Preparation method of uniformly dispersed nano lanthanum oxide

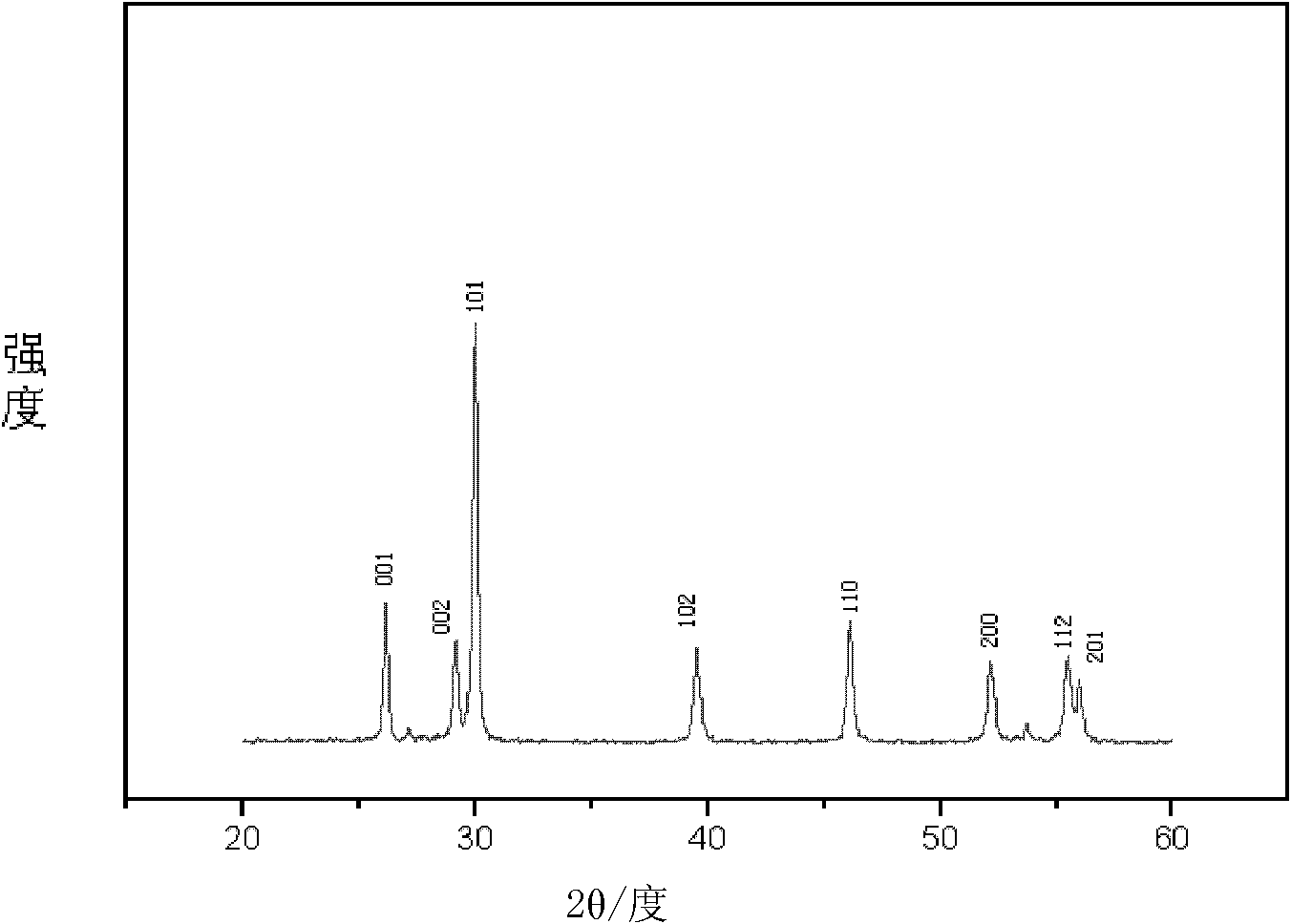

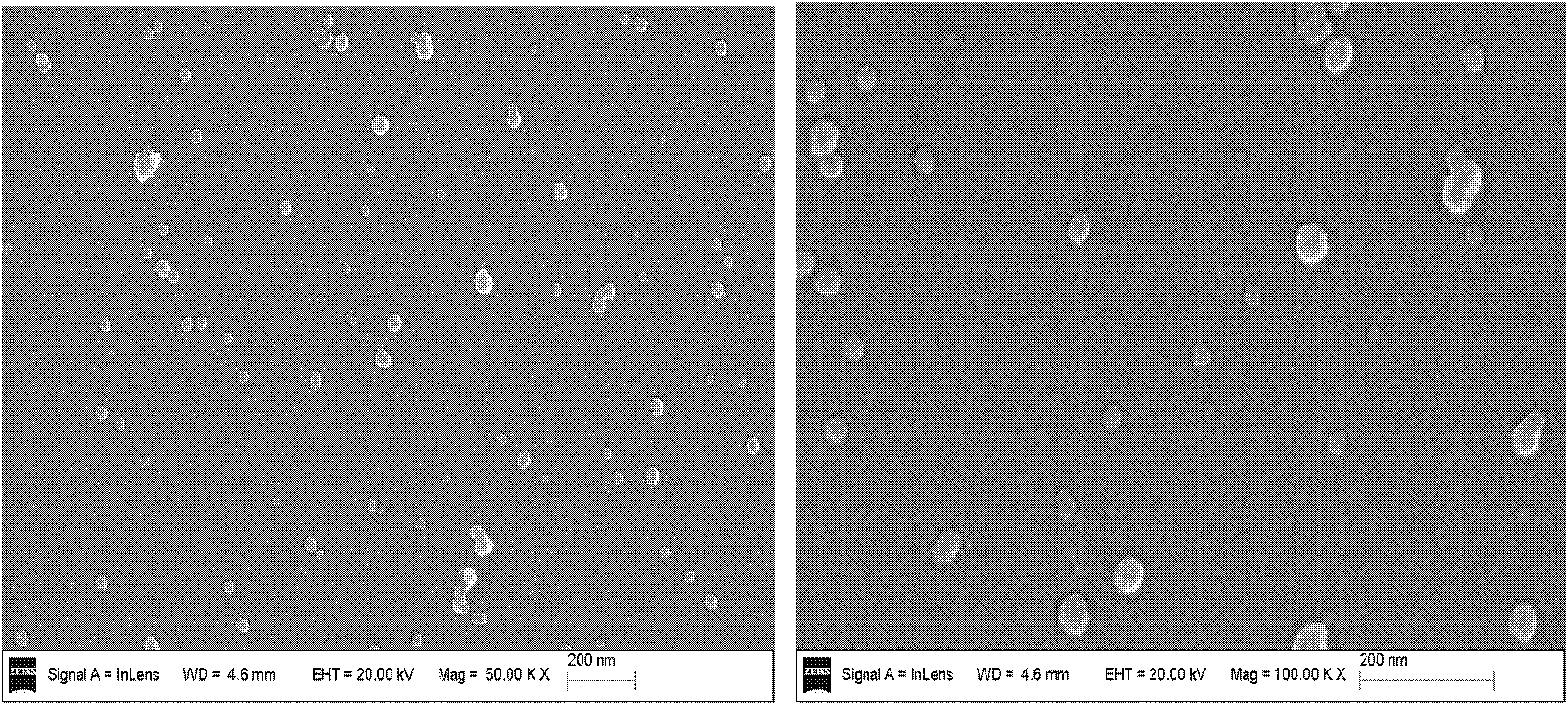

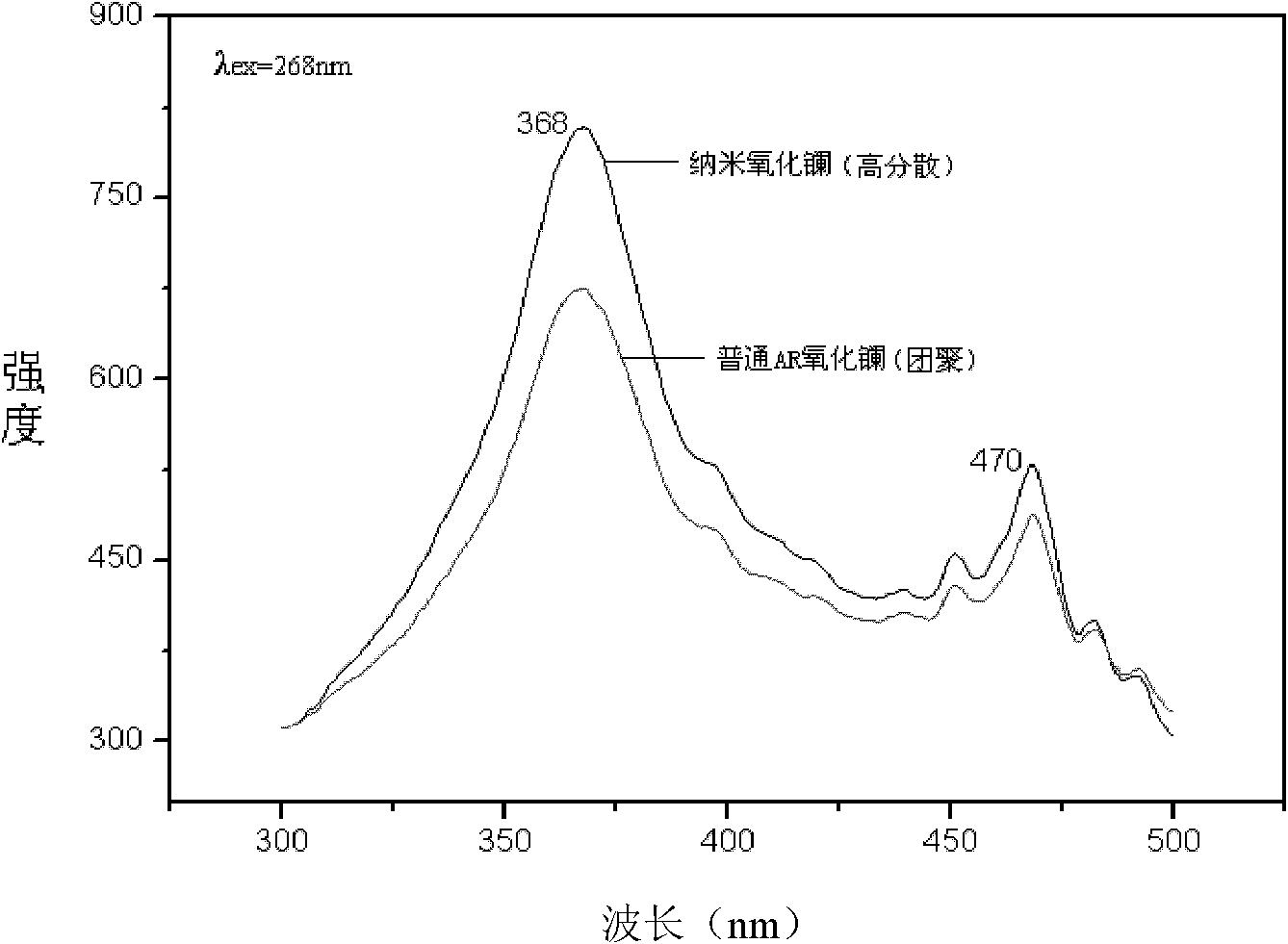

A technology of nano-lanthanum oxide and lanthanum hydroxide, which is applied in the field of controllable preparation of homogeneously dispersed nano-lanthanum oxide powder, can solve problems such as uneven distribution, expensive raw materials, and harsh conditions, and achieve low process cost, good dispersion, and The effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 1g of carbon black N330 with a particle size of about 10nm as the initial dispersant, add 10g of nitric acid with a concentration of 16mol / L as the carbon black oxidant, heat it to 50°C for 5h, dry and activate it at 120°C for 12h after centrifugal washing, and obtain modified carbon Black N330; 5.4g of La(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to form a 0.1mol / L solution, then 0.54g of modified carbon black N330 was added, and ultrasonically dispersed for 15 minutes to obtain a uniformly dispersed black liquid, which was designated as liquid A; 1.5g of NaOH was dissolved in deionized In water, make a solution of 0.3mol / L, which is recorded as B solution; fully mix A solution and B solution in a rotating liquid film nucleation reactor at room temperature to obtain a black precipitate; transfer the black precipitate into a three-necked flask, Crystallize and grow at ℃ for 4 hours, wash with centrifuge until neutral, dry at 80℃ for 12 hours to obtain the...

Embodiment 2

[0024] Take 1g of carbon black N550 with a particle size of about 15nm as the initial dispersant, add 30g of nitric acid with a concentration of 10mol / L as the carbon black oxidant, heat it to 70°C for 8h, dry and activate it at 140°C for 20h after centrifugal washing, and obtain modified carbon Black N550; 2.26g of LaCl 3 ·7H 2O was dissolved in deionized water to form a 0.05mol / L solution, then 0.15g of modified carbon black N550 was added, and ultrasonically dispersed for 10 minutes to obtain a uniformly dispersed black solution, which was recorded as A solution; 0.75g of NaOH was dissolved in deionized Prepare a solution of 0.15 mol / L in ionic water, and record it as liquid B; fully mix liquid A and liquid B in a rotating liquid film nucleation reactor at room temperature to obtain a black precipitate; transfer the black precipitate into a three-necked flask, and Crystallization and growth at 40°C for 5 hours, centrifugation and washing until Cl-free - , dry at 70°C for ...

Embodiment 3

[0026] Take 1g of carbon black N770 with a particle size of about 55nm as the initial dispersant, add 40g of nitric acid with a concentration of 2mol / L as the carbon black oxidant, heat it to 60°C for 4h, dry and activate it at 150°C for 24h after centrifugal washing, and obtain modified carbon Black N770; add 0.5g of La 2 (SO 4 ) 3 9H 2 O was dissolved in deionized water to form a 0.01mol / L solution, then 0.03g of modified carbon black N770 was added, and ultrasonically dispersed for 5 minutes to obtain a uniformly dispersed black solution, which was recorded as solution A; 0.15g NaOH was dissolved in deionized Prepare a solution of 0.03mol / L in water, which is denoted as liquid B; fully mix liquid A and liquid B in a rotating liquid film nucleation reactor at room temperature to obtain a black precipitate; transfer the black precipitate into a three-necked flask, Crystallization growth under the crystallization conditions for 6h, centrifugal washing to no SO 4 2- , dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com