Novel ink stone

A kind of inkstone, a new type of technology, applied in the direction of ink station, coating, printing, etc., can solve the problems of ink storage performance reduction, solidification, inkstone strength reduction, etc., to achieve the effect of preventing ink from solidification and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

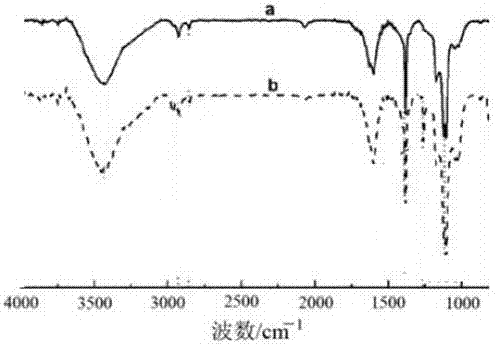

[0038] The addition of silica-modified polyester can enhance the toughness of the inkstone while maintaining the hardness, reduce the hardness of the inkstone caused by cracks caused by the dissolution phenomenon, and reduce the possibility of the inkstone being broken. The preparation method of described silicon dioxide modified polyester comprises:

[0039] The first step is to pulverize silicon dioxide, dry at high temperature, pass through a 100-mesh sieve, and add 200ml of an aqueous solution of surface modifier sodium stearate for every 300g of sieved silicon dioxide powder (hard The content of sodium bicarbonate is 3g), stirred at room temperature at high speed for 30 minutes, filtered, the filter cake was washed 3 times with absolute ethanol, each ethanol consumption was 30ml, the filter cake was dried, and ground into powder;

[0040] In the second step, based on 5g of dimethyl phthalate, for every 5g of dimethyl terephthalate, 10g of 1,2-propanediol and 1g of tetra-n...

Embodiment 1

[0067] Embodiment 1 Alcohol amine modified epoxy resin

[0068] Add solvent absolute ethanol and bisphenol A type epoxy resin E51 into the reaction vessel, the molar ratio of the two is 4:1, stir and preheat at 60°C for 50 minutes, then slowly add diglycolamine, diethylene glycol The molar ratio of amine to bisphenol A epoxy resin E51 is 0.3:1, and the temperature is raised to 85°C for 3 hours, and then the temperature is lowered to 60°C and then neutralized by adding glacial acetic acid to form a salt. Bisphenol A epoxy resin E51 is mixed with ice The mol ratio of acetic acid is 1:0.3, reacts for 40 minutes, adds deionized water, obtains alcohol amine modified epoxy resin, the ratio of bisphenol A type epoxy resin and deionized water is that 1mol resin corresponds to 10ml deionized water, obtains Alcohol modified epoxy resin.

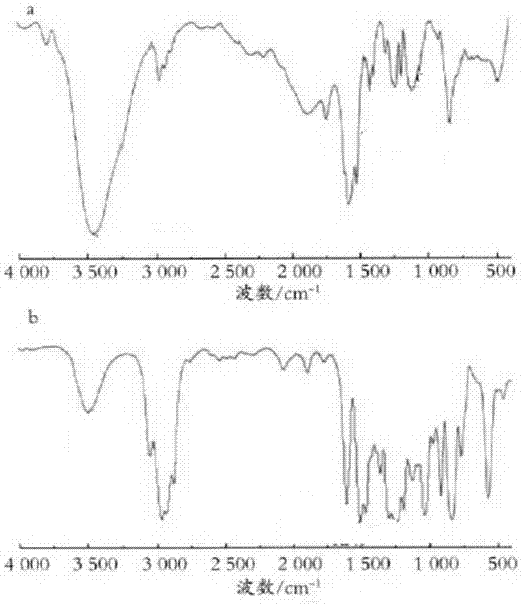

[0069] The infrared spectrum of the product is shown in figure 1 , a is the spectrum of epoxy resin before modification, b is the spectrum of epoxy ...

Embodiment 2

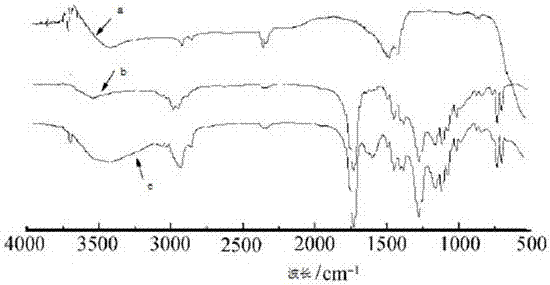

[0070] Example 2 Silica modified polyester

[0071] Silica is pulverized, dried at high temperature, and passed through a 100-mesh sieve. For every 300 g of sieved silica powder, add 200 ml of an aqueous solution of surface modifier sodium stearate (the content of sodium stearate in the 100 ml solution is 3g), stirred at room temperature for 30 minutes at high speed, filtered, the filter cake was washed 3 times with absolute ethanol, and the amount of ethanol was 30ml each time, the filter cake was dried, and ground into powder, taking 5g of dimethyl phthalate as the measurement basis For every 5g of dimethyl terephthalate, 10g of 1,2-propanediol, and 1g of tetra-n-butyl titanate added to the reaction vessel, nitrogen gas was introduced into the reaction vessel, and the temperature was raised. Stirring was started after the materials were melted. Control the reaction temperature at 180 degrees, when the acid value drops to 8mgKOH / g, lower the temperature, further add 30g malei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com