Fireproof high-strength honeycomb paper core and preparation method thereof

A honeycomb paper core, high-strength technology, applied in the field of materials, can solve the problems of non-fire prevention, poor compressive strength, etc., achieve good flame retardancy, improve overall mechanical properties and flame retardancy, and good mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

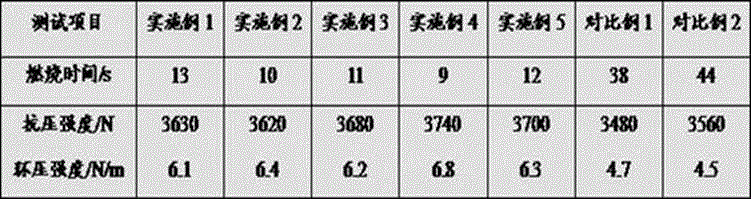

Examples

Embodiment 1

[0023] A fireproof high-strength honeycomb paper core, the honeycomb paper core is prepared from the following components in parts by weight: 32 parts of papermaking sludge, 16 parts of silicon sludge, 24 parts of bamboo fiber, 8 parts of loofah pulp, L- 3 parts of alanine, 4 parts of 50-150 mesh fly ash, 2 parts of sodium phosphate, 0.5 parts of borax, 2 parts of yttrium oxide, 1 part of glass fiber, 3 parts of marble powder, 2 parts of lanthanum hydroxide, 1.5 parts of indium oxide , 3 parts of ammonium polyphosphate, 2 parts of maltodextrin, 1.2 parts of itaconic acid, 3 parts of zinc sulfate, 1 part of aluminate coupling agent LD-B-1.

[0024] The preparation method of the above-mentioned fireproof high-strength honeycomb paper core includes the following preparation steps:

[0025] Step 1: weighing according to the above parts by weight;

[0026] Step 2: crushing, beating, screening, concentrating and removing impurities from bamboo fiber, loofah pulp, papermaking sludge...

Embodiment 2

[0031] A fireproof high-strength honeycomb paper core, the honeycomb paper core is prepared from the following components in parts by weight: 4 parts of papermaking sludge, 25 parts of silicon sludge, 36 parts of bamboo fiber, 14 parts of loofah pulp, L- 9 parts of alanine, 8 parts of 50-150 mesh fly ash, 6 parts of sodium phosphate, 3 parts of borax, 6 parts of yttrium oxide, 5 parts of glass fiber, 8 parts of marble powder, 5 parts of lanthanum hydroxide, 4.8 parts of indium oxide , 10 parts of ammonium polyphosphate, 6 parts of maltodextrin, 2.7 parts of itaconic acid, 7 parts of zinc sulfate, 4 parts of aluminate coupling agent DL-411.

[0032] The preparation method of the above-mentioned fireproof high-strength honeycomb paper core includes the following preparation steps:

[0033] Step 1: weighing according to the above parts by weight;

[0034] Step 2: crushing, beating, screening, concentrating and removing impurities from bamboo fiber, loofah pulp, papermaking sludg...

Embodiment 3

[0039] A fireproof high-strength honeycomb paper core, the honeycomb paper core is prepared from the following components in parts by weight: 43 parts of papermaking sludge, 20 parts of silicon sludge, 30 parts of bamboo fiber, 11 parts of loofah pulp, L- 6 parts of alanine, 6 parts of 50-150 mesh fly ash, 4 parts of sodium phosphate, 1.8 parts of borax, 4 parts of yttrium oxide, 3 parts of glass fiber, 5 parts of marble powder, 3.5 parts of lanthanum hydroxide, 3 parts of indium oxide , 6 parts of ammonium polyphosphate, 4 parts of maltodextrin, 2 parts of itaconic acid, 5 parts of zinc sulfate, 2.5 parts of aluminate coupling agent DL-427.

[0040] The preparation method of the above-mentioned fireproof high-strength honeycomb paper core includes the following preparation steps:

[0041] Step 1: weighing according to the above parts by weight;

[0042] Step 2: crushing, beating, screening, concentrating and removing impurities from bamboo fiber, loofah pulp, papermaking slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com