LTCC (low-temperature co-fired ceramic) material with low dielectric constant, low loss and near-zero-temperature coefficient and preparation method

A technology with low dielectric constant and temperature coefficient, applied in the field of electronic ceramic materials and its manufacturing, can solve the problems of inability to co-fire low melting point metals, high sintering temperature, difficult low temperature sintering, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

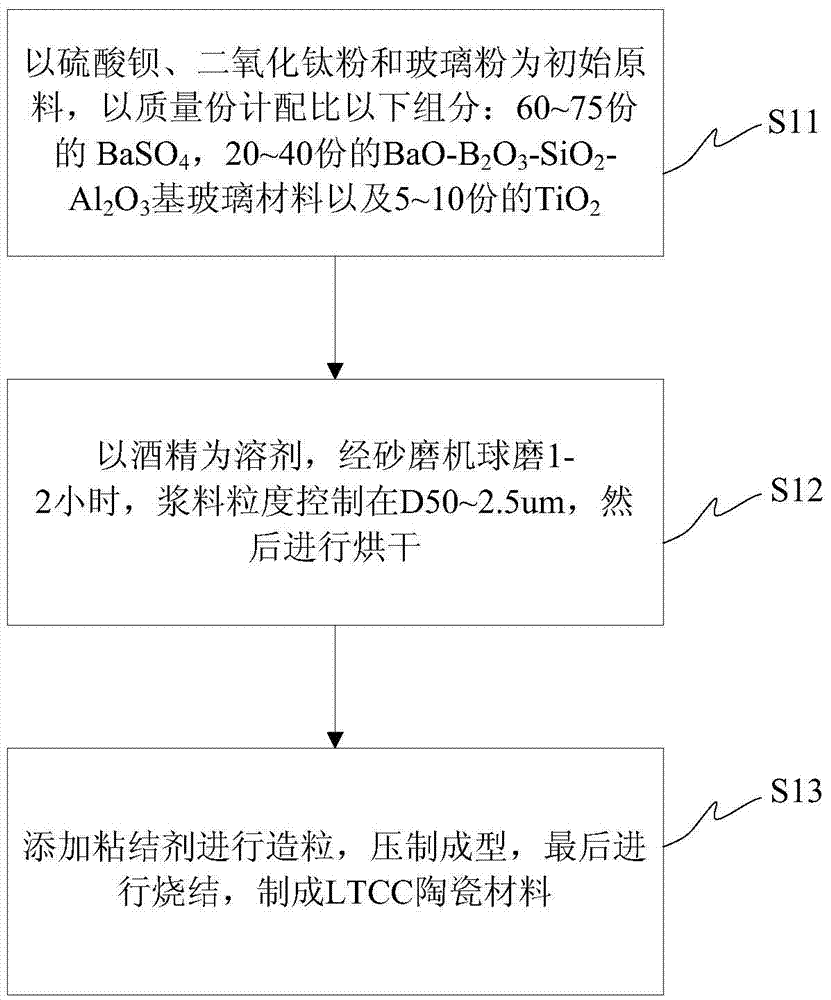

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a low dielectric constant, low loss, and near-zero temperature coefficient LTCC ceramic material, which is a glass-ceramic material made by combining glass and ceramics. The LTCC ceramic material includes the following components in parts by mass: x parts of BaSO 4 , y parts of BaO-B 2 o 3 -SiO 2 -Al 2 o 3 base glass material and z parts of TiO 2 , where x+y+z=100.

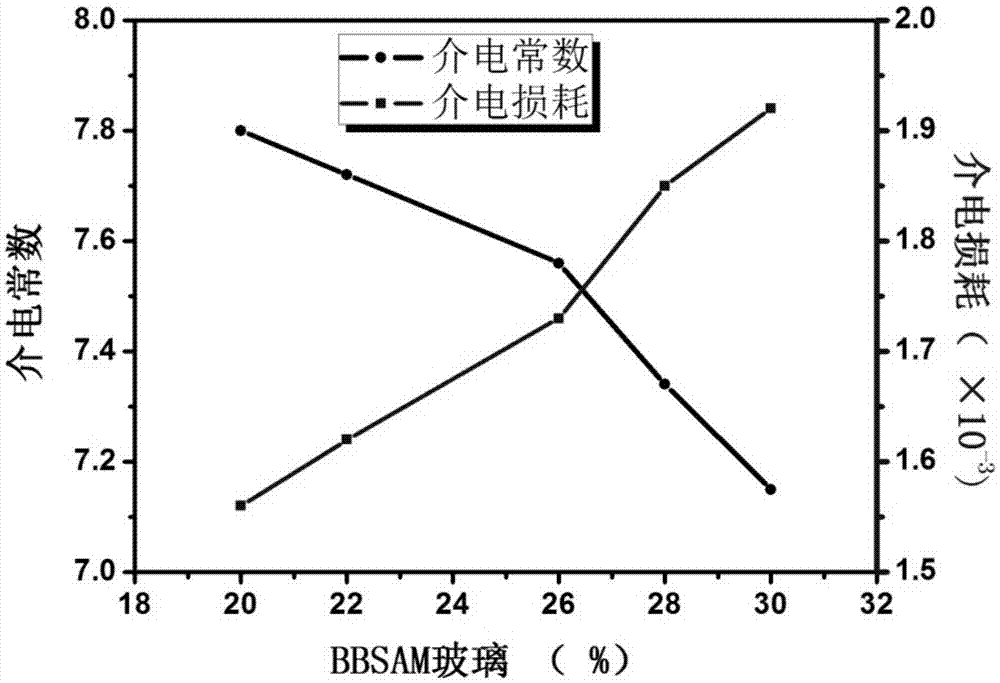

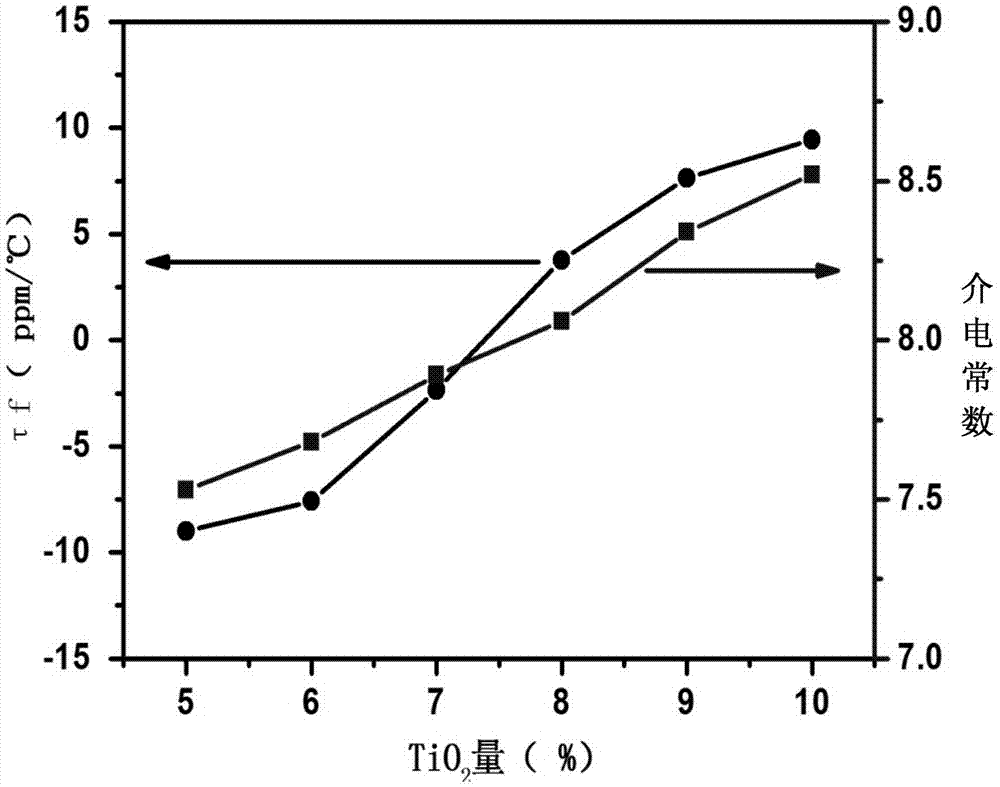

[0034] As an example, the LTCC ceramic material includes the following components in parts by mass: 60-75 parts of BaSO 4 , 20-40 parts of BaO-B 2 o 3 -SiO 2 -Al 2 o 3 Base glass material and 5-10 parts of TiO 2 .

[0035] As an example, the BaO-B 2 o 3 -SiO 2 -Al 2 o 3 The base glass material includes the following components by mass ratio: 25-35% BaO, 20-40% B 2 o 3 , 40-60% SiO 2 , 1-10% Al 2 o 3 , 0-2% MgO, and no more than 2% Na 2 O+K 2 O+Li 2 O. The present invention adopts the above-mentioned glass system because the glass (BBSAM) system has a lower...

Embodiment 2

[0050] This embodiment provides a LTCC ceramic material with low dielectric constant, low loss, and near-zero temperature coefficient and its preparation method. The basic scheme is as in Embodiment 1, wherein:

[0051] In this example, BaO-B 2 o 3 -SiO 2 -Al 2 o 3 Base glass material powder (BBSAM-2) is melted according to the following composition: BaO 25%, B 2 o 3 23%, SiO 2 44%, Al 2 o 3 5.5%, MgO 0.5%, Na 2 O 0.5%, K 2 O 0.5%, Li 2 O1%; the melting temperature is 1400°C, the melting time is 2hr, the glass is also poured into water to quench, and wet milled until the particle size D50 is about 2.5um.

[0052] The composition of the low temperature co-fired ceramic material is in parts by mass, and the proportion is: (100-a) (30% glass powder (BBSAM-2) + 70% barium sulfate (BaSO 4 ))+a titanium dioxide (TiO 2 ), wherein the range of a is 5-10. The mixture is wet ground until the particle size D50 is about 2.5um.

[0053] The obtained low-temperature co-fired ...

Embodiment 3

[0055] This embodiment provides a LTCC ceramic material with low dielectric constant, low loss, and near-zero temperature coefficient and its preparation method. The basic scheme is as in Embodiment 1, wherein:

[0056] In this example, BaO-B 2 o 3 -SiO 2 -Al 2 o 3 The base glass material powder is melted according to the following composition (BBSAM-3): BaO 20%, B 2 o 3 25%, SiO 2 47%, Al 2 o 3 5%, MgO 1%, Na 2 O 0.5%, K 2 O 0.5%, Li 2 O 1%; the melting temperature is 1400°C, the melting time is 2hr, the glass is also poured into water to quench, and wet milled until the particle size D50 is about 2.5um.

[0057] The composition of the low temperature co-fired ceramic material is in parts by mass, and the proportion is: 70 parts of barium sulfate (BaSO 4 ), 6 parts of titanium dioxide, 24 parts of BBSAM-3 glass. The mixture is wet ground until the particle size D50 is about 2.5um.

[0058] The resulting low-temperature co-fired ceramic material was sintered at 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com