Sulfuric acid evaporator for refined acid producing apparatus

A production device and evaporator technology, applied in evaporator adjustment/control, evaporation, sulfur compounds, etc., can solve problems such as poor inspection and maintenance conditions, difficulty in controlling liquid level, high cylinder pressure and thermal expansion compensation requirements, and achieve The effect of convenient medium treatment, not easy to local corrosion, and easy on-site inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

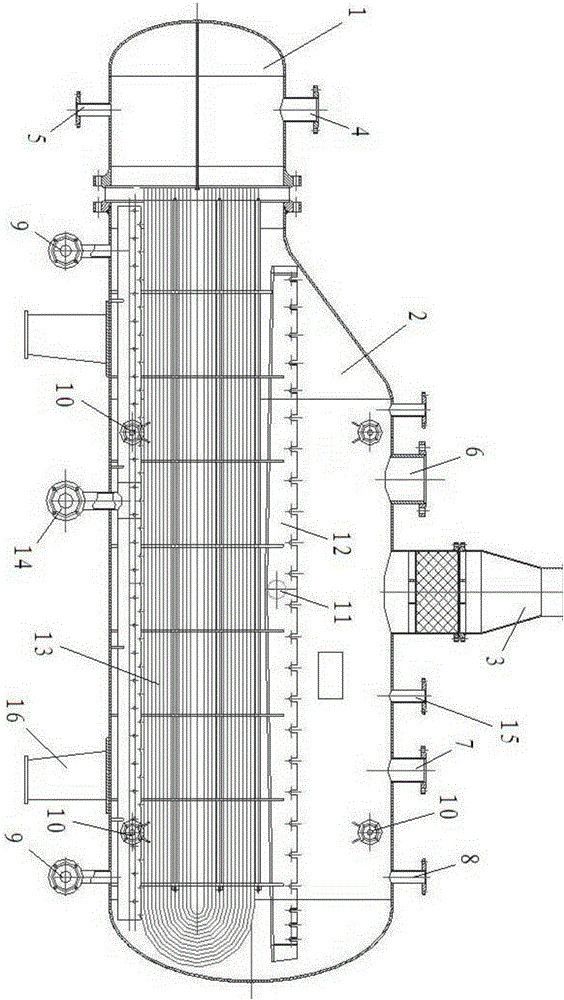

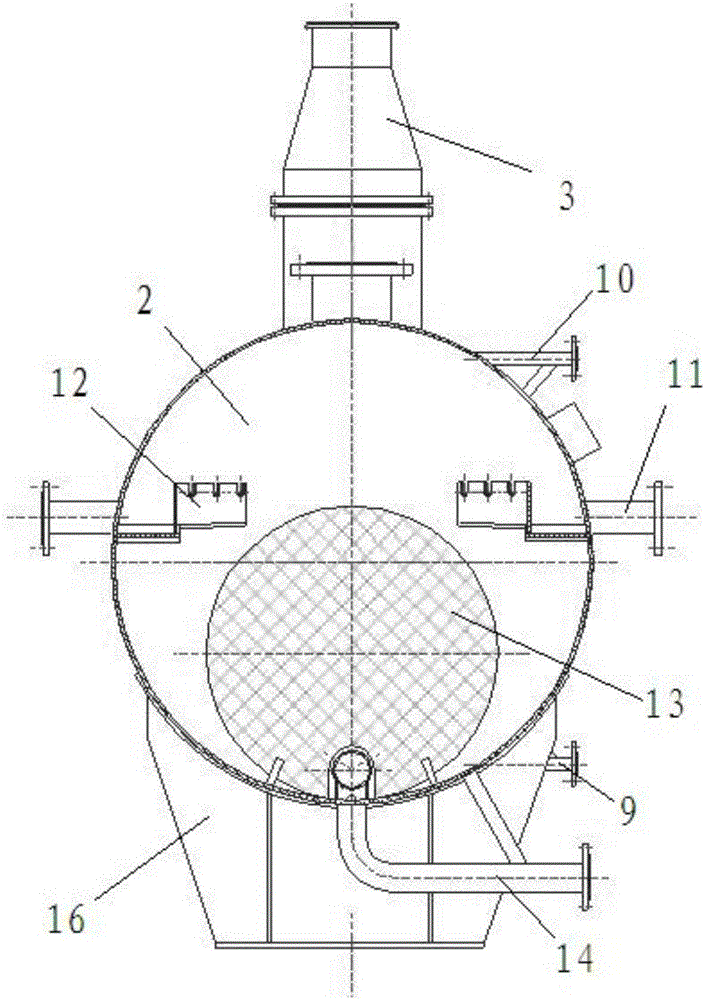

[0020] to combine Figure 1-Figure 3 As shown, a sulfuric acid evaporator used in a refined acid production device has a niacin tank 2 and a water vapor tank 1, and the niacin tank 2 and the water vapor tank 1 are connected by a flange. The bottom of the nicotinic acid tank body 2 is provided with a nicotinic acid inlet 14, and the top is provided with SO 3 The gas outlet 3 is provided with a nicotinic acid outlet 11 on both side walls of the middle part of the nicotinic acid tank body 2 , and a base 16 is arranged at the lower end of the nicotinic acid tank body 2 .

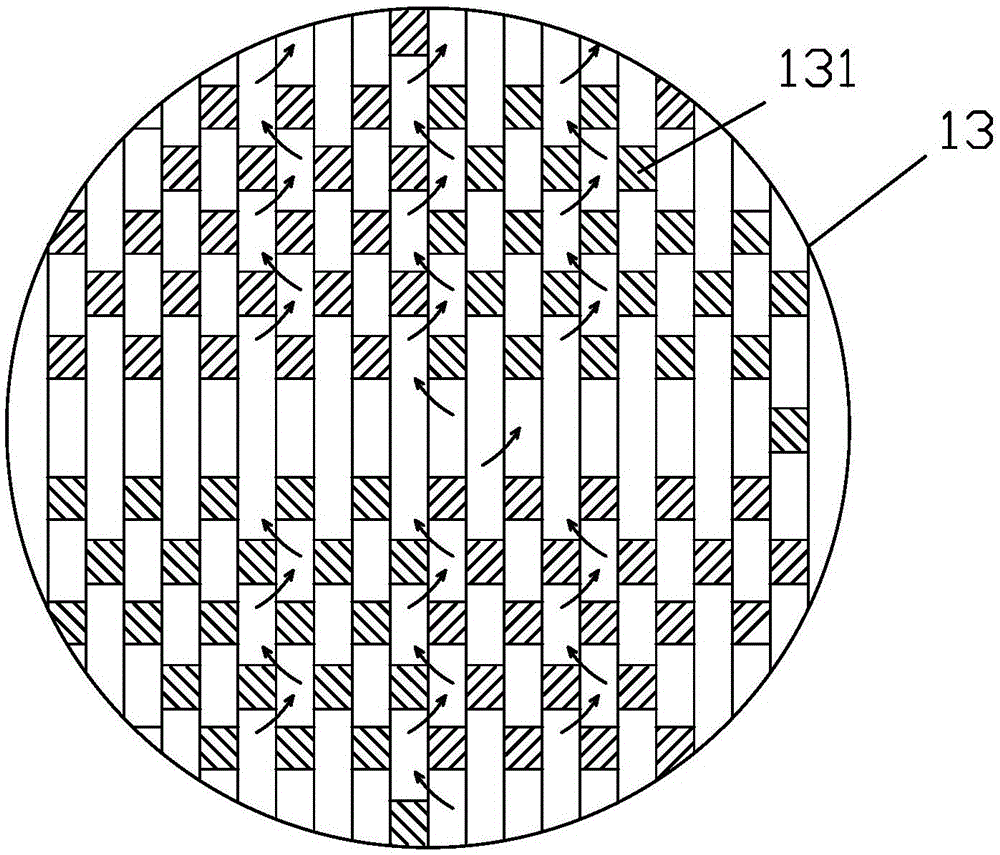

[0021] The top of the water vapor tank 1 is provided with a steam inlet 4, and the bottom is provided with a condensate outlet 5. The nicotinic acid tank 2 is provided with a U-shaped tube bundle 13. The entrance of the U-shaped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com