Catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride and preparation method thereof

The technology of succinic anhydride and catalyst is applied in the field of supported nickel catalyst and its preparation, which can solve the problems of high catalyst cost and high reaction pressure, and achieve the effects of simple preparation method, high dispersion and high hydrogenation selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

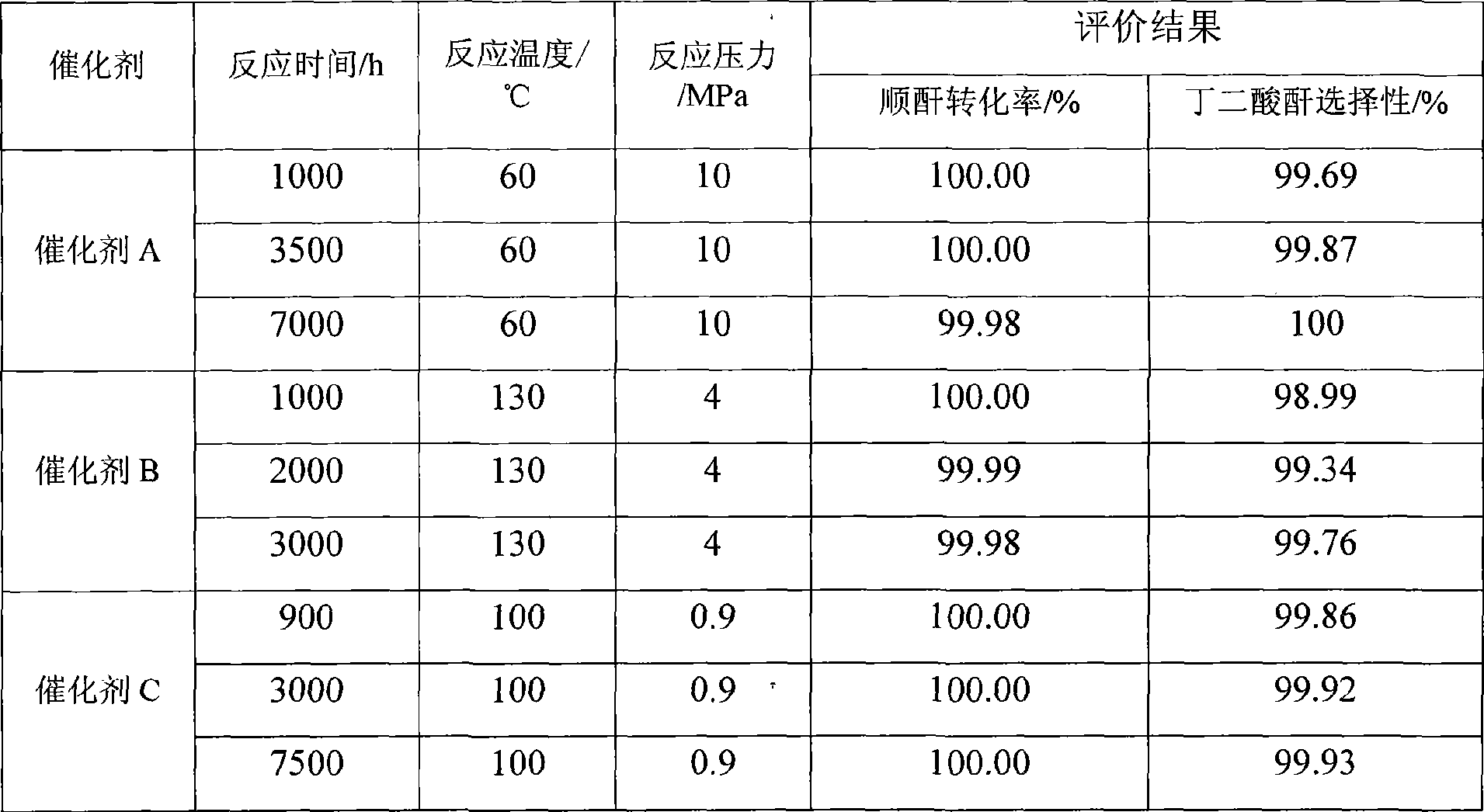

Embodiment 1

[0029] Take a certain amount of SiO 2 The carrier was calcined in a muffle furnace at 400°C for 6 hours in an air atmosphere, cooled to room temperature and used for later use; 127.19g of nickel nitrate hexahydrate, 10.19g of copper nitrate trihydrate and 82ml of 25wt%-28wt% ammonia were prepared to prepare 200ml of mixed nickel Salt solution; take 200ml of the above-mentioned prepared nickel salt solution and impregnate it into the above-mentioned 100g of the treated carrier, and let it stand at room temperature for 0.5h; Roast at 400°C for 8 hours in air atmosphere; hydrogen space velocity at normal pressure is 300 hours -1 , reduced at 350°C for 4h, and then deactivated with oxygen to obtain catalyst A after cooling down to room temperature.

Embodiment 2

[0031] Take a certain amount of Al 2 o 3 The carrier was calcined in a muffle furnace at 800° C. for 3 hours in an air atmosphere, cooled to room temperature and then used for later use; the rest was the same as in Example 1 to obtain catalyst B.

Embodiment 3

[0033] Take a certain amount of SiO 2 4 wt% SiO 2 -Al 2 o 3 The composite oxide carrier was calcined in a muffle furnace at 600° C. for 5 hours in an air atmosphere, cooled to room temperature and then used for later use; the rest was the same as in Example 1 to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com