Coating reinforcing agent, preparation method thereof and phosphate-metal aluminum powder coating using reinforcing agent

A metal aluminum powder and reinforcing agent technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of inability to meet the working requirements of exhaust pipes, weakened high temperature resistance of coatings, and reduced performance, so as to improve the bonding performance and improve the resistance. High temperature performance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

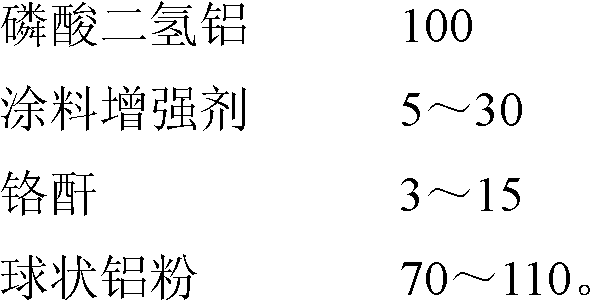

Method used

Image

Examples

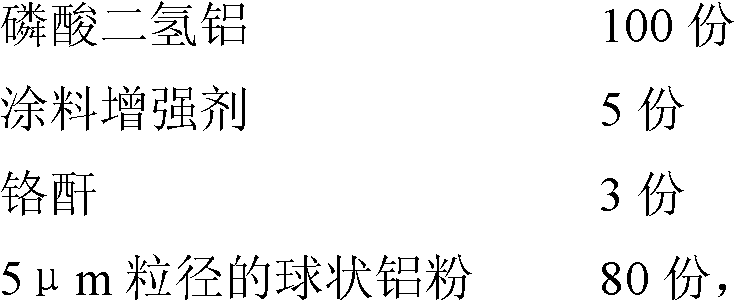

Embodiment 1

[0024] The paint enhancer of this embodiment is a rare earth enhancer, and the enhancer is configured by the following method:

[0025] (1) According to the weight ratio, combine 100 parts of phosphoric acid and lanthanum hydroxide (H 3 LaO 3 ) 35 parts are put into a container for exothermic reaction; after 30-60 minutes of reaction, a thick translucent gel material is obtained;

[0026] (2) Add an appropriate amount of deionized water to the container, and after sufficient stirring, the above gel substance dissolves in the water and forms a white milky liquid;

[0027] (3) Put the container in an oven at 100°C, and keep it warm for 2 hours to obtain a translucent gel that is thick and paste; during the heat preservation process, the container can be taken out of the oven and stirred, and the stirring can make the inside of the container The solution is more uniform, which promotes the reaction;

[0028] (4) Take out the container from the oven, and continue to add deionized water in...

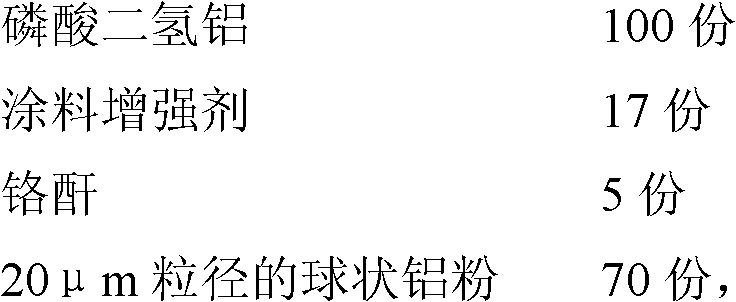

Embodiment 2

[0034] The paint enhancer in this embodiment is a rare earth enhancer, and the enhancer is configured by the following method:

[0035] (1) According to the weight ratio, 100 parts of phosphoric acid and lanthanum hydroxide (H 3 LaO 3 ) 38 parts are put into a container for exothermic reaction; after 30-60 minutes of reaction, a thick translucent gel material is obtained;

[0036] (2) Add an appropriate amount of deionized water to the container, and after sufficient stirring, the above gel substance dissolves in the water and forms a white milky liquid;

[0037] (3) Put the container into an oven at 120°C, and keep it warm for 4 hours to obtain a translucent gel that is thick and paste; during the heat preservation process, the container can be taken out of the oven and stirred;

[0038] (4) Take out the container from the oven, and continue to add deionized water into the container, and finally prepare a solution with a total weight of 250 parts. The solution is stirred for 2 to 3 ho...

Embodiment 3

[0044] The paint enhancer in this embodiment is a rare earth enhancer, and the enhancer is configured by the following method:

[0045] (1) According to the weight ratio, combine 100 parts of phosphoric acid and lanthanum hydroxide (H 3 LaO 3 ) Put 40 parts into a container for exothermic reaction; after 30-60 minutes of reaction, a thick translucent gel material is obtained;

[0046] (2) Add an appropriate amount of deionized water to the container, and after sufficient stirring, the above gel substance dissolves in the water and forms a white milky liquid;

[0047] (3) Put the container into an oven at 140°C and keep it warm for 6 hours to obtain a translucent gel in a thick paste; during the heat preservation process, the container can be taken out of the oven and stirred;

[0048] (4) Take out the container from the oven, and continue to add deionized water into the container, and finally prepare a solution with a total weight of 250 parts. The solution is stirred for 2 to 3 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com