Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214 results about "Sio2 al2o3" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

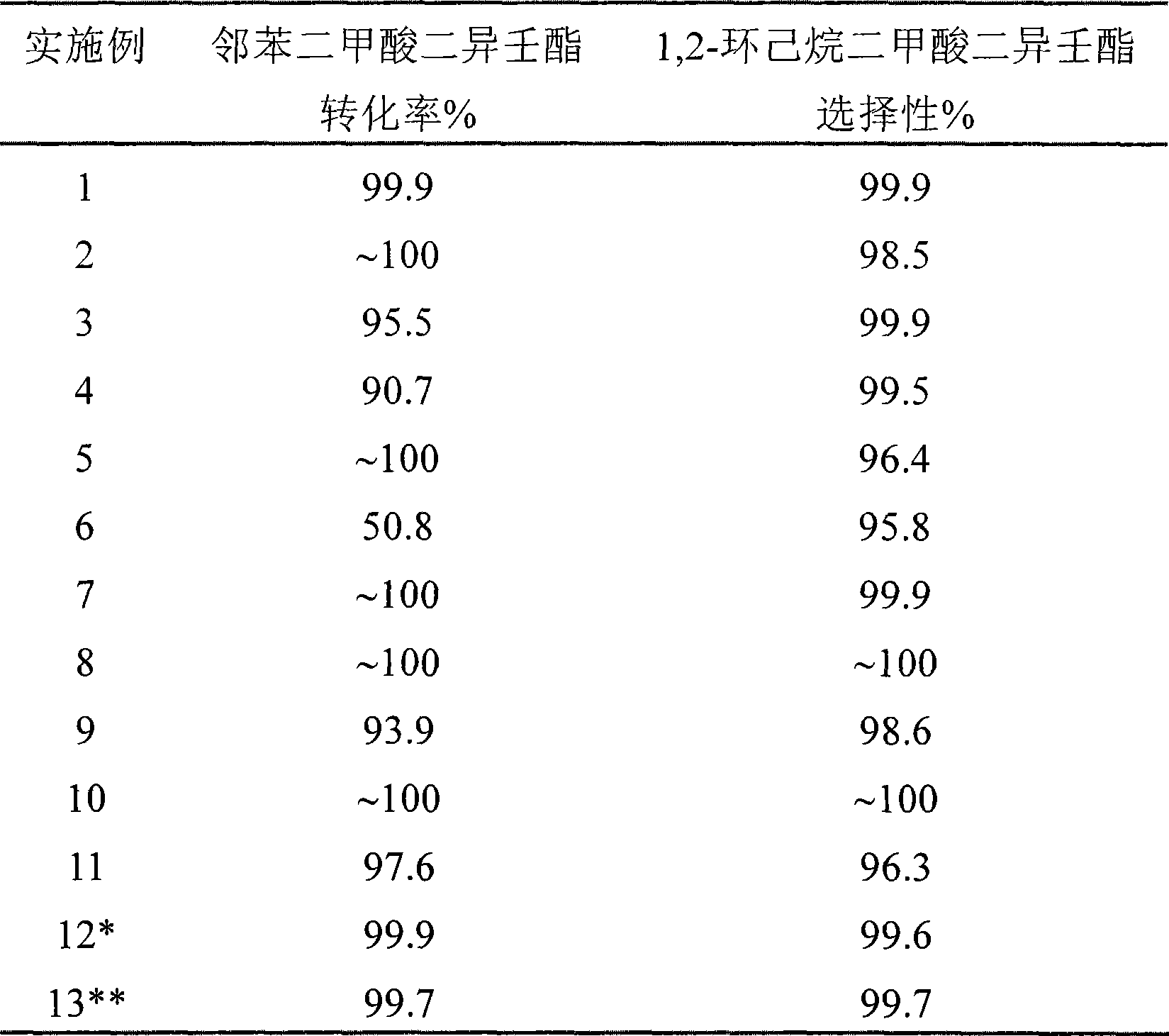

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

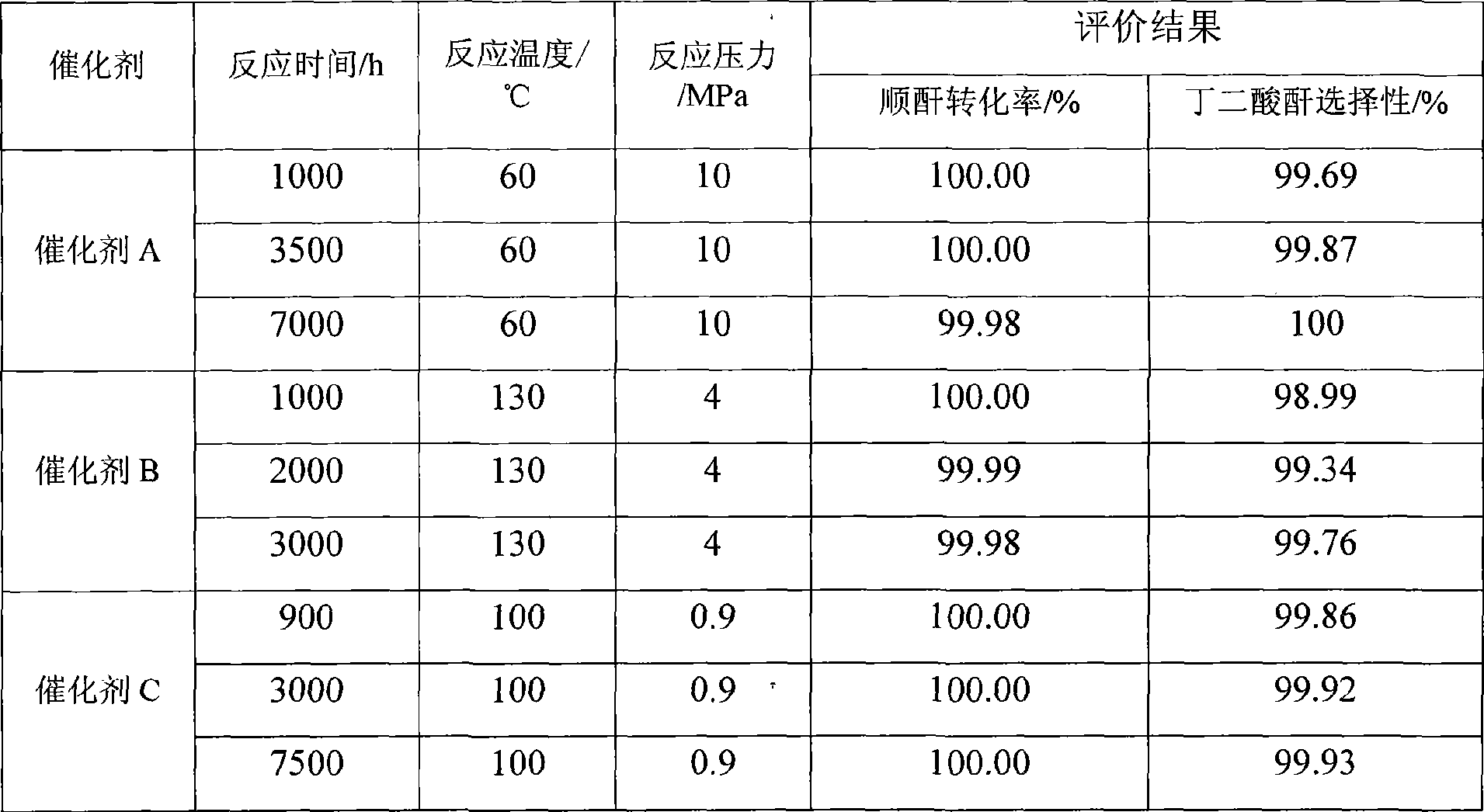

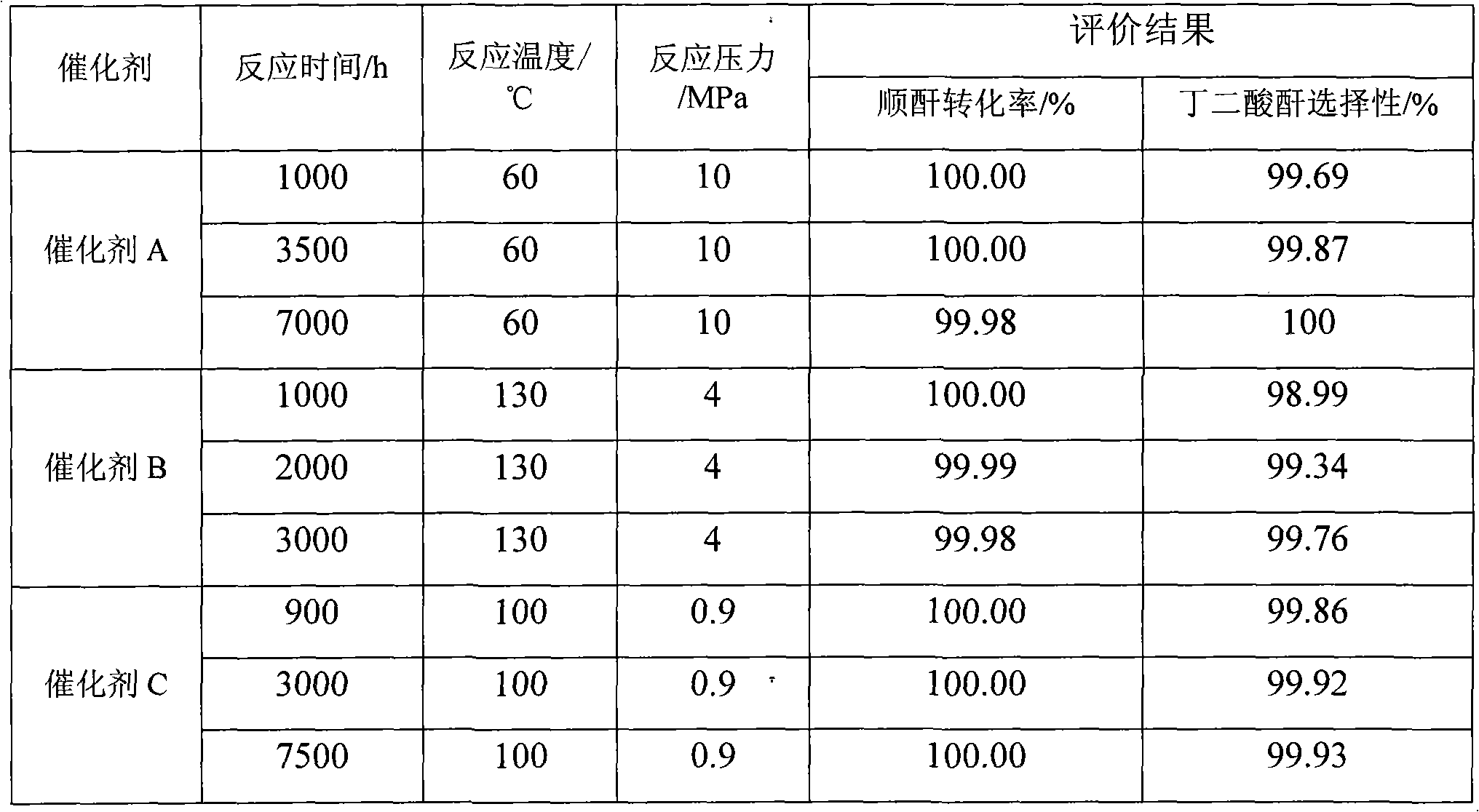

Catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride and preparation method thereof

ActiveCN101502802AHigh yieldHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedHigh activity

The invention provides a catalyst for continuously producing butanedioic anhydride by maleic anhydride hydrogenation. The catalyst is a nickel loaded catalyst prepared by an equivalent-volume impregnation method, wherein in the catalyst, the content of nickel is 13 to 20 weight percent, the content of accelerating agent is 1 to 7 weight percent, and a carrier is a composite oxide of SiO2 and Al2O3 or SiO2-Al2O3. A preparation method for the catalyst comprises the following steps: impregnating impregnation solution blended by ammonia water and active metal salt solution on a carrier subjected to baking pretreatment at a temperature between 400 and 800 DEG C by the equivalent-volume impregnation method to form the catalyst through drying, baking and reducing treatment. The catalyst is applied to continuously preparing the butanedioic anhydride by maleic anhydride hydrogenation on a fixed bed reactor, the conversion rate of maleic anhydride is more than or equal to 99.98 percent, and the selectivity of the butanedioic anhydride is more than or equal to 98.85 percent. The catalyst achieves the technical-scale continuous production of the butanedioic anhydride, and has the advantages of high activity, good selectivity, high yield (more than or equal to 98.83 percent) and long service life.

Owner:SHANXI UNIV

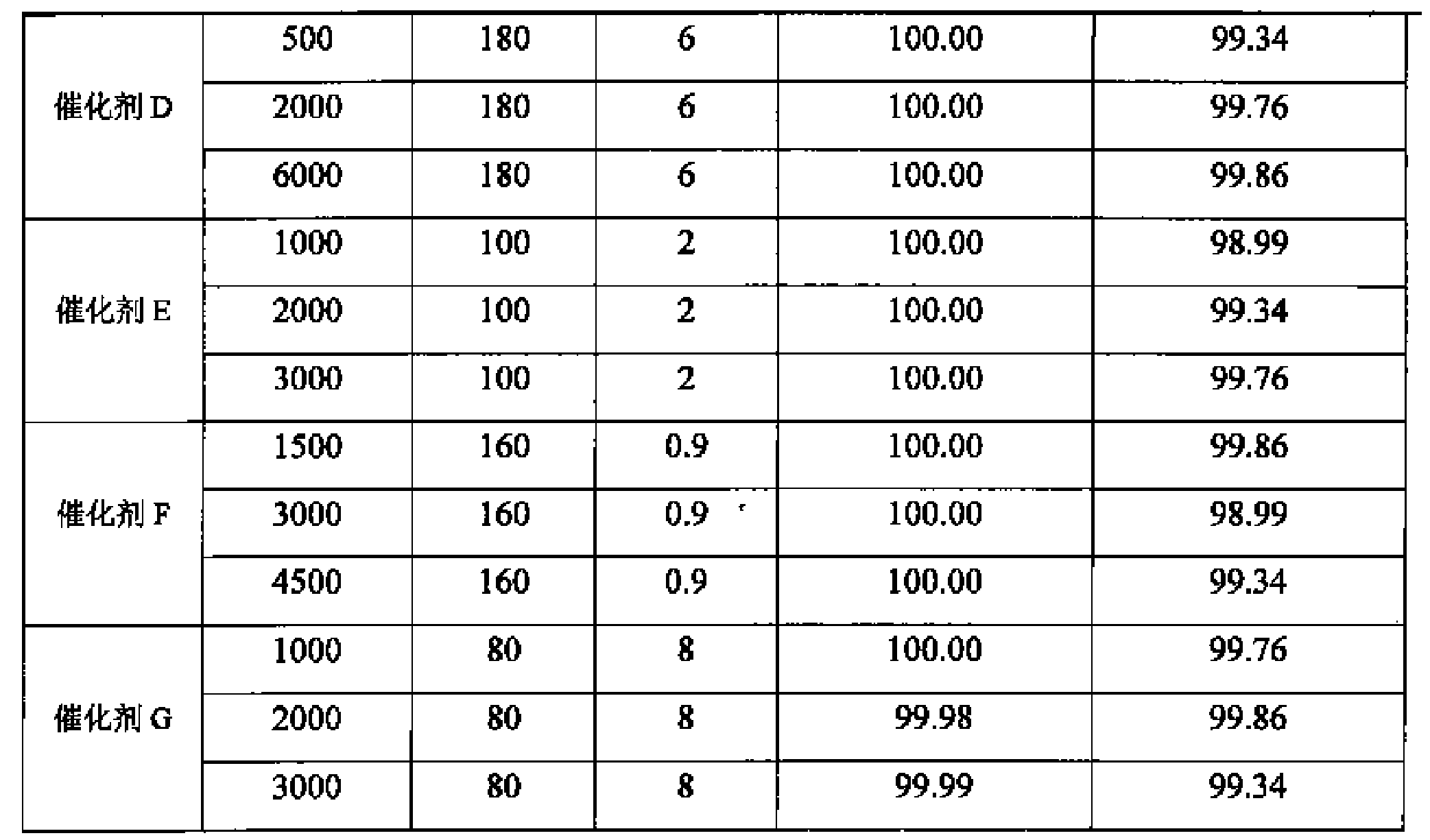

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

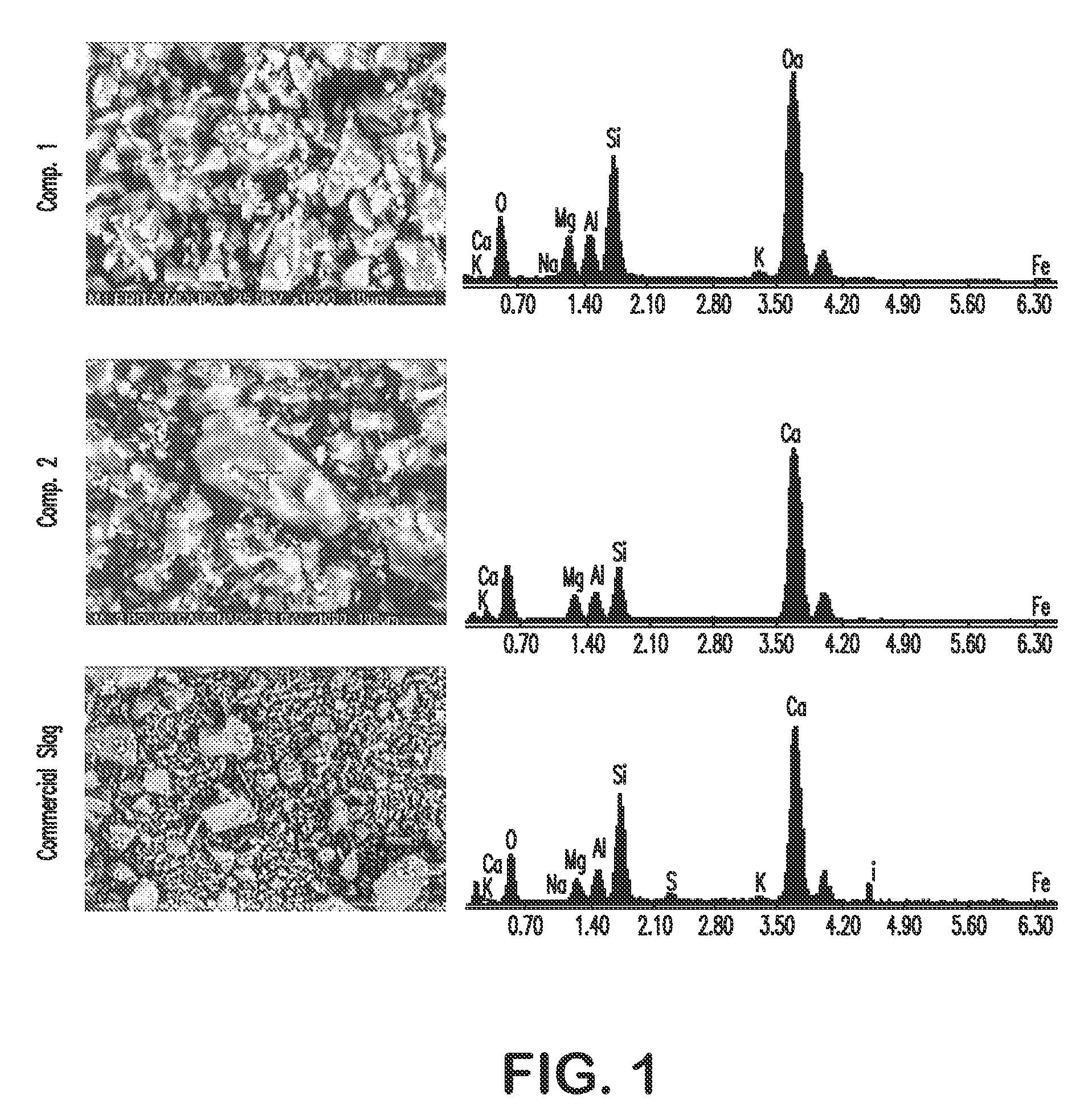

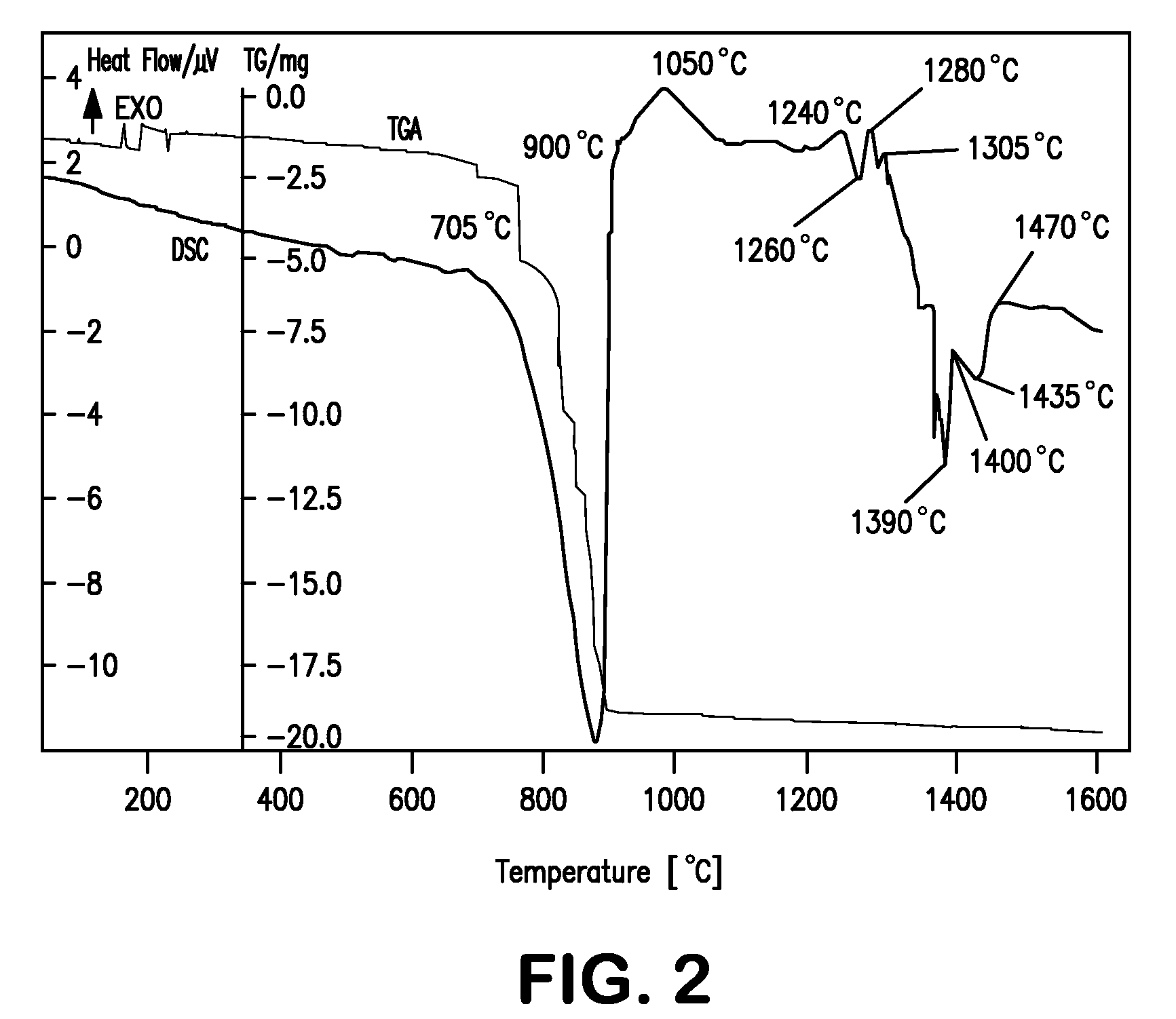

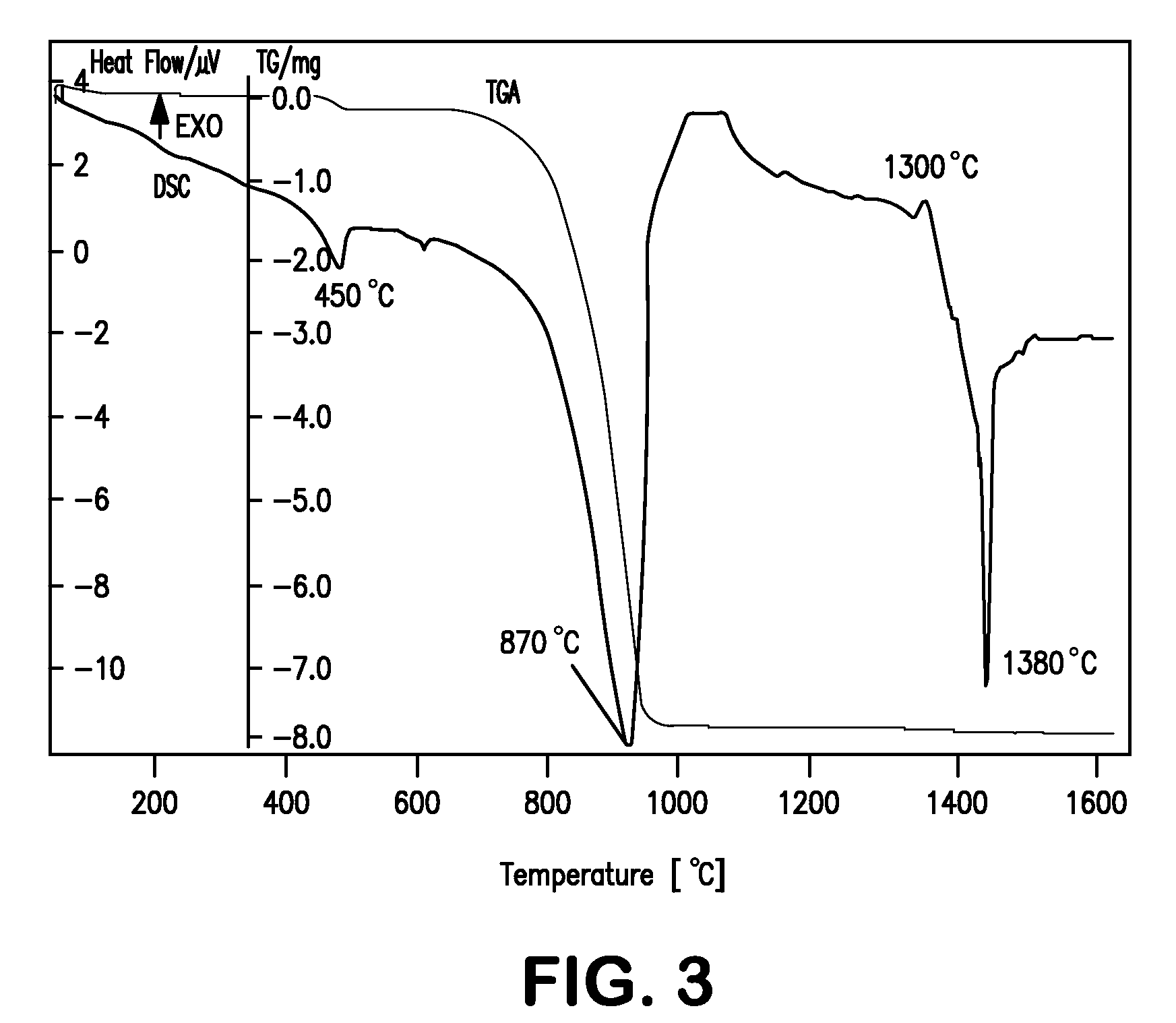

Homogenous synthetic mud-to-cement cementing glasses

A synthetic glass family in the quaternary phase field of CaO—SiO2-Al2O3-MgO (CSAM) with hydraulic and pozzolanic properties for use in differing applications in the gas and oil well cementing area. A method of making a mud-to-cement (MTC) slurry and a method for treating oil and gas wells with the MTC slurry containing a homogenous amorphous synthetic glass made from a mixture of inorganic materials selected from the group consisting of CSAM, wherein the cementing glasses with the mixture of inorganic materials are in a 100% amorphous phase with a degree of crystallization of zero.

Owner:INTREVEP SA

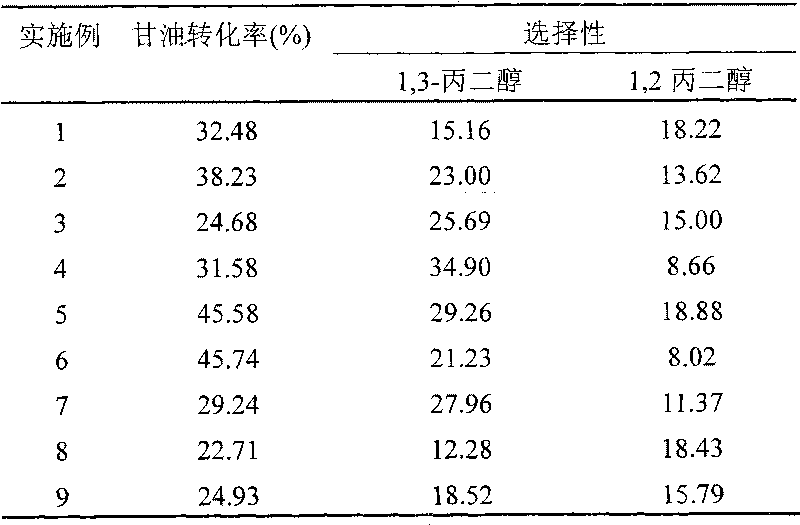

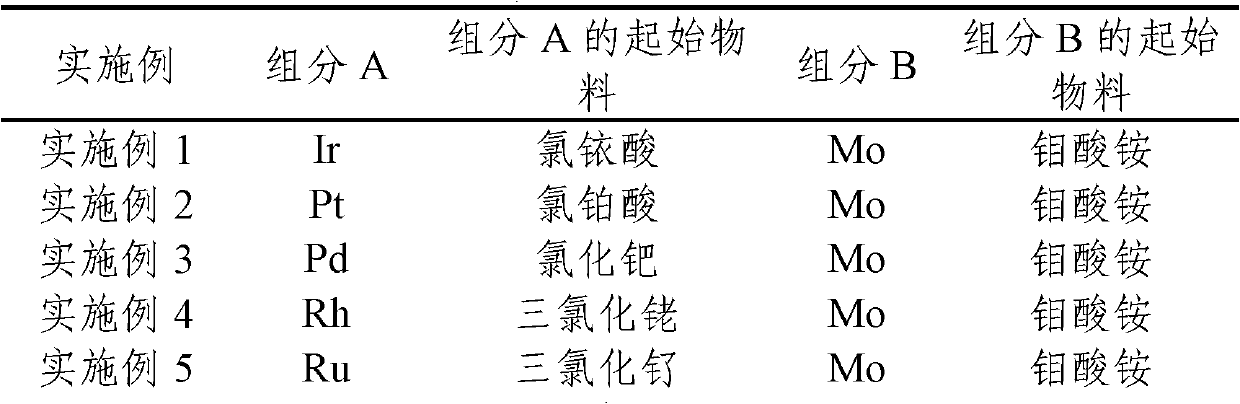

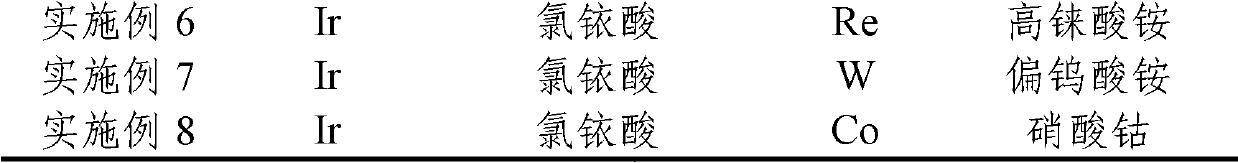

Method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol

ActiveCN101723801AHigh selectivityImprove conversion ratePreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureReaction temperature

The invention relates to a method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol. A reaction system comprises glycerol, hydrogen, catalyzer and two or more of dissolvants. In the reaction system, the weight ratio of the dissolvants to the glycerol is 0.2-9.8:1, and the weight ratio of the catalyzer to the glycerol is 0.2-2:1; the reaction conditions are shown as follows: the reaction temperature is 80-300 DEC G, the hydrogen pressure is 0.1-18.0MPa, and the contact time of the glycerol and the catalyzer in the reaction process is 0.3-50h; the catalyzer contains a carrier and active components carried on the carrier, wherein the carrier is ZrO2, SiO2-Al2O3 or Al2O3, and the active components are one or more of Ru, Pt, Pd and Rh. The invention can obviously increase the selectivity of generating 1,3-propylene glycol by hydrogenizing glycerol or increase the percent conversion of glycerol and reduce the generation of the byproduct of 1,2-propylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Diesel oil hydrotreating catalyst and method for preparing the same

ActiveCN1803996AIncrease cetane numberImprove desulfurizationHydrocarbon oils treatmentMolecular sieveDiaspore

The disclosed catalyst special to low-grade diesel fuel hydrotreatment comprises: given the catalyst, 1-70wt% SiO2-Al2O3 with quasi-thin diaspore structure, 1-60wt% Y-form molecular sieve, and 5-80wt% Al2O3; wherein, given the oxide, 1-15wt% VIII metal constituent, and 10-40wt% VIB metal constituent. The product is prepared by mixing, forming, baking and then adding at least one of former metal constituent.

Owner:CHINA PETROLEUM & CHEM CORP +1

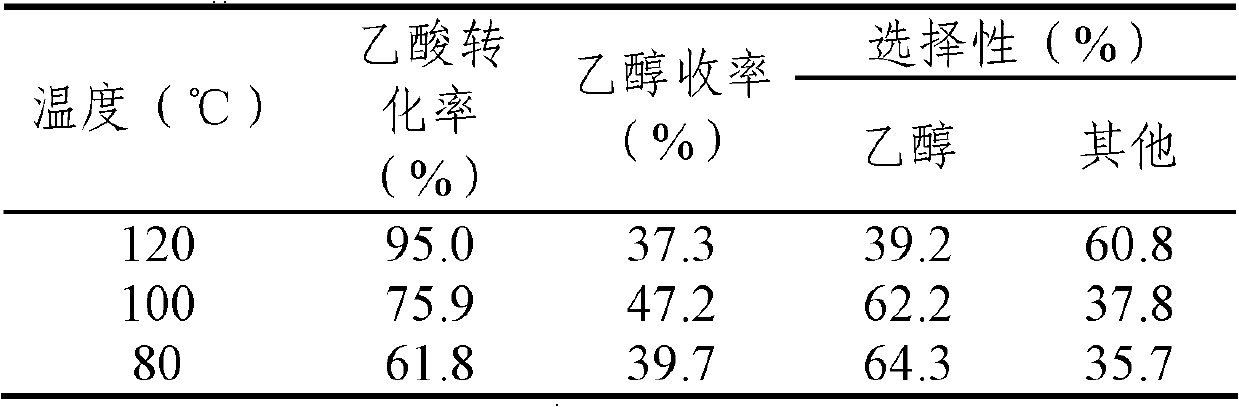

Method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation

ActiveCN103288596AOrganic compound preparationHydroxy compound preparation3-Hydroxypropionic acidPropanoic acid

The invention relates to a method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation. According to the method, any one of acetic acid, propionic acid, valeric acid, stearic acid, oleic acid, palmitic acid, levulinic acid, lactic acid, succinic acid, 3-hydracrylic acid and other organic acids is taken as a reactant, and an A-B / X supported catalyst is adopted, wherein the component A is any one or more than two from Ir, Pt, Pd, Rh and Ru, the assistant B is any one or more than two from Mo, Re and W, the carrier X is any one in SiO2, activated carbon, titanium oxide, zirconium oxide, SiO2-Al2O3 (the mass content of Al2O3 accounts for 17 percent) and molecular sieves, the mass load amount of A in the catalyst is 0.5-10 percent, the molar ratio of the assistant B to A is 0.01-1.0, the reaction pressure is 2-20 MPa, and the reaction temperature is 40-180 DEG C. The catalyst has the characteristics of mild reaction conditions, high reaction activity and good selectivity, and a novel effective way for preparing monohydric alcohol or dihydric alcohol from biomass is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sectional type ammonia generating device for discomposing solid urea

InactiveCN102635427AReduce generationLow reaction temperatureExhaust apparatusDispersed particle separationWater vaporReaction temperature

The invention belongs to the field of cleaning of the tail gas of a diesel engine, and particularly relates to a sectional type ammonia generating device for discomposing solid urea, wherein the device can be used for treating the tail gas of a motor vehicle. The device consists of an ammonia reaction tank, an urea pyrolysis catalysis device and an isocyanic acid hydrolysis catalysis device, which are sequentially arranged in the ammonia reaction tank according to an airflow direction; the front end of the ammonia reaction tank is provided with an urea inlet, the back end of the ammonia reaction tank is provided with an ammonia outlet, and a steam transporting conduit is arranged nearby the urea inlet; the urea pyrolysis catalysis device is formed by a multi-layer wire mesh carrier which is coated with a glass coating layer SiO2-Al2O3 and loaded with a urea pyrolysis catalyst Pt, Ag or Pd; and the isocyanic acid hydrolysis catalysis device is formed by a metal honeycomb carrier coated with the isocyanic acid hydrolysis catalyst SiO2-Al2O3. Due to the urea pyrolysis catalyst and the isocyanic acid hydrolysis catalyst, the device is used for catalyzing each stage of ammonia generation by ammonia, so that the reaction temperature can be reduced, the reaction can be accelerated, and the energy can be saved.

Owner:JILIN UNIV

Protective slag of large-profile round billet continuous-casting crystallizer and method for preparing same

The invention discloses a protective slag of a large-profile round billet continuous-casting crystallizer and a method for preparing same. The protective slag comprises the following components by weight percentage: 27-33% of SiO2, 24-30% of CaO, 1-3% of MgO, not more than 2% of Fe2O3, 5-10% of Al2O3, 4-9% of Na2O, 1-4% of F, 0.5-2.5% of MnO and 15-20% of C (solid). The components of the protective slag of the continuous casting crystallizer are selected according to the regions of fake siliceous lime in a three-element system CaO-SiO2-Al2O3; out of the components for composing the protectiveslag, the CaO is taken as a main alkaline material, the SiO2 is taken as a main acid material, the Na2O, the CaF2 and the Li2O are taken as main flux agents, and the carbon component is taken as a framework material and a fusing speed controlling agent. By organic combination of the basic materials and the flux agents, the chemical components of the protective slag are adjusted, so as to adjust the physico-chemical indexes of the protective slag, such as fusing temperature, viscosity, crystallization performance, absorbing and including capability, heat conducting capability and the like and meet the requirements of keeping normal slag consumption, thickness of liquid slag layer and reasonable heat conducting amount under a special profile condition, thus ensuring the thickness of the billet shell at the outlet end of the crystallizer and realizing non-gluing continuous casting production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

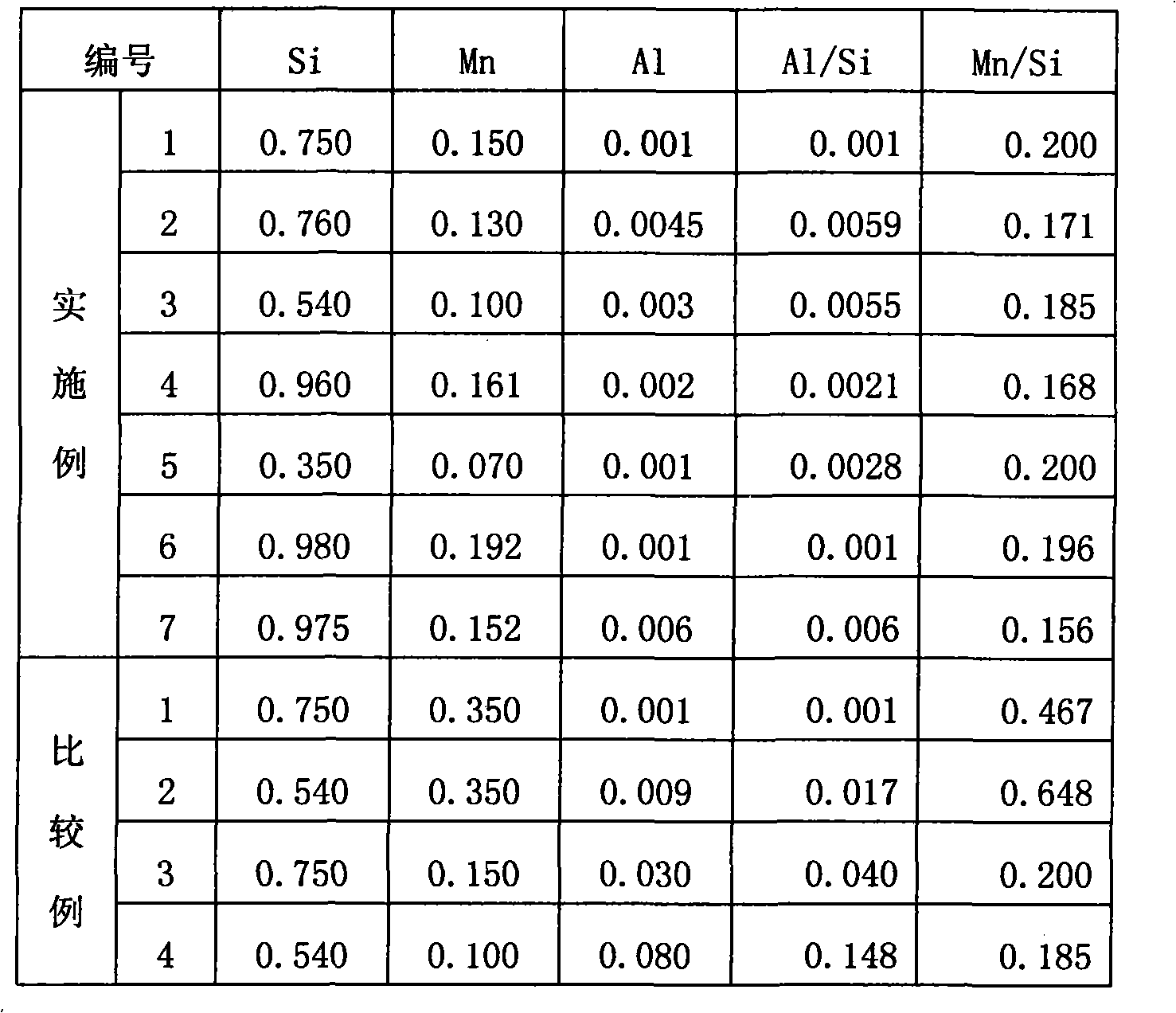

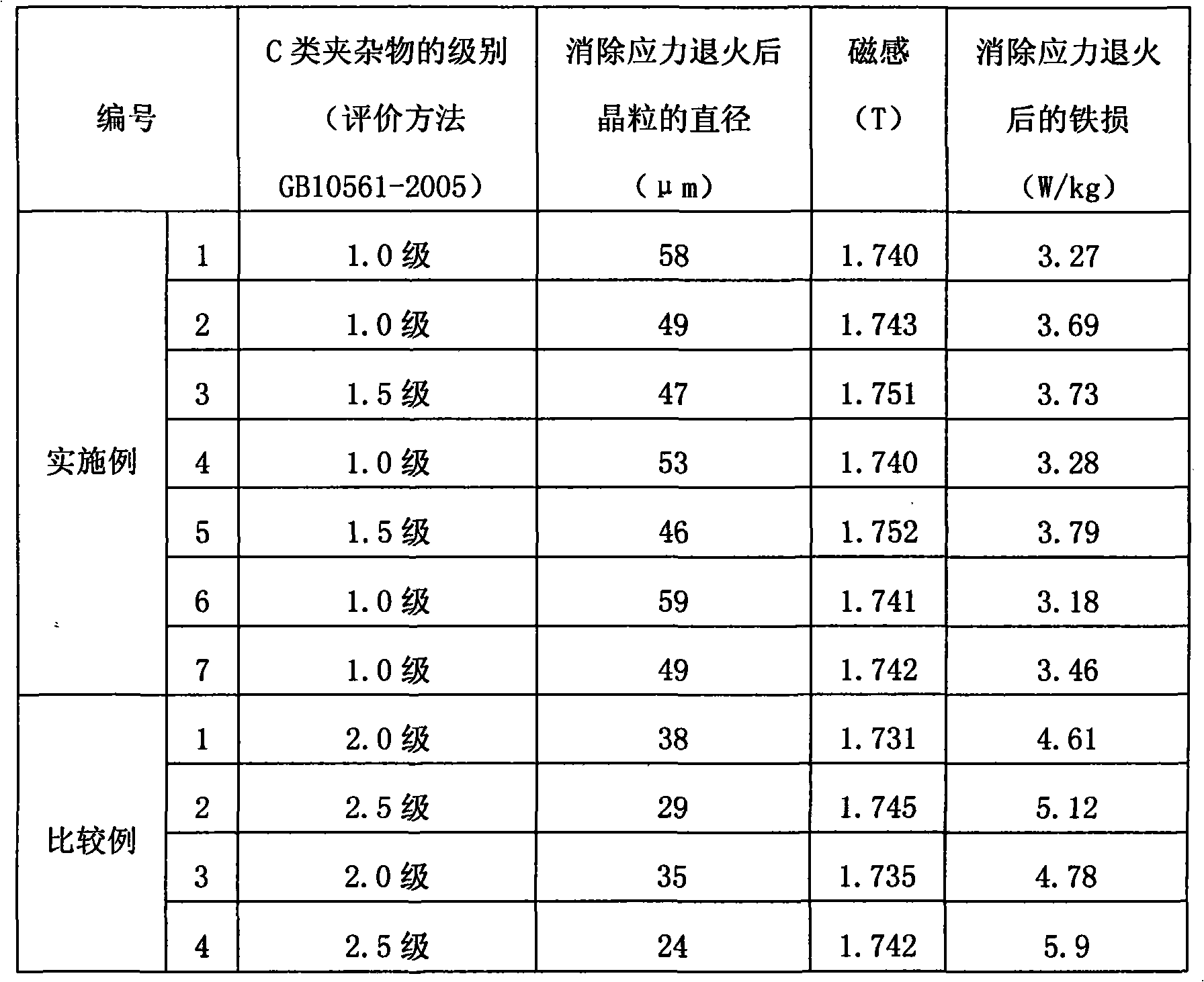

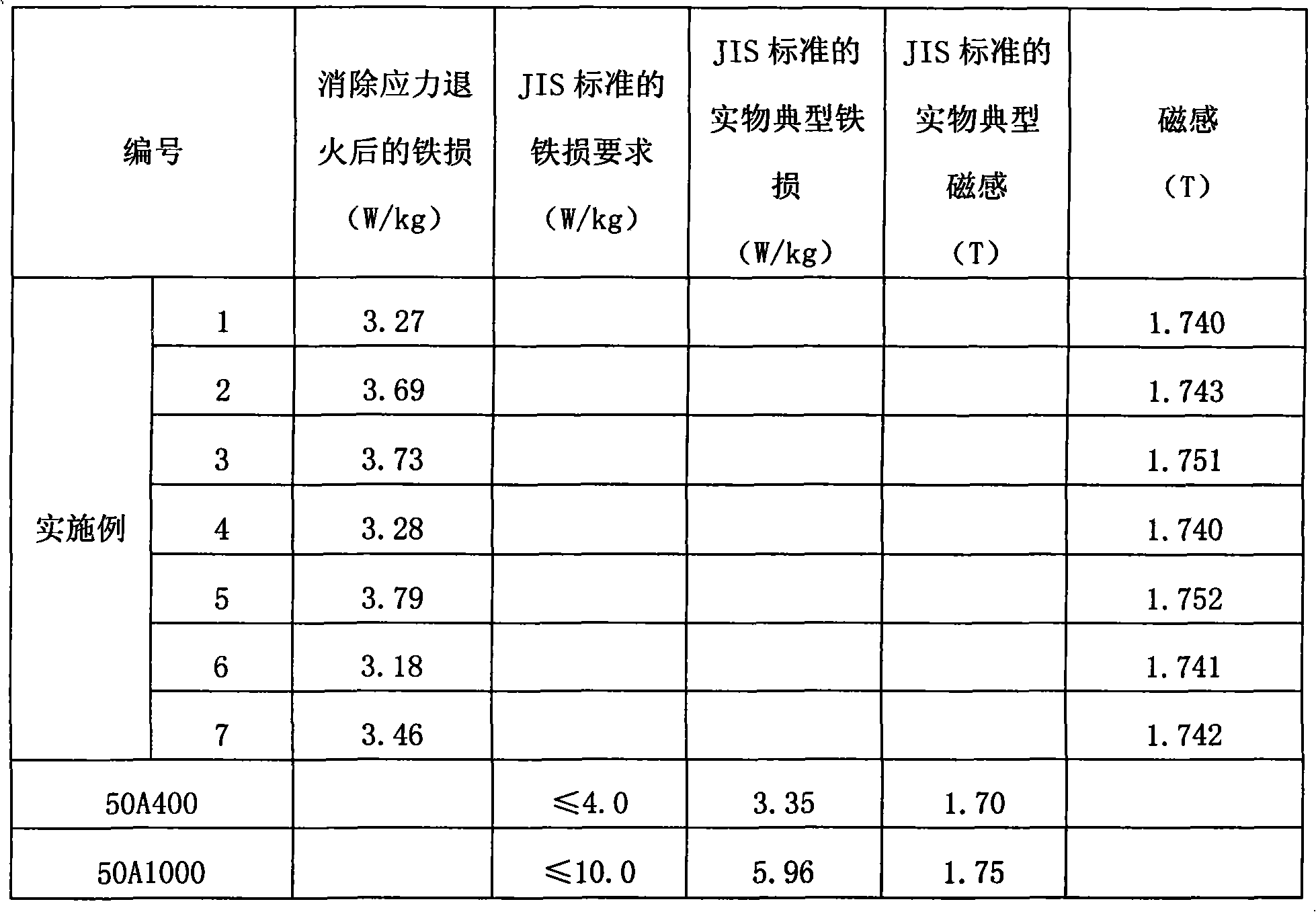

Non-oriented electrical sheet steel with good iron loss and manufacturing method thereof

The invention provides a non-oriented electrical sheet steel with good iron loss, which is characterized in that the non-oriented electrical sheet steel with good iron loss comprises the following components in percentage by weight: C: <= 0.003%, Si: <=1.0%, Mn: <=0.20%, Al: <= 0.001-0.009%, S: <=0.004%, N: <=0.003%, Ti: <= 0.0020%, Al / Si: 0-0.006 and Mn / Si: 0-0.2, wherein the proportion of three element inclusion SiO2-Al2O3-MnO is as follows: SiO2: >=95%, Al2O3: 2-3% and MnO: <=2%, and the balance Fe and inevitable impurities. The invention also provides a manufacturing method for the steel. An optimal component range of Si, Mn and Al is set through research, the level of the oxidized inclusion and precipitates are controlled, growth of grains is promoted and the non-oriented electrical sheet steel with low iron loss is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

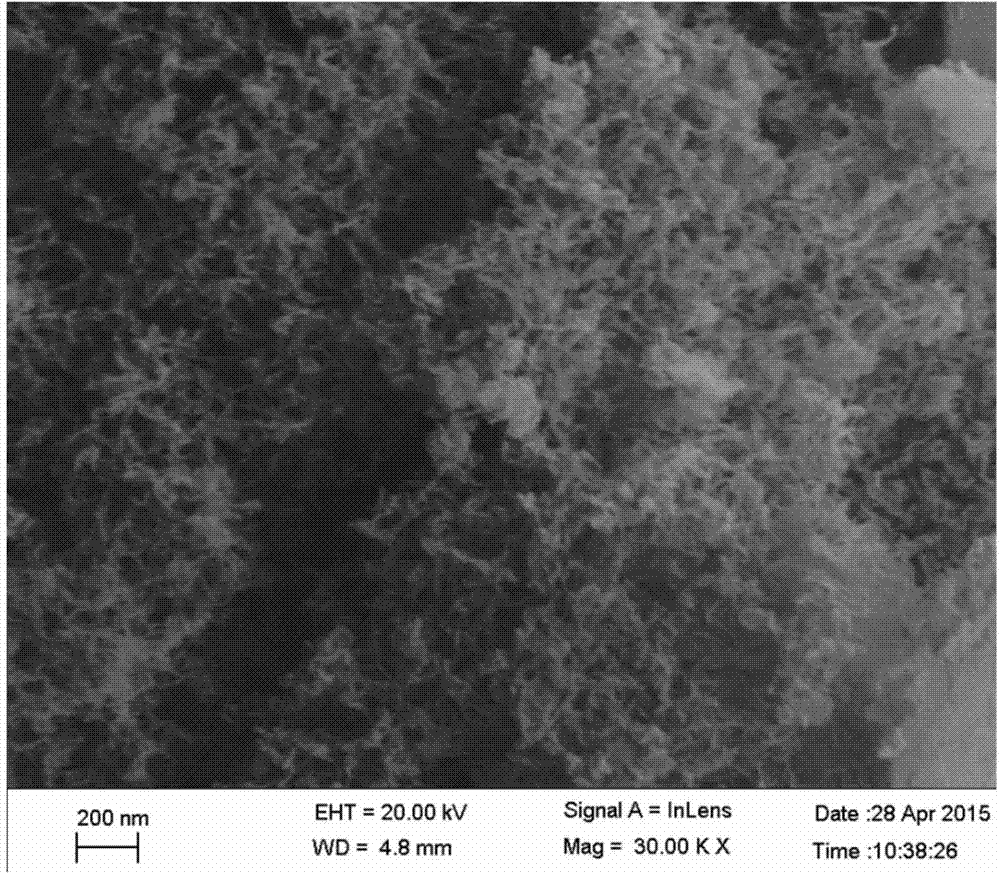

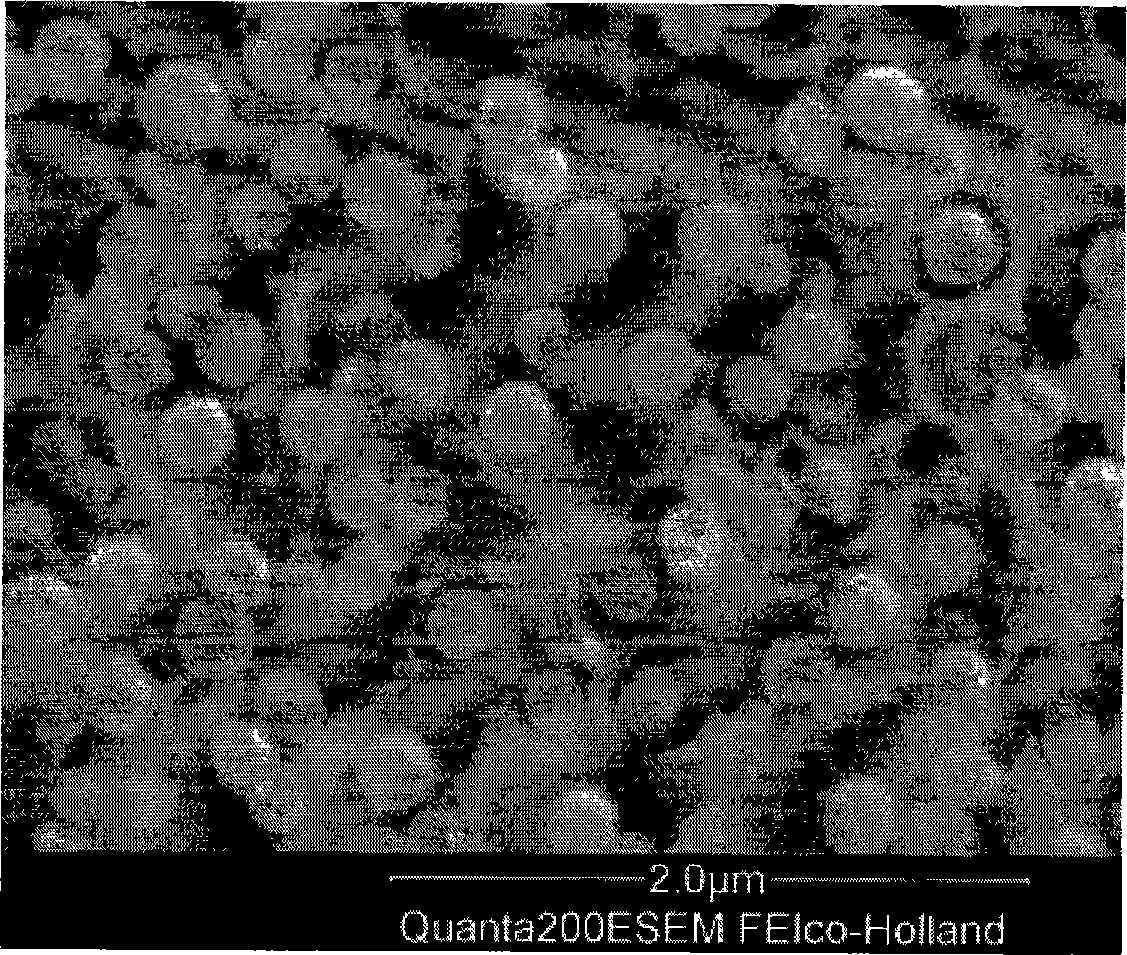

Preparation method of mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material

The invention relates to a preparation method of a mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material, which comprises the following steps: by using surface-pretreated mullite fibrofelt as a reinforcer, tetraethyl orthosilicate as a silicon source, cheap inorganic aluminum salt as an aluminum source and epoxide as a network formation agent, uniformly mixing, and carrying out sol-gel, aging and supercritical drying to obtain the mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material. In the preparation process, no catalyst is needed, and a one-step method is adopted to greatly optimize the preparation technique. Thus, the heat-insulating material has the advantages of low cost, smooth surface and controllable thickness, and can resist the temperature of 1200 DEG C in an air atmosphere. The room temperature thermal conductivity is 0.023-0.027 W.m<-1>K<-1>, and the apparent density is 0.18-0.22 g / cm<3>. The method has the advantages of simple materials, low cost and simple technique, is simple to operate in the technical process, and can easily implement large-scale production.

Owner:NANJING UNIV OF TECH

Non-fluorin environment protection opacifiedglass material and method for manufacturing same

InactiveCN101244889AGood opacification effectHigh opacityGlass furnace apparatusGlass furnacePhosphate

The invention relates to a fluorine-free environmental opaque glass material and a preparation method thereof and belongs to the new material field of glass. Composition of the glass material is SiO2-Al2O3-B2O3P2O5-MgO-CaO-SrO-BaO-Li2O-Na2O-K2O. The preparation method comprises that raw materials are mixed to make an even batch, then the batch is put into a corundum crucible, and then the batch is casted and molded after being melted and insulated under 1500 DEG C to 1520 DEG C for 3 hours, and then the batch is insulated and annealed under 550 DEG C to 560 DEG C for 1 hour. The preparation of the invention replaces the fluoride with a small amount of phosphate to generate opaque effect, and no environmental pollution can be caused in the industrial production of the opaque glass, and the short service life of glass furnaces and safety problems caused by fluorine can be avoided, and a compact net structure reconstruction technology is adopted to adjust the relative contents of SiO2 and P2O5, meanwhile, alkali metals or alkaline earth metal oxides are introduced, and the glass produces significant opaque effect under the spontaneous phase separation in the process of cooling, and a small amount of B2O3 is introduced to enhance the opaque effect of the glass, meanwhile, a certain amount of Al2O3 is introduced to endow the glass with excellent chemical stability.

Owner:QILU UNIV OF TECH

Biological microcrystalline glass prepared by utilizing phosphate tailings and preparation method thereof

The invention relates to biological microcrystalline glass prepared by utilizing phosphate tailings and a preparation method thereof. The biological microcrystalline glass comprises the following raw materials in parts by weight: 30 to 35 parts of the phosphate tailings, 15 to 25 parts of quartz sand, 10 to 16 parts of aluminium hydroxide, 20 to 28 parts of calcium hydrophosphate, 9 to 13 parts of calcium fluoride, 0 to 5 parts of magnesium oxide, 0 to 5 parts of zinc oxide and 0.5 part of sodium borate, wherein the utilization rate of the tailings reaches more than 30%. Compared with a product produced by utilizing conventional chemical raw materials, the biological microcrystalline glass has better physical and chemical properties and realizes reduction in the raw material cost by more than 30%. Based on the SiO2-Al2O3-P2O5-CaO-CaF2 system, the magnesium and the zinc are utilized to replace the partial calcium, so that a new magnesium-series wagnerite phase and a zinc-series zinc pointed crystal phase are generated, and therefore, the brittleness of the biological microcrystalline glass is improved while the mechanical strength is improved. In addition, the biocompatibility, the bioactivity and the chemical stability of the biological microcrystalline glass are improved.

Owner:CHINESE ACAD OF GEOLOGICAL SCI

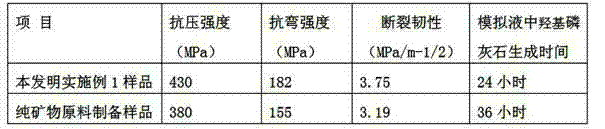

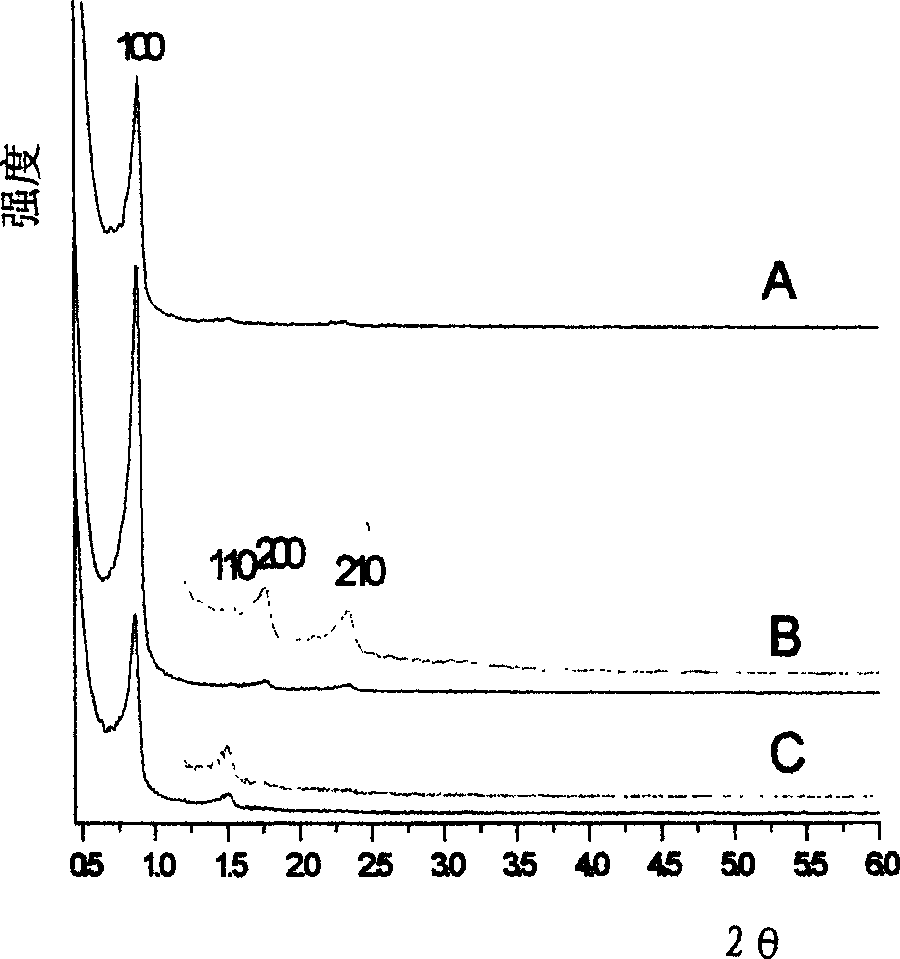

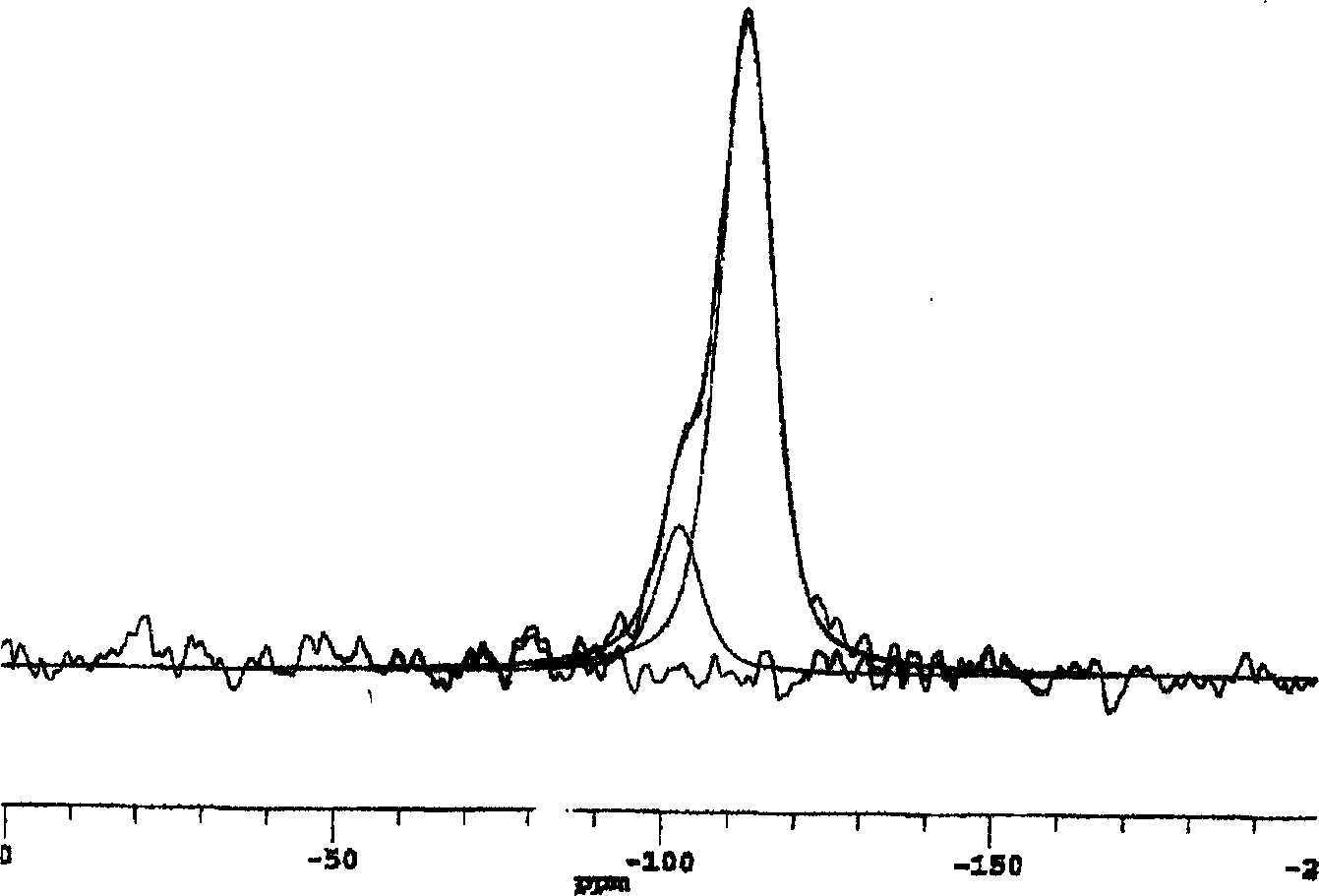

Ordered mesoporous molecnlar sieve material with wltrahigh hydrothermal stability and synthesis method thereof

InactiveCN1483671ASpecial high temperature resistanceGood hydrothermal stabilityCrystalline aluminosilicate zeolitesSynthesis methodsSURFACTANT BLEND

A ordered porous molecule sieve having a super high hydrothermal stability and a formula of SiO2-Al2O3-MxOy, wherein Al / Si=0-1.0, M / Si=0-0.05, M=Fe3+, B3+ and a completely condensation of siliceous species on the pore wall, Q4 / Q3 =3-7, can be synthesized according to the steps of 1) making a pattern plate reagent 2) preparing raw powder 3) getting rid of the pattern plate reagent. Particularly, making pattern plate reagent includes mixing the F-C surfactant with C-H surfactant, dissolving them in water, making the PH below 1 or 8-10. Crystallizing temperature is of 160-250 deg.C. to obtain the raw powder.

Owner:JILIN UNIV

Core-shell structure magnetic microsphere aluminum oxide and method for preparing the same

InactiveCN101112687AHigh sphericityMeet the use requirementsCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMicrosphereProtection layer

The invention provides a core-shell structure magnetic micro-spherical alumina MeFe2O4-SiO2-Al2O3 and the preparation method. According to the positioning effect of the LDHs laminated metal element, the invention firstly prepares the Me-Fe2+-Fe3+-LDHs laminated precursor by introducing the Me2+, Fe2+ and Fe3+ into the hydrotalcite laminate, and the spinel ferrite MeFe2O4 is formed by high-temperature roasting; the Na2SiO3.9H2O or silicon ester hydrolysis is adopted to coat a SiO2 protection layer on the surface of the MeFe2O4, the organic alcohol aluminum hydrolysis method is adopted to coat the alumina layer for a plurality of times, and finally the magnetic micro-spherical alumina MeFe2O4-SiO2-Al2O3 is obtained. The method saves the forming process of the traditional preparation method, and adjusts the magnetic structure and pore structure of the samples by changing the thickness of the SiO2 protection layer and the adding quantity of the magnetic object MeFe2O4 for meeting the application requirement of the magnetic stable bed process.

Owner:BEIJING UNIV OF CHEM TECH

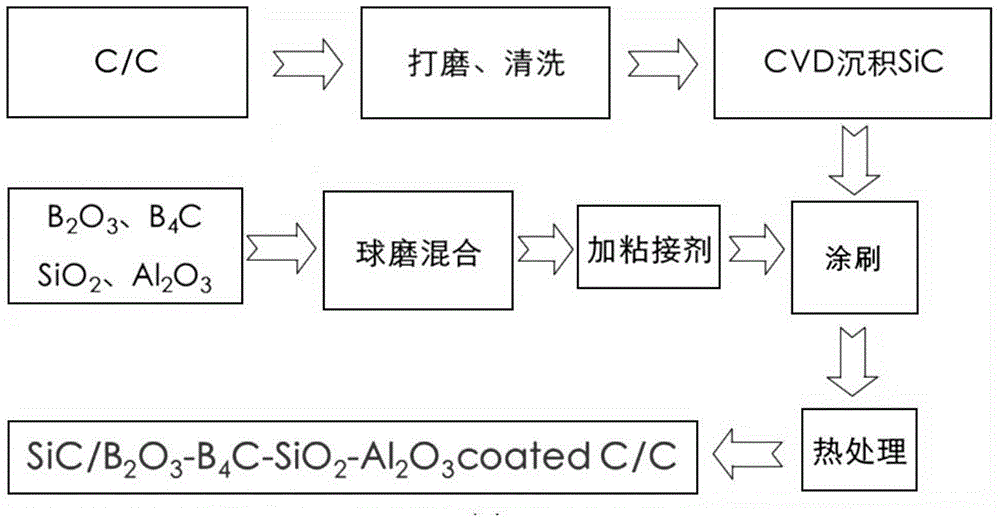

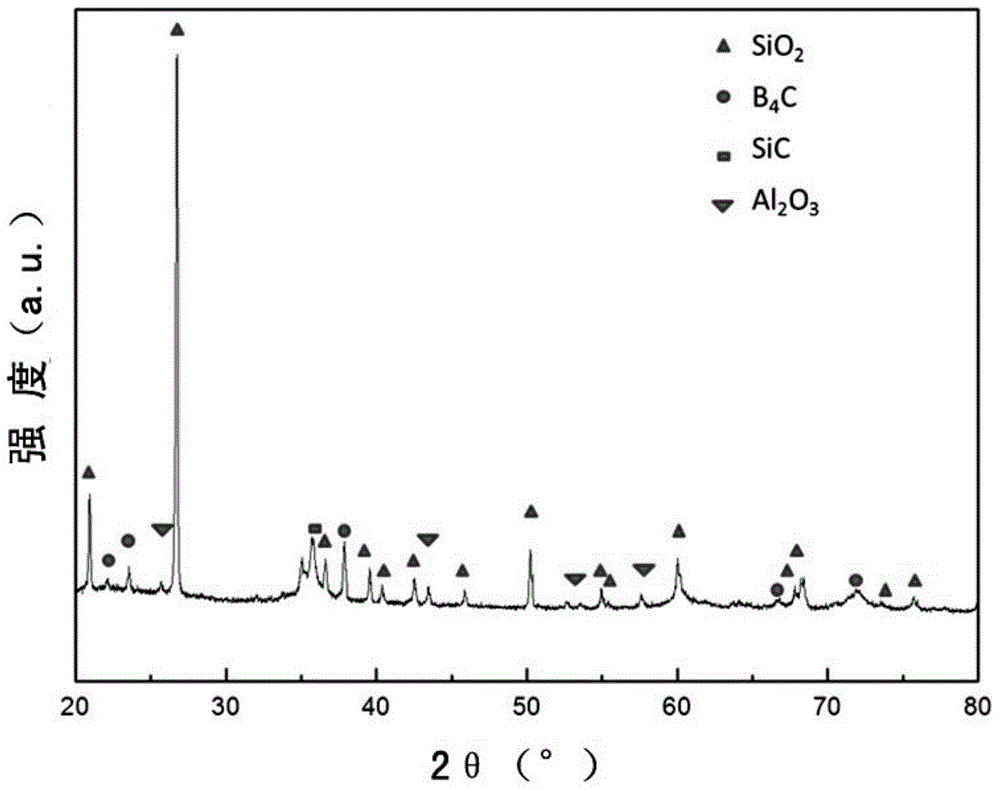

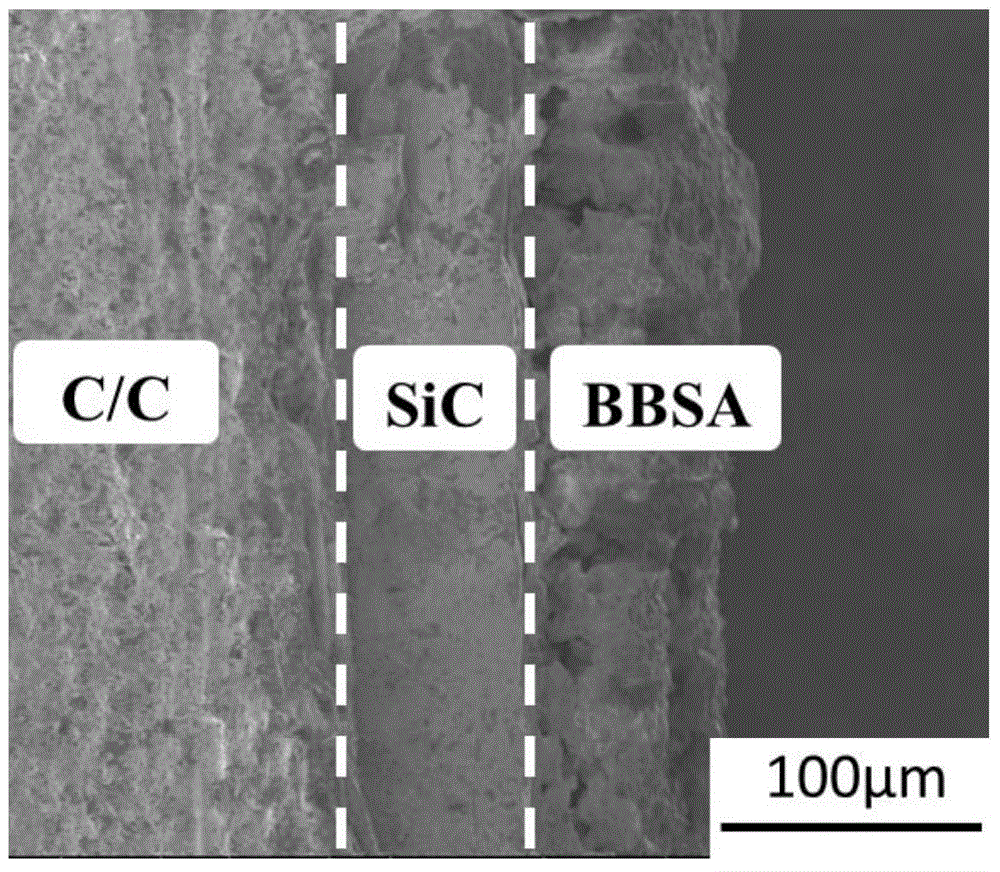

Preparation method of low-temperature long-time oxidation-resistant coating layer on carbon/carbon composite material surfaces

ActiveCN105646007ALong-term anti-oxidation achievedOxidation weight loss rate is smallCarbon compositesAdhesive

The invention discloses a preparation method of a low-temperature long-time oxidation-resistant coating layer on carbon / carbon composite material surfaces, and belongs to the technical field of carbon / carbon composite material antioxidation. The preparation method comprises following steps: firstly, chemical vapor deposition is adopted so as to realize precipitation of high crystallinity silicon carbide on the carbon / carbon composite material surfaces as a transitional inner coating layer; boron oxide, boron carbide, silicon dioxide, and aluminium oxide are taken as coating layer raw materials, silica sol is taken as an adhesives, and painting-sintering technology is adopted so as to obtain a B4C-B2O3-SiO2-Al2O3 outer layer on the silicon carbide inner layer; and finally the SiC / B4C-B2O3-SiO2-Al2O3 composite oxidation-resistant coating layer is formed on the carbon / carbon composite material surfaces. The low-temperature long-time oxidation-resistant coating layer is capable of realizing long-term antioxidation of the carbon / carbon composite material at 600 to 1000 DEG C, and oxidation weight loss ratio is smaller than 1%. It is observed via observation using scanning electron microscopes, the low-temperature long-time oxidation-resistant coating layer is capable of forming compact glass phase at usage environment spontaneously, and realizing oxidation protection.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

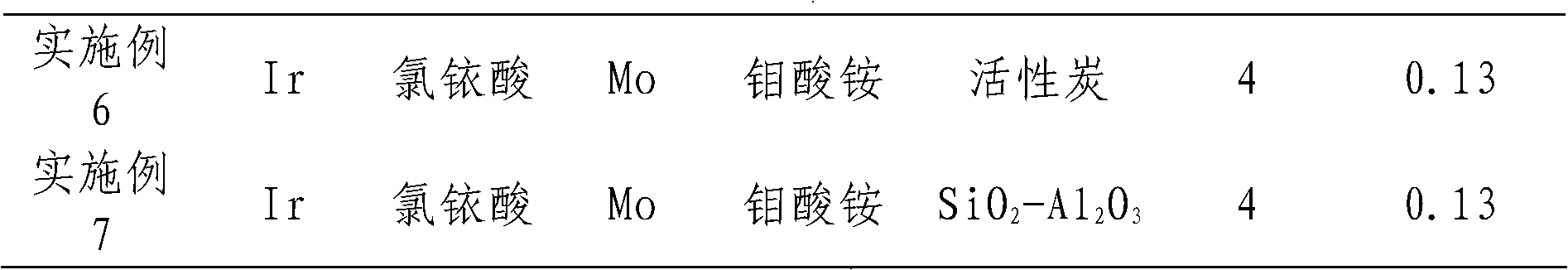

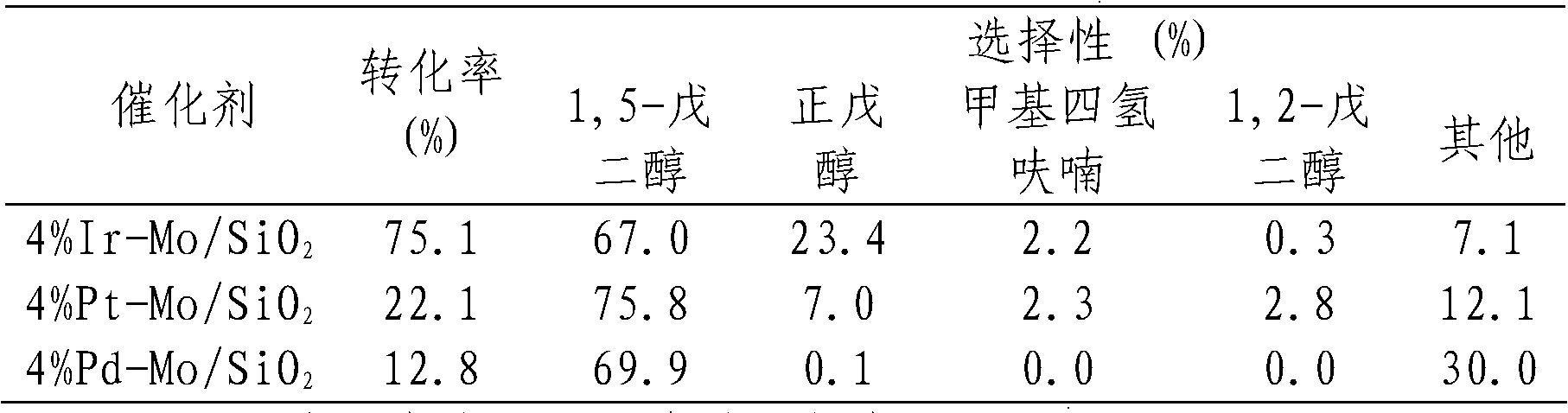

Method for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol

InactiveCN102911011APreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonHydrogen

The invention relates to a novel A-B / X or A / X supported catalyst for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol obtained from forestry and agricultural residues. The component A refers to one or more of precious metals Ir, Pt and Pd, the auxiliary B refers to one or more of Mo, Re and W, and the carrier X refers to any one of SiO2, activated carbon and SiO2-Al2O3. The capacity of the precious metal A in the catalyst is 0.5-10%, the molar ratio of the auxiliary B to the precious metal A is 0.0-1.0, the reaction pressure is 2-20MPa, and the reaction temperature is 80-150 DEG C. The catalyst has the advantages of mild reaction conditions, high reactivity and high selectivity, and a novel effective way for preparation of 1,5-pentadiol from biomass of forestry and agricultural residues is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst to produce methyl methacrylate efficiently at low cost and preparation method of catalyst

ActiveCN109395732AImprove performanceLow priceOrganic compound preparationCarboxylic acid esters preparationMolecular sieveParticulates

The invention discloses a preparation method of a catalyst to produce methyl methacrylate efficiently at low cost. The catalyst is made by a polymeric protection process and is a supported catalyst with an active center supported on a support; the active center includes gold and a rare-earth metal; the support is one of SiO2, SiO2-Al2O3, CaCO3, carbon material, and molecular sieve material; the catalyst is 0.05-0.98% by weight in gold loading capacity and 1-2.5% by weight in rare-earth metal loading capacity. The preparation method is suitable for preparing a gold particulate catalyst having uniform particle size and high activity; the preparation process is simple; the preparation method is convenient to perform; active component loading capacity is low; the catalyst has excellent activity and good stability; the catalyst is prepared at low cost; methylacrolein conversion rate and MMA (methyl methacrylate) selectivity are high; the preparation method is suitable for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

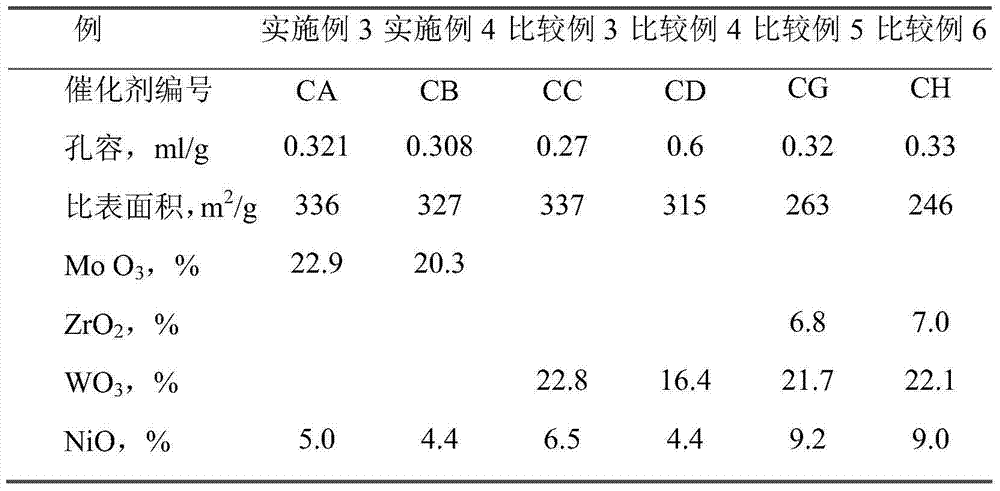

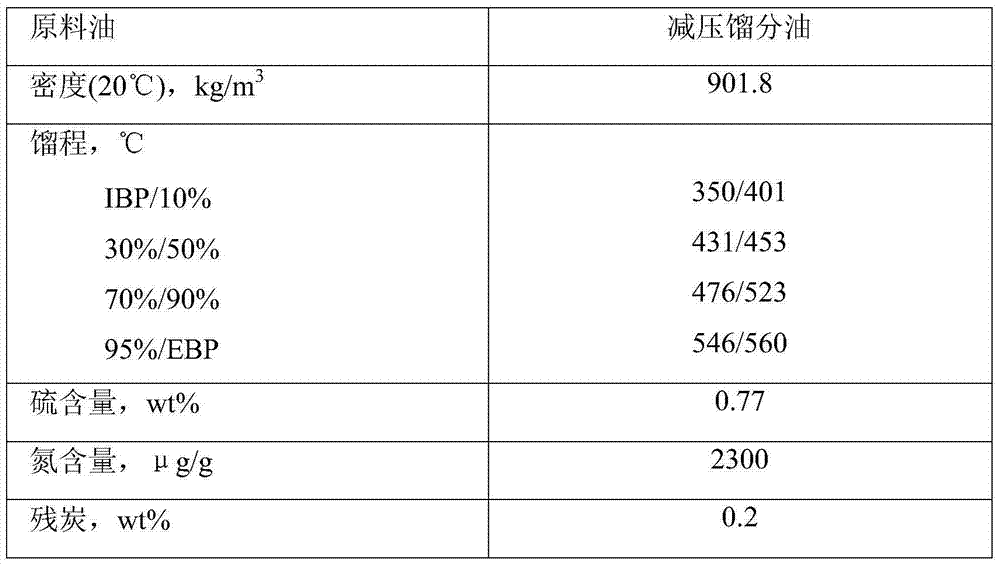

Medium oil type hydrocracking catalyst

InactiveCN1508226ALow number of acid centersModerate acidity in infraredMolecular sieve catalystsHydrocarbon oil crackingMetalZeolite

The invention discloses a medium-oil-type hydrocracking catalyst to furthest produce medium fractional oil. It disperses a Y-shaped zeolite in unformed SiO2-Al2O3 base material as catalyst carrier. It contains 5w%-25w% Y-shaped zeolite in which SiO2 / Al2O3 mol ratio is 40-60, 20w%-50w% unformed SiO2-Al2O3, 15w%-30w% bonding agent, 10w%-30w% VIB-family metal, and 4w%-10w% VIII-family metal, the atomic ratio of VIB / (VIB+VIII) equal to 0.3-0.8.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 1,5-pentanediol via selective hydrogenolysis of tetrahydrofurfuryl alcohol

The invention relates to a method for preparing a novel A-B / X or A / X carried catalyst of 1,5-pentanediol by performing a selective hydrogenolysis reaction on tetrahydrofurfuryl alcohol obtained from forestry and agricultural residues taken as raw materials. According to the novel A-B / X or A / X carried catalyst, wherein the component A is any one or more than one of Rh, Ir, Pt, Pd and Ru; the assistant B is any one or more than one of V, Nb and Ta; the carrier X is any one of SiO2, activated carbon, SiO2-Al2O3, titanium oxide and zirconium oxide; the carrying quantity of a precious metal A in the catalyst is between 0.5% and 10%; the molar ratio of the assistant B to the precious metal A is 0.01-1.0; the reaction pressure is between 1MPa and 20MPa; and the reaction temperature is between 50 DEG C and 150 DEG C. The novel A-B / X or A / X carried catalyst has the characteristics of moderate reaction condition, high reaction activity and good selectivity, thereby providing a novel effective way for preparing the 1,5-pentanediol by utilizing biomasses of the forestry and agricultural residues.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride

ActiveCN101502802BHigh yieldHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedHigh activity

Owner:SHANXI UNIV

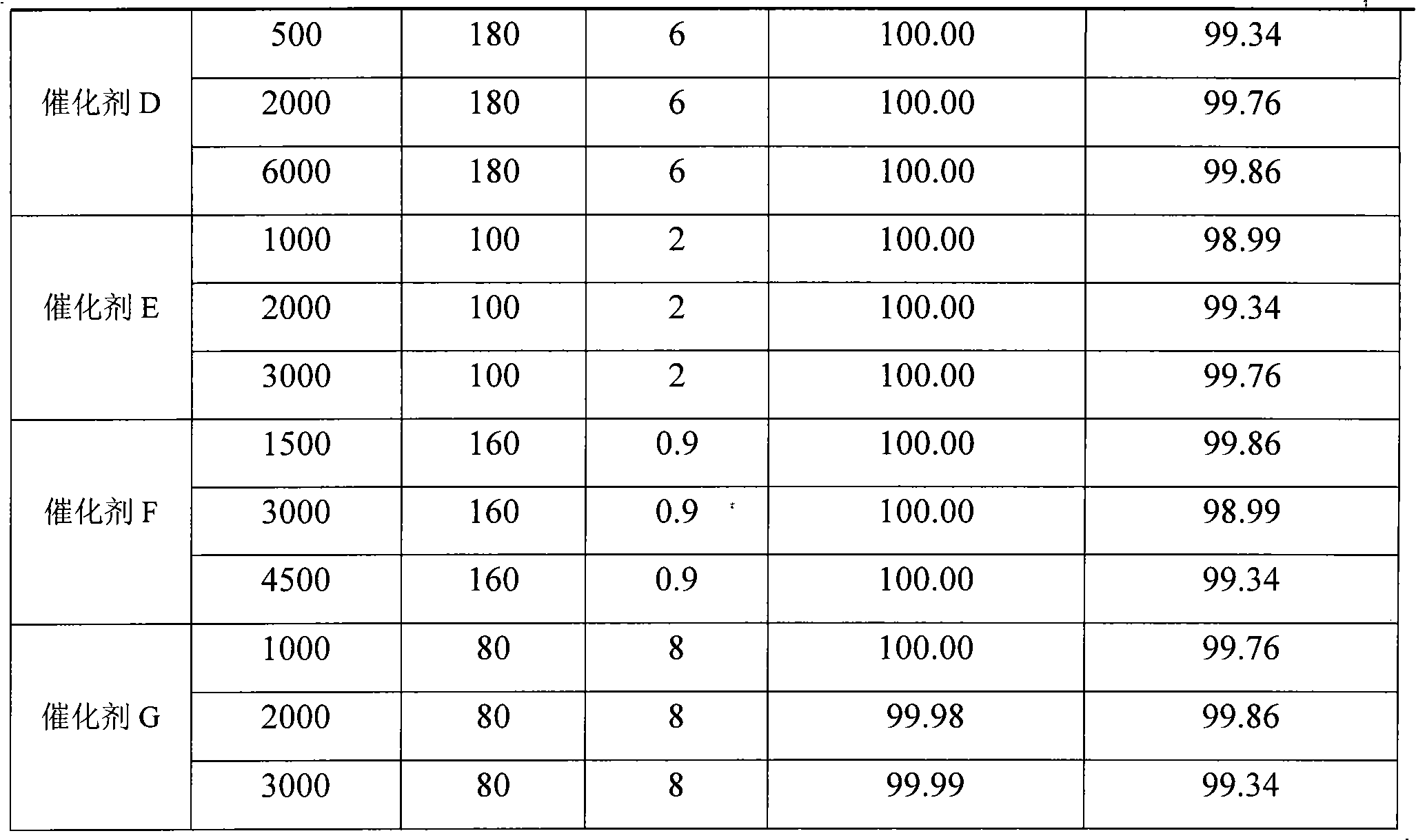

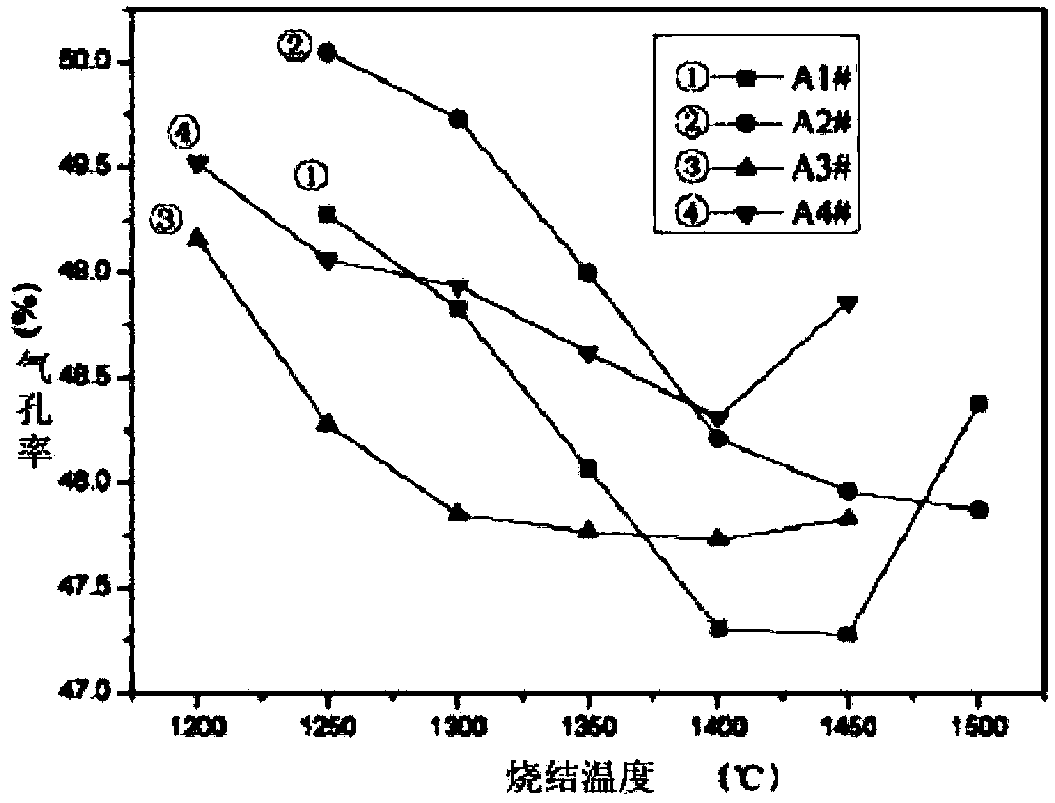

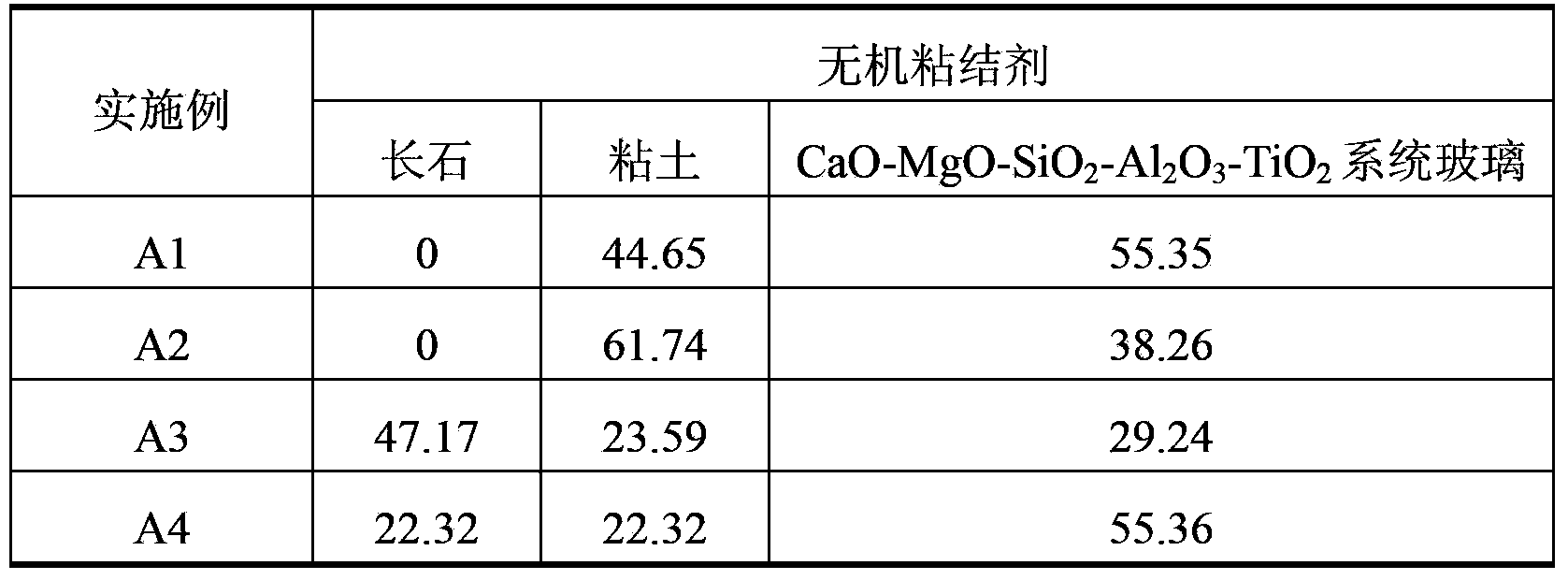

Porous ceramic prepared by adopting different inorganic binders and preparation method thereof

The invention discloses porous ceramic prepared by adopting different inorganic binders, which comprises the following raw material components: inorganic binders, aggregates and pore forming materials, wherein the mass ratio of the inorganic binders, the aggregates to the pore forming materials is 3 : 17 : 2; the raw material components of the inorganic binders are CaO-MgO-SiO2-Al2O3-TiO2 system glass, feldspar and clay, and the mass proportional range of the components is 29.24-100 : 0-47.14 : 22.32-61.74. According to the invention, different cheap inorganic binders are used for connecting aggregates to prepare the porous ceramic which has high strength and high air porosity, and can be applied to filtration and separation, so that the overall performance is excellent, the maximum bending strength can reach 33.34 MPa, and the apparent porosity is 48.25%.

Owner:TIANJIN UNIV

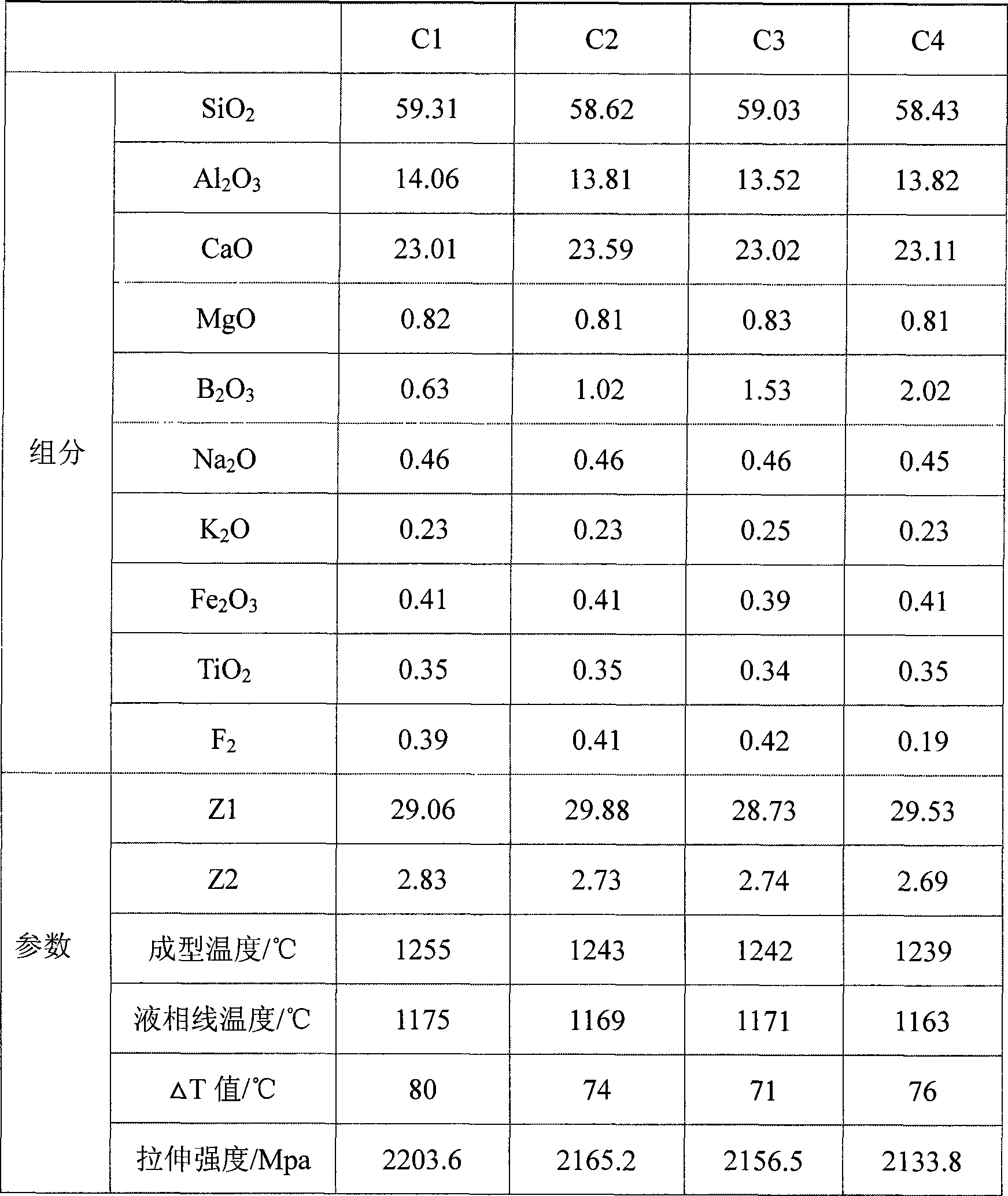

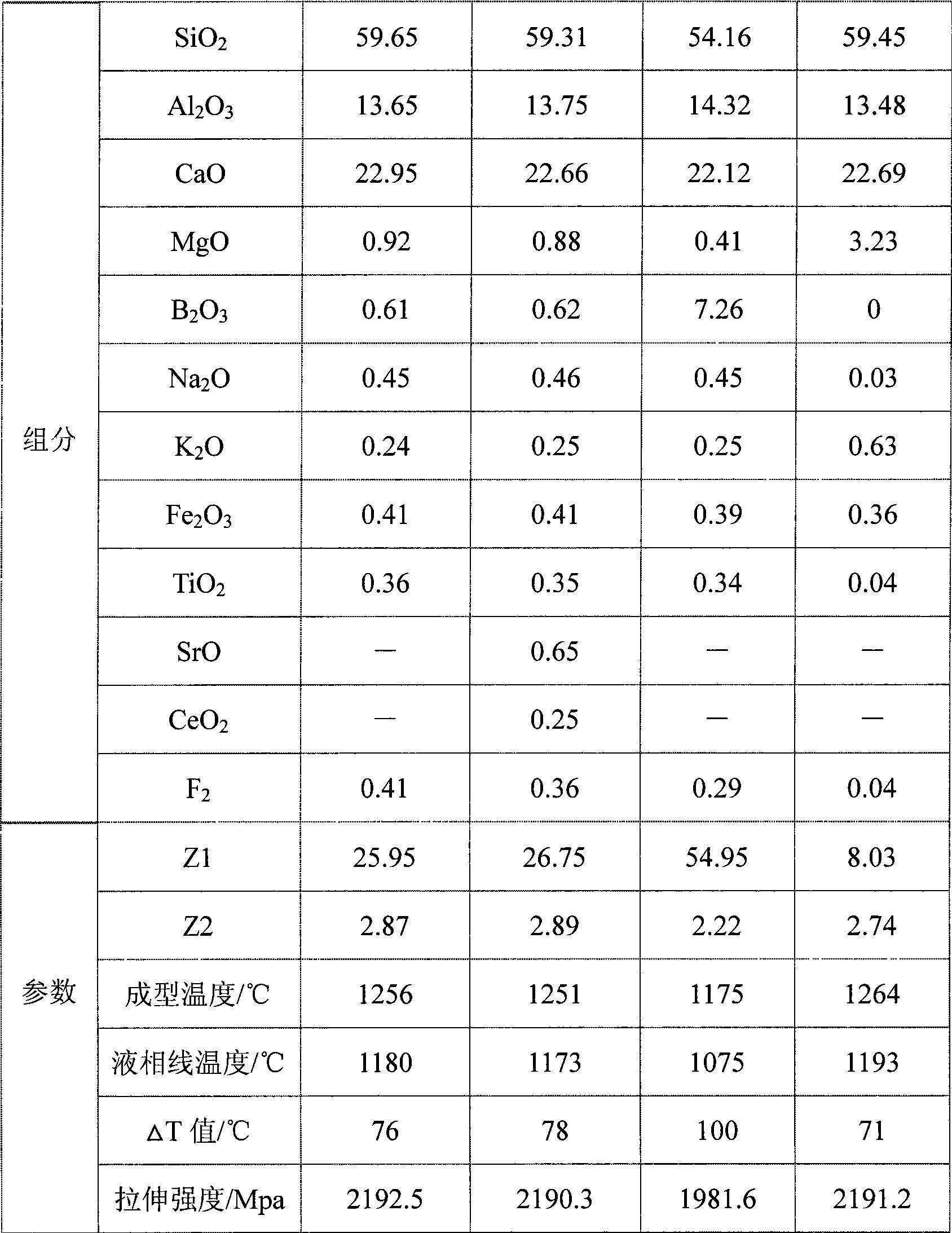

Novel glass fibre composition

The invention relates to a glass fiber composition. The composition comprises the following compositions in percentage by weight: 58 to 65 percent of SiO2, 20 TO 26 percent of CaO, 9 to 17 percent of Al2O3, 0.5 to 1 percent of MgO, 0 to 5 percent of B2O3, 0 to 1 percent of F2, 0.1 to 1 percent of TiO2, 0 to 0.8 percent of K2O and Na2O, 0.1 to 0.5 percent of Fe2O3, and 0 to 0.6 percent of SO3. The glass fiber composition uses SiO2-Al2O3-CaO three-element system as basis, introduces MgO and B2O3 with low content, and reasonably designs the gross weight of alkaline metal oxides and the proportional relationship between the MgO and the CaO, not only contributes to the improvement of the mechanical strength, the high temperature resistance and the chemical stability of the glass, but also has excellent drawing performance; furthermore, the glass fiber composition has low cost in raw materials, and meets the requirement of environmental protection.

Owner:JUSHI GRP CO

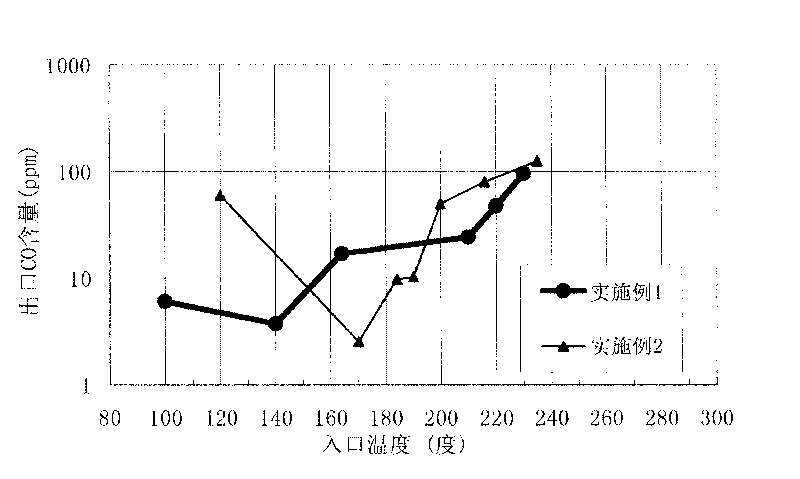

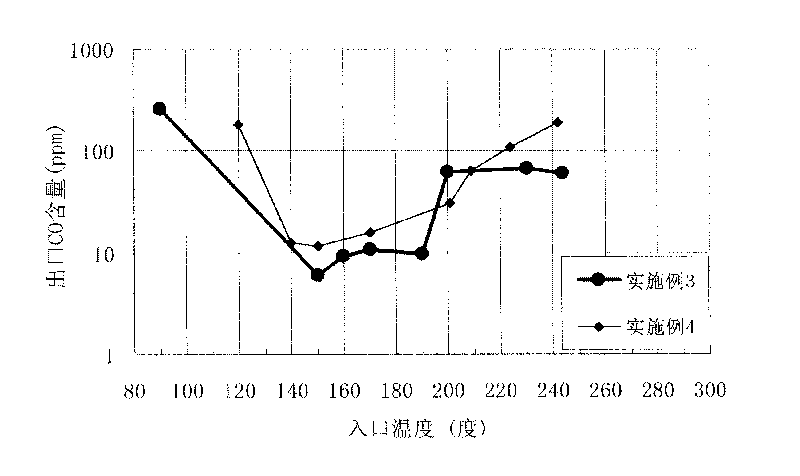

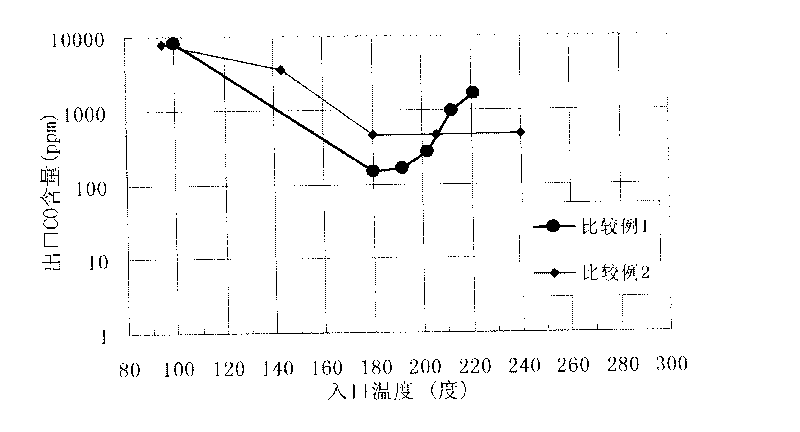

Method for preparing catalyst for removing CO by selective oxidation

InactiveCN101690892AThickness is easy to controlPosition is easy to controlHydrogen separation using solid contactCatalyst activation/preparationMetal colloidsReducing agent

The invention provides a method for preparing a catalyst for removing CO from a hydrogen-rich atmosphere by selective oxidation. The catalyst is characterized in that the carrier thereof adopts Al2O3 or SiO2-Al2O3 with the weight percentage of SiO2 being 3-40%; and the active component thereof is one or more than one selected from the following noble metal elements: Ru, Rh, Pd and Pt. Based on a metallic colloid method, the method of the invention for preparing the catalyst comprises the following steps: adding surfactant to the aqueous solution of metal salt of the active components in the noble metal elements; slowly adding reducing agent drop by drop while stirring intensely, so as to obtain stable noble metal colloid with the particle size thereof being 2-10nm through reduction by a reducing agent; properly regulating loading conditions and loading the noble metal colloid onto the carrier, so as to obtain a loading-type metal colloid catalyst; and subjecting the metal colloid catalyst to room-temperature airing, oven-drying and reducing, to obtain the finished catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Inorganic-organic compound hole sealing coating

InactiveCN101654380AReduce coefficient of frictionImprove hydrophobicity and oleophobicityPorosityFouling layer

The invention relates to an inorganic-organic compound hole sealing coating comprising two parts of a hole sealing layer and an anti-fouling layer, wherein the hole sealing layer is formed by an inorganic hole sealing agent through a dipping-pulling method and a thermal processing method on a test sample after surface processing, the anti-fouling layer is formed by an organic anti-fouling agent through the dipping-pulling method and the thermal processing method on the hole sealing layer, and the inorganic hole sealing agent is an SiO2-Al2O3 colloidal sol hole sealing agent; the organic anti-fouling agent is polytetrafluoroethylene diluent which is prepared by taking polytetrafluoroethylene dispersing liquid, distilled water and a non-ionic type surfactant as raw materials. The preparationmethod of the inorganic-organic compound hole sealing coating provided by the invention comprises two parts of preparing the inorganic hole sealing layer and preparing the organic anti-fouling layer.The inorganic hole sealing layer provided by the invention can obviously lower the porosity of the coating and obviously enhance the erosion resistance performance and the high-temperature resistanceperformance of the coating; the organic anti-fouling layer can effectively lower the surface energy of the coating, enables stains not to be easy to attach to the surface of the coating and has favorable anti-fouling function.

Owner:WUHAN UNIV OF TECH

Nano grade transition metal oxidation catalyst and its preparing method and use

InactiveCN1714936AHigh activityEnhanced anti-toxicityCatalyst carriersCatalyst activation/preparationMischmetalGranularity

The present invention is efficient oxidizing catalyst for organic waste water treating and its preparation process and application. The carrier prepared with composite powder of Ti, Si, Al and RE oxide and in the average granularity smaller than 100 nm is loaded with at least two kinds of transition metal to prepare the catalyst. The catalyst contains TiO2-SiO2-Al2O3 65-85 wt%, RE oxide 5-15 wt%, and transition oxide 5-30 wt%. The preparation process of the catalyst includes preparing carrier powder with the carrier components and through precipitation, homogenization, ageing, filtering, washing, pulping, dispersing, fluidizing at supercritical condition to eliminate water and activating; forming the carrier, soaking, fluidizing and drying, and activating to obtain the catalyst. The catalyst is used in acid organic waste water treatment and has COD degrading rate higher than 95 %, ammonia nitrogen oxidizing conversion rate higher than 99 % and chroma eliminating rate higher than 95 %.

Owner:CNPC JILIN CHEM GROUP CORP

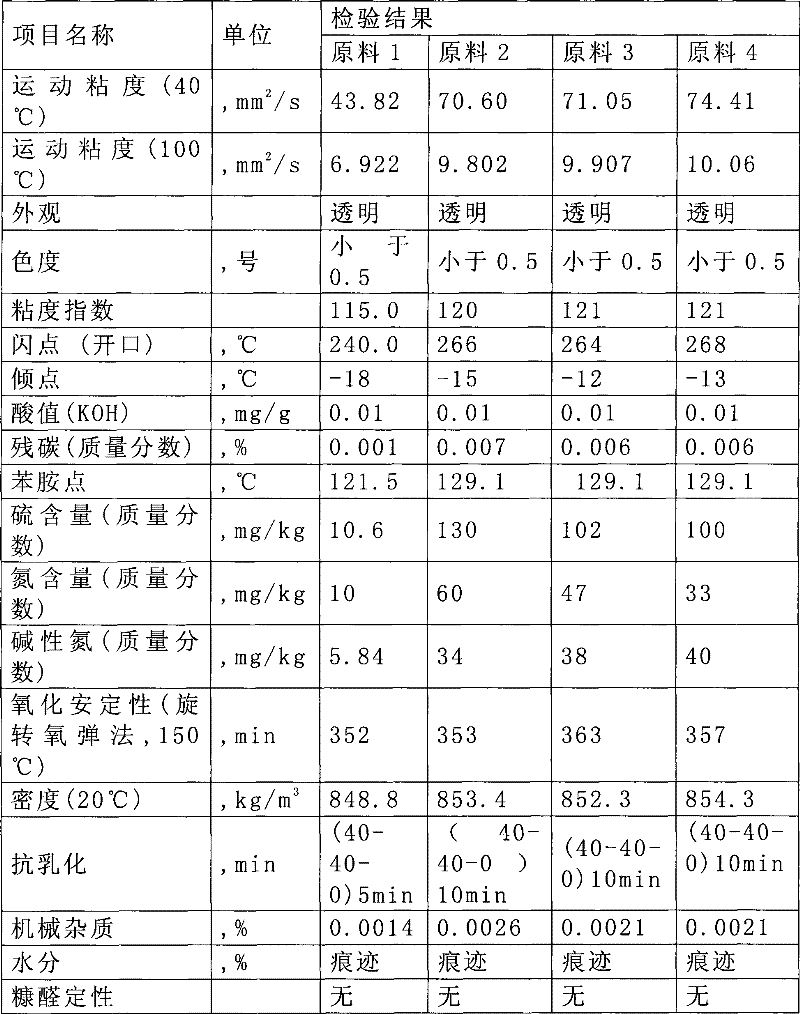

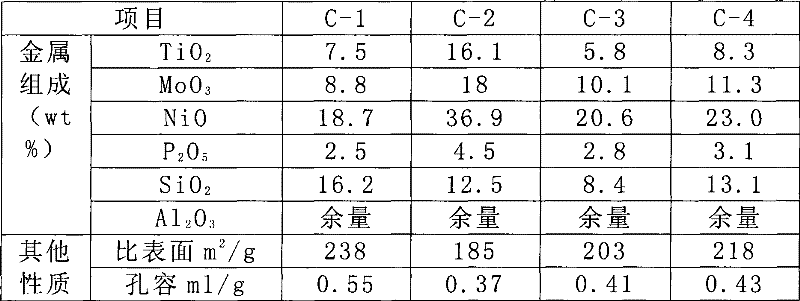

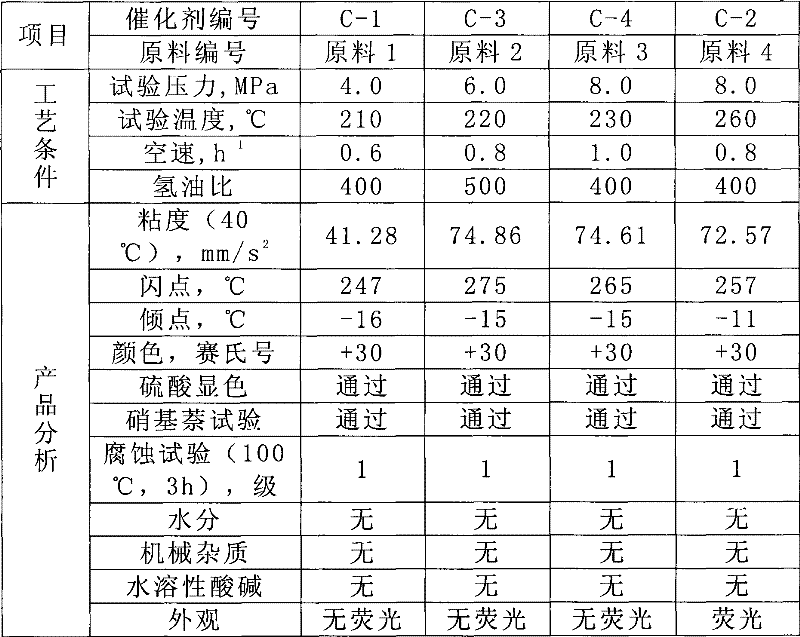

Process for preparing high-viscosity technical white oil

ActiveCN101343558BLarger than surfaceConcentrated hole distributionRefining to eliminate hetero atomsActive componentSulfur

The invention relates to a high viscosity industrial white oil production method, which takes the catalytic cracking mesoplasm lube base oil as the raw material, anti-sulfur catalyst is adopted, the industrial white oil is generated through the first stage hydrogenation, the reaction temperature is 200 DEG C to 320 DEG C, the reaction hydrogen partial pressure is 4.0 MPa to 8.0 MPa, the liquid volume space velocity is 0.3 to 1.5 h-1, and the hydrogen oil volume rate is 200 to 1000; the catalyst carrier is SiO2-Al2O3 modified by TiO2, an active component takes the catalyst weight as the datum, the NiO content is 10 wt percent to 40 wt percent, the MoO3 content is 15 wt percent to 20 wt percent, the TiO2 content is 3 wt percent to 8 wt percent, the surplus is a SiO2-Al2O3 carrier, the catalyst active component content is low, the sulfur-resistant and nitrogen poisoning ability is high, the method is suitable for the impurities, such as sulfur, nitrogen and the like, and the mesoplasm lube base oil with a higher aromatics content, and the superior grade high viscosity industrial white oil is generated by adopting the first stage hydrogenation technology.

Owner:PETROCHINA CO LTD

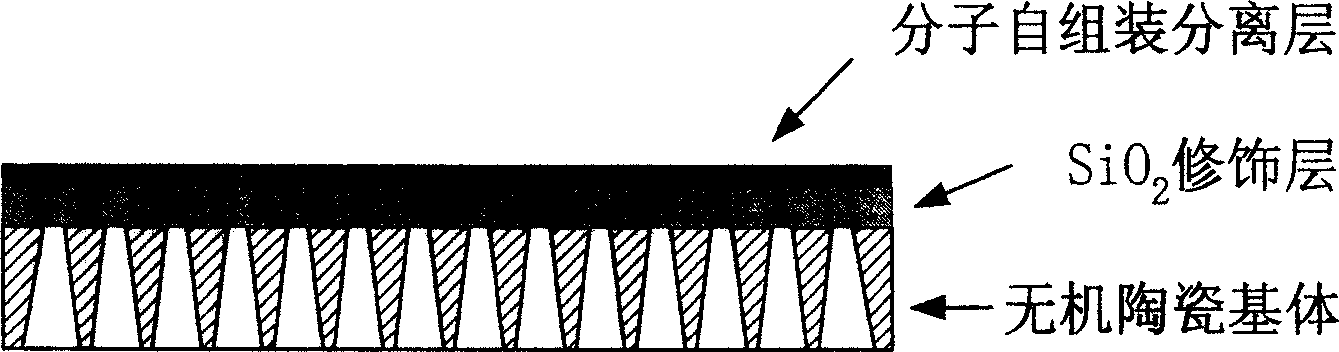

Process for preparing organic and inorganic composite film by autoassembling tech

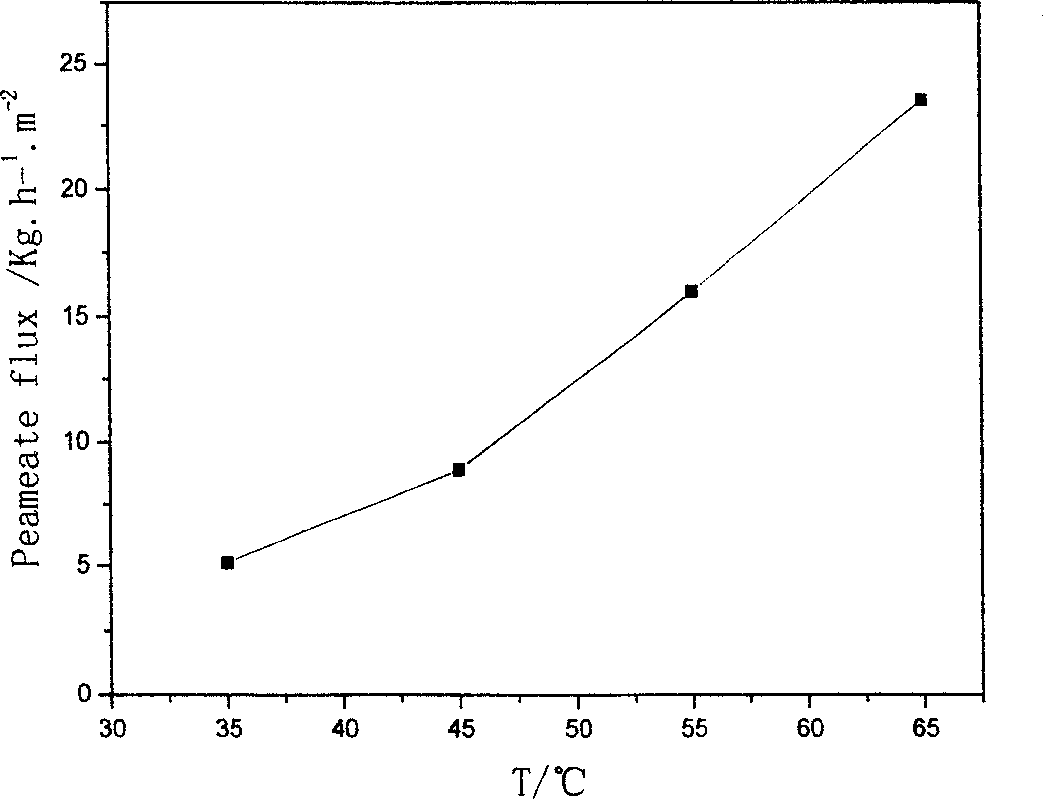

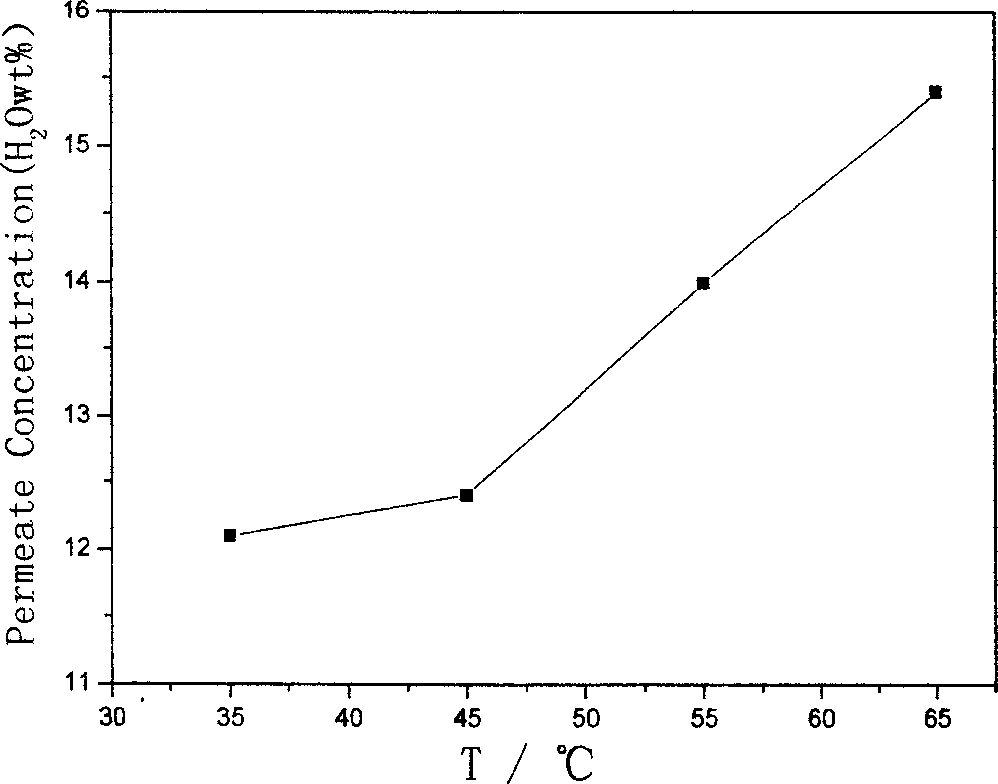

ActiveCN1724128AExcellent pervaporation separation performanceControl thicknessSemi-permeable membranesComposite filmHYDROSOL

A process for preparing the composite organic-inorganic membrane by self-assembling technique includes such steps as mixing ethyl silicate, de-ionized water, absolute alcohol and acid catalyst, heating to obtain SiO2 sol, ageing, coating it on the one surface of Al2O3 ceramic substrate, drying, calcining, washing to obtain SiO2-Al2O3 substrate, preparing poly-cationic electrolyte solution and poly-anionic electrolyte solution by use of hydrochloric acid, immersing the SiO2 side of said substrate in the poly-cationic solution and washing with clean water, immersing in polyanionic solution and washing with clean water, and repeating said alternative immersing and washing steps to form nano-class compact membrane layer.

Owner:NANJING UNIV OF TECH

Rare earth medium slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909749AImprove electrical performanceImprove wettabilityNon-conductive material with dispersed conductive materialResistor manufactureSolid componentMass ratio

The invention relates to a rare-earth meidum slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component is the glass in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group, and the components of each oxidant have the mass percentages as: SiO2(30-65%), Al2O3(5-26%), CaO(18-38%), B2O3(2-16%), La2O3(0.3-15%), Co2O3(0.05-6%), TiO2(1-10%), ZrO2(1-10%). And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing organic solvent carrier; (3), mixing material in three-dimension and rolling with three rollers; (4), preparing medium slurry; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friend, better sinter property, better print property, and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

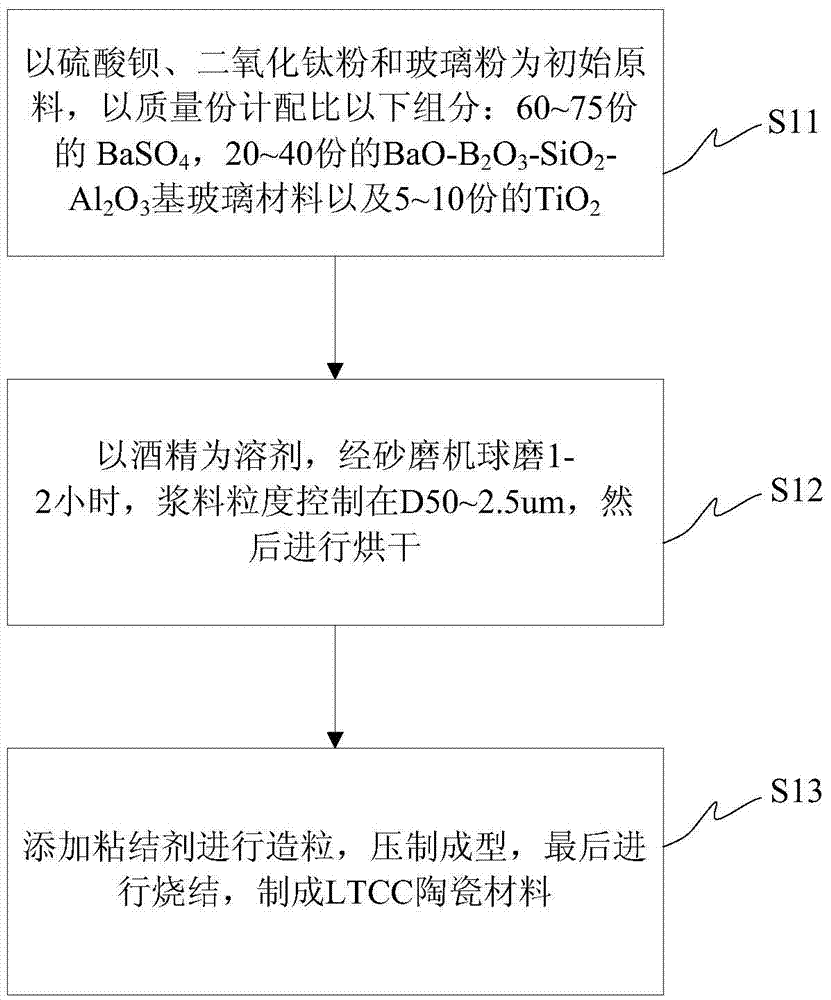

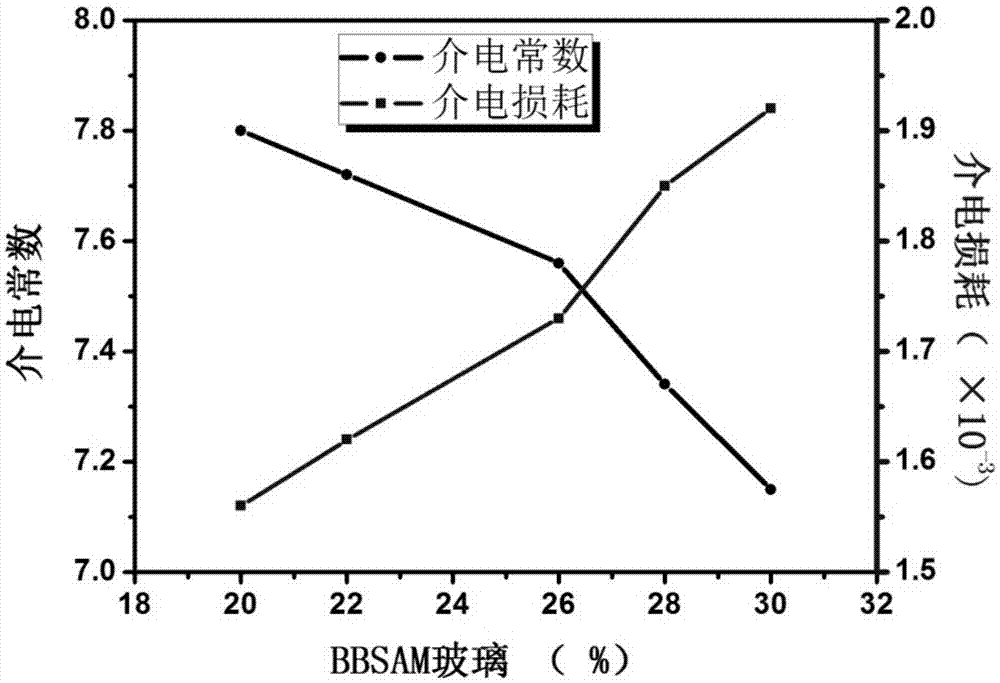

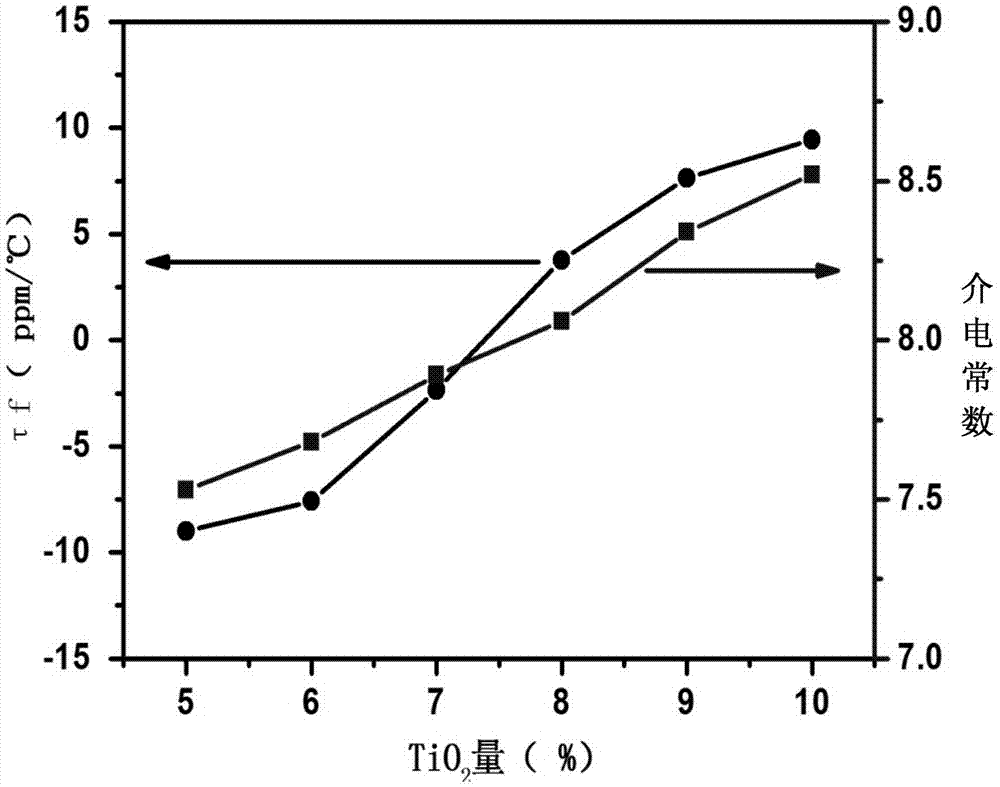

LTCC (low-temperature co-fired ceramic) material with low dielectric constant, low loss and near-zero-temperature coefficient and preparation method

The invention provides an LTCC (low-temperature co-fired ceramic) material with a low dielectric constant, low loss and a near-zero-temperature coefficient and a preparation method. According to the LTCC material, on the basis of a BaSO4 ceramic powder, glass of a BaO-B2O3-SiO2-Al2O3 system is adopted for assisted combustion to reduce sintering temperature, and TiO2 is adopted for adjusting a resonance frequency temperature coefficient, so that 900 DEG C low-temperature sintering can be realized. Under 60GHz, the dielectric constant of the LTCC material is 5.5-9, the low dielectric loss is smaller than 2*10<3>, and the near-zero-temperature coefficient is tua f-+ / -10ppm / DEG C. In addition, the preparation method has the advantages of cheap production raw material, low production cost and simple preparation process. The LTCC material can be applied to manufacture of microwave devices such as low-temperature co-fired ceramic systems, multilayer dielectric resonators, microwave antennas and filters, and has high application value in industry.

Owner:上海晶材新材料科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com