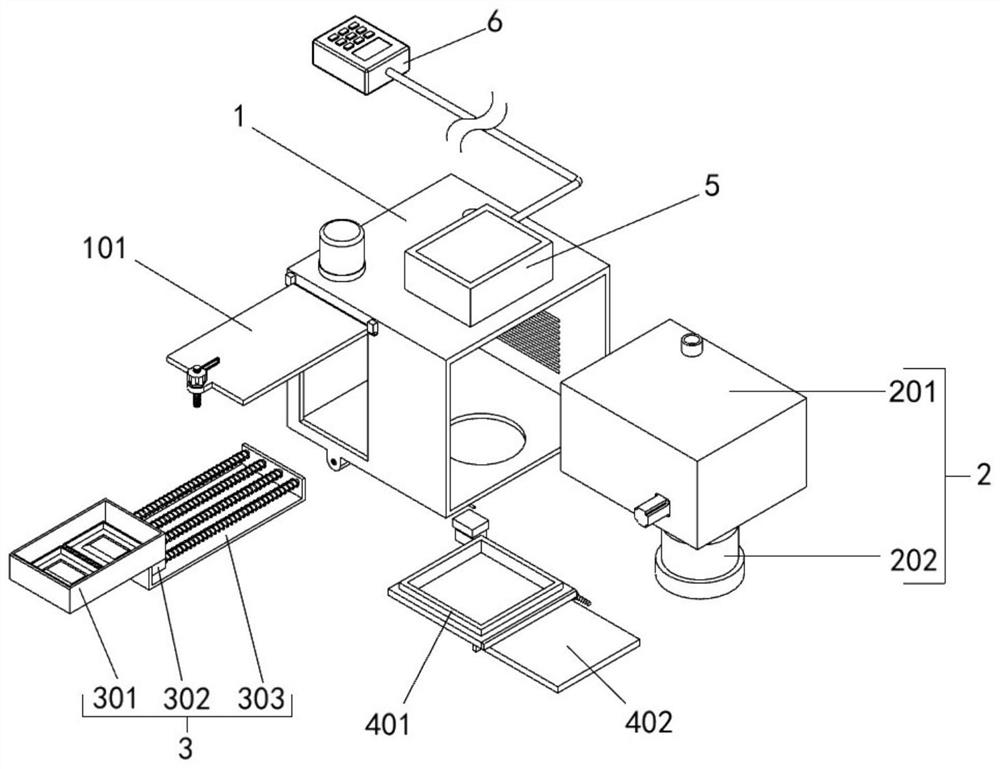

Laser galvanometer scanning system

ActiveCN113433687AImprove the efficiency of laser scanningImprove processing efficiencyDispersed particle separationOptical elementsGalvanometerLaser scanning

The invention provides a laser galvanometer scanning system, belongs to the technical field of laser galvanometers, and aims at solving problems that in the scanning process of an existing laser galvanometer, due to the fact that a single light beam galvanometer is adopted for scanning, laser scanning efficiency is low, and then technical cost is increased. The system comprises a shell, wherein a galvanometer supporting mechanism is arranged in the shell, and an inspection opening is formed in a left end of the front side in the shell; a drying piece is arranged in the shell and located at the inspection opening, a through hole is formed in the right side of the bottom end face of the shell, and a protection piece is arranged on a bottom end face of the shell and located outside the through hole; a control box is installed on a top end face of the shell and connected with a control switch through a wire, and an audible and visual alarm is installed at a left included angle of the front side of the top end face of the shell. The multi-beam galvanometer scanning system is adopted for scanning, laser scanning efficiency is greatly improved, then the technical cost is reduced, machining efficiency is improved, and the machining time is shortened.

Owner:深圳市力智鉴实业有限公司

Aluminum alloy fishing barrel

The invention discloses an aluminum alloy fishing barrel. The aluminum alloy fishing barrel comprises a barrel body and a lifting handle arranged at the upper part of the barrel body, wherein the barrel body is made of aluminum alloy; the aluminum alloy is prepared from the following components in percentage by weight: 0.40 to 0.44 percent of Si, 0.64 to 0.66 percent of Mg, 0.02 percent of Cu, 0.23 to 0.25 percent of Fe, 0.02 to 0.03 percent of Sr, 0.14 percent of La, 0.18 percent of Nd, 0.03 to 0.05 percent of Zn, 0.02 to 0.05 percent of Ti and the balance being Al. The aluminum alloy fishing barrel has the advantages of smooth surface, wider hardness range and good stress corrosion resistance.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

Stress-corrosion-resistant aluminum alloy

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

Environment-friendly and efficient anti-corrosion garbage can

InactiveCN106742904AAvoid corrosionEasy to breatheWaste collection and transferRefuse receptaclesWater storage tankEngineering

The invention discloses an environment-friendly and efficient anti-corrosion garbage can, and relates to the field of garbage cans. The environment-friendly and efficient anti-corrosion garbage can comprises a can body. A garbage inlet is formed in the upper end of the can body, and rolling wheels are arranged at the lower end of the can body. A side door is arranged on the can body and hinged to the can body. First sliding grooves and second sliding grooves are formed in the symmetric positions of the inner wall of the can body correspondingly. The second sliding grooves are formed under the first sliding grooves correspondingly. A first rectangular frame is arranged between the first sliding grooves and can move along the first sliding grooves. An arc-shaped filter screen is arranged at the lower end of the first rectangular frame. A second rectangular frame is arranged between the second sliding grooves and can move along the second sliding grooves. An arc-shaped water storage tank is arranged at the lower end of the second rectangular frame. A flowerpot is arranged on the outer wall of the can body and arranged below the arc-shaped water storage tank. A water pipe is arranged between the arc-shaped water storage tank and the flowerpot. By means of the design, the structure is simple and reasonable, solid and liquid garbage separation treatment is achieved, and energy saving and environment friendliness are achieved.

Owner:SHANGHAI XUNXI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com