Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132 results about "Lanthanum hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum hydroxide is La(OH)₃, a hydroxide of the rare-earth element lanthanum.

Methane oxidative coupling with la-ce catalysts

ActiveUS20180353940A1More efficient processHigh selectivityHeterogenous catalyst chemical elementsCatalystsCeriumOxygen

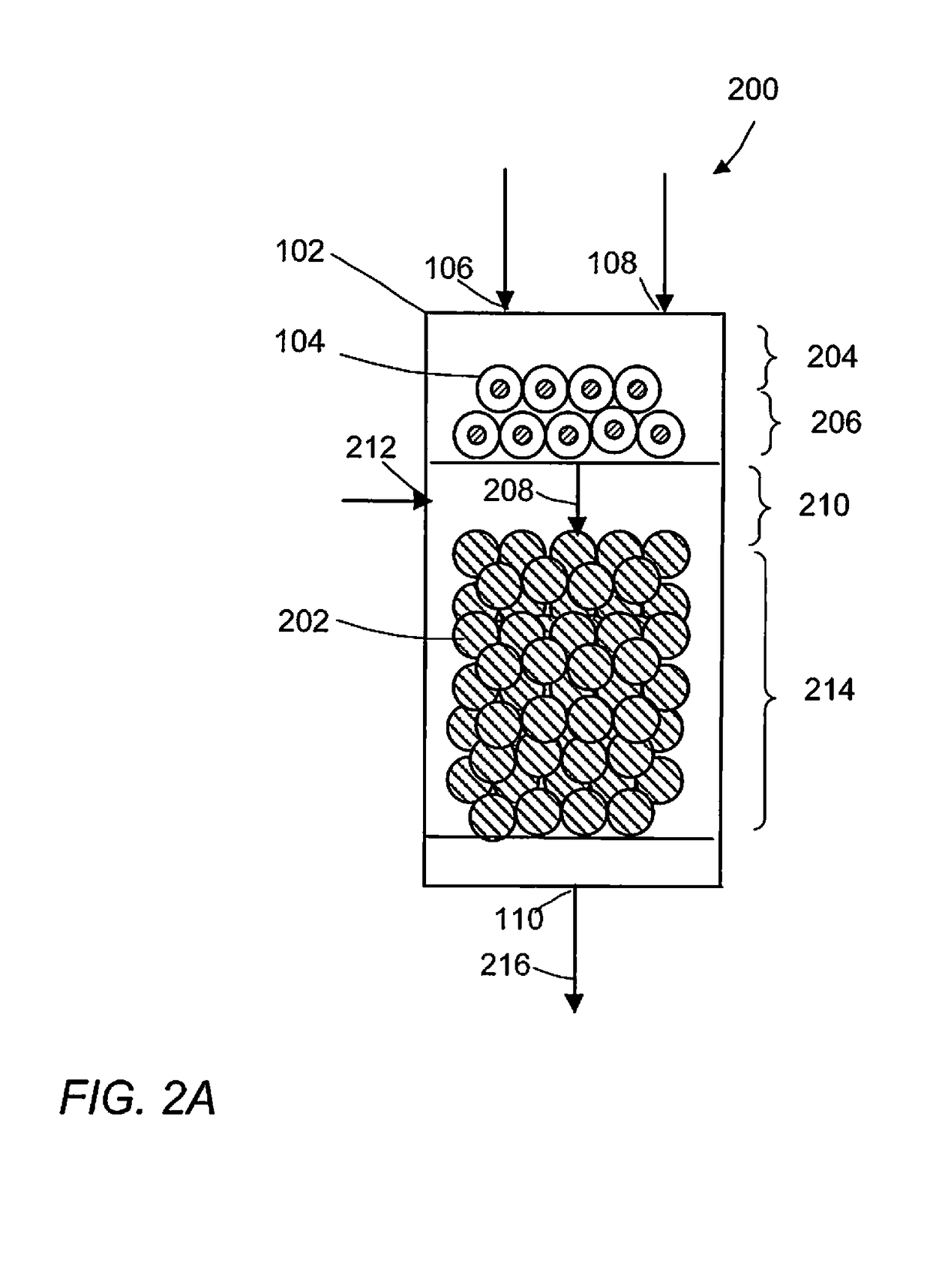

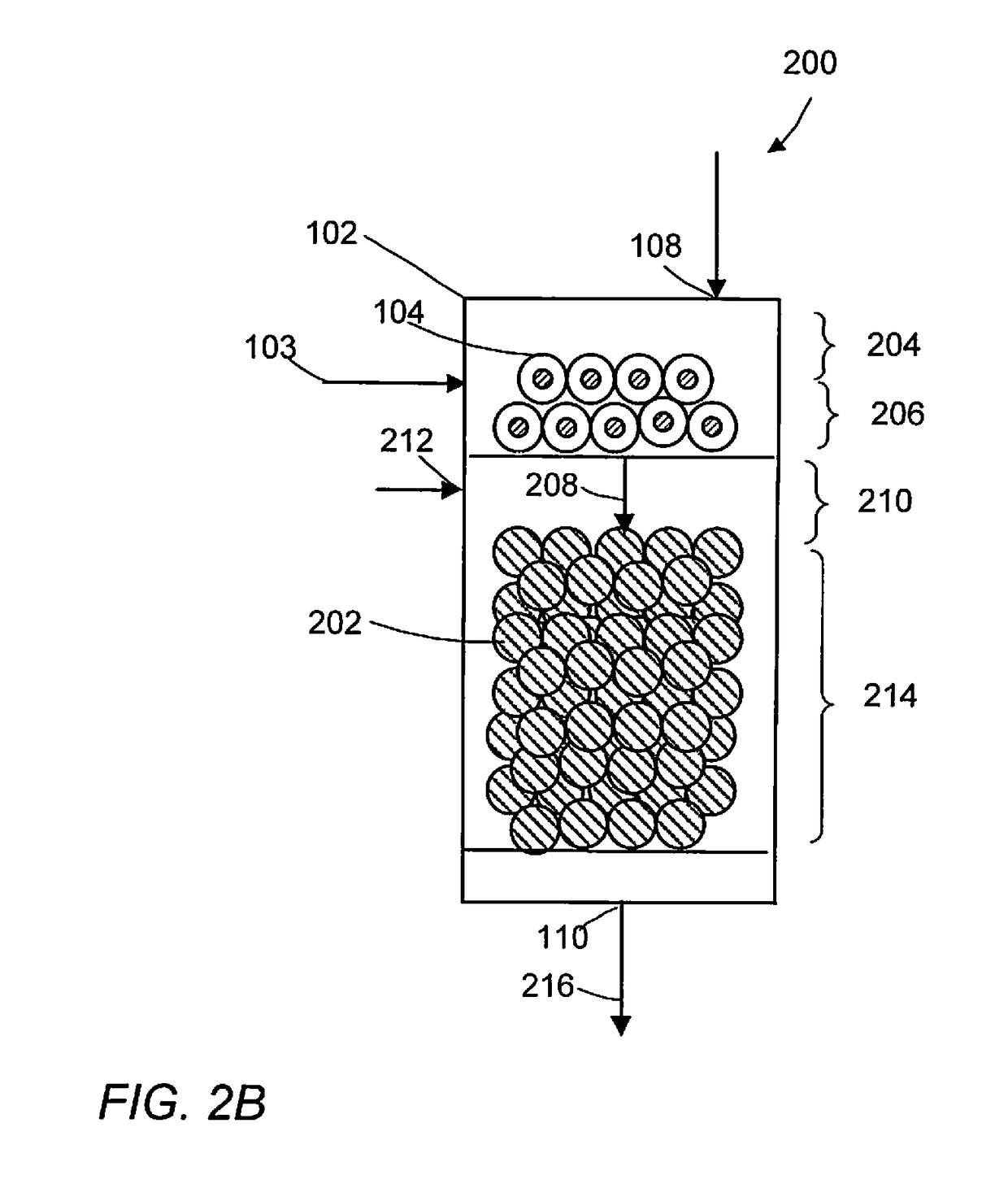

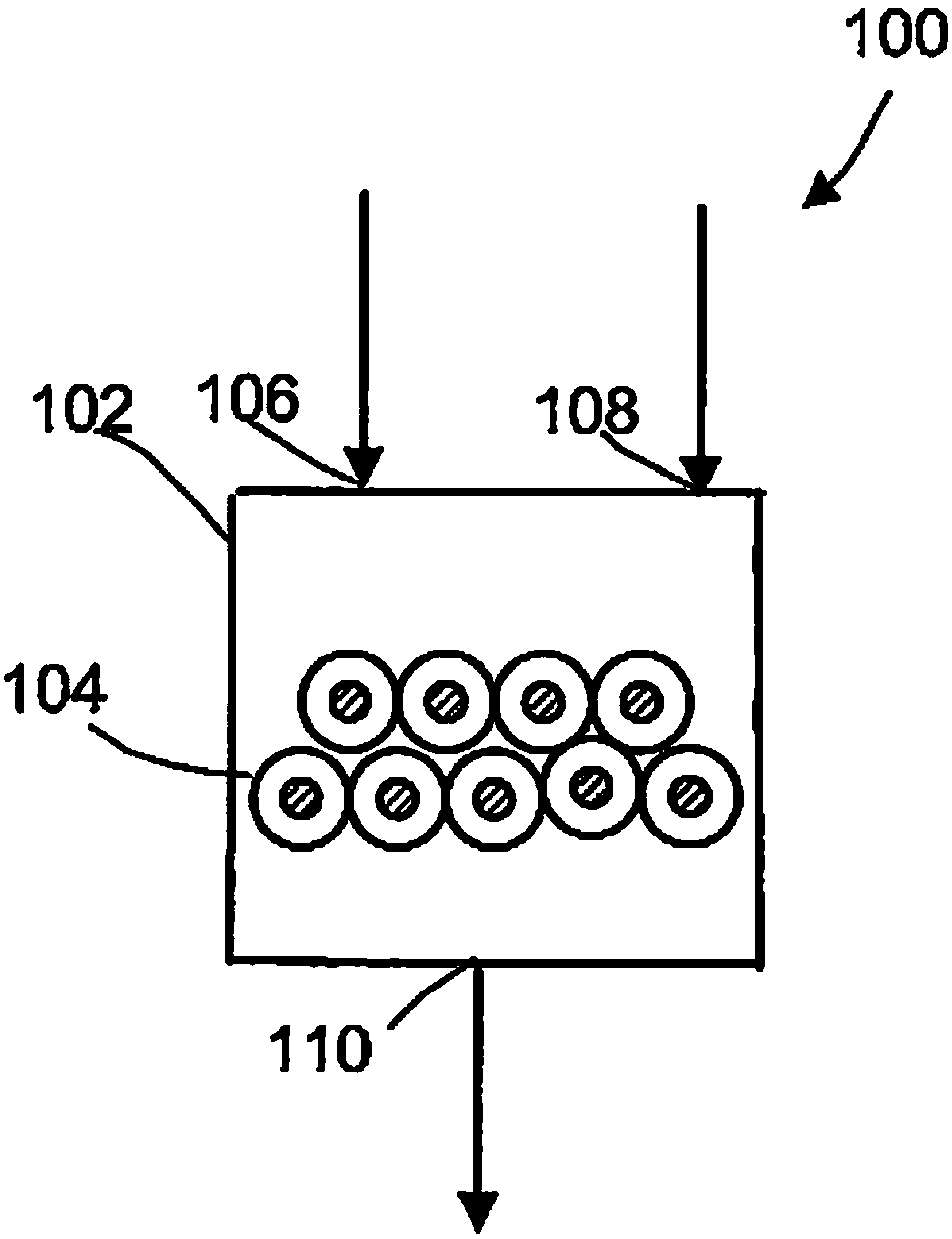

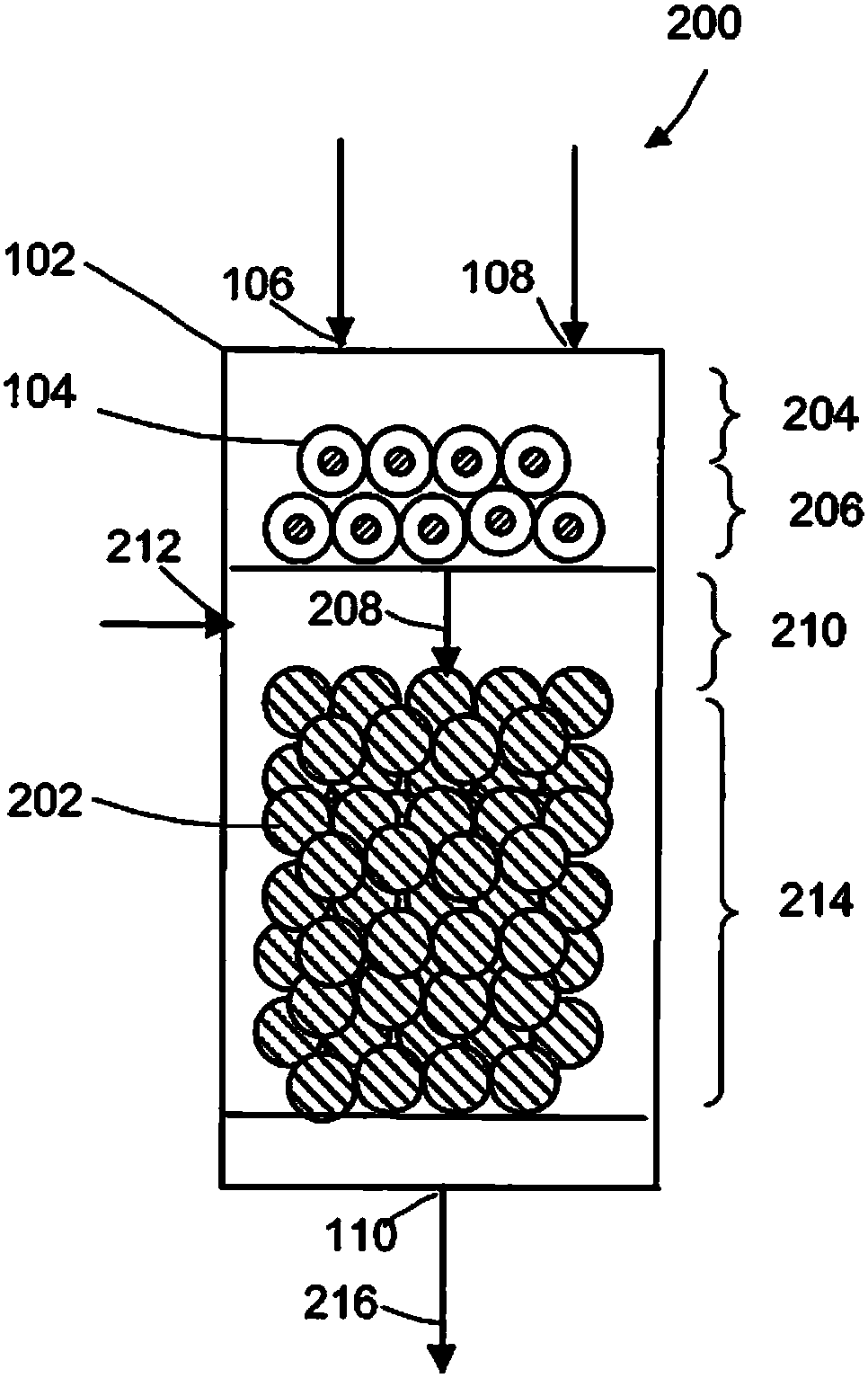

A metal oxide catalyst capable of catalyzing an oxidative coupling of methane reaction is described. The metal oxide catalyst includes a lanthanum (La) cerium (Ce) metal oxide and further including a lanthanum hydroxide (La(OH)3) crystalline phase. The catalyst is capable of catalyzing the production of C2+ hydrocarbons from methane and oxygen. Methods and systems of using the metal oxide catalyst to produce C2+ hydrocarbons from a reactant gas are also described.

Owner:SABIC GLOBAL TECH BV

Preparation method of active carbon fiber phosphorous removing agent carrying lanthanum hydroxide

The invention relates to a preparation method of an active carbon fiber phosphorous removing agent carrying lanthanum hydroxide. The invention belongs to the technical field of phosphorous removing agent preparation technology. The novel phosphorous removing agent provided by the invention has advantages of high phosphorous removing rate, high absorption rate, and the like. The phosphorous removing rate reaches above 99.5%. The method of the invention is characterized in that: a mixed suspension composed of a concentration of lanthanum nitrate solution and a concentration of sodium hydroxide solution is adopted; a certain amount of active carbon fiber is added to the mixed suspension; the mixture is stirred, filtered, washed, and a solid phosphorous removing agent is finally obtained. According to the phosphorous removing agent, a weight ratio of active carbon fiber to lanthanum hydroxide is 1:1 to 1:1.2.

Owner:SHANGHAI UNIV

Method for preparing nm-class composite rare earth molybdenum material by sol-gal process

The invention discloses an infusible metal material, belonging to compound nanometer material field. Especially relates to a method for using sol-gel method to produce nanometer compound rare earth molybdenum material. The method is, in ammonium molybdate solution, the lemon acid is poured in, and then the rare earth nitrate solution is added into the mixed solution. They are dried in the drying box, and form the dry gel. Then the dry gel is baked in furnace, forms compound of molybdenum trioxide and lanthana or lanthanum hydroxide. Finally, they are reduced for 1.5-2.5 hours under temperature of 400-450deg.C and 800-900deg.C in hydrogen furnace. The reduced compound rare earth lanthana is formed under pressure, and it is heated and baked into shape under high temperature and pressure in hydrogen furnace. The material particle is tiny, the density can reach to 95% of the ideal density, the rare earth oxide exists with nanometer particle, the emitting ability is strong, and it can be used as new negative material.

Owner:XI AN JIAOTONG UNIV

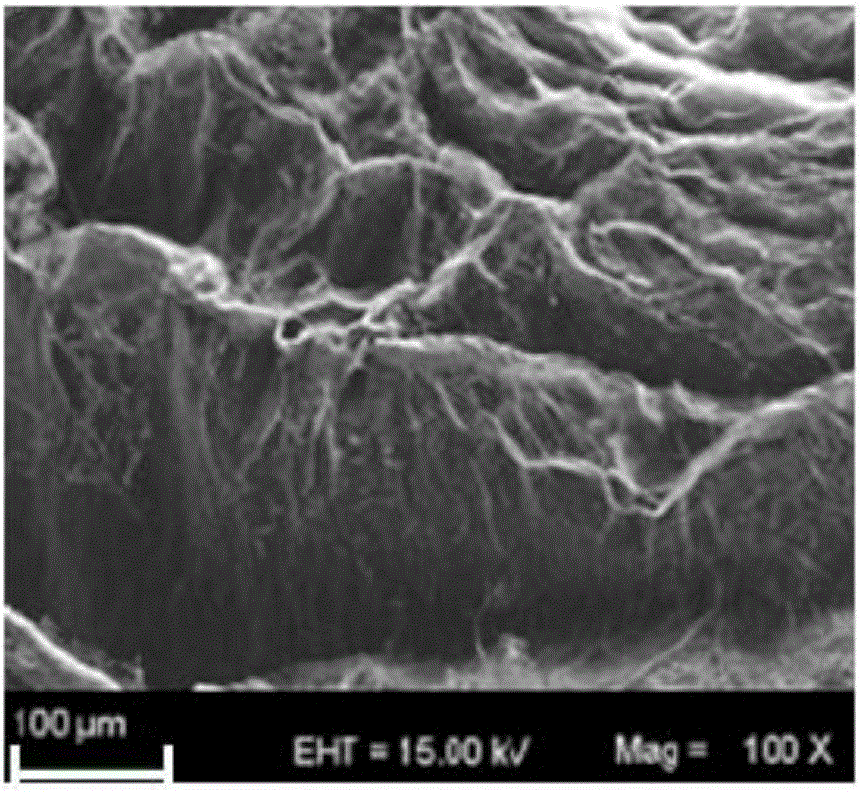

Complex alloy permeation agent and method for preparing permeation layer

InactiveCN102127732ASmooth appearanceUniform thicknessSolid state diffusion coatingHeat penetrationAlloy

The invention relates to a complex alloy permeation agent and a method for preparing a permeation layer, designed aiming at the surface antisepsis of common steel spare parts, such as railway track fasteners, bolts, elastic bars, concrete preembedded parts, and the like. The complex alloy permeation agent comprises zinc powder, aluminum powder, alumina powder, lanthanum hydroxide powder and ammonium chloride. The process line for preparing the permeation layer comprises the following steps of: pretreating a working piece; loading the working piece into a furnace and adding the permeation agent; heating a converter and keeping the temperature for permeation; and cooling the working piece when reaching a temperature and discharging the working piece. Heat penetration is carried out under confirmed process specifications so as to form corrosion-resistant and wearable complex alloy permeation layer with a certain thickness and a compact structure on the surface of the working piece. The invention has simple process and is easy to implement. A Zn-Al-Fe-La complex alloy permeation layer obtained by adopting the conventional process has the thickness about 100 micros, the hardness up to 240-320 HV and the salt-air corrosion up to 680 h.

Owner:安徽天通达克罗涂复科技有限公司

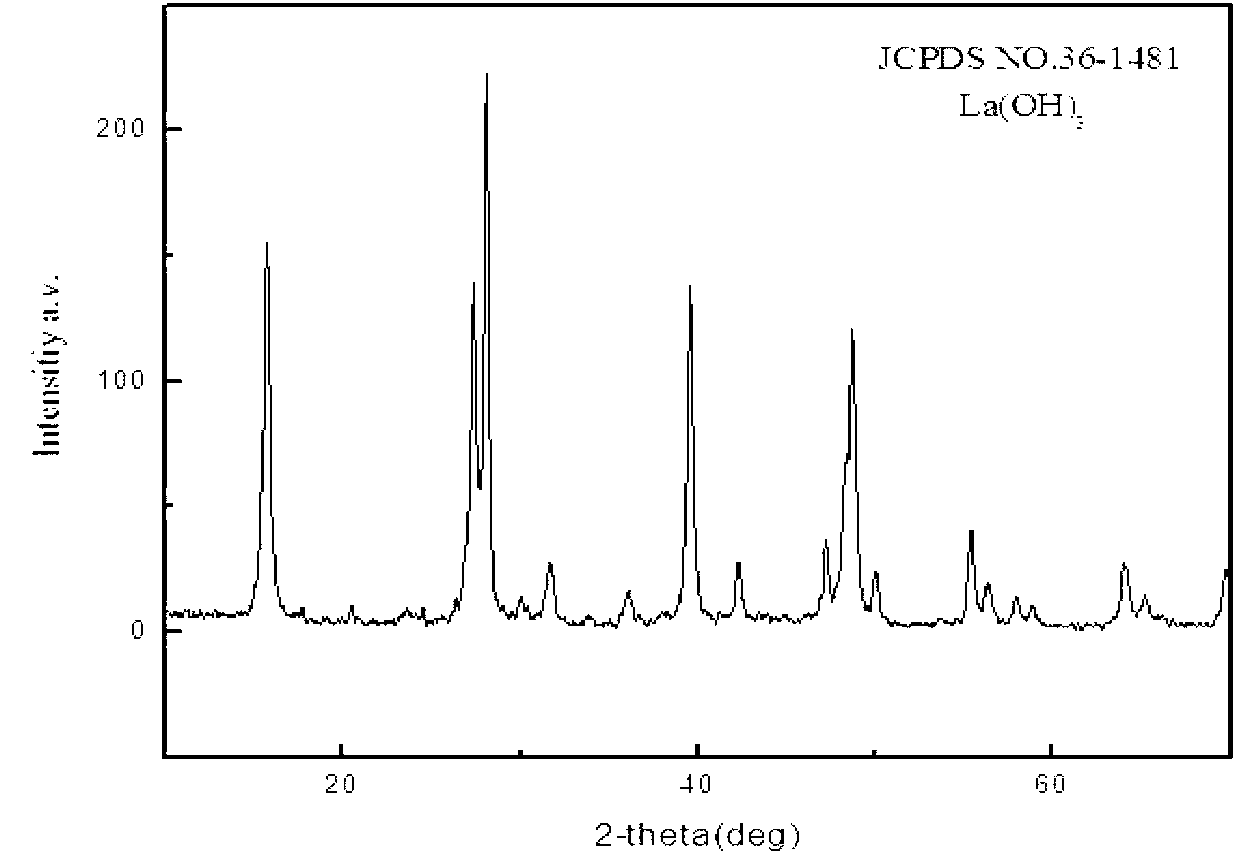

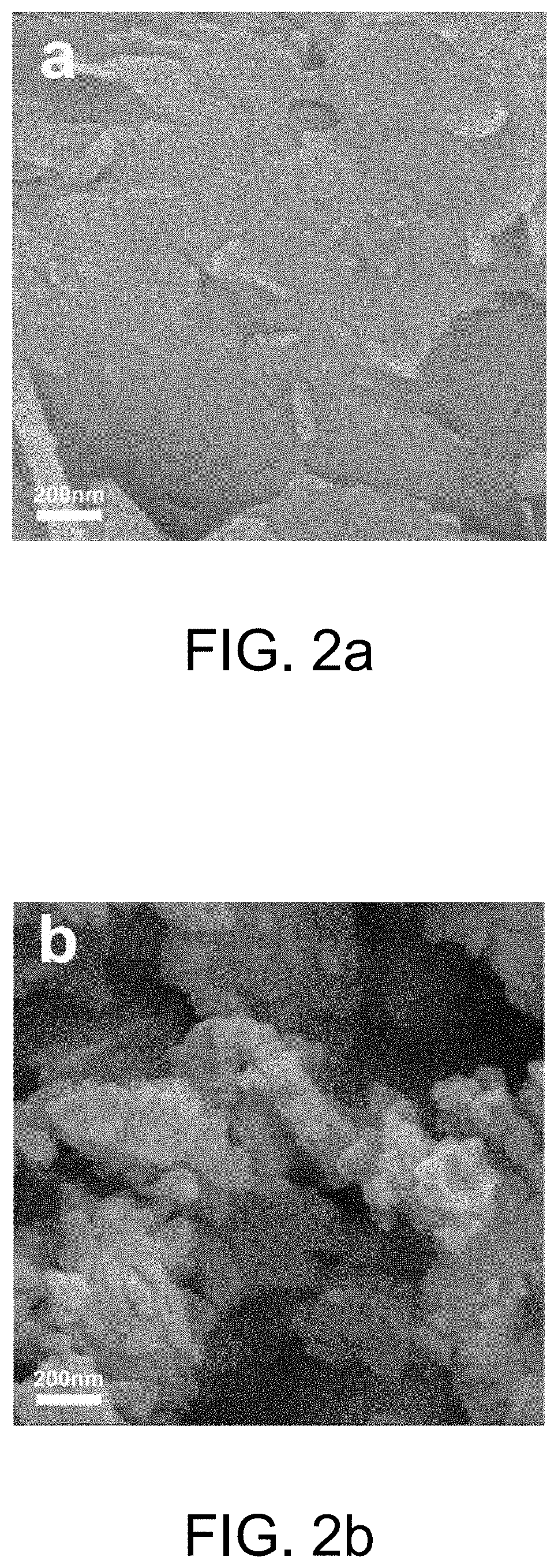

Method for preparing platy lanthanum hydroxide nanocrystalline through microwave-ultrasonic method

InactiveCN102936028AShort reaction timesReduce energy consumptionNanotechnologyRare earth metal compoundsPolyethylene glycolPotassium hydroxide

The invention provides a method for preparing platy lanthanum hydroxide nanocrystalline through a microwave-ultrasonic method. Analytically pure lanthanum nitrate hexahydrate and polyethylene glycol are added in deionized water to obtain a solution B; a potassium hydroxide or sodium hydroxide solution is added in the solution B to form a precursor solution C; the precursor solution C is poured into a four-neck round-bottom flask, the flask is put in a microwave-ultraviolet-ultrasonic trinity synthesis reaction apparatus, microwave heating and ultrasonic combination under a temperature-time mode is selected, the precursor solution C is cooled to the room temperature naturally after reaction is finished, a product is collected through centrifugation and then washed several times by deionized water and absolute ethyl alcohol, and the product is dried to obtain the final product platy lanthanum hydroxide nanocrystalline. The method adopts a simple microwave-ultrasonic preparation process, is short in reaction time period and low in energy consumption, reaction can be finished in liquid phase in one time, and no after-treatment is needed. La(OH)3 particles made by the method are of platy structures and are large in specific surface area, good in dispersibility and excellent in performance.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of surface modified pine needle loaded lanthanum hydroxide phosphorus adsorbent

ActiveCN105289521AControl Dissolution ProblemsIncreased internal pore structureOther chemical processesWater/sewage treatment by sorptionForest industryAlcohol

The invention discloses a preparation method of surface modified pine needle loaded lanthanum hydroxide phosphorus adsorbent. Surface modified pine needles serve as the carrying material, and surfaces of the pine needles are loaded with lanthanum hydroxide through the chemical deposit effect. According to the main preparation process, smashed pine needle cuticle is broken and organic substances in pine needle tissue structures are extracted through an alkali-alcohol mixed solution, and therefore the surfaces of pine needle tissue are loaded with lanthanum hydroxide through deposition. The phosphorus adsorbent is stable in phosphorus removal effect, convenient to recover and little in organic substance dissolution in the adsorption process; meanwhile, forestry by-products are utilized as resources, and quite good application prospects and environment benefits are achieved.

Owner:WUXI XINDU ENVIRONMENTAL PROTECTION EQUIP

Activated carbon fiber adsorbent loaded with lanthanum hydroxide and preparation method thereof

InactiveCN102350306AImprove adsorption capacityFast adsorption rateOther chemical processesWater/sewage treatment by sorptionActivated carbonFiber

The invention relates to an activated carbon fiber adsorbent loaded with lanthanum hydroxide and a preparation method thereof. An activated carbon fiber is taken as a substrate of the absorbent and the lanthanum hydroxide is loaded on the substrate, wherein a scope of a weight ratio of the lanthanum hydroxide to the activated carbon fiber is 0-0.85. Under an acoustic cavitation effect of ultrasonic waves, a periodical oscillating effect is achieved in liquid, thereby achieving a smaller dimension of deposited crystallite, achieving uniform size distribution and excellent dispersity, strengthening a transmitting process, causing the lanthanum hydroxide to efficiently enter into the activated carbon fiber, and efficiently promoting a loading capacity and shortening preparation time. The adsorbent prepared by using the method provided by the invention has the advantages of high adsorption capacity, high adsorption rate and the like. An ultrasonic depositing method has the advantages that a required instrument is simple, operation is convenient, a compounding temperature is low, an easily occurring conglobating defect of a traditional depositing method is overcome, and an industrial application prospect is excellent.

Owner:SHANGHAI UNIV

Gel for recovering phosphorus from water and preparation method and application thereof

ActiveCN106693923AHigh mechanical strengthGood chemical stabilityOther chemical processesAlkali metal oxides/hydroxidesCross-linkPolyvinyl alcohol

The invention belongs to the fields of wastewater treatment and high-molecular materials, and discloses a preparation method of gel for recovering phosphorus from water. The preparation method comprises the following steps: 1) dissolving polyvinyl alcohol in water completely to form a solution I, dissolving sodium alginate in deionized water completely to form a solution II, dissolving lanthanum hydroxide in water completely to form a solution III, and mixing the solution I, the solution II and the solution III to form a mixed liquor I; 2) adding the obtained mixed liquor I into mixed liquor II, performing a cross-linking reaction on the polyvinyl alcohol and the sodium alginate to form a polymer interpenetrating network structure, and embedding the lanthanum hydroxide in the polymer interpenetrating network structure to obtain gel; 3) flushing the obtained gel with deionized water repeatedly. In the preparation method, the lanthanum hydroxide is embedded into a copolymer of the polyvinyl alcohol and the sodium alginate by using the balling performance of the sodium alginate, the stability of the polyvinyl alcohol and the affinity of the lanthanum hydroxide to the phosphorus, so that an environment-friendly phosphorus recovering material is prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

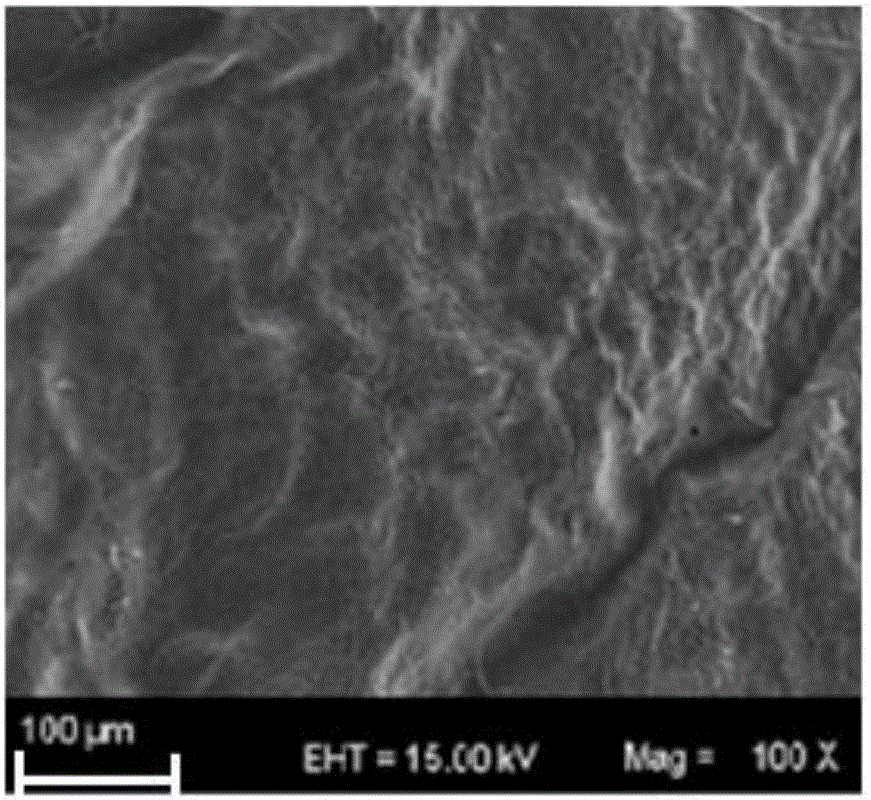

Coating reinforcing agent, preparation method thereof and phosphate-metal aluminum powder coating using reinforcing agent

ActiveCN102492324AImprove bindingImprove high temperature resistanceAnti-corrosive paintsPhosphoric acidStructure based

The invention relates to a coating reinforcing agent. The coating reinforcing agent is characterized by comprising a liquid-state component A and a solid-state component B, wherein the coating reinforcing agent comprises 100 parts by weight of the component A and 35-40 parts by weight of the component B; and the liquid-state Component A is phosphoric acid, and the solid-state component B is lanthanum hydroxide or lanthanum oxide. The phosphoric acid-rare earth reinforcing agent is prepared through the reaction between the phosphoric acid and solid rare earth ( lanthanum hydroxide or lanthanum oxide), and after the rare earth reinforcing agent is added into an ordinary phosphate-metal aluminum powder coating, a phosphate in the reinforcing agent and a metal oxide in the phosphate-metal aluminum powder coating constitute a three-dimensional reticular structure based on hydrogen bond association, so that metal micro-powder is fixed in the three-dimensional reticular structure; therefore the binding ability of the coating is effectively improved, and the coating has better corrosion resistance.

Owner:ZHEJIANG MOTORBACS TECH +1

Methane oxidative coupling with la-ce catalysts

InactiveCN108025287AHeterogenous catalyst chemical elementsHydrocarbons from unsaturated hydrocarbon additionPtru catalystPhysical chemistry

A metal oxide catalyst capable of catalyzing an oxidative coupling of methane reaction is described. The metal oxide catalyst includes a lanthanum (La) cerium (Ce) metal oxide and further including alanthanum hydroxide (La(OH)3) crystalline phase. The catalyst is capable of catalyzing the production of C2+ hydrocarbons from methane and oxygen. Methods and systems of using the metal oxide catalystto produce C2+ hydrocarbons from a reactant gas are also described.

Owner:SABIC GLOBAL TECH BV

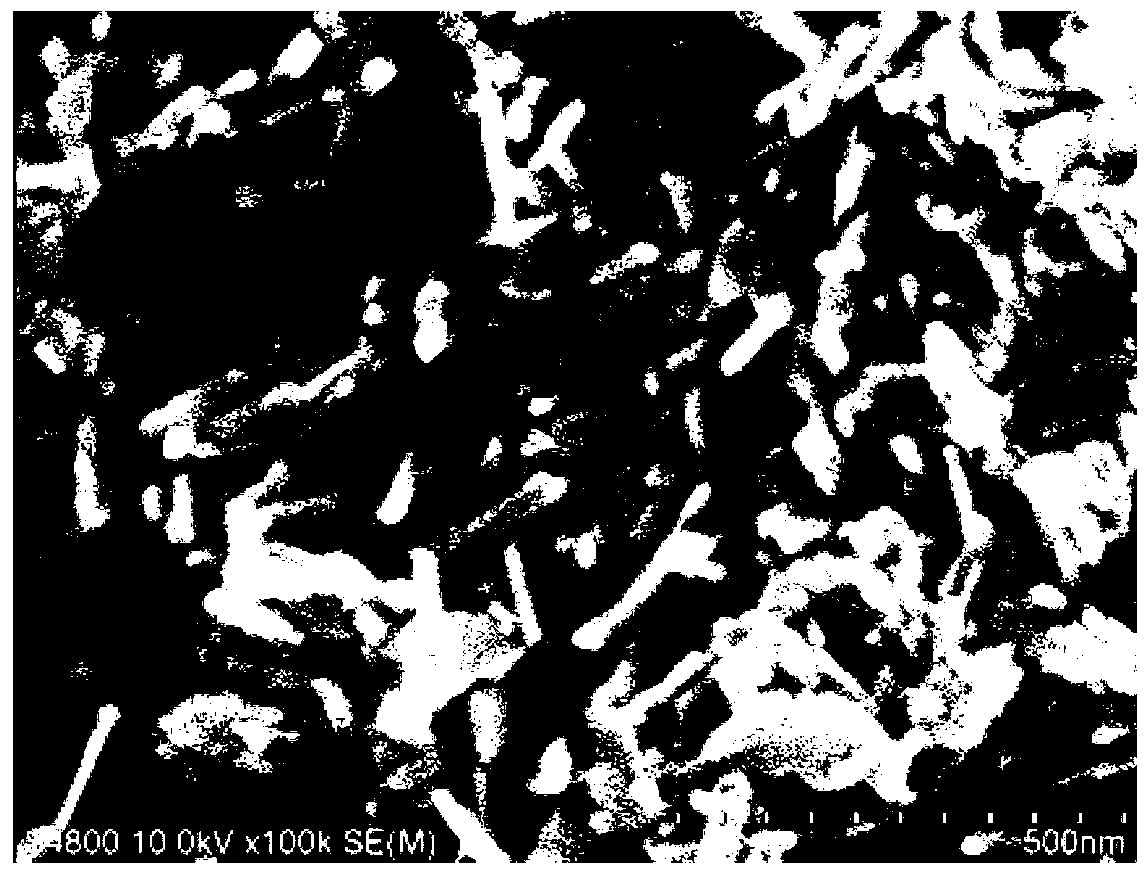

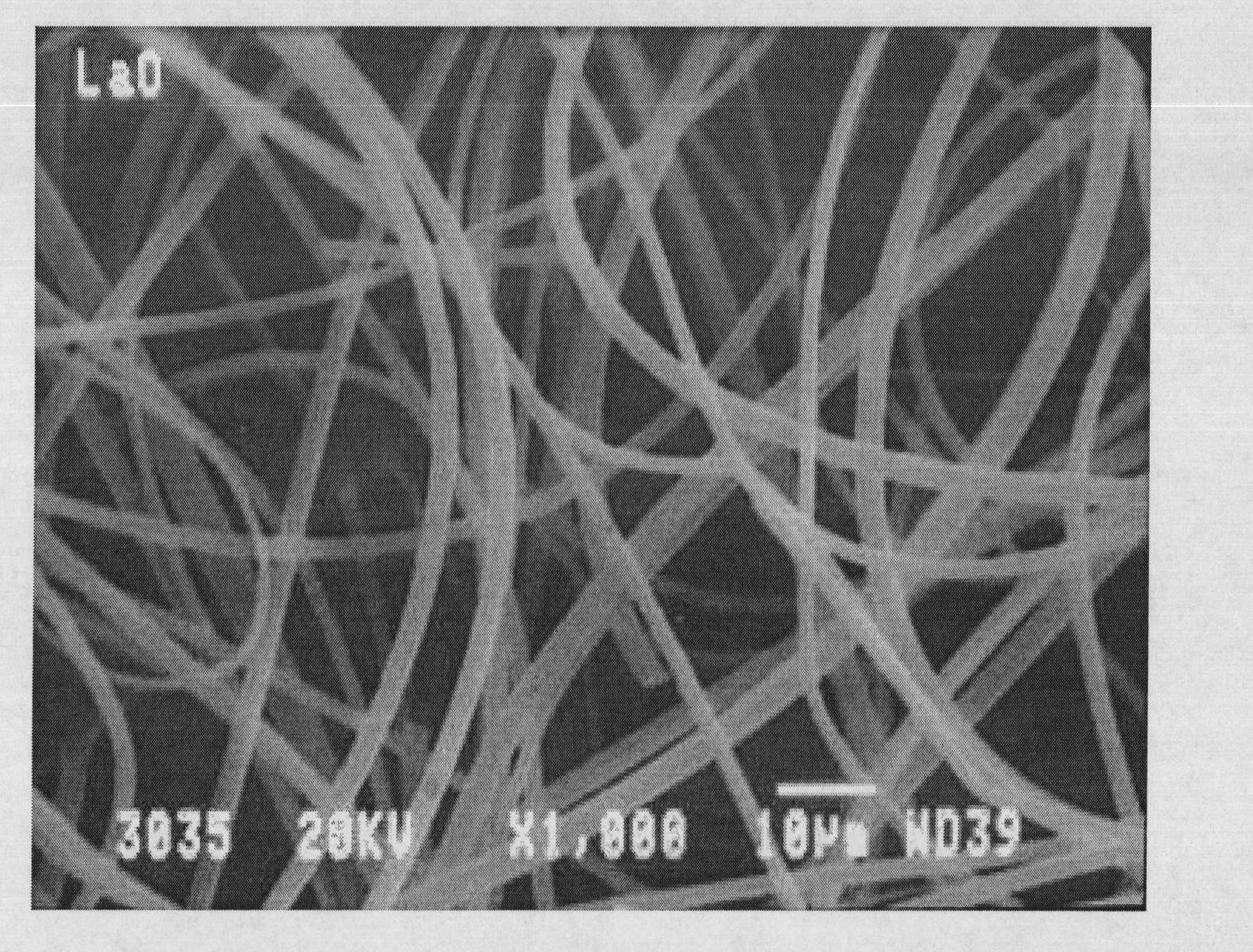

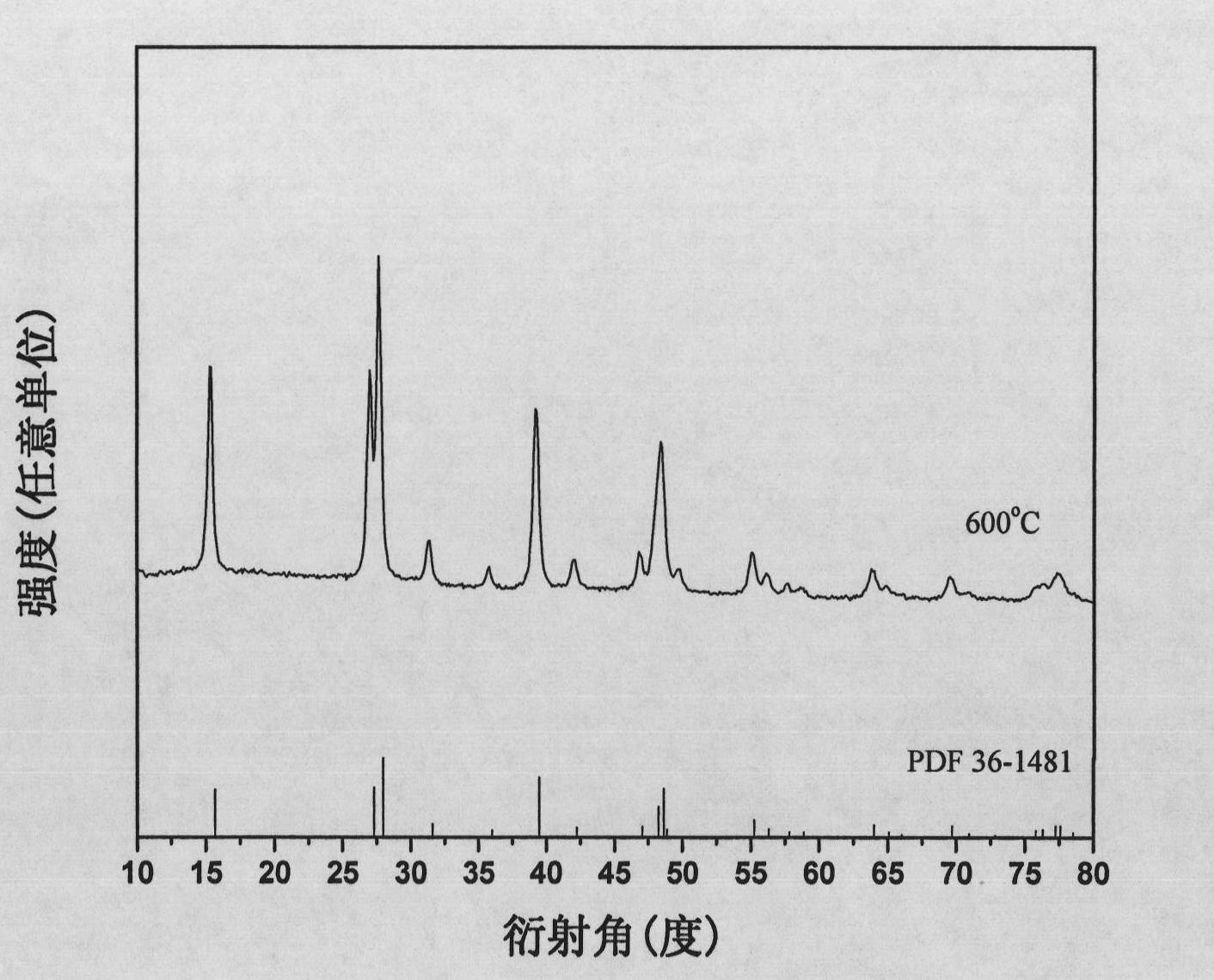

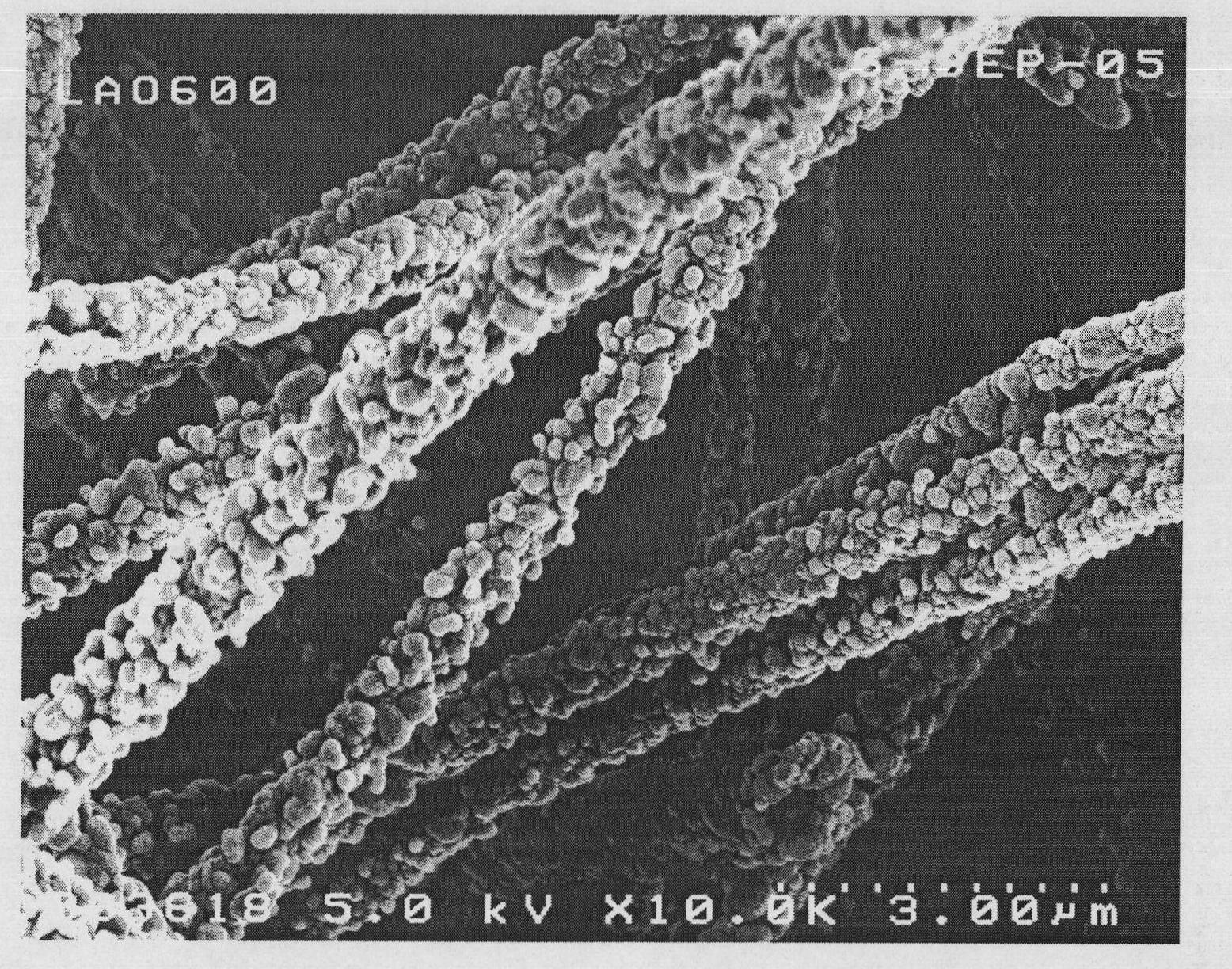

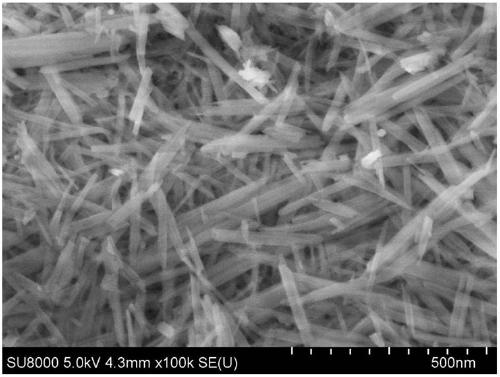

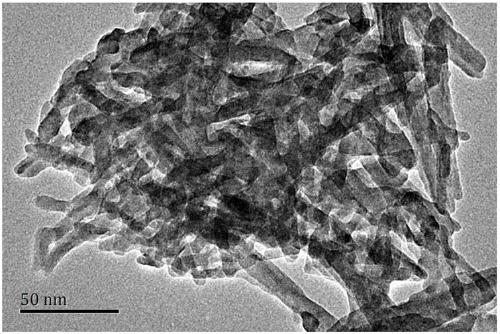

Method for preparing lanthanum hydroxide porous hollow nano-fiber and chain-like nano-fiber

InactiveCN101787574AInorganic material artificial filamentsFilament/thread formingFiberPolymer science

The invention relates to a method for preparing lanthanum hydroxide porous hollow nano-fiber and chain-like nano-fiber, which belongs to the technical field of preparing one-dimensional inorganic nanometer materials. The method comprises: (1) a step of preparing spinning solution, which is to dissolve lanthanum nitrate and polyvinylpyrrolidone in distilled water to form spinning solution; (2) a step of preparing PVP / La(NO3)3 composite fiber, which is to adopt an electrostatic spinning technique, voltage of 20 to 25 kV, indoor temperature of 20 to 28 DEG C and relative humidity of 50 to 60 percent; (3) a step of preparing La(OH)3 porous hollow nano-fiber and chain-like nano-fiber, which is to perform heat treatment on the composite fiber. The La(OH)3 porous hollow nano-fiber consists of smaller nano-particles while the solid chain-like nano-fiber consists of bigger particles mutually connected, and the fiber is 500 to 800 nanometers in diameter and more than 100 mu m in length and belongs to the series of hexagonal crystals.

Owner:CHANGCHUN UNIV OF SCI & TECH

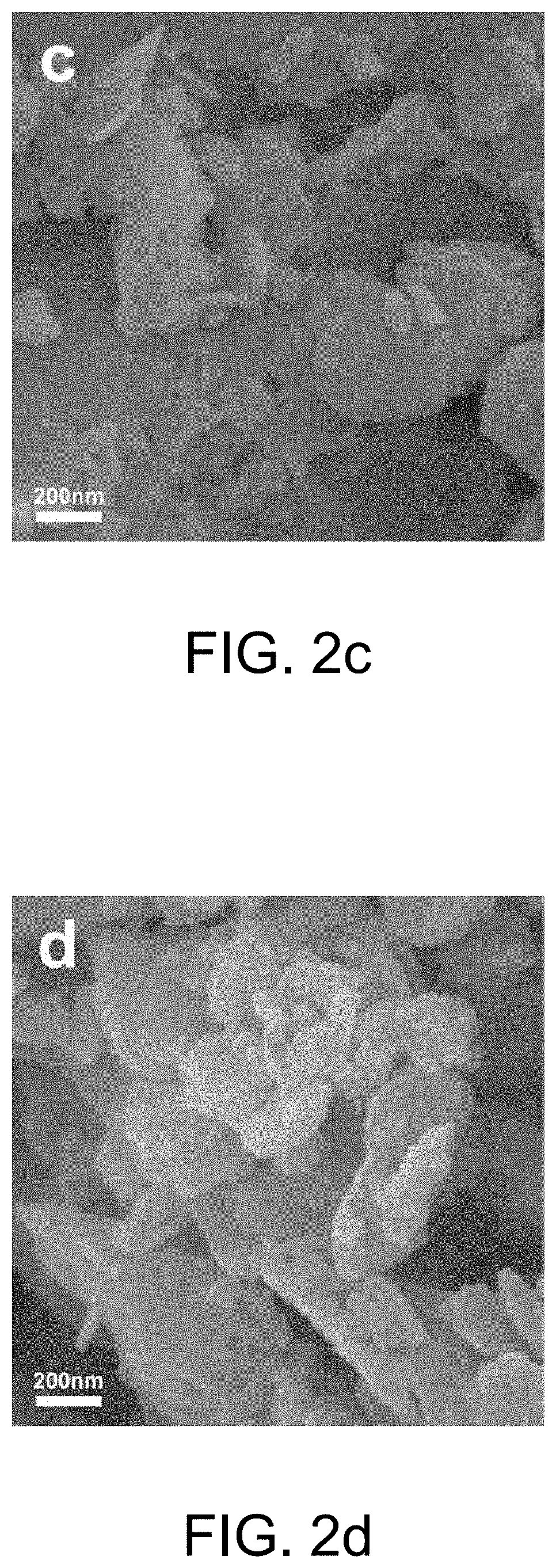

Preparation method of bar-shaped lanthanum hydroxide nanocrystal

ActiveCN102942203AShort reaction timesReduce energy consumptionMaterial nanotechnologyRare earth metal compoundsDispersityEthylenediamine

The invention provides a preparation method of a bar-shaped lanthanum hydroxide nanocrystal. The method comprises the following steps of: adding nona-lanthanum sulfate and ethylenediamine tetraacetic acid into deionized water respectively to obtain a solution B; adjusting the pH of the solution B to 8.0-12.0 with an ammonia water solution to obtain a precursor solution C; pouring the precursor solution C into a four-neck round-bottom flask, putting the four-neck round-bottom flask into a microwave-ultraviolet ray-ultrasonic wave three-in-one synthesis reaction instrument, selecting a microwave heating-ultraviolet irradiation combined reaction in a temperature-time mode, and naturally cooling to the room temperature after the reaction; and centrifugally collecting a product, washing repeatedly with deionized water and absolute ethyl alcohol respectively, and drying to obtain a final product, i.e., bar-shaped lanthanum hydroxide nanocrystal. A simple microwave-ultraviolet ray synthesis method preparation process is adopted, so that the method has the advantages of short reaction time period, low energy consumption, low cost, convenience in operating, one-time completion of a reaction in a liquid phase, and no need of subsequent treatment. La(OH3) particles prepared with the method have bar-shaped structures, are small in size, have high dispersity, and can be applied in the catalysis field and the optics field.

Owner:上海球球云环保科技有限公司

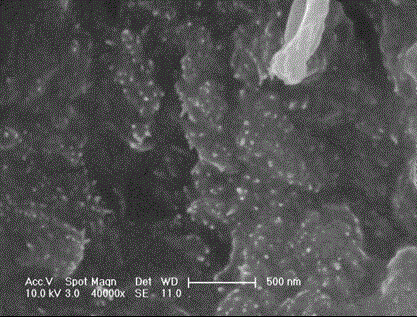

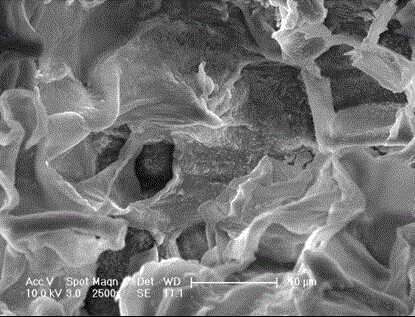

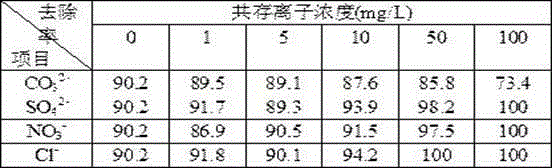

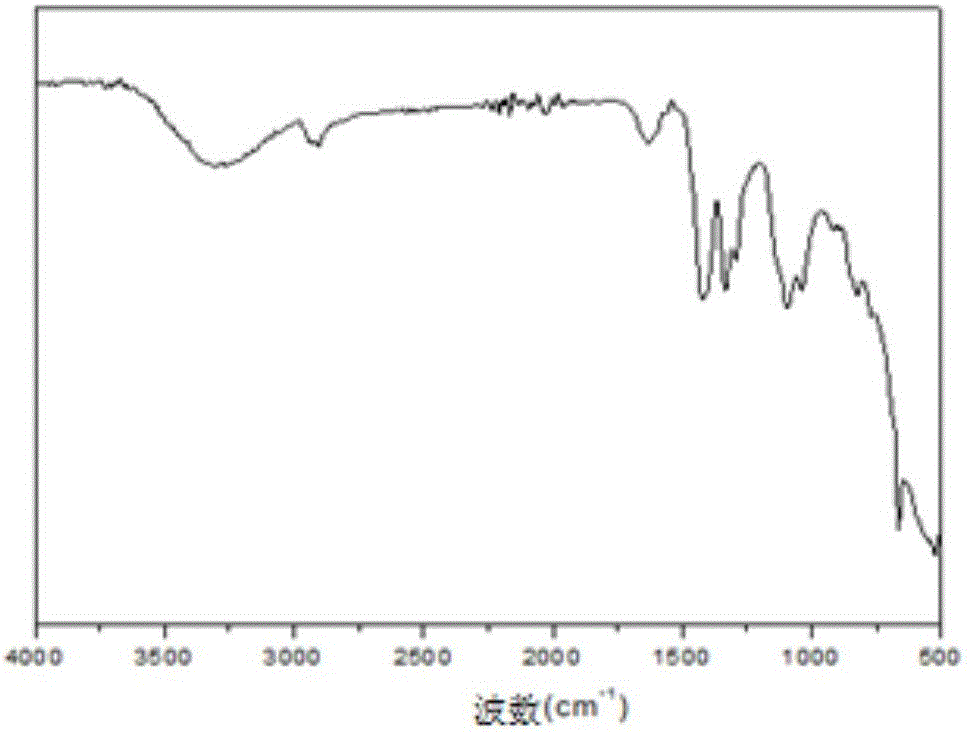

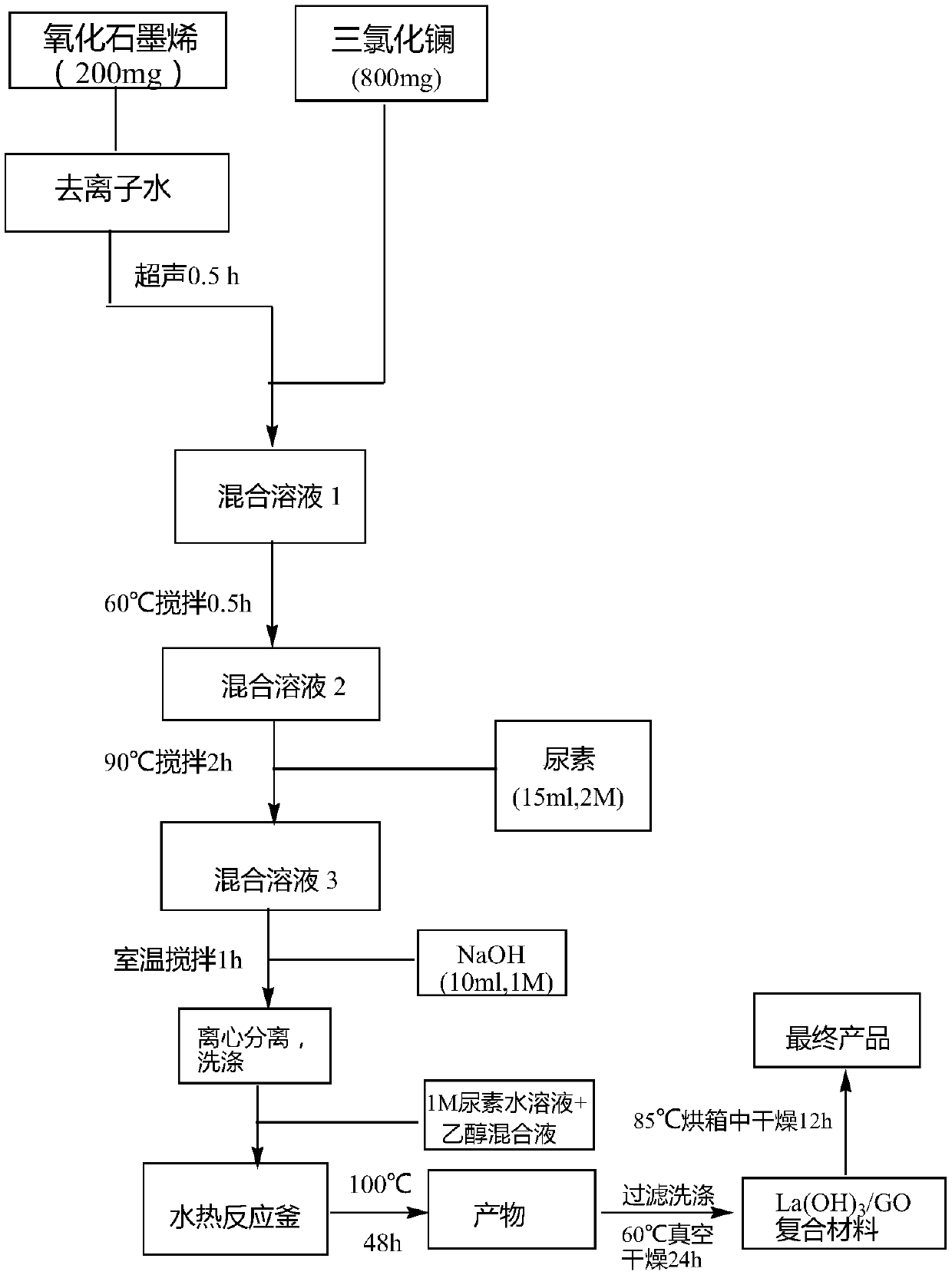

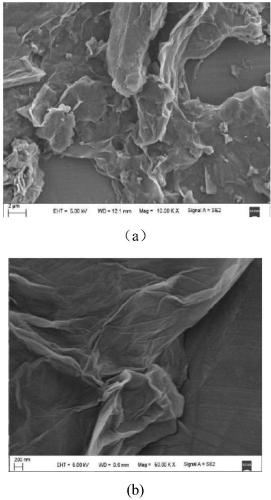

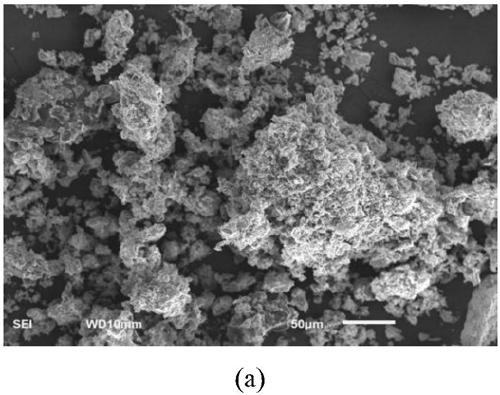

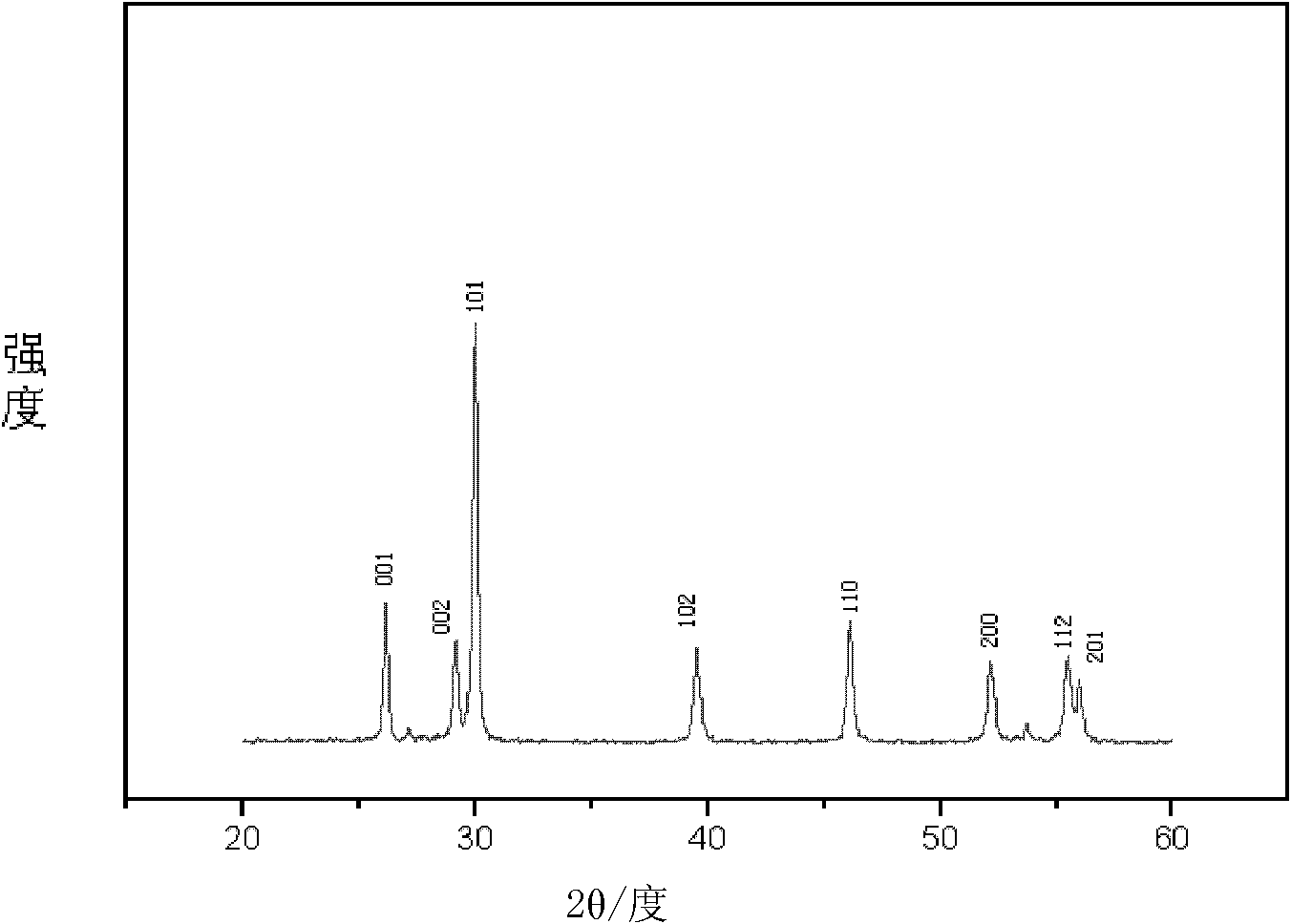

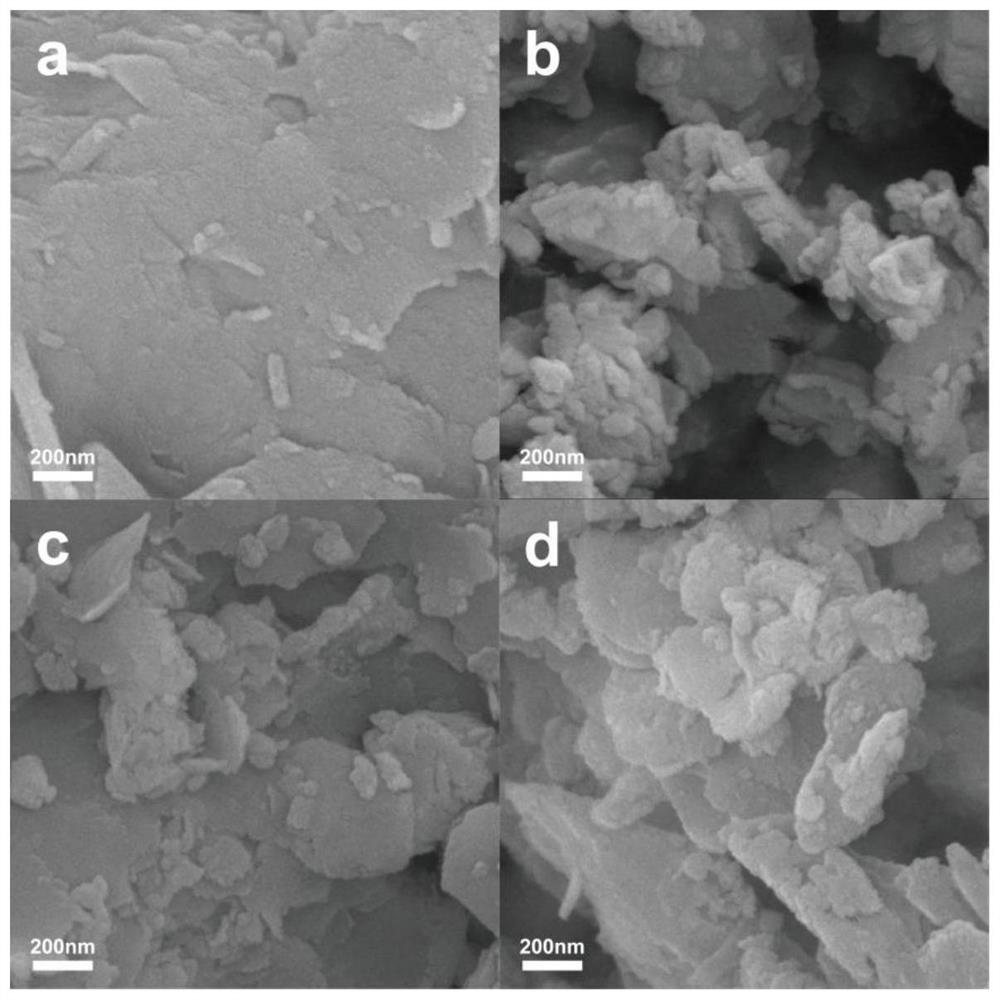

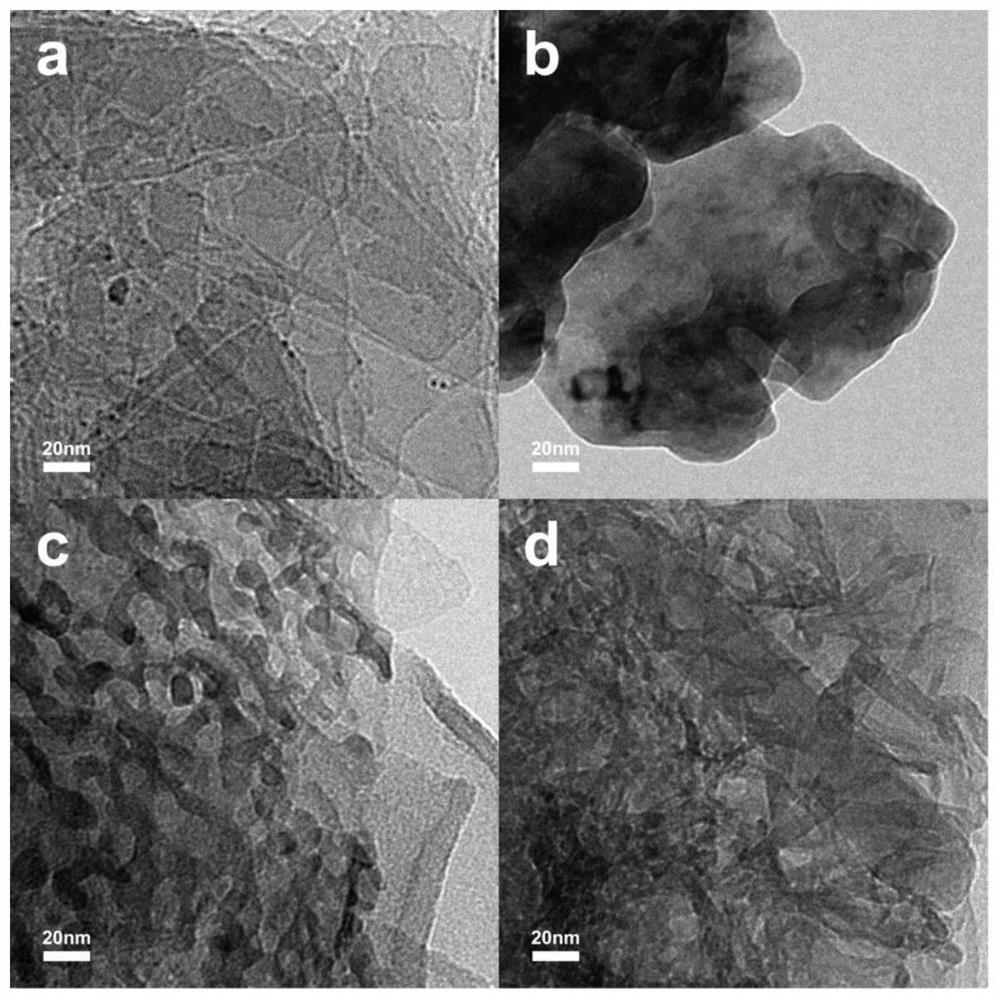

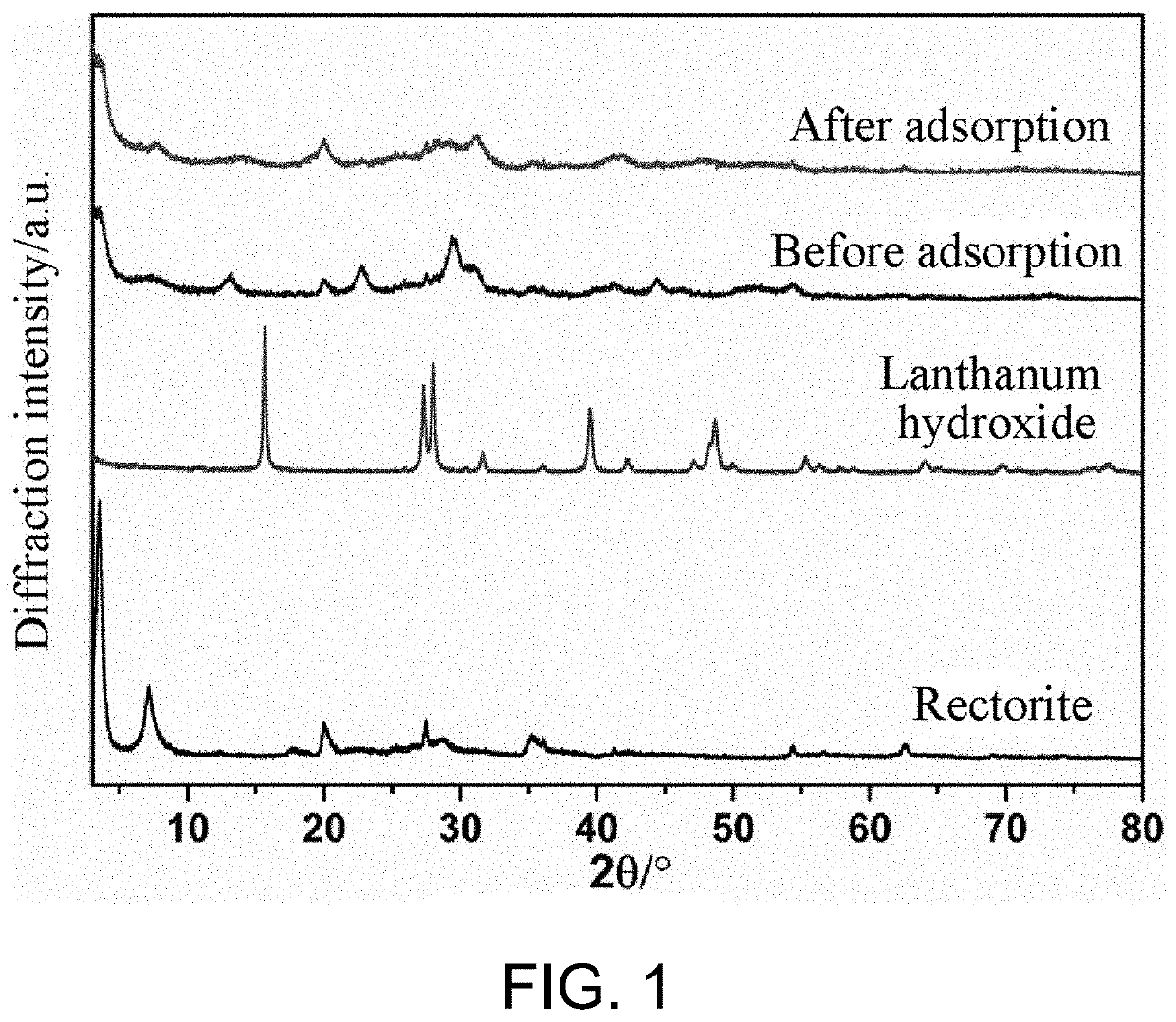

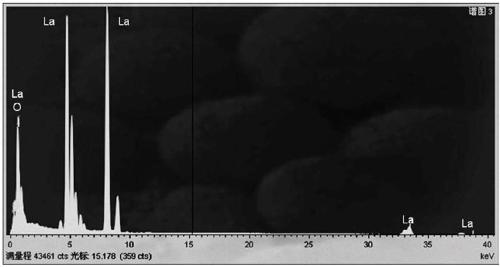

Synthetic method and adsorption property of graphene oxide-lanthanum hydroxide composite material

The invention belongs to the technical field of water treatment agents, and discloses a graphene oxide-lanthanum hydroxide composite material and a synthetic method. The graphene oxide-lanthanum hydroxide composite material (La(OH)3 / GO) prepared by a direct precipitation method and a water / solvothermal synthesis method is used for adsorbing and removing Congo red (CR) and phosphate ions (PO4<3->)in a solution, a structure of the La(OH)3 / GO composite material is characterized by SEM, XRD, FT-IR and the like, the adsorption effects of the Congo red (CR) and the phosphate ions (PO4<3->) are discussed under different conditions such as pH, temperature and initial mass concentration, and the optimal adsorption conditions are determined. The adsorption effect is remarkable, and far exceeds theadsorption effect of adsorption materials reported in a lot of literatures.

Owner:MINNAN NORMAL UNIV

Nano-lanthanum hydroxide modified lignin porous carbon as well as preparation method and application thereof

ActiveCN109433153AExcellent adsorption capacityImprove removal efficiencyOther chemical processesWater contaminantsPorous carbonLanthanum hydroxide

The invention discloses nano-lanthanum hydroxide modified lignin porous carbon as well as a preparation method and application thereof. The preparation method comprises the following steps: preparingacetic acid lignin porous carbon: dissolving acetic acid lignin into a strong alkaline solution according to the ratio of 1 g to 5 mL, uniformly mixing and then drying to constant weight; carbonizinga dried solid mixture in an inert atmosphere, cooling to room temperature and then washing to neutral; carrying out vacuum drying to constant weight to obtain the acetic acid lignin porous carbon; preparing the nano-lanthanum hydroxide modified lignin porous carbon: adding the acetic acid lignin porous carbon into an ethanol aqueous solution of lanthanum chloride heptahydrate for uniformly mixing,adjusting a pH value of the solution, raising the temperature, fully reacting, sufficiently washing a reaction product and carrying out vacuum drying to constant weight to obtain the nano-lanthanum hydroxide modified lignin porous carbon. Highly-dispersed lanthanum hydroxide nanoparticles retain on the surface of the lanthanum hydroxide modified lignin porous carbon prepared by the preparation method disclosed by the invention; the absorption experiment shows that the modified acetic acid lignin porous carbon has a remarkable adsorbing effect on phosphorus, which is remarkably improved as compared with unmodified acetic acid lignin porous carbon.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Preparation method of uniformly dispersed nano lanthanum oxide

InactiveCN102161498AReduce processing costsEase of mass productionNanotechnologyRare earth metal compoundsNarrow rangeRare earth

The invention relates to a controllable preparation method of uniformly dispersed nano lanthanum oxide powder, belonging to the technical field of preparation of inorganic functional materials. In the preparation method, soluble trivalent lanthanum, sodium hydroxide, nitric acid and carbon black are used as raw materials, a black lanthanum hydroxide precursor is firstly prepared, and then temperature-programmed calcination is prepared to finally obtain the nano lanthanum oxide powder. The process has low cost, is easy to control and is convenient for industrial production, and the particle size of the prepared nano rare earth lanthanum oxide is within a range of 15nm-40nm; the nano rare earth lanthanum oxide has the advantages of small particle size, narrow range, good dispersibility, high purity and the like; in addition, the preparation method is superior to the traditional preparation method, because the traditional preparation method has the defects of expensive raw materials, high cost, complicated process, strict conditions and the like and is not suitable for large-scale and industrial production moreover, lanthanum oxide prepared by the traditional preparation method has the defects of large grain size and nonuniform distribution.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of phosphorous removal adsorbent of expanded graphite loading lanthanum hydroxide

The invention relates to the technical field of a phosphorous removal adsorbent of expanded graphite loading lanthanum hydroxide and a preparation method of the phosphorous removal adsorbent. By taking expanded graphite as a matrix, the phosphorous removal adsorbent is loaded with hydroxide of a metal lanthanum, namely La(OH)3. The preparation method comprises the following steps: firstly preparing a 0.2-0.12mol / L lanthanum nitrate solution; preparing a lanthanum hydroxide precipitate; adding 0.2g of expanded graphite; oscillating for 20-120 minutes at constant temperature of 25 DEG C; after oscillation, centrifugalizing; taking out a solid in an upper layer; drying for 12 hours at 105 DEG C; and sealing for later use. The phosphorous removal adsorbent has a relatively high removal effect on phosphorous in water and the adsorption capacity can reach 16-20mg / g, and moreover, the phosphorous removal adsorbent further has the advantages of being easy to recover, stable to remove phosphorous, corrosion-resistant, heat-resistant, non-toxic and the like. The phosphorous removal adsorbent is simple in preparation process, low in energy consumption and short in time and has a broad application prospect.

Owner:SHANGHAI UNIV

Ceramic silicon carbide grinding wheel containing carbon reinforced fiber

The invention discloses a ceramic silicon carbide grinding wheel containing carbon reinforced fiber. The ceramic silicon carbide grinding wheel is prepared from following raw materials, by weight, 55 to 65 parts of silicon carbide, 30 to 35 parts of diamond abrasive, 10 to 13 parts of a short carbon fiber pre-dispersed material, 2 to 3 parts of a sintering additive, 4 to 5 parts of lanthanum hydroxide, 1 to 3 parts of potassium carbonate, 4 to 5 parts of kaolin powder, 2 to 3 parts of stearamide, 2 to 3 parts of epoxy resin, 1 to 2 parts of polyvinyl alcohol, and 80 to 90 parts of deionized water. The added short carbon fiber is capable of improving mechanical properties of silicon carbide, increasing breaking tenacity of ceramic, increasing strength and compactness of ceramic biscuit, and satisfying mechanical processing requirements; the added kaolin powder and epoxy resin are taken as binding agents, holding strength with the abrasive is increased, firm bonding is realized, hardness and grinding performance of the ceramic silicon carbide grinding wheel are improved, and service life is prolonged.

Owner:凤阳徽亨商贸有限公司

Novel hydroxide lanthanum-modified hydroxyapatite material and preparation method and application thereof

ActiveCN109046229AEasy to prepareEasy to operateOther chemical processesWater contaminantsSlagHydroxyapatites

The present invention provides a novel hydroxide lanthanum-modified hydroxyapatite material and a preparation method and application thereof. The preparation method comprises the following steps of dissolving lanthanum chloride or lanthanum oxide into an acid solution, adding hydroxyapatite, and adjusting the pH (potential of hydrogen) value of the mixed solution to the alkaline property by an alkaline solution; putting the mixed solution after stirring into an ultrasonic device, and treating by ultrasonic waves for a period of time; putting onto a stirrer, and continuing to stir for a certainperiod of time; sealing, aging, filtering, and drying, so as to obtain filter slag; roasting at high temperature, so as to obtain the novel hydroxide lanthanum-modified hydroxyapatite material. The novel hydroxide lanthanum-modified hydroxyapatite material has the characteristics that the particle size is controllable, the specific surface area is large, the hole size of the particle is large, and the loading is uniform; the material is applied to remove the phosphate radicals in wastewater, the removal rate of phosphate radicals reaches 97.5% or above, and the purpose of high-efficiency andhigh-load phosphor removal is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

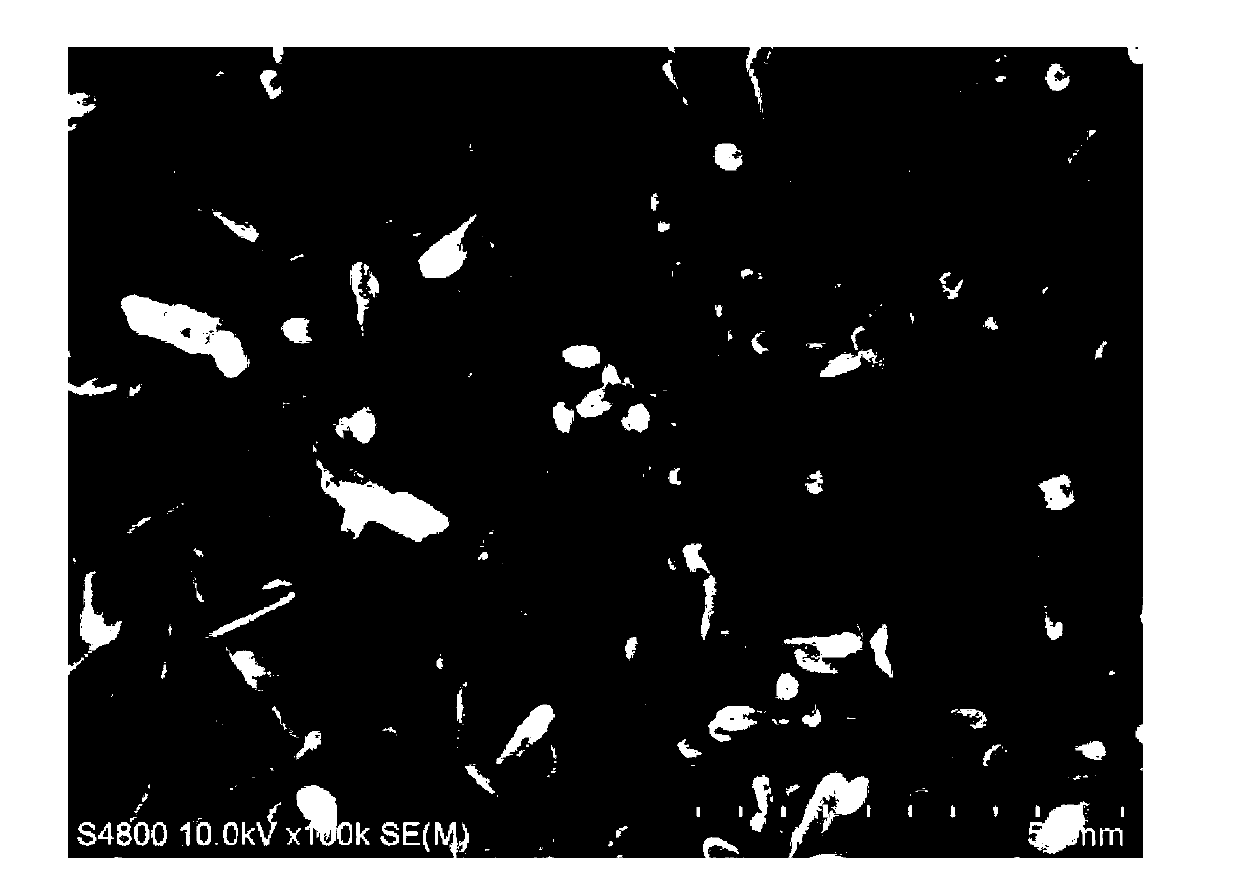

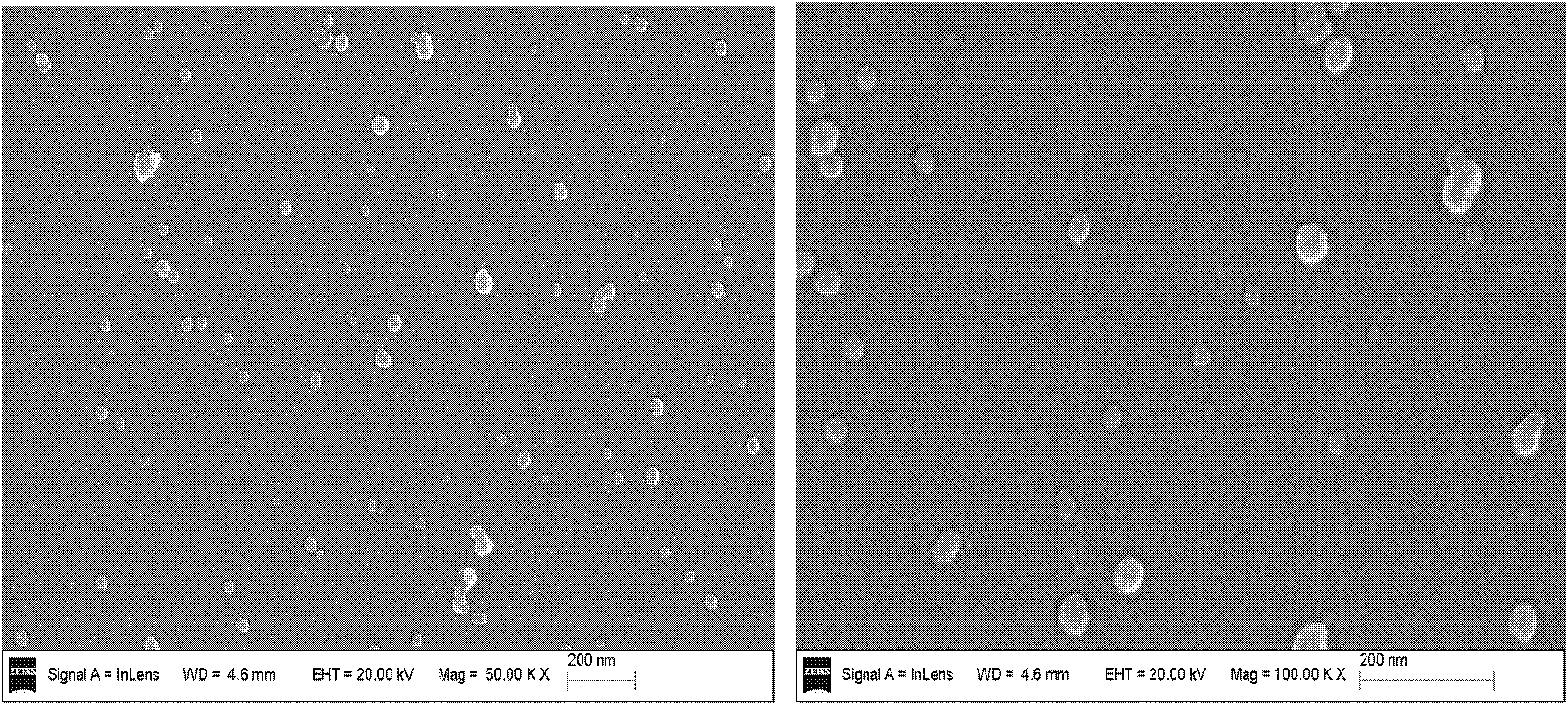

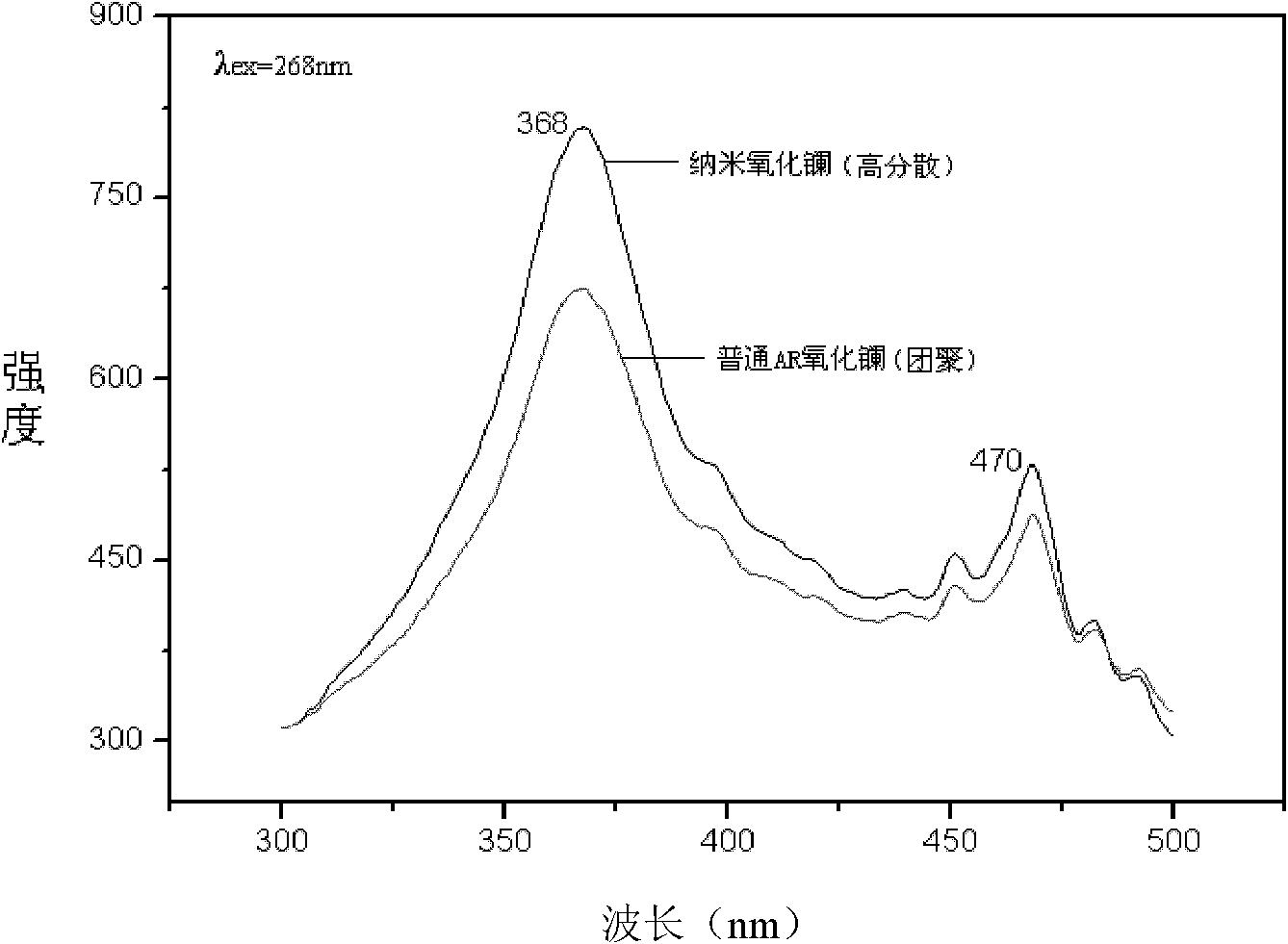

Preparation method for high dispersion nano lanthanum hydroxide

ActiveCN110563018ASmall particle sizeUniform particle size distributionNanotechnologyRare earth metal compoundsLiquid mediumOrganic solvent

The invention discloses a preparation method for high dispersion nano lanthanum hydroxide. The preparation method comprises the following steps of dissolving lanthanum salt in water, organic solventsor mixtures of the water and the organic solvents to obtain lanthanum salt solutions; dissolving alkali in water, organic solvents or mixtures of the water and the organic solvents to obtain alkali liquor; adding the lanthanum salt solutions and the alkali liquor into a common reactor or a super-gravity rotating packed bed for precipitating crystallization reaction to obtain lanthanum hydroxide suspensions; placing the lanthanum hydroxide suspensions into a thermostat for aging treatment; adding the serous fluid after aging treatment to modifiers for modification; cooling the modified serous fluid to normal temperature, and ultra-filtering or centrifugally washing the serous fluid to obtain filter cakes; and dispersing the filter cakes into liquid media to obtain high dispersion nano lanthanum hydroxide liquid, or drying the filter cakes to obtain high dispersion nano lanthanum hydroxide powder. According to the method, the one-dimensional size of prepared lanthanum hydroxide particlesis 15-250 nm, and the particles are not agglomerated but dispersed for no less than 6 months.

Owner:BEIJING UNIV OF CHEM TECH

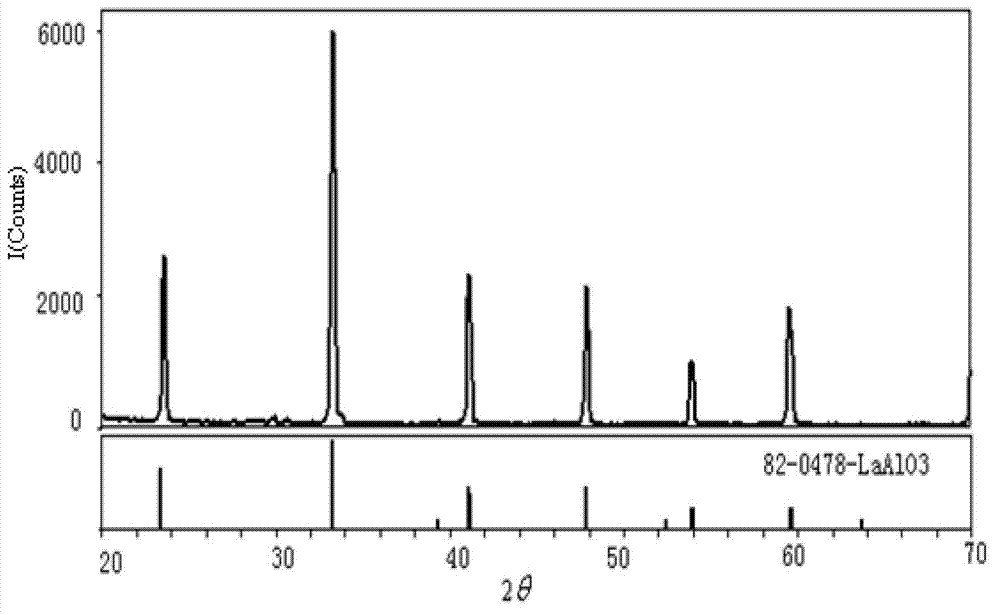

Method for preparing lanthanum aluminate powder efficiently

InactiveCN103112881ASmall granularityIncrease contact areaMaterial nanotechnologyRare earth metal compoundsAluminium hydroxideLanthanum hydroxide

The invention relates to a method for preparing lanthanum aluminate powder efficiently. The method comprises the following steps: (1) adding water into lanthanum oxide, wherein the mass of the added water is 1-20 times more than that of the lanthanum oxide, stirring, controlling the material temperature to be 30-250 DEG C and keeping warm for 1-8 hours, thus obtaining lanthanum hydroxide by the hydrothermal method; (2) adding aluminum hydroxide into a system of lanthanum hydroxide obtained by the hydrothermal method and water, wherein the mole ratio of the aluminum hydroxide to the lanthanum oxide is 2:1, using the water as medium, fully mixing the aluminum hydroxide with the lanthanum hydroxide by stirring, and filtering after stirring for 1-10 minutes; and (3) keeping the mixture of the aluminum hydroxide and the lanthanum hydroxide at the temperature of 1000-1400 DEG C for 1-5 hours, and thereby obtaining the lanthanum aluminate powder. The method for preparing lanthanum aluminate powder efficiently has the advantages that (a) the preparation technology is environment-friendly; and (b) the preparation efficiency is high. The aluminum hydroxide and the lanthanum hydroxide are fully mixed and the mixture is easy to filter, the calcination temperature is low, and the combining time is short. The method for preparing lanthanum aluminate powder efficiently is suitable for preparing lanthanum aluminate powder in large scales.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

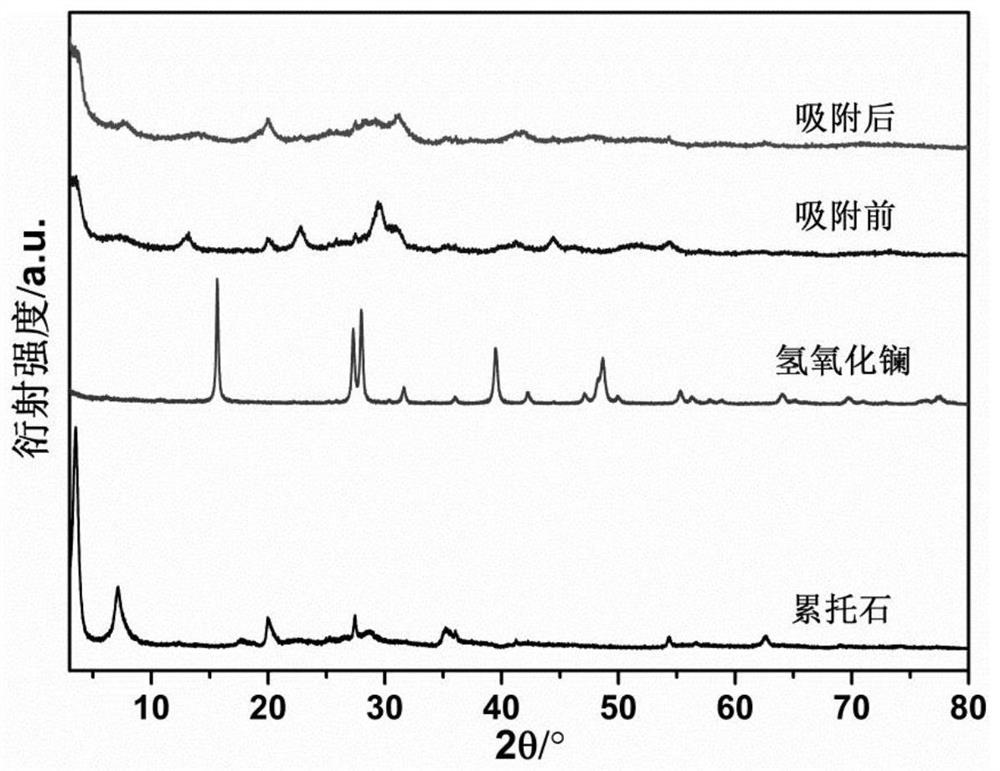

Two-dimensional clay-based composite phosphorus removing agent as well as preparation method and application thereof

ActiveCN112044393AImprove phosphorus removal effectSave raw materialsOther chemical processesAluminium silicatesCalcium hydroxideAluminium hydroxide

The invention belongs to the field of material preparation, and particularly discloses a two-dimensional clay-based composite phosphorus removing agent and a preparation method. The two-dimensional clay-based composite phosphorus removing agent provided by the invention takes two-dimensional clay, hydroxide (such as lanthanum hydroxide, calcium hydroxide, magnesium hydroxide and aluminum hydroxide) and urea as raw materials, and the high-performance composite phosphorus removing agent is prepared by adopting a roasting method. Phosphorus in phosphorus-containing wastewater is effectively removed by utilizing the synergistic interaction among the components of the composite phosphorus removal agent through a physicochemical combination method. According to the method, the defects of high consumption and secondary pollution easily caused when the metal hydroxide, the metal oxide and the metal salt are independently used as the chemical phosphorus removal agent are overcome, and meanwhile, the application field of the two-dimensional clay is expanded. The composite phosphorus removing agent has the characteristics of simple process, short flow, low cost, simple and feasible operationand the like, and has optimistic industrial application prospect.

Owner:CENT SOUTH UNIV

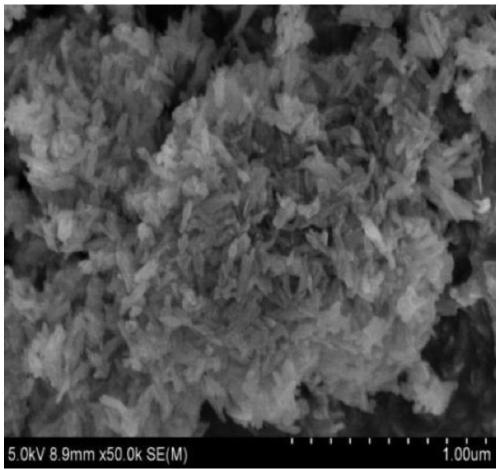

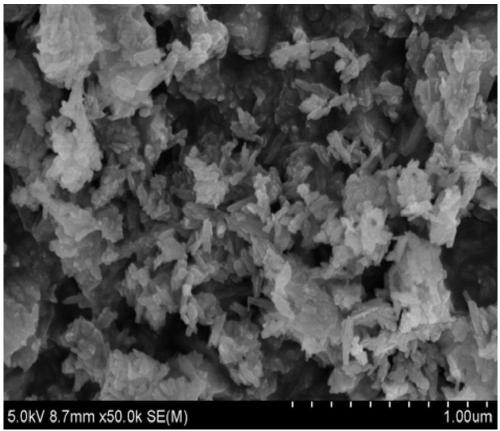

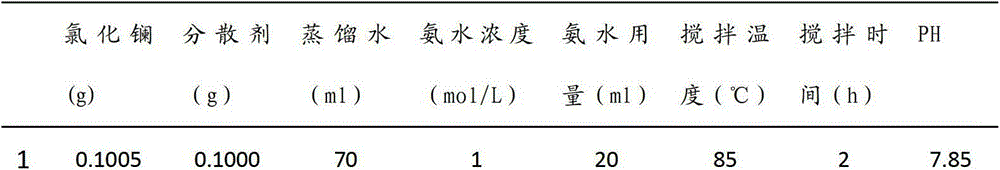

Controllable synthesis of lanthanum hydroxide nano-particles

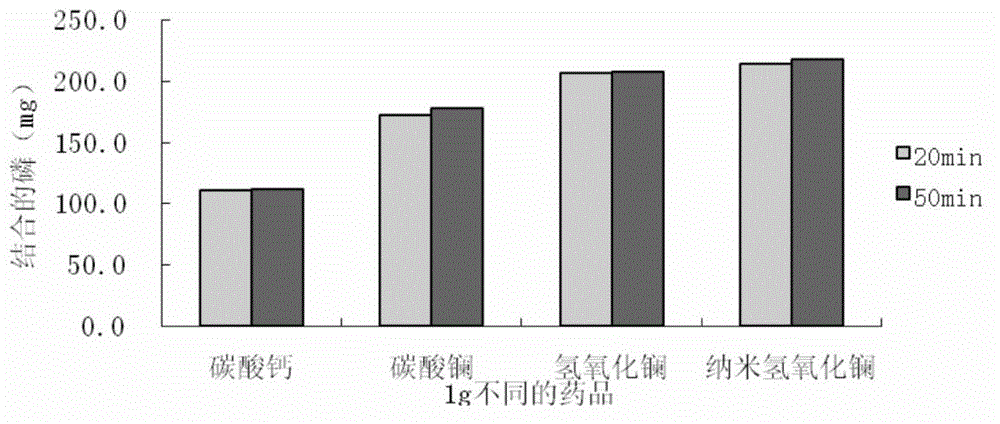

The invention relates to a method that lanthanum hydroxide nano-particles with the even sizes are synthesized by utilizing of a coprecipitation method. The method comprises that a certain proportion (weight ratio) of a dispersing agent (the dispersing agent: lanthanum chloride=0.8:1) is stirred in a magnetic mode in lanthanum chloride dilute solution with certain density to enable the dispersing agent to be fully dissolved, the temperature is risen, and hartshorn with certain density is slowly dripped to react for 1-3 hours. White precipitate is obtained through centrifugal separation after cooling, ethanol and deionized water are used for washing the white precipitate respectively, and at last lanthanum hydroxide nano-particles are obtained through drying.

Owner:INNER MONGOLIA MEDICAL UNIV

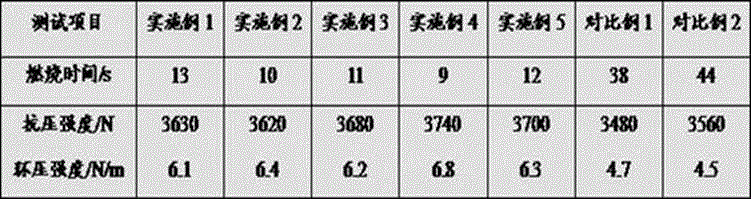

Fireproof high-strength honeycomb paper core and preparation method thereof

InactiveCN106012657AHigh compressive strengthImprove mechanical propertiesWaste product additionPaper coatingFiberCardboard

The invention discloses a fireproof high-strength honeycomb paper core and a preparation method thereof. The honeycomb paper core is prepared from, by weight, papermaking sludge, silicon sludge, bamboo fiber, loofah sponge, L-alanine, coal ash, sodium phosphate, borax, yttrium oxide, glass fiber, diamond powder, lanthanum hydroxide, indium oxide, ammonium polyphosphate, maltodextrin, itaconic acid, zinc sulfate and aluminate coupling agent. Compressive strength of the honeycomb paper core prepared by the method is up to higher than 3620 MPa, ring crushing strength is up to 6.1 N / m, and the honeycomb paper core presents good mechanical strength; flame-retardant performance testing results show that burning time of the honeycomb paper core is within 15s, flame-retardant performance is excellent, and the defects on integral mechanical performance and flame-retardant performance of a honeycomb paper board can be improved greatly.

Owner:苏州倍力特物流设备有限公司

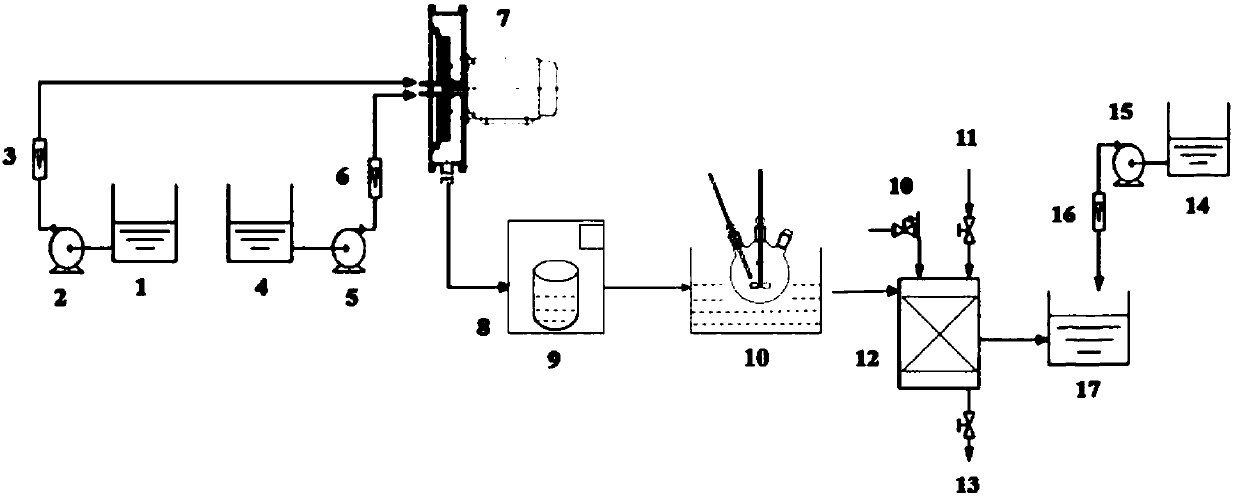

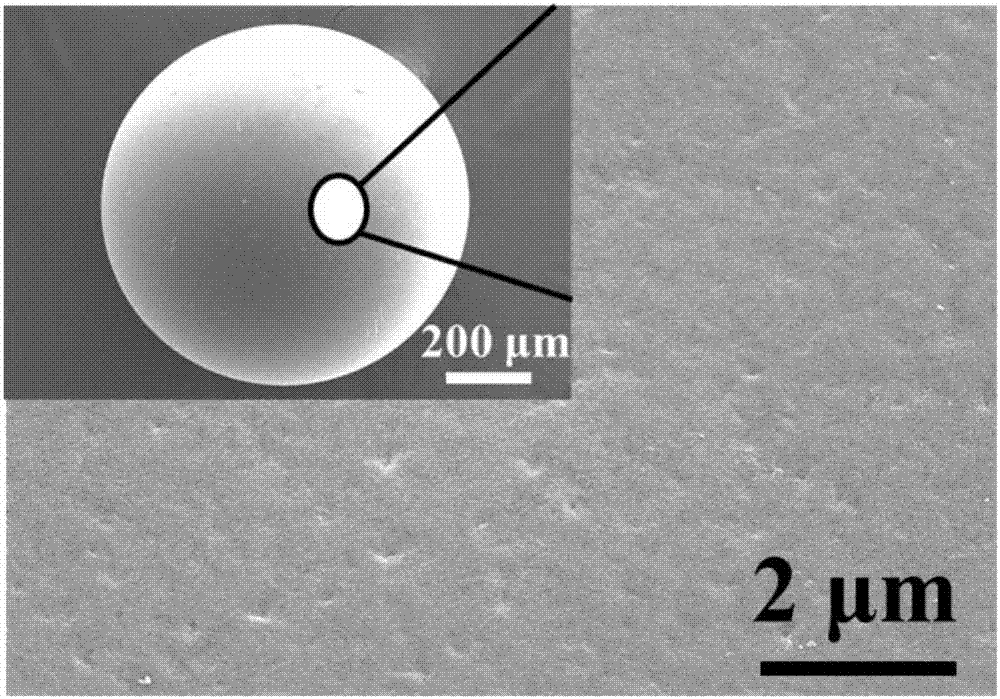

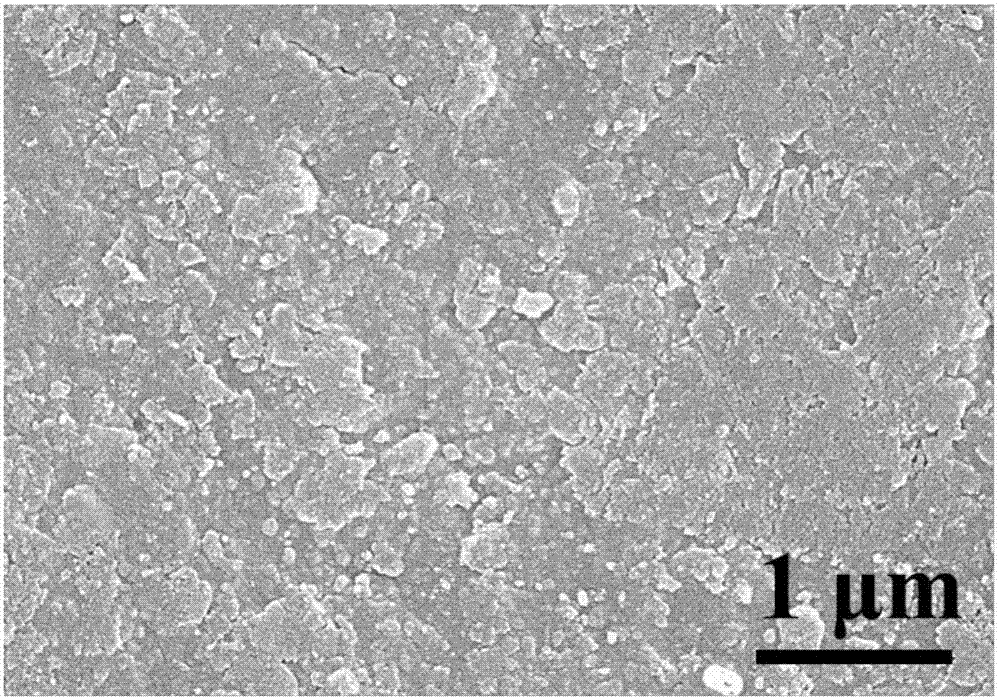

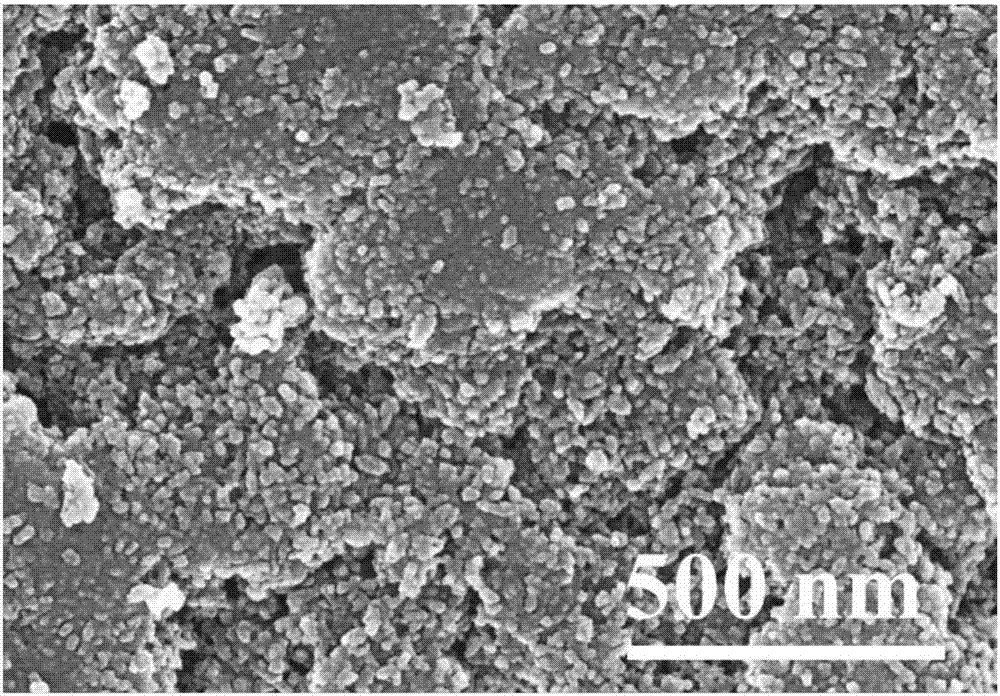

Preparation of nano-lanthanum hydroxide composite material and method for removing trace phosphorus in waste water

ActiveCN107983319ASolve the technical bottleneck of low adsorption mass transfer rate and low utilization rateHas strong positive electric field characteristicsOther chemical processesWater contaminantsSorbentPolystyrene

The invention discloses a preparation method of a nano-lanthanum hydroxide composite material, mainly comprising the following steps: putting macroporous ion exchange resin into a Tris-HCl buffer solution, reacting to obtain a macroporous polystyrene matrix material of which the surface is coated with polydopamine, filtering, putting into an La (III) salt solution, diffusing lanthanum salt to theouter surface of a sphere, and performing ammonium hydroxide in-situ precipitation to obtain the nano-lanthanum hydroxide composite material of which the loading amount is 5.9 to 35.2 percent. A method for removing trace phosphorus in waste water by using the composite material comprises the following steps: filling an adsorption column with the composite resin, then enabling trace phosphate infected water to directly flow through a filter column with an adsorbent from top to bottom, and when the concentration of phosphate in effluent is higher than 0.5mg / L, desorbing by using mixed liquor ofNaOH and NaCl and effectively regenerating. The treatment efficiency is high, the treatment capacity is great, the environmental protection benefit is obvious, and the content of the phosphate in theeffluent of the phosphate-infected waste water can be lowered to 50ppb or less.

Owner:YANSHAN UNIV

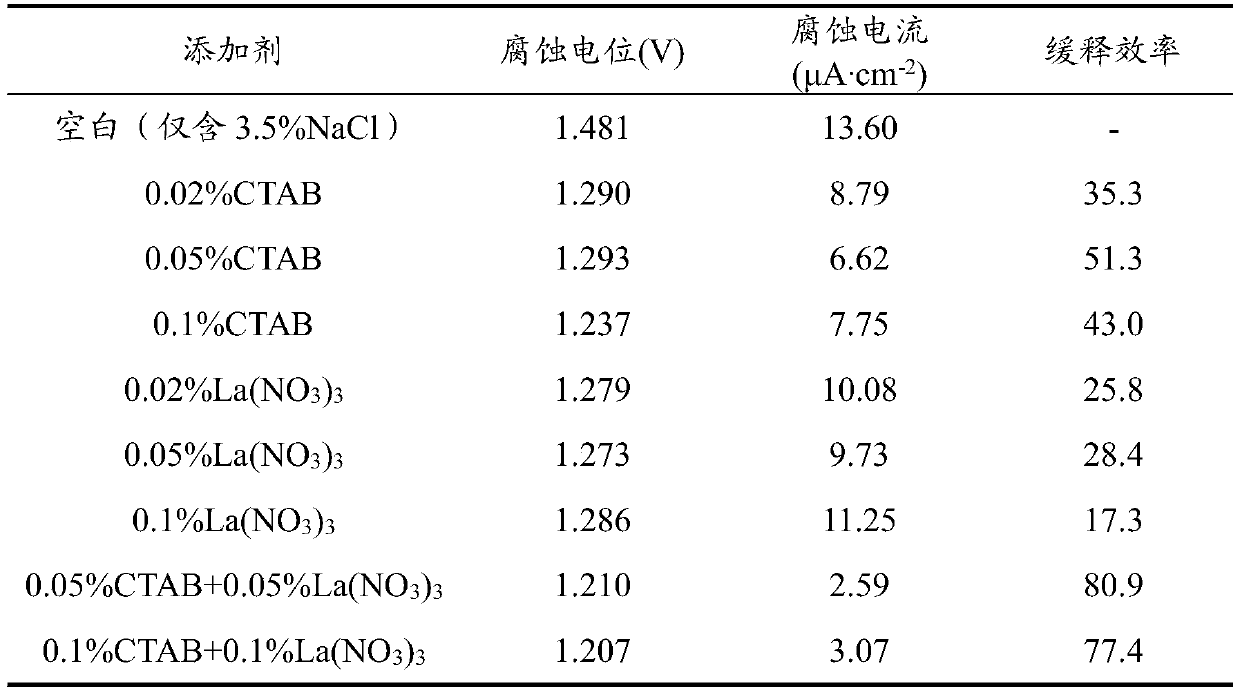

Composite corrosion inhibitor electrolyte, application thereof and magnesium air battery

ActiveCN110364787AImprove release efficiencyControl depositionFuel and primary cellsFuel and secondary cellsEngineeringLanthanum hydroxide

The invention provides a composite corrosion inhibitor electrolyte, an application thereof and a magnesium air battery, and belongs to the field of air batteries. In the invention, La<3+> in lanthanumnitrate can react with OH<-> in the solution to generate lanthanum hydroxide to precipitate, and the structure and appearance of a passive film are changed, so that hydrogen evolution is inhibited, the damage effect of nitrate ions on the passive film is weak, and the integrity of the primary passive film is ensured, thereby having a good protection effect on internal battery materials, and inhibiting the hydrogen evolution. CTAB is a cationic surfactant, can significantly reduce the surface tension, change the surface state of metal / electrolyte, gather on the surface of active metal by utilizing the electrostatic adsorption of NH<2+>, reduce the surface energy of the metal and increase the corrosion activation energy, thereby slowing down the corrosion rate, and simultaneously forming alayer of hydrophobic protection film on the surface layer of the metal, thus hindering the charge and ion transfer, hindering the reaction process and reducing the corrosion rate.

Owner:易航时代(北京)科技有限公司

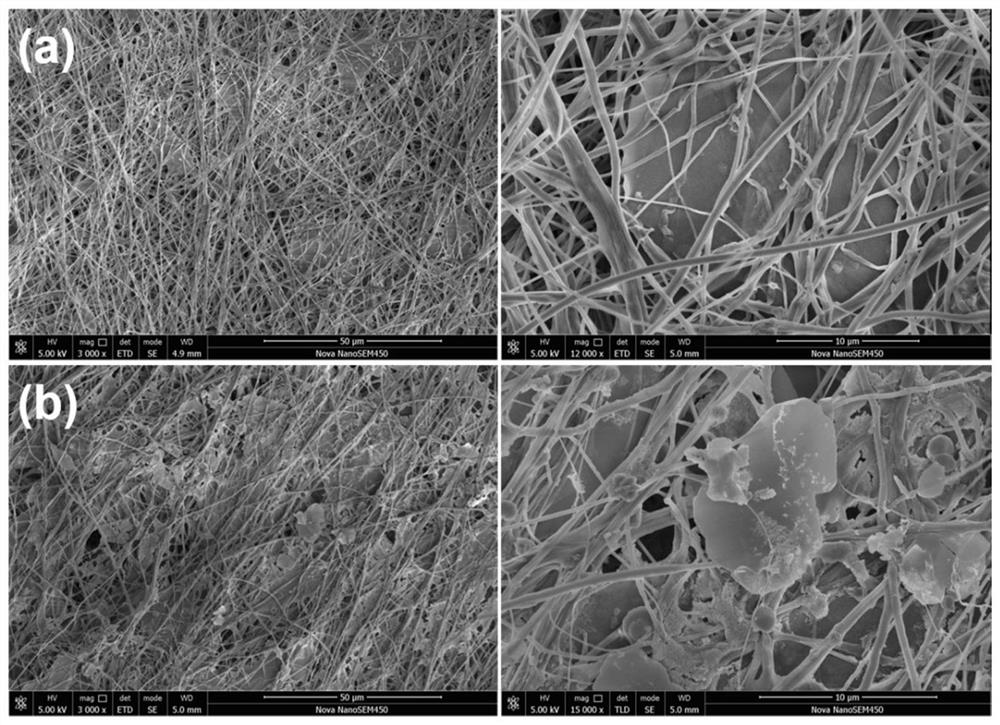

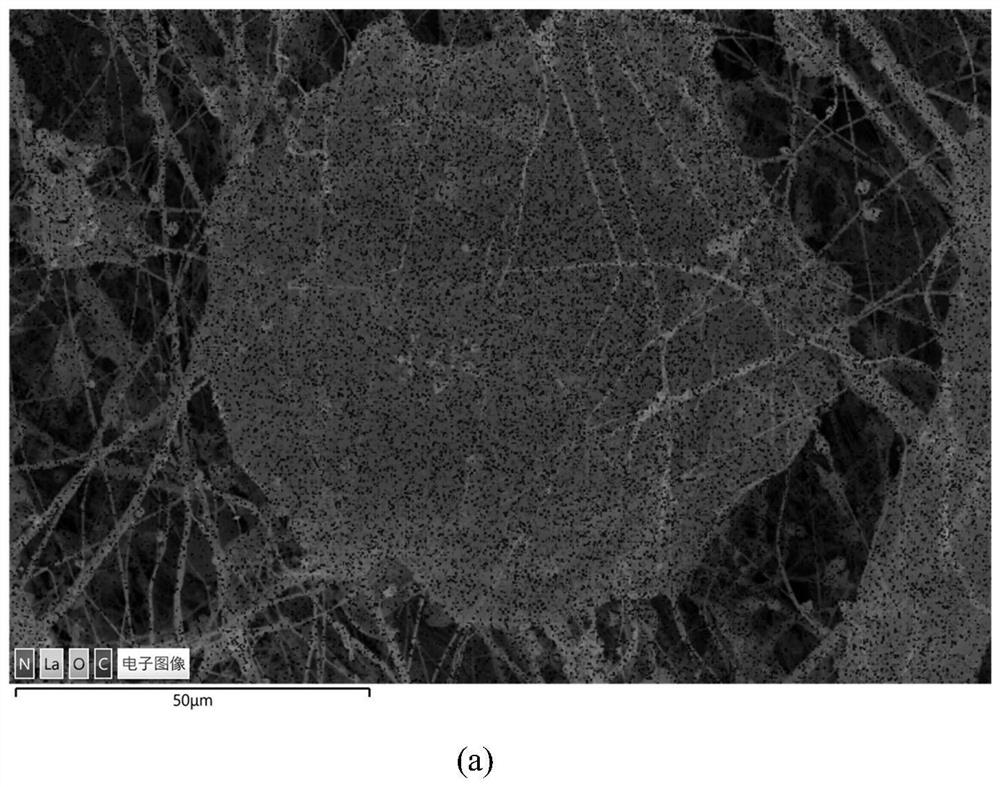

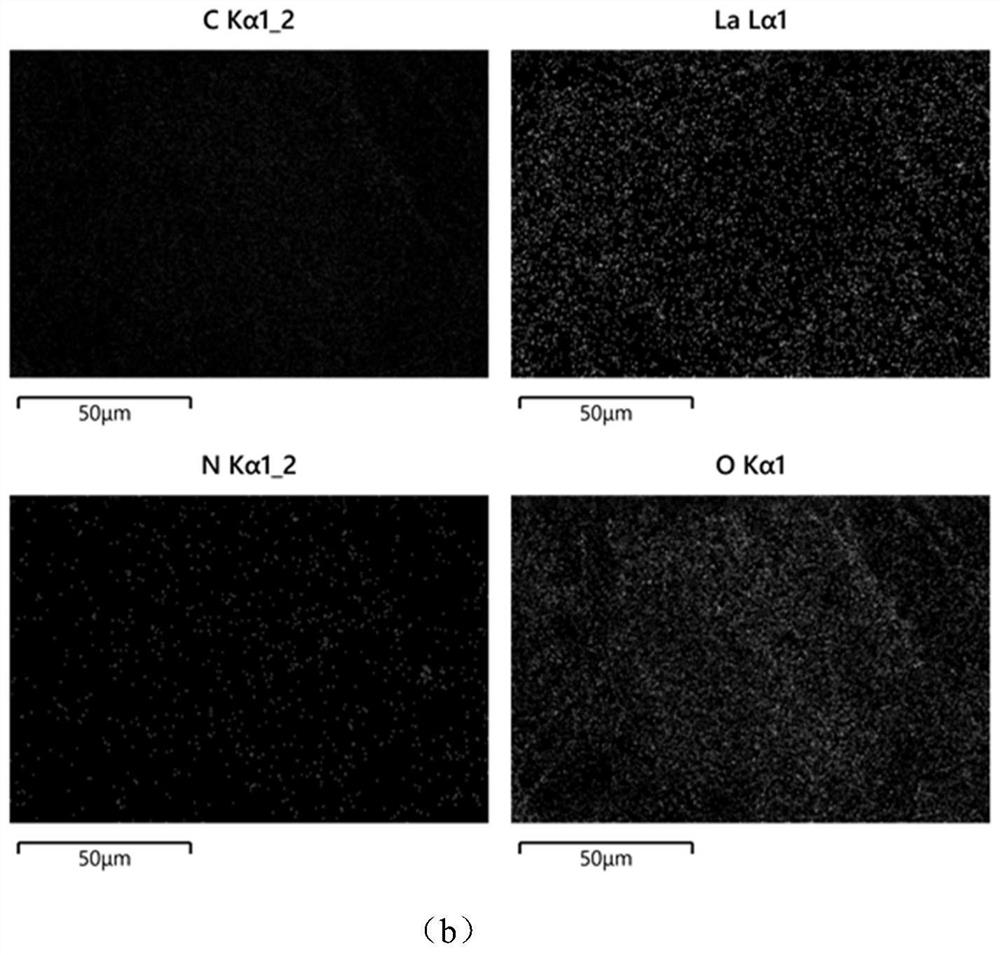

Carbon nitride/lanthanum hydroxide nanofiber membrane as well as preparation method and application thereof

ActiveCN112076785AAvoid reunionEasy to separateHydrogen peroxideWater/sewage treatment by irradiationElectron holeCarbon nitride

The invention provides a carbon nitride / lanthanum hydroxide nanofiber membrane as well as a preparation method and application thereof. Nanofiber loading and lanthanum electron-deficient orbital characteristics are combined, an electrostatic spinning nanofiber membrane serves as a support to load carbon nitride, the agglomeration of the carbon nitride is prevented, the specific surface area thereof is increased, lanthanum hydroxide grows on a carbon nitride sheet layer in situ, and by means of the unique electron-deficient orbital structure of the lanthanum hydroxide, the separation of carbonnitride photo-induced electrons and holes is promoted, so that the photocatalytic activity is improved. In the prepared carbon nitride / lanthanum hydroxide nanofiber membrane, the carbon nitride and the lanthanum hydroxide are wrapped in nanofibers, and lanthanum hydroxide nanosheets grow on a carbon nitride sheet layer in situ. The prepared carbon nitride / lanthanum hydroxide nanofiber membrane canbe used for catalytically degrading dyes and catalytically producing hydrogen under visible light. The problems that carbon nitride is prone to agglomeration, aftertreatment is tedious, and the visible light utilization rate is low are solved.

Owner:SICHUAN UNIV

Production technology of low-sulfur lanthanum hydroxide

The invention discloses a production technology of low-sulfur lanthanum hydroxide. The production technology comprises the following steps: (1) dissolving lanthanum carbonate in nitric acid to obtain a lanthanum nitrate solution; (2) regulating the pH value of the lanthanum nitrate solution obtained in the step (1) to 1.5-2, heating, adding the lanthanum carbonate to regulate the pH value to 4-4.5, and filtering to obtain filtrate; (3) concentrating and crystallizing the filtrate obtained in the step (2) to obtain a lanthanum carbonate crystal, and carrying out centrifugal dewatering; (4) dissolving the lanthanum carbonate crystal obtained by the centrifugal dewatering in the step (3), adding ammonium hydroxide to regulate the pH value to 7, standing to obtain a mixture which contains precipitates, and heating the mixture; (5) carrying out plate frame filtering on the heated mixture in the step (4) to obtain the precipitates; (6) drying the precipitates obtained in the step (5) on a vulcanization bed to obtain a low-sulfur lanthanum hydroxide finished product. In the lanthanum hydroxide product produced by the method, the sulfur content is less than 0.002%, and the contents of other metal impurities including calcium, iron, sodium, potassium, lead, manganese, magnesium, chromium, copper, zinc and the like are all less than 0.0005%.

Owner:乐山沃耐稀电子材料有限公司

Method for preparing lithium manganate by wet-doping method

InactiveCN103337619AIncrease the average oxidation stateSuppress purityCell electrodesManganates/permanganatesOxidation stateManganate

Owner:HUNAN DAHUA NEW ENERGY

Two-dimensional clay based composite phosphorus removing agent and preparation method and application thereof

ActiveUS20200385276A1Low costEfficient phosphorus removal propertyOther chemical processesAluminium silicatesCalcium hydroxideAluminium hydroxide

The present invention belongs to the field of material preparation, and particularly relates to a two-dimensional clay based composite phosphorus removing agent and a preparation method. The two-dimensional clay based composite phosphorus removing agent provided by the present invention takes two-dimensional clay, hydroxide (such as lanthanum hydroxide, calcium hydroxide, magnesium hydroxide and aluminum hydroxide) and urea as raw materials, and the composite phosphorus removing agent with high property is prepared by a roasting method. Through a combined physical and chemical method, phosphorus in the phosphorus-containing wastewater is effectively removed by the synergic interaction between components of the composite phosphorus removing agent. The invention overcomes the defects of large consumption and secondary pollution easily caused by using metal hydroxides, metal oxides and metal salts separately as chemical phosphorus removing agents, and simultaneously expands the application fields of the two-dimensional clay.

Owner:CENT SOUTH UNIV

Nanometer lanthanum oxide defluoridation adsorbent and preparation method thereof

InactiveCN109174066ANo secondary leakageCause secondary pollutionOther chemical processesWater contaminantsIce waterDissolution

The invention relates to a nanometer lanthanum hydroxide defluoridation adsorbent and a preparation method thereof. The preparation method comprises: 1, putting a reactor container in ice water at 10-35 DEG C and adding deionized water into the reactor container, 2, adding lanthanum nitrate solid powder into the deionized water in the step 1 and carrying out stirring dissolution through a stirrer,3, slowly adding a sodium hydroxide solution into the lanthanum nitrate solution and adjusting pH to 8.5-9.0, 4, repeatedly rinsing the solution in the step 3 through deionized water, 5, dehydratingthe washed slurry through a centrifuge and then drying the slurry, 6, grinding the dried slurry and screening dry powder of lanthanum hydroxide, and 7, mixing the dry powder of lanthanum hydroxide, microcrystalline cellulose and hydroxypropylmethylcellulose b and carrying out granulation through a wet granulator and a spheronizator. The preparation method is simple. The nanometer lanthanum hydroxide defluoridation adsorbent has high fluorine ion adsorbing efficiency and a long regeneration cycle.

Owner:XIAN ENVIROMENTAL PROTECTION IND TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com