Two-dimensional clay-based composite phosphorus removing agent as well as preparation method and application thereof

A compound dephosphorization agent and dephosphorization agent technology, applied in the direction of chemical instruments and methods, alkali metal compounds, other chemical processes, etc., to achieve the effects of wide application range, short preparation time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The invention provides a two-dimensional clay-based composite phosphorus removal agent and a preparation method, and the specific preparation steps are as follows:

[0063] (1) pulverize the two-dimensional clay to below 45 μm with an ultrafine pulverizer to obtain a two-dimensional clay powder for use;

[0064] (2) Mix 1 part of two-dimensional clay powder with 0.2 to 3 parts of M metal hydroxide (lanthanum hydroxide, calcium hydroxide, magnesium hydroxide, aluminum hydroxide, etc.), and grind them uniformly;

[0065] (3) in step (2), add 5~20 parts of urea, grind evenly, obtain ternary mixture;

[0066] (4) Putting the ternary mixture obtained in step (3) into a muffle furnace, calcining at a temperature of 400-600° C. for 1-5 hours (heating rate is 3-10° C. / min), and obtaining a two-dimensional clay-based composite Phosphorus remover.

Embodiment 1

[0070] (1) Weigh 0.1 g of rectorite powder and 0.1 g of lanthanum hydroxide, mix and grind them uniformly to obtain a mixture of rectorite and lanthanum hydroxide;

[0071] (2) take 1g of urea, join in the mixture of step (1), grind evenly, obtain rectorite-lanthanum hydroxide-urea ternary mixture;

[0072] (3) Putting the ternary mixture obtained in step (2) into a muffle furnace (air atmosphere), calcining at a temperature of 450 ° C for 3 h (heating rate is 5 ° C / min), to obtain a rectorite-based composite phosphorus removal Its phosphorus removal performance is shown in Table 1.

[0073] Detection experiment:

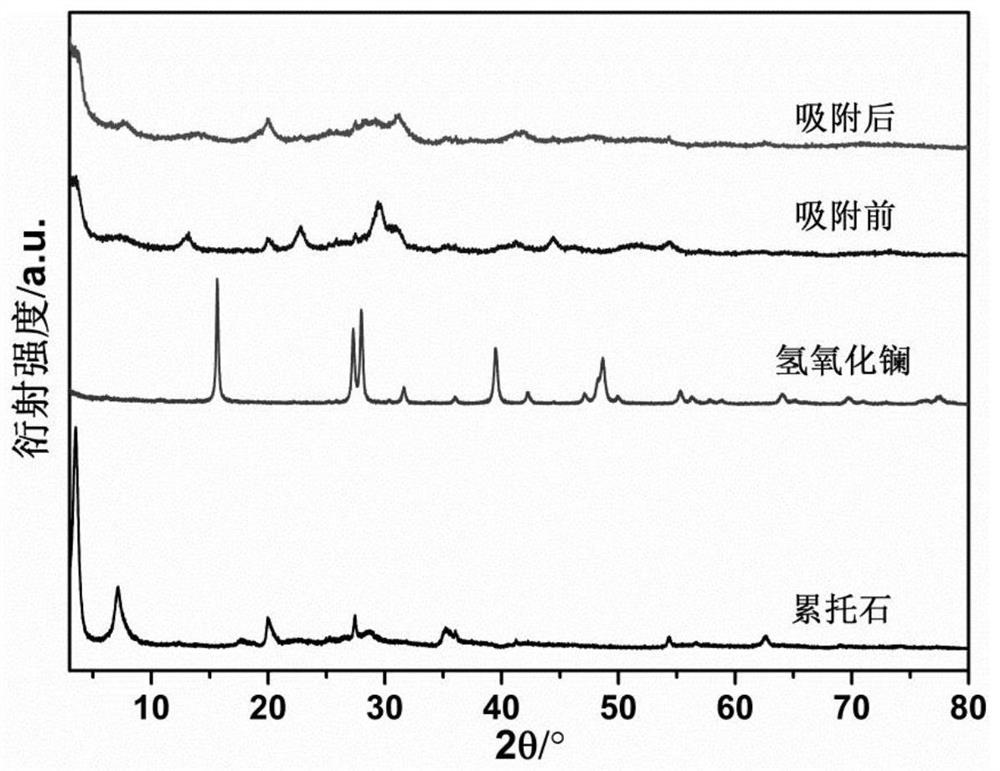

[0074] 1. Take the raw materials of Example 1 and the rectorite-based composite phosphorus removal agent before and after adsorption of phosphorus to carry out wide-angle X-ray diffraction analysis, and the results are as follows figure 1 As shown, the lanthanum oxide was in situ composited during the calcination process, and the rectorite structure was not destro...

Embodiment 2

[0079] (1) Weigh 0.1 g of rectorite powder and 0.1 g of calcium hydroxide, mix and grind them evenly to obtain a mixture of rectorite and calcium hydroxide;

[0080] (2) take by weighing 1g urea, join in step (1) mixture, grind evenly, obtain rectorite-calcium hydroxide-urea ternary mixture;

[0081] (3) Putting the ternary mixture obtained in step (2) into a muffle furnace (air atmosphere), calcining at a temperature of 450 ° C for 3 h (heating rate is 5 ° C / min), to obtain a rectorite-based composite phosphorus removal Its phosphorus removal performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com