Preparation method for high dispersion nano lanthanum hydroxide

A technology of lanthanum hydroxide and high dispersion, applied in the field of nanomaterials, can solve the problems of serious agglomeration of nanometer lanthanum hydroxide particles, serious agglomeration of lanthanum hydroxide particles, irregular particle morphology, etc., so as to shorten the production cycle and improve the production. Efficiency, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

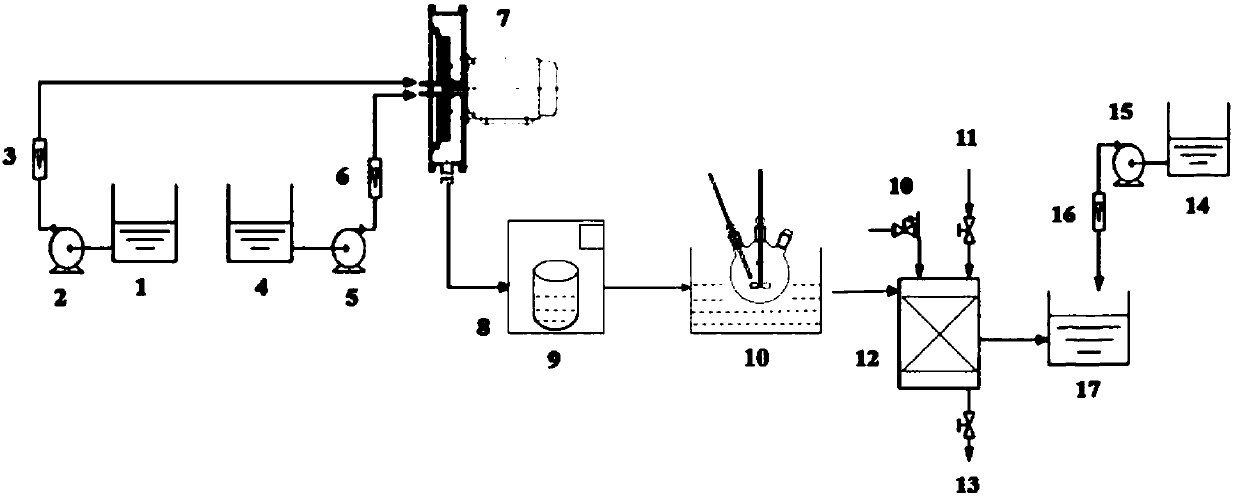

[0057] A kind of preparation method of highly dispersed nanometer lanthanum hydroxide of the present invention, comprises the steps:

[0058] 1) dissolving the lanthanum salt in water, an organic solvent or a mixture of water and an organic solvent to obtain a lanthanum salt solution; dissolving an alkali in water, an organic solvent or a mixture of water and an organic solvent to obtain a lye;

[0059] 2) adding lanthanum salt solution and lye into a common reactor or a high-gravity rotating packed bed for precipitation and crystallization reaction to prepare lanthanum hydroxide suspension;

[0060] 3) putting the lanthanum hydroxide suspension into an incubator for aging treatment;

[0061] 4) adding a modifier to the aged slurry for modification;

[0062] 5) cooling the modified slurry to normal temperature, and washing by ultrafiltration or centrifugation to obtain a filter cake;

[0063] 6) Dispersing the filter cake into a liquid medium to obtain a highly dispersed nan...

Embodiment 1

[0090] A preparation method for highly dispersed nanometer lanthanum hydroxide, comprising the steps of:

[0091] 1) Dissolve 0.74g of lanthanum nitrate hexahydrate in 50mL of deionized water, and sonicate for 0.2h; dissolve 0.24g of sodium hydroxide in 50mL of deionized water, and sonicate for 0.2h;

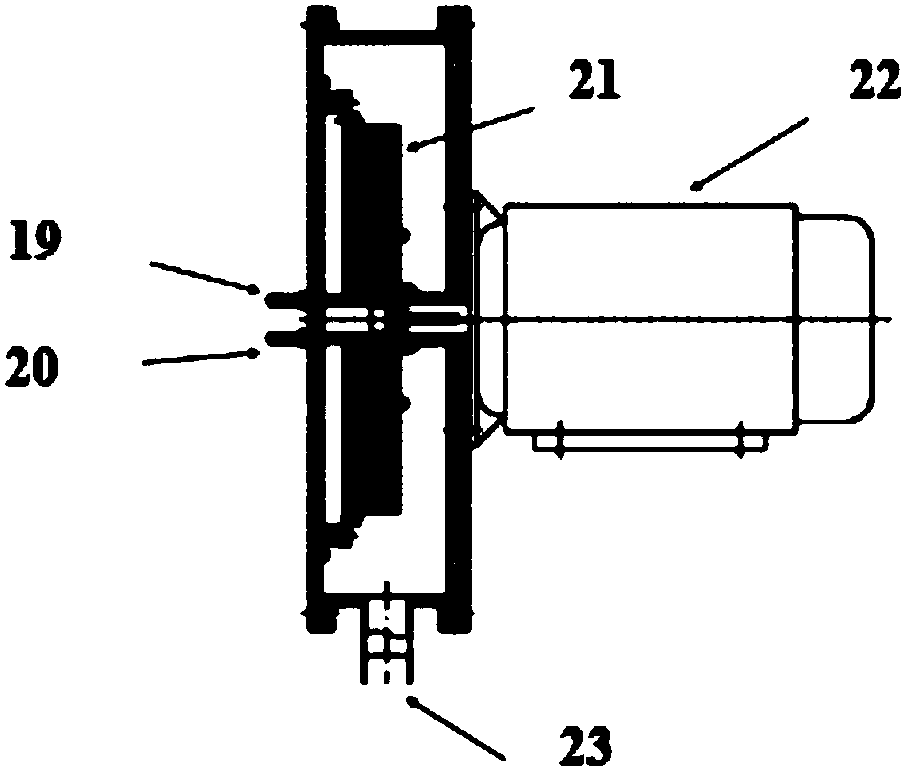

[0092] 2) After adjusting the temperature of the lanthanum nitrate hexahydrate solution and the sodium hydroxide solution to 16°C, they were passed into the baffled high-gravity rotary bed reactor through a peristaltic pump at a feed flow rate of 100mL / min, and the rotary bed speed was 1500rpm. Obtain lanthanum hydroxide suspension;

[0093] 3) Place the obtained lanthanum hydroxide suspension in an incubator at a constant temperature, adjust the temperature to 16° C., and age for 3 hours;

[0094] 4) Add Tween to the aged slurry for modification, the amount of modifier is 5wt%, the water bath temperature is 70°C during modification, and the modification time is 1h;

[0095] 5...

Embodiment 2

[0110] A preparation method for highly dispersed nanometer lanthanum hydroxide, comprising the steps of:

[0111] 1) Dissolve 0.74g of lanthanum chloride heptahydrate in 50mL of deionized water and sonicate for 0.2h; dissolve 0.24g of sodium hydroxide in 50mL of deionized water and sonicate for 0.2h;

[0112] 2) After adjusting the temperature of the lanthanum chloride heptahydrate solution and the sodium hydroxide solution to 16°C, they were fed into the high-gravity rotating bed through a peristaltic pump at a feed rate of 100mL / min, and the rotating bed speed was 1500rpm to obtain lanthanum hydroxide suspension;

[0113] 3) Place the obtained lanthanum hydroxide suspension in an incubator at a constant temperature, adjust the temperature to 16° C., and age for 3 hours;

[0114] 4) Add Tween to the aged slurry for modification, the amount of modifier is 5wt%, the water bath temperature is 70°C during modification, and the modification time is 1h;

[0115] 5) cooling the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com