Process for aldehyde removal from alcohols by treatment with bisulphite

A technology of bisulfite and sodium bisulfite, applied in the field of purifying alcohol, can solve problems such as value reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

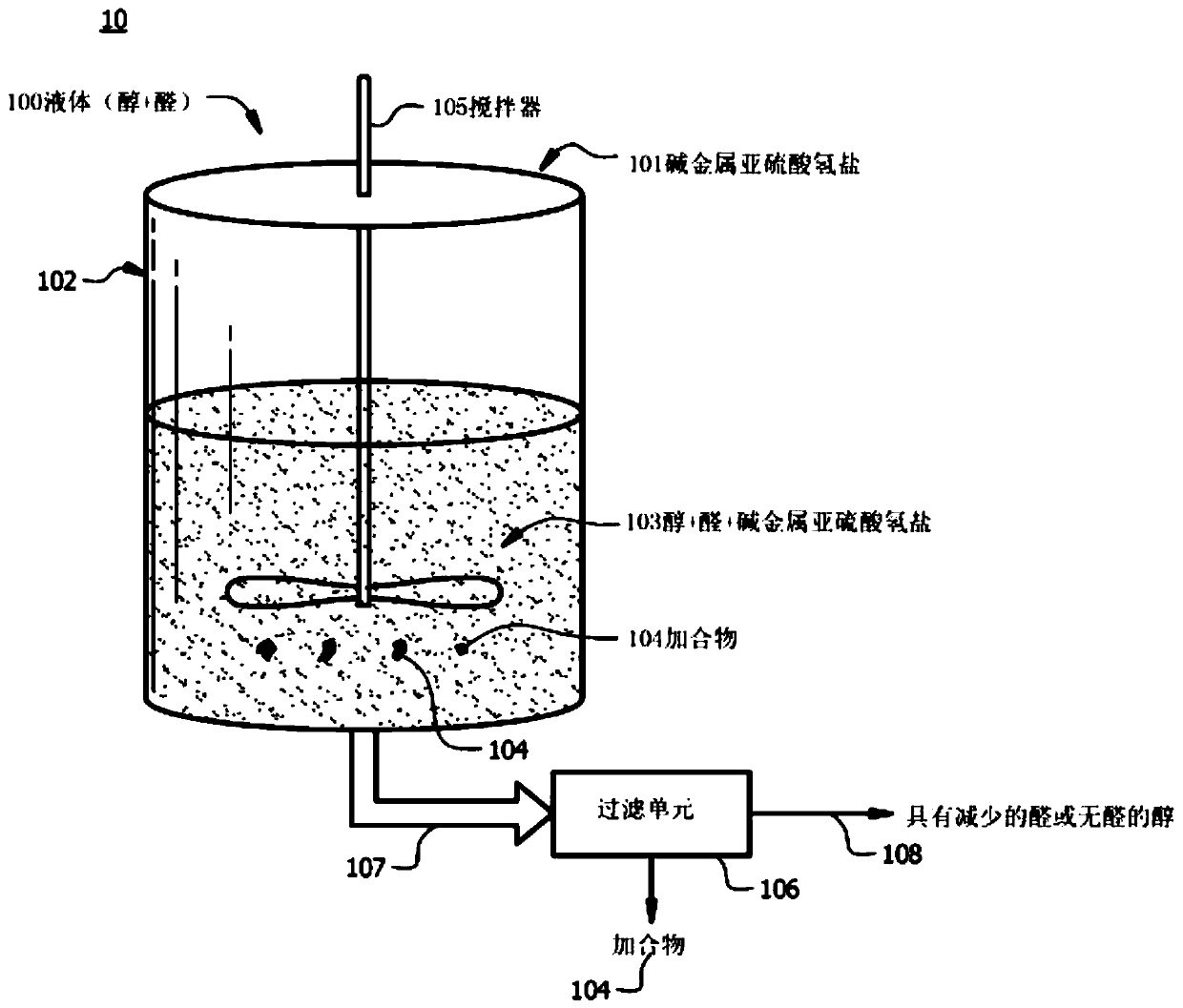

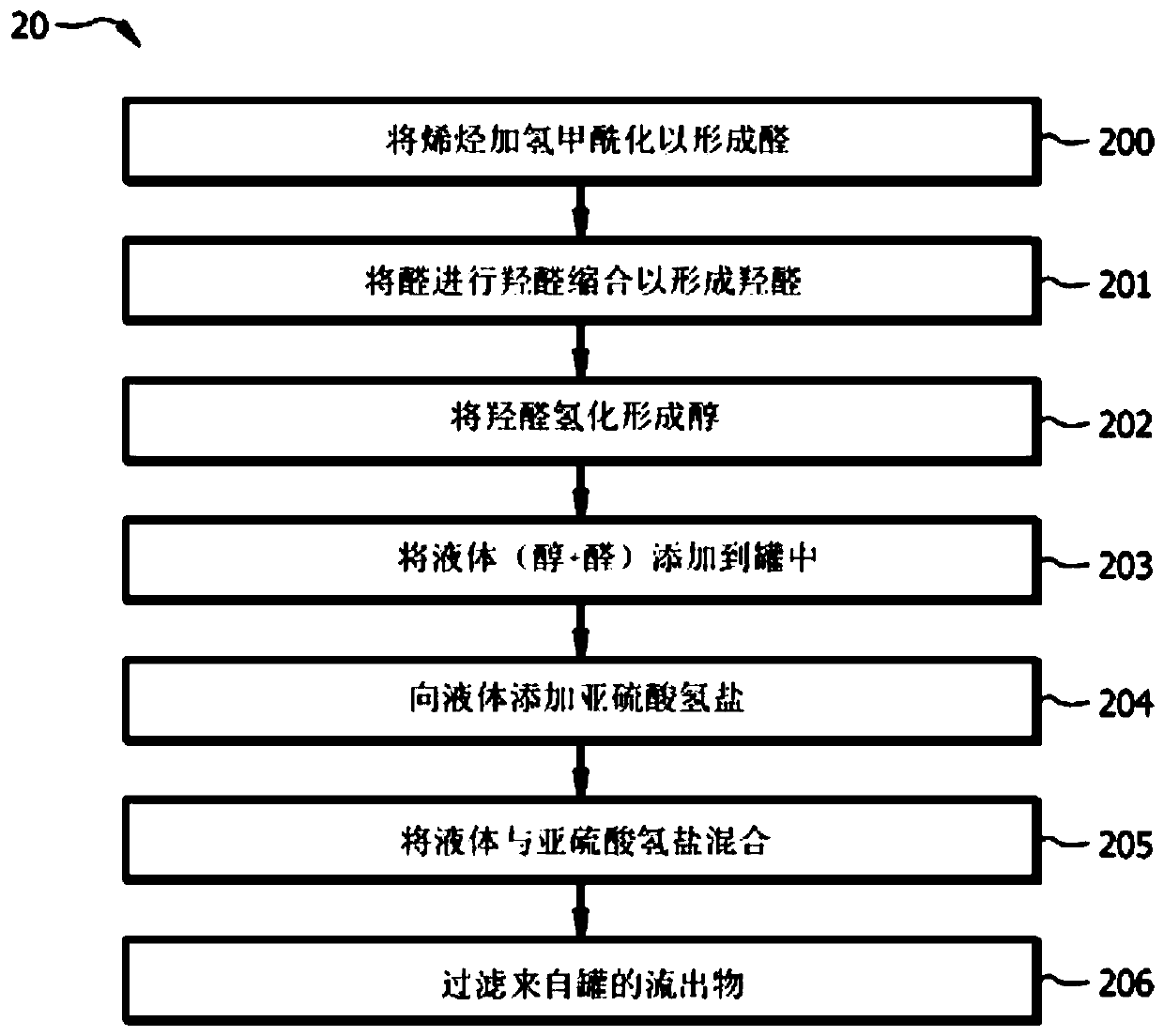

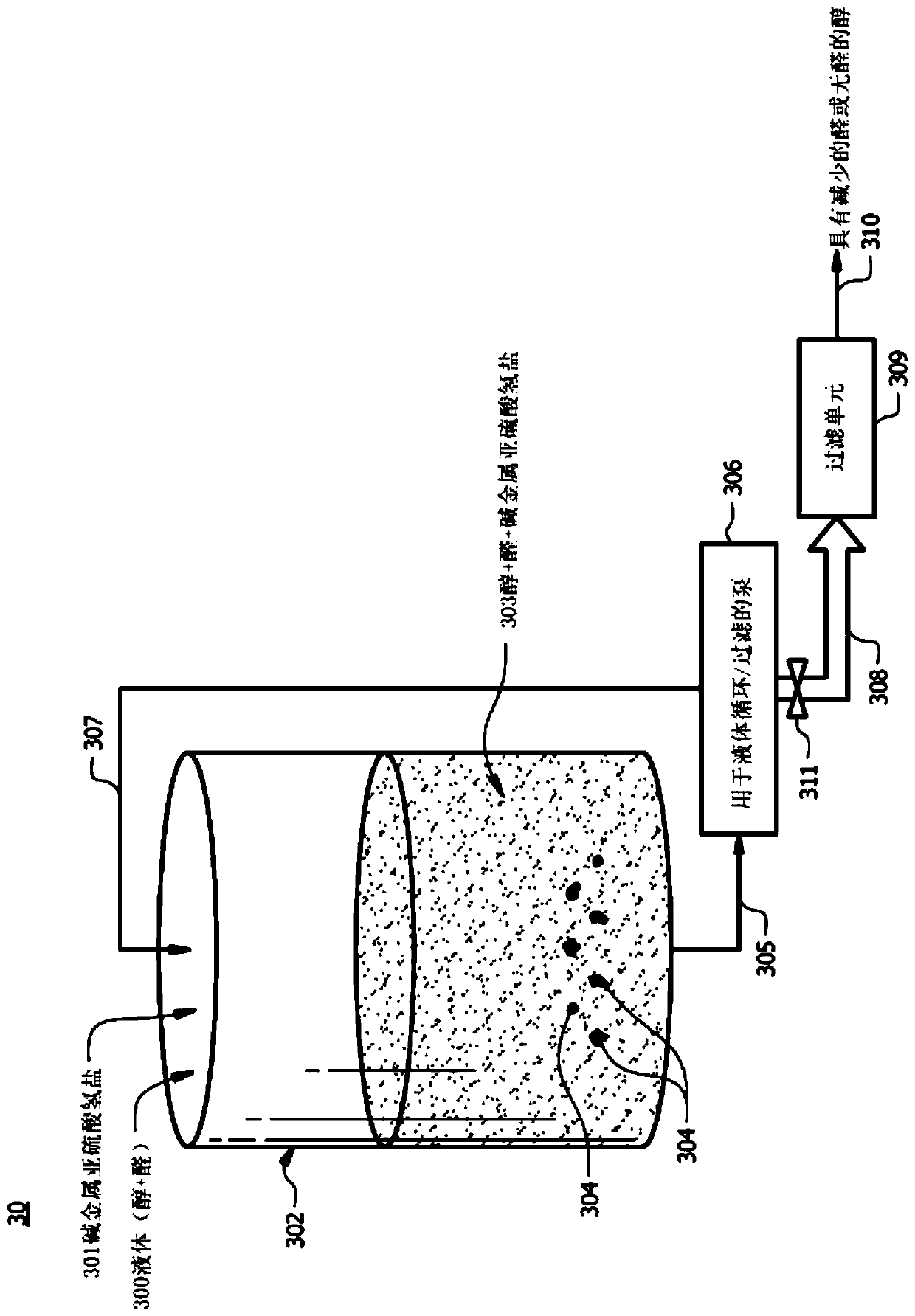

Method used

Image

Examples

Embodiment

[0048] As part of the disclosure of the present invention, specific examples are included below. The examples are for illustrative purposes only and are not intended to limit the invention. Those skilled in the art will readily recognize parameters that can be changed or modified to produce substantially the same results.

[0049] Example

[0050] (Purification of 2-ethylhexanol)

[0051]37 ml of a 2-ethylhexanol solution with 361.27 ppm of aldehyde was stirred with 0.5 g of sodium sulfite at room temperature (25° C.) for 1 hour. The mixture was filtered and analyzed for aldehydes by gas chromatography (GC). The sodium bisulfite treated sample had 35 ppm aldehyde, which corresponds to greater than 90% reduction of the aldehyde (see Table 1).

[0052] Table 1

[0053] Sample name Average concentration of aldehyde (ppm) Feed 361.27 processed sample 35.68

[0054] The results of this example demonstrate the effectiveness of the concept of using s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com