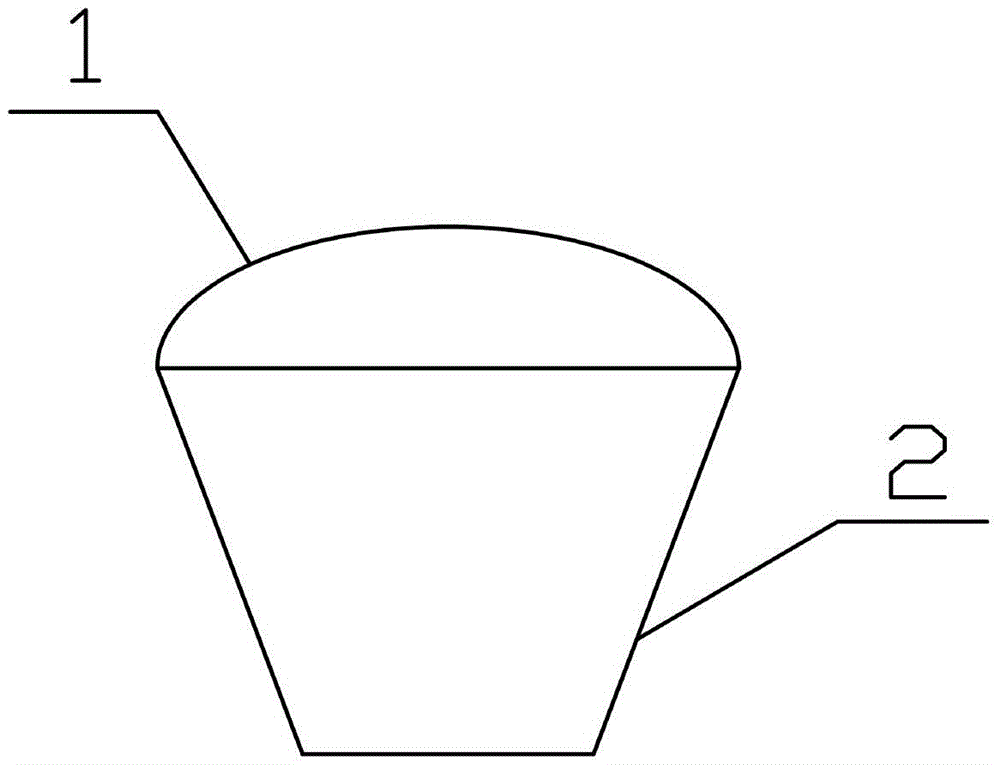

Aluminum alloy fishing barrel

A technology of aluminum alloy and salvage barrel, which is applied in ship salvage, ship, transportation and packaging, etc. It can solve problems such as stress corrosion and achieve good stress corrosion resistance, high hardness and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The weight percentages of the components in the aluminum alloy in this example are as follows: Si: 0.40%, Mg: 0.64%, Cu: 0.02%, Fe: 0.23%, Sr: 0.03%, La: 0.14%, Nd: 0.18%, Zn : 0.03%, Ti: 0.05%, and the rest is Al.

[0016] The above components are used to prepare aluminum alloy profile products. The specific preparation method is: after mixing the components evenly, they are homogenized in the aluminum rod furnace to improve the uniformity of the overall performance, so that the material has both appropriate hardness and toughness. Then it is cooled by air, and the ingot is heated at 450-500°C, and then sent to the extruder for extrusion. The temperature of the extrusion barrel is 400°C±10°C, and the extrusion speed is 3-6m / min. After mist quenching, after cutting, cooling bed cooling, stretching and straightening, artificial aging is carried out. The holding temperature is 250°C±10°C, and the time is 180min, to obtain the finished aluminum alloy. After testing, the h...

Embodiment 2

[0018] The weight percentages of the components in the aluminum alloy in this example are as follows: Si: 0.44%, Mg: 0.66%, Cu: 0.02%, Fe: 0.25%, Sr: 0.02%, La: 0.14%, Nd: 0.18%, Zn : 0.05%, Ti: 0.02%, and the rest is Al.

[0019] The above components are used to prepare aluminum alloy profile products. The specific preparation method is: after mixing the components evenly, they are homogenized in the aluminum rod furnace to improve the uniformity of the overall performance, so that the material has both appropriate hardness and toughness. Then it is cooled by air, and the ingot is heated at 450-500°C, and then sent to the extruder for extrusion. The temperature of the extrusion barrel is 400°C±10°C, and the extrusion speed is 3-6m / min. After mist quenching, after cutting, cooling bed cooling, stretching and straightening, artificial aging is carried out. The holding temperature is 250°C±10°C, and the time is 180min, to obtain the finished aluminum alloy. After testing, the h...

Embodiment 3

[0021] The weight percentages of the components in the aluminum alloy in this example are as follows: Si: 0.42%, Mg: 0.65%, Cu: 0.02%, Fe: 0.24%, Sr: 0.03%, La: 0.14%, Nd: 0.18%, Zn : 0.05%, Ti: 0.04%, and the rest is Al.

[0022] The above components are used to prepare aluminum alloy profile products. The specific preparation method is: after mixing the components evenly, they are homogenized in the aluminum rod furnace to improve the uniformity of the overall performance, so that the material has both appropriate hardness and toughness. Then it is cooled by air, and the ingot is heated at 450-500°C, and then sent to the extruder for extrusion. The temperature of the extrusion barrel is 400°C±10°C, and the extrusion speed is 3-6m / min. After mist quenching, after cutting, cooling bed cooling, stretching and straightening, artificial aging is carried out. The holding temperature is 250°C±10°C, and the time is 180min, to obtain the finished aluminum alloy. After testing, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com