Conductor rail and manufacturing method thereof

A technology of conductive rails and brushes, which is applied in the direction of power rails, etc., can solve the problems of high manufacturing cost and high forming requirements of brush plates, and achieve the effects of less corrosion, easy deformation, and reasonable deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

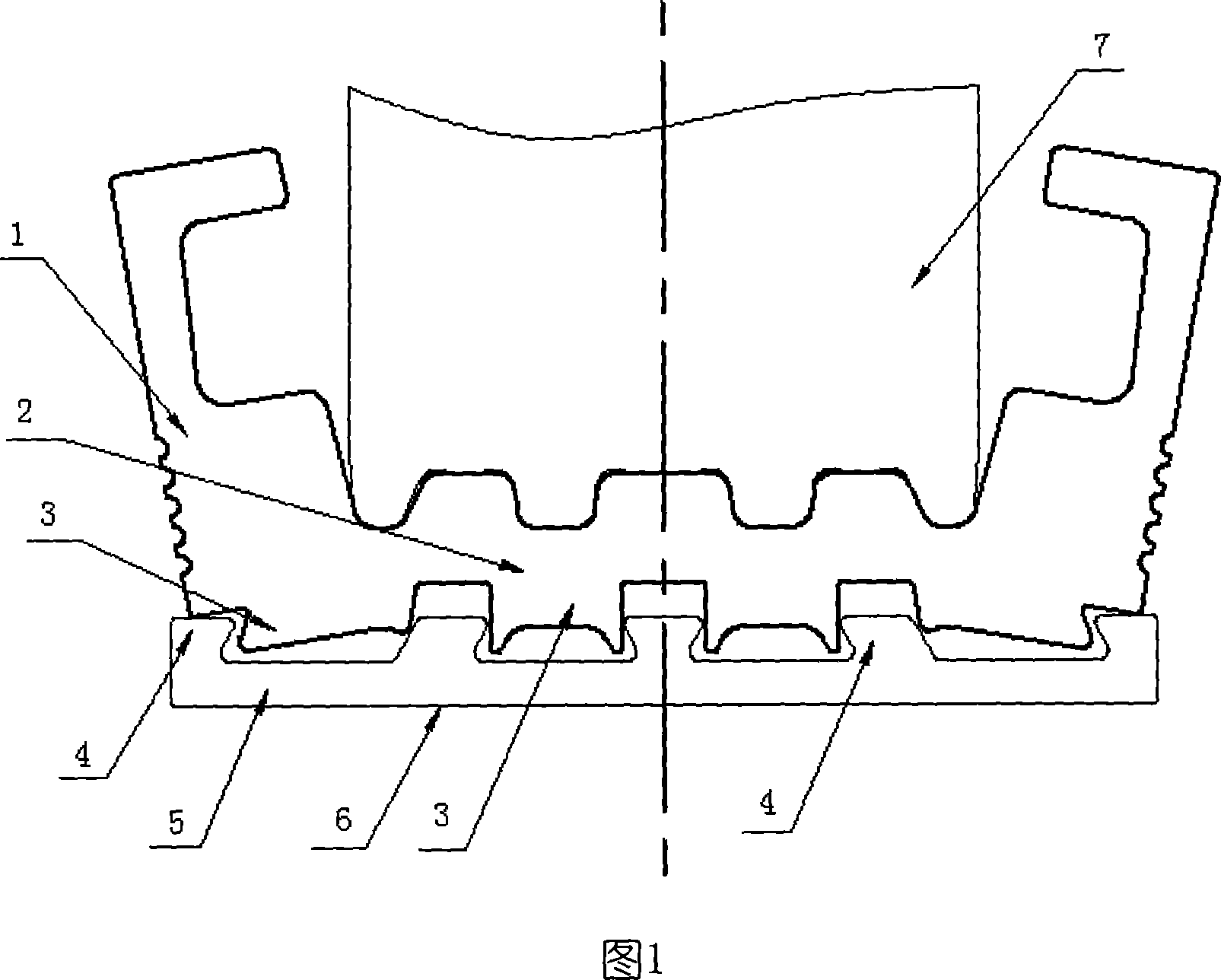

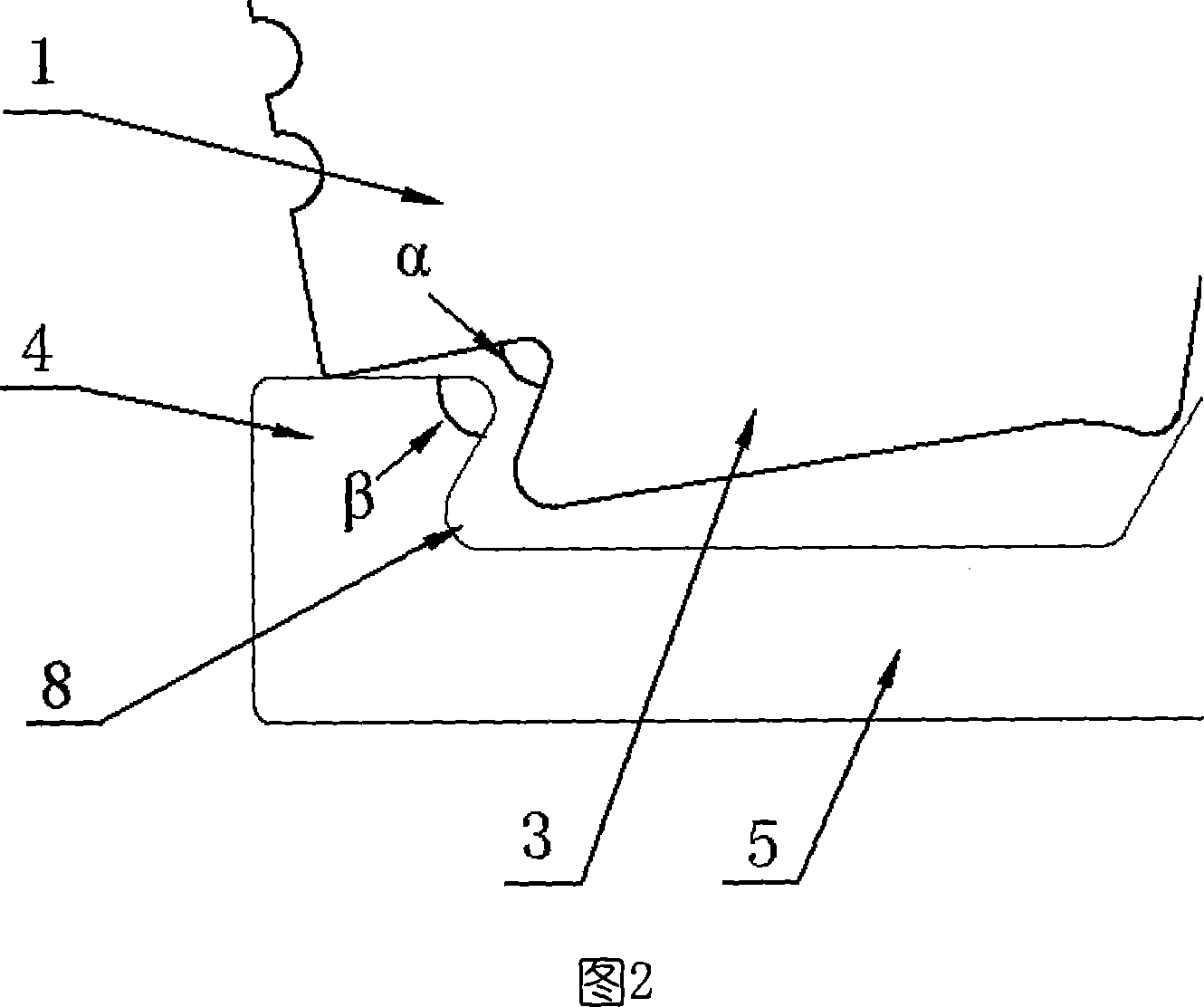

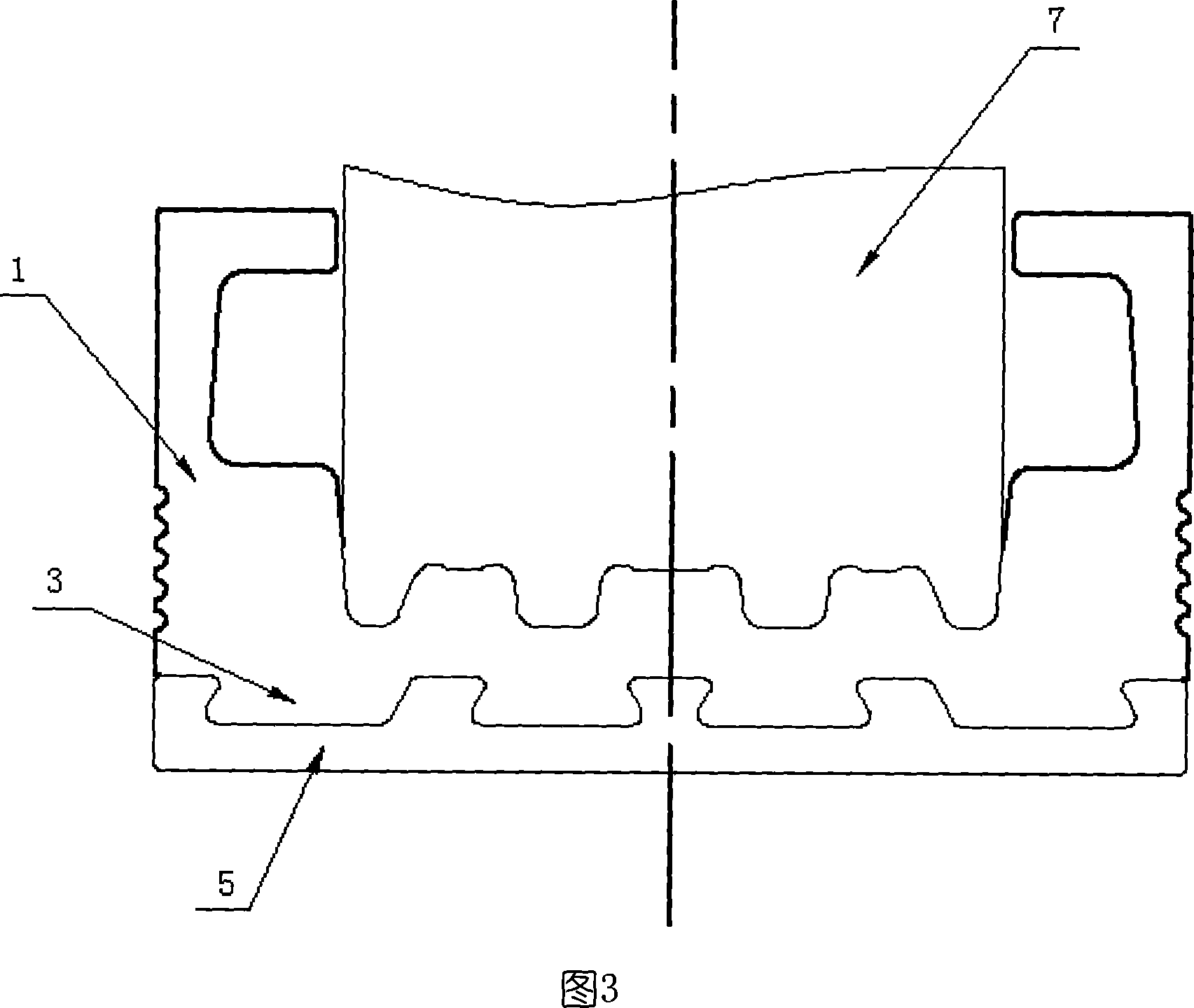

[0025] Specific embodiment 1 of the present invention, as shown in Fig. 1, 3, a kind of conductive rail, comprises the electric brush surface 5 that matrix 1 and wear-resistant material are made, and the back of electric brush surface 5 has protruding slat 4 inlay In the base body 1 , the portion between the strip 4 and the back of the brush face 5 forms a recess 8 , which is filled with the material of the base body 1 .

[0026] As shown in Figure 1, the interlaced filling part of the matrix 1 and the slats 4 is located between the two outermost slats 4 on the back of the brush surface 5; before assembly, the bottom of the filling part 3 of the matrix 1 is sunken upwards, and A space is formed between the backs of the brush faces 5 , and after the assembly is completed, the space is squeezed and disappears, and the bottom of the filling part 3 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com