Chemical modification-based salt-resistant high-temperature-resistant resin filtrate reducer as well as preparation method and application thereof

A fluid loss reducer and chemical modification technology, used in resin type anti-salt anti-high temperature fluid loss reducer, petroleum industry, can solve the problems of poor biodegradability, application limitation, poor degradability, etc., to achieve environmental performance Excellent, cost-effective, easily biodegradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

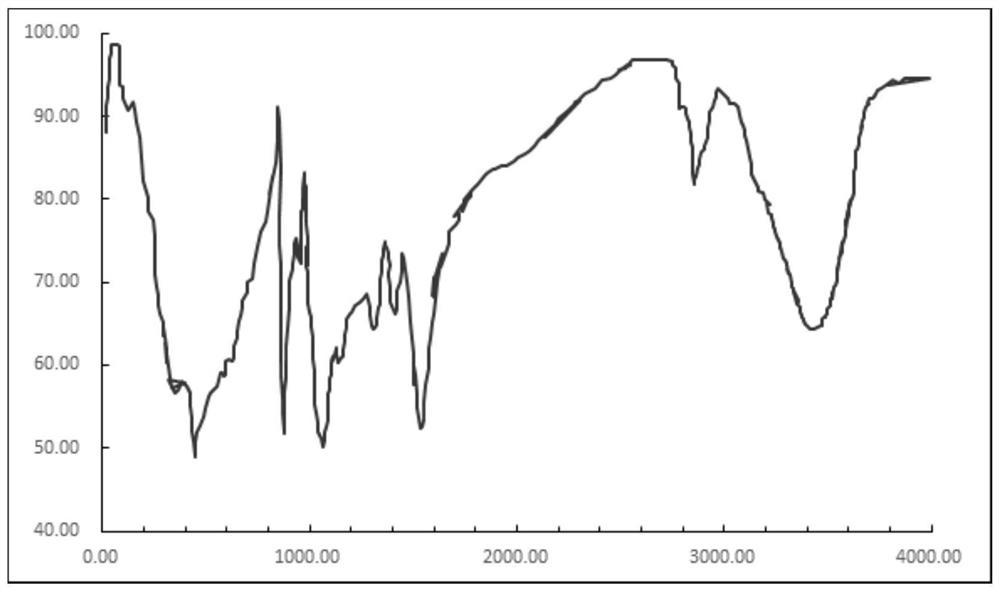

Image

Examples

preparation example Construction

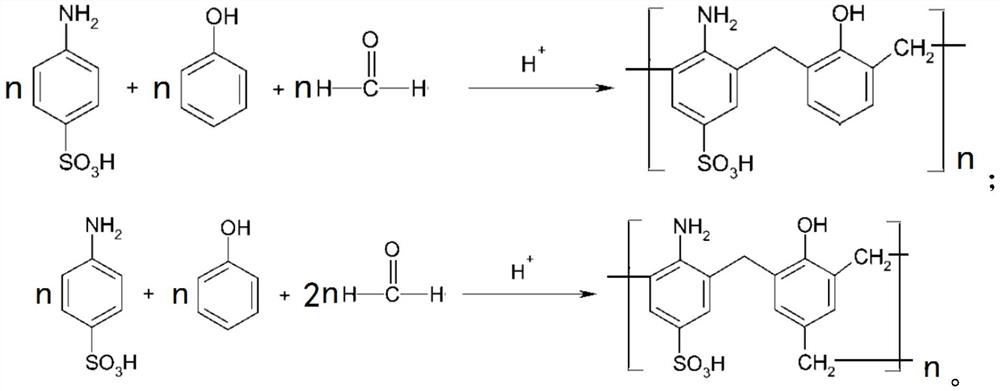

[0021] The invention provides a method for preparing a resin-based anti-salt and high-temperature fluid loss reducer based on chemical modification, comprising the following steps:

[0022] S1. Polymerizing p-aminobenzenesulfonic acid, phenol and paraformaldehyde to obtain an oligomerization product;

[0023] S2, reacting the enzymatically hydrolyzed lignin with bisulfite and the oligomerization product in an alkaline environment to obtain a resinous salt-resistant and high-temperature fluid loss reducer.

[0024] Focusing on the development direction of green chemicals and green synthesis, the present invention prepares a temperature-resistant, salt-resistant, biodegradable resin fluid loss control agent through molecular design, which is beneficial for application.

[0025] The present invention uses chemical modification to prepare anti-salt and high-temperature fluid loss reducer products. The product is mainly prepared from the following raw materials: p-aminobenzenesulfo...

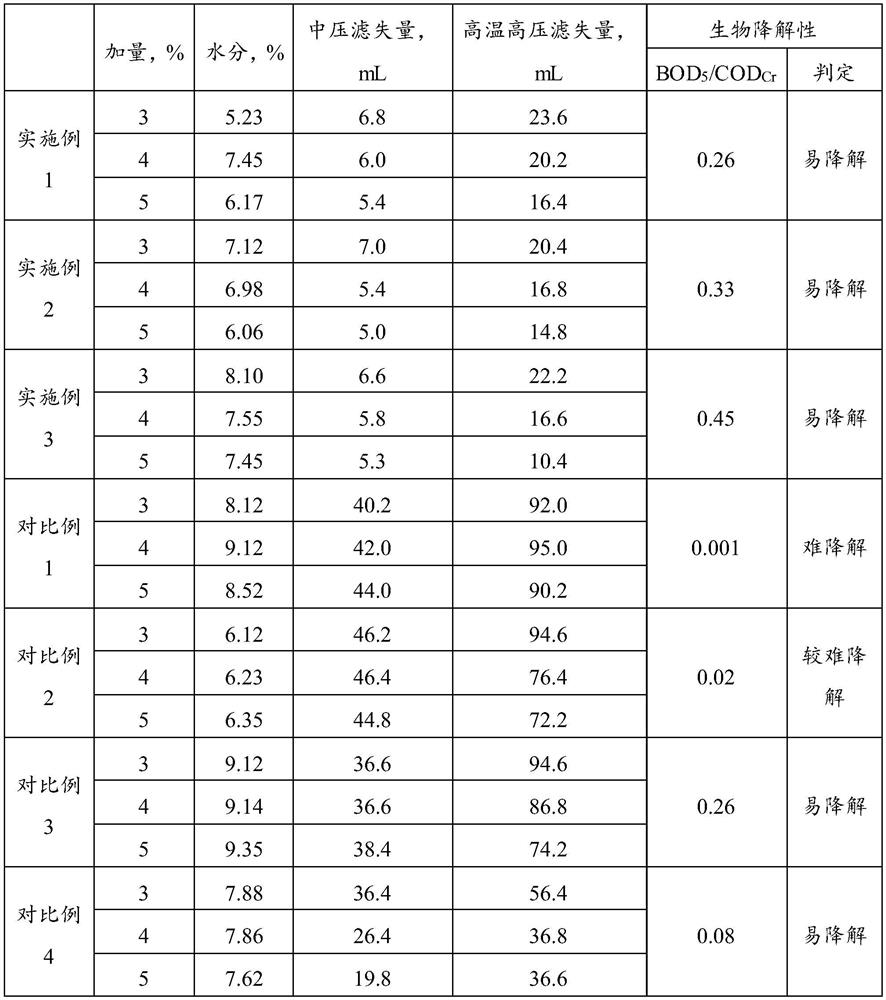

Embodiment 1

[0048] The anti-salt and anti-high temperature fluid loss reducer described in this embodiment is made of the following raw materials in parts by mass:

[0049] 100 parts of water, 20 parts of p-aminobenzenesulfonic acid, 30 parts of enzymatic lignin, 20 parts of phenol, 15 parts of paraformaldehyde, 4.5 parts of anhydrous sodium bisulfite, 1.5 parts of sodium carbonate.

[0050] The preparation method comprises the following process steps:

[0051] Add 100 parts of clean water into the reaction kettle, and under stirring, add p-aminobenzenesulfonic acid, phenol, and paraformaldehyde in sequence according to the above mass ratio, and slowly heat to 60°C for reaction. The reaction time is 2 hours, and sodium carbonate is added to adjust the pH. When the value reaches 10, add enzymatic lignin and anhydrous sodium bisulfite to continue the reaction for 2 hours, then raise the temperature to 95°C, and continue the reaction for 4 hours to obtain a viscous liquid. Finally, the visco...

Embodiment 2

[0054] The anti-salt and anti-high temperature fluid loss reducer described in this embodiment is made of the following raw materials in parts by mass:

[0055] 110 parts of water, 35 parts of p-aminobenzenesulfonic acid, 40 parts of enzymatic lignin, 30 parts of phenol, 20 parts of paraformaldehyde, 5.0 parts of anhydrous sodium bisulfite, 2.0 parts of sodium carbonate;

[0056] The preparation method comprises the following process steps:

[0057] Add 110 parts of clear water into the reaction kettle, and under stirring, add p-aminobenzenesulfonic acid, phenol, and paraformaldehyde in sequence according to the above mass ratio, and slowly heat to 65°C for reaction. The reaction time is 1.5h, and sodium carbonate is added to adjust When the pH value reaches 10, add enzymatic lignin and anhydrous sodium bisulfite to continue the reaction for 1.5 hours, then raise the temperature to 100°C, continue the reaction for 3.5 hours to obtain a viscous liquid, and finally dry the visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com