Gel for recovering phosphorus from water and preparation method and application thereof

A manufacturing method and technology for recycling water, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as difficult operation and recycling, achieve high removal rate, improve adsorption capacity, and enhance mechanical strength and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

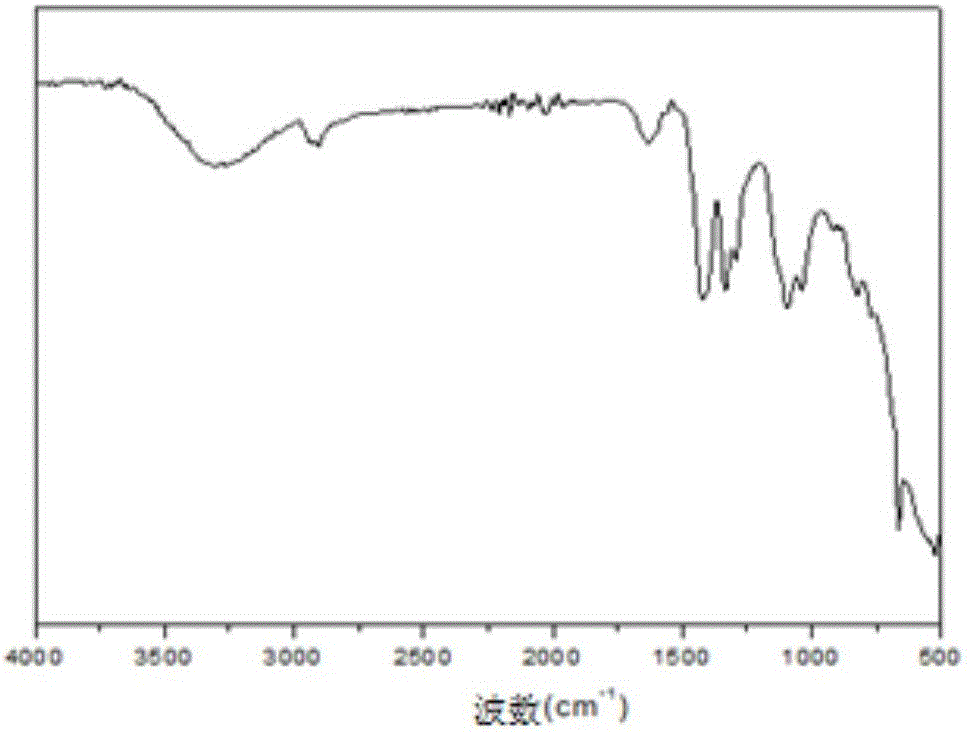

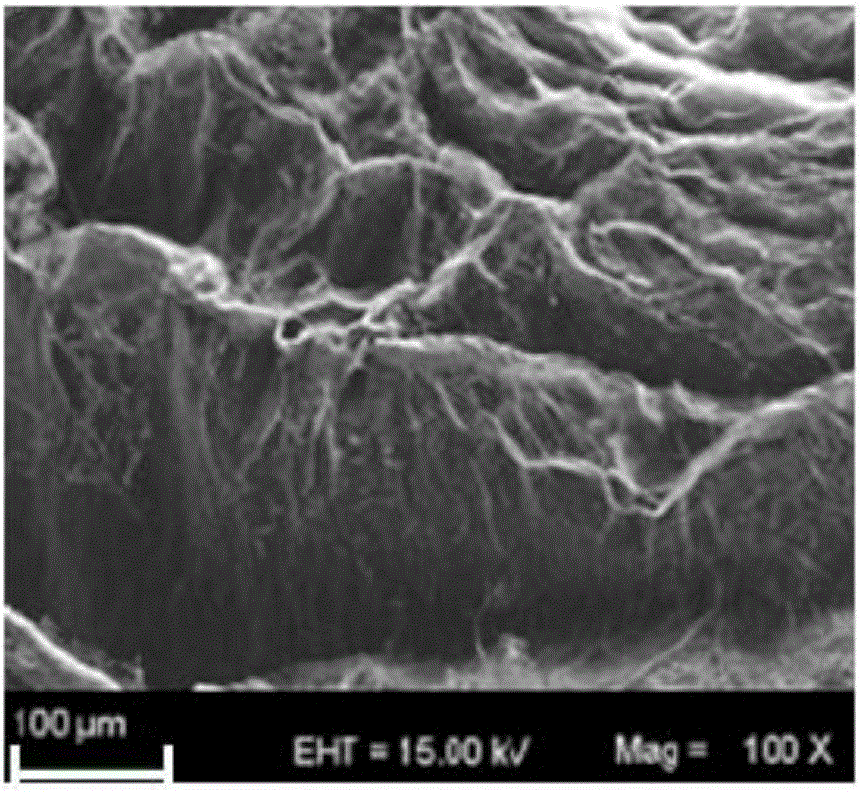

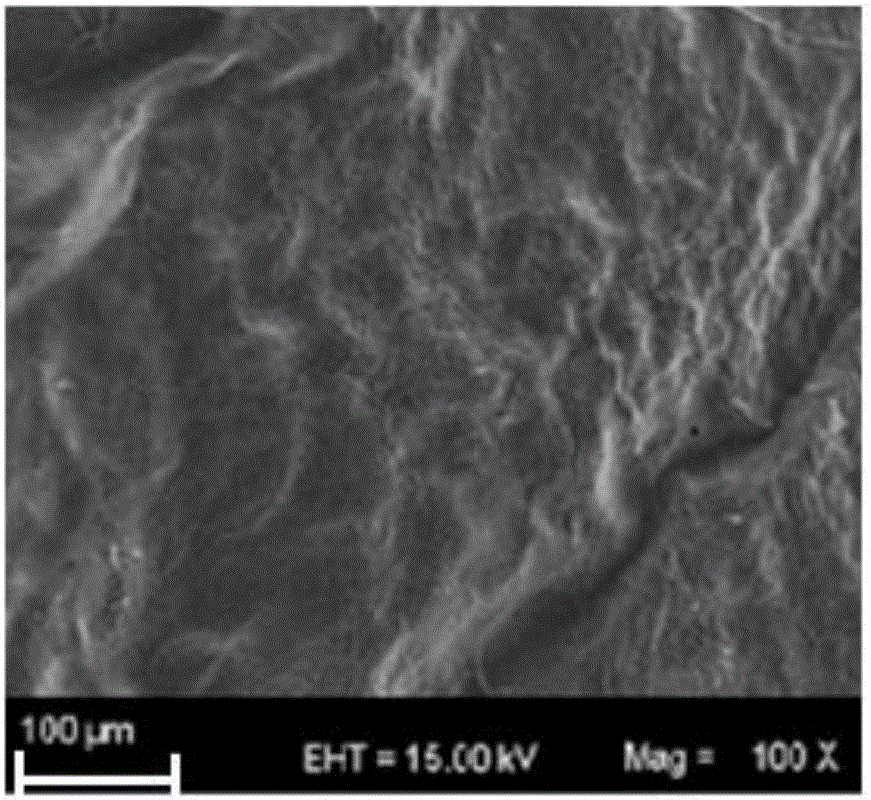

Method used

Image

Examples

Embodiment 1

[0021] 1) Dissolve 4.0g polyvinyl alcohol (PVA) in water, stir mechanically and heat in a water bath to form solution I, weigh 2.0g sodium alginate (SA) and dissolve it in 48mL deionized water and magnetically stir to form solution II, weigh 1.0 g of lanthanum hydroxide was dissolved in 49 ml of water and stirred magnetically to form solution III, then preferably, lanthanum hydroxide was ultrasonically stirred for 1 hour and then continued to stir; then solution I, solution II and solution III were mixed, Stir mechanically until completely mixed to form a mixture I;

[0022] 2) Add the resulting mixed solution I to a mixture containing 4wt% boric acid and 3wt% AlCl 3 Cross-linking in the mixed solution II for 10 hours;

[0023] 3) The obtained gel was repeatedly rinsed with deionized water and soaked for 2 hours to remove unreacted monomers and a small amount of impurities.

Embodiment 2

[0025] 1) Dissolve 2.0g polyvinyl alcohol (PVA) in water, stir mechanically and heat in a water bath to form solution I, weigh 1.0g sodium alginate (SA) and dissolve it in 49mL deionized water and magnetically stir to form solution II, weigh 1.0 g of lanthanum hydroxide was dissolved in 49 ml of water and stirred magnetically to form solution III, then preferably, lanthanum hydroxide was ultrasonically stirred for 1 hour and then continued to stir; then solution I, solution II and solution III were mixed, Stir mechanically until completely mixed to form a mixture I;

[0026] 2) Add the resulting mixed solution I to a mixture containing 2wt% boric acid and 1wt% AlCl 3 Cross-linking in the mixed solution II for 14 hours;

[0027] 3) Wash the obtained gel repeatedly with deionized water and soak for 1 hour to remove unreacted monomers and a small amount of impurities.

Embodiment 3

[0029] 1) Dissolve 3.5g polyvinyl alcohol (PVA) in water, stir mechanically and heat in a water bath to form solution I, weigh 1.5g sodium alginate (SA) and dissolve it in 48.5mL deionized water and magnetically stir to form solution II, weigh Take 1.0g of lanthanum hydroxide dissolved in 49ml of water and magnetically stir to form solution III, then preferably, lanthanum hydroxide is ultrasonicated for 1 hour while stirring and then continue to stir; then solution I, solution II and solution III are mixed , mechanically stirred until completely mixed to form a mixed liquid I;

[0030] 2) Add the resulting mixed solution I to a mixture containing 3wt% boric acid and 2wt% AlCl 3 Cross-linking in the mixed solution II for 12 hours;

[0031] 3) Wash the obtained gel repeatedly with deionized water and soak for 3 hours to remove unreacted monomers and a small amount of impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com