Processing method of multiple bamboo sheet sandwiching solid stick

A processing method and solid technology, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of rough product surface, waste of moso bamboo raw materials, low utilization rate of moso bamboo, etc., and achieve smooth and beautiful surface, not easy to crack and not easy to mildew Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

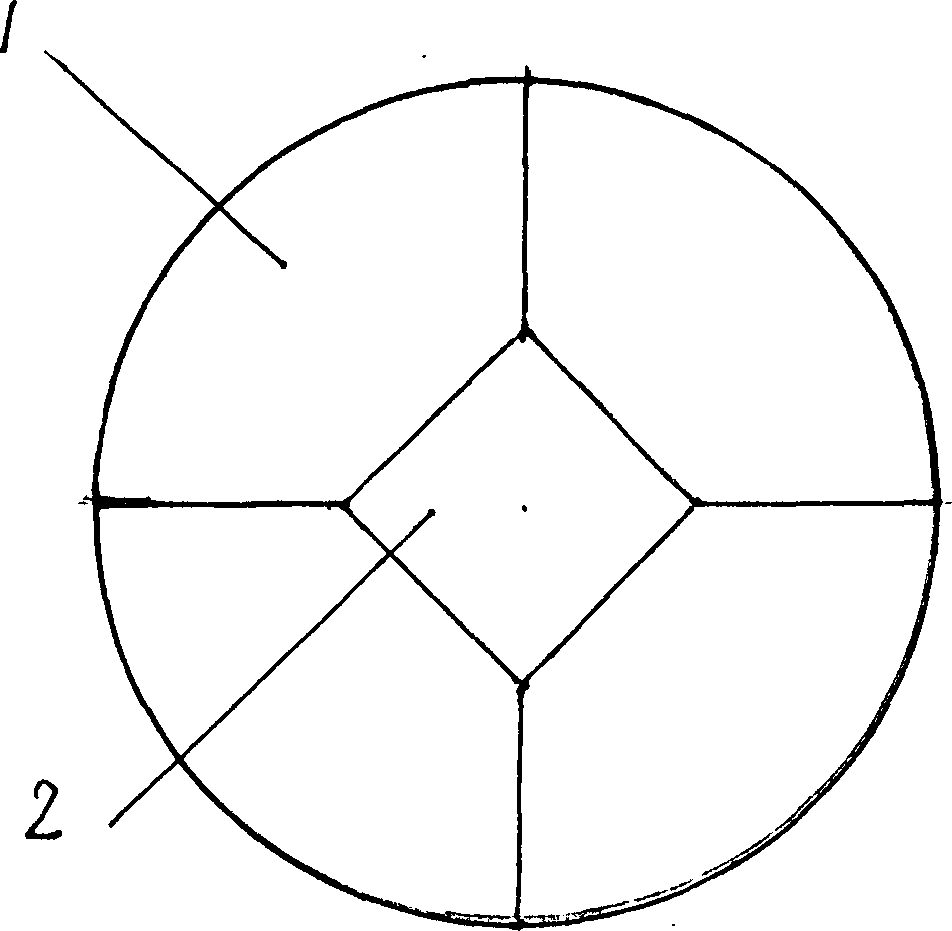

[0012] Embodiment 1 (square core stick)

[0013] Cut the bamboo into sections, split and cut them into fan-shaped bamboo slices with a cross-section bottom angle of 135° and a circular arc of 90°. Adhesively bundled on a core strip with a square section in turn, then put it into a hot press to form, take it out, polish it with a polishing machine, and then paint it to get the finished product.

Embodiment 2

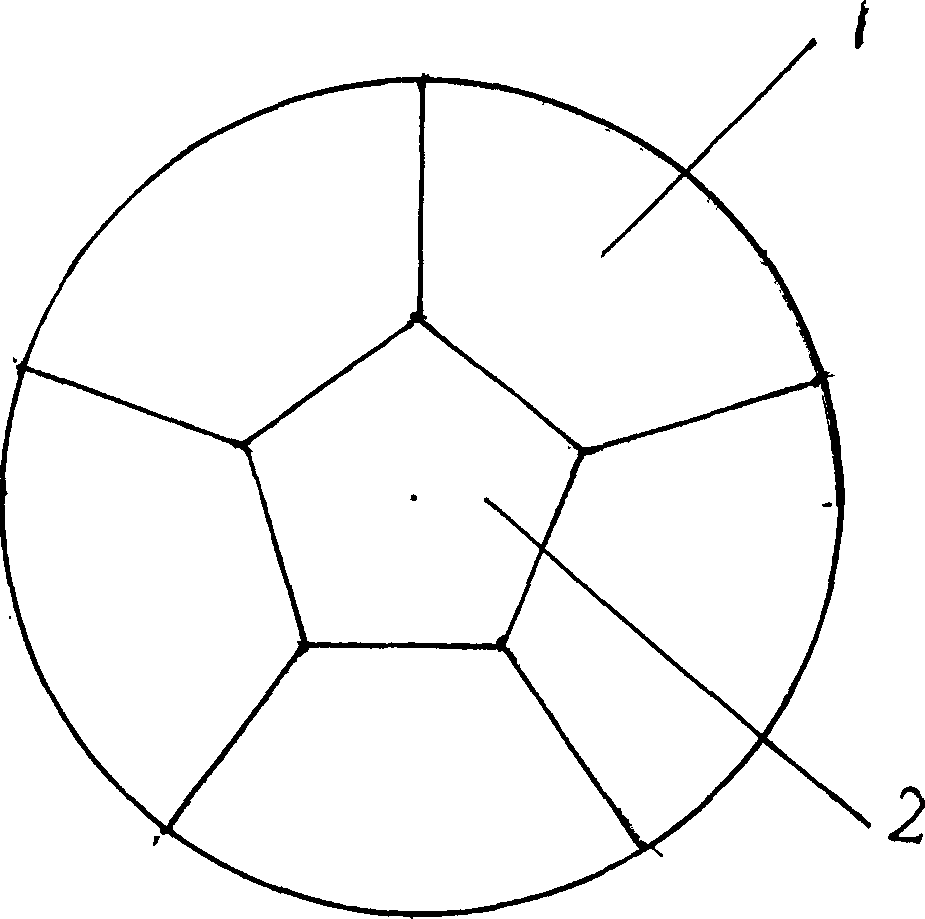

[0014] Embodiment 2 (pentagonal core stick)

[0015] Cut the bamboo into sections, split and cut them into fan-shaped bamboo slices with a cross-section bottom angle of 126° and a circular arc of 72°. Adhesion is bundled on a core strip with a pentagonal cross-section in turn, and then placed in a hot press for molding, taken out, polished with a polishing machine, and then painted to obtain the finished product.

Embodiment 3

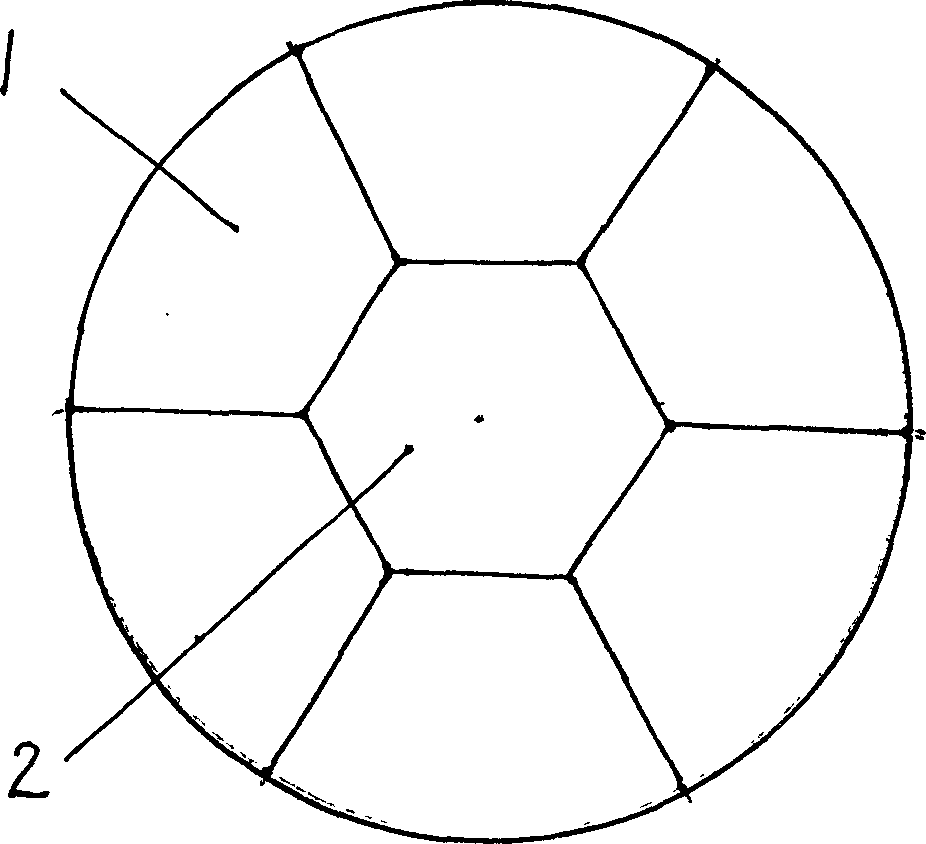

[0016] Embodiment 3 (hexagonal core stick)

[0017] Cut the bamboo into sections, split and cut them into fan-shaped bamboo slices with a bottom angle of 120° and a circular arc of 60°. After killing insects, removing mildew, drying, and disinfecting, the six bamboo slices are glued together with plants. Bundled in sequence on a core strip with a hexagonal cross-section, then put it into a hot press for molding, take it out, polish it with a polishing machine, and then paint it to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com