Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Uniform internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor

ActiveCN105133813AImprove wear resistanceStrong environmental protectionNon-macromolecular adhesive additivesLaminationPolyesterFiber

The invention discloses an environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor, and relates to the technical field of wood-plastic floor production. The environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor comprises a base material layer and a decorative layer. The base material layer is made from the following raw materials, by mass, 50 to 55 parts of straw powder, 35 to 40 parts of hard resin, 12 to 15 parts of amino resin, 10 to 13 parts of modified bamboo powder, 5 to 8 parts of calcium carbonate, 4 to 6 parts of chlorinated paraffin, 3 to 5 parts of polyvinyl alcohol, 3 to 4 parts of polyester fiber, 2 to 4 parts of magnesium hydroxide, 2 to 3 parts of nanometer sponge, 1 to 2 parts of triethanolamine, 8 to 11 parts of glycerol and 10 to 13 parts of ethanol. The decorative layer is made through steps of immersing color or texture decorative paper in an adhesive, and paving the dried and solidified decorative paper on the base material layer, wherein the adhesive is made from the following raw material by mass. The environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor has a double-layer structure which is a structure of a novel wood-plastic floor, the surface of the decorative layer is flat and smooth, so the wood-plastic floor is easy to maintain and clean, good in wear resistance and corrosion resistance. The base material layer can stop moisture, so defects that a present floor easily bents, deforms, shrinks in dry conditions and expands in wet conditions.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Barrel stretch forming process and barrel manufactured by process

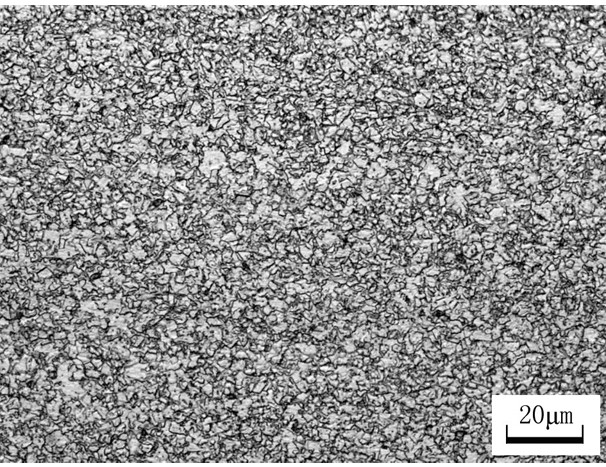

InactiveCN105107922ASimple structureReduce usageShaping toolsHollow articlesCrystal structureEngineering

The invention relates to a barrel stretch forming process capable of manufacturing a barrel by using a round stock and the barrel manufactured by the process. The barrel stretch forming process comprises the following the steps: supply the round stock; continuously carrying out one-time positive stretch and one-time negative stretch for the round stock in sequence. The barrel achieves the effect of the smooth outer surface and cannot generate stretch marks or a bubbling phenomenon. The barrel stretch forming process continuously carries out one-time positive stretch and one-time negative stretch for the round stock in sequence, so that the forming of the barrel can be completed, and the traditional three steps of stretch procedures is not needed. Moreover, material feeding and internal stress are uniform in the positive and negative stretch processes, the crystal structure is good, the outer surface is smooth, and the stretch marks or the bubbling phenomenon cannot occur. The manufacturing procedure is reduced, the use of corollary equipment is reduced, the cost of labor resources is reduced, the reject rate is lowered, and the production cost is reduced.

Owner:李侨志

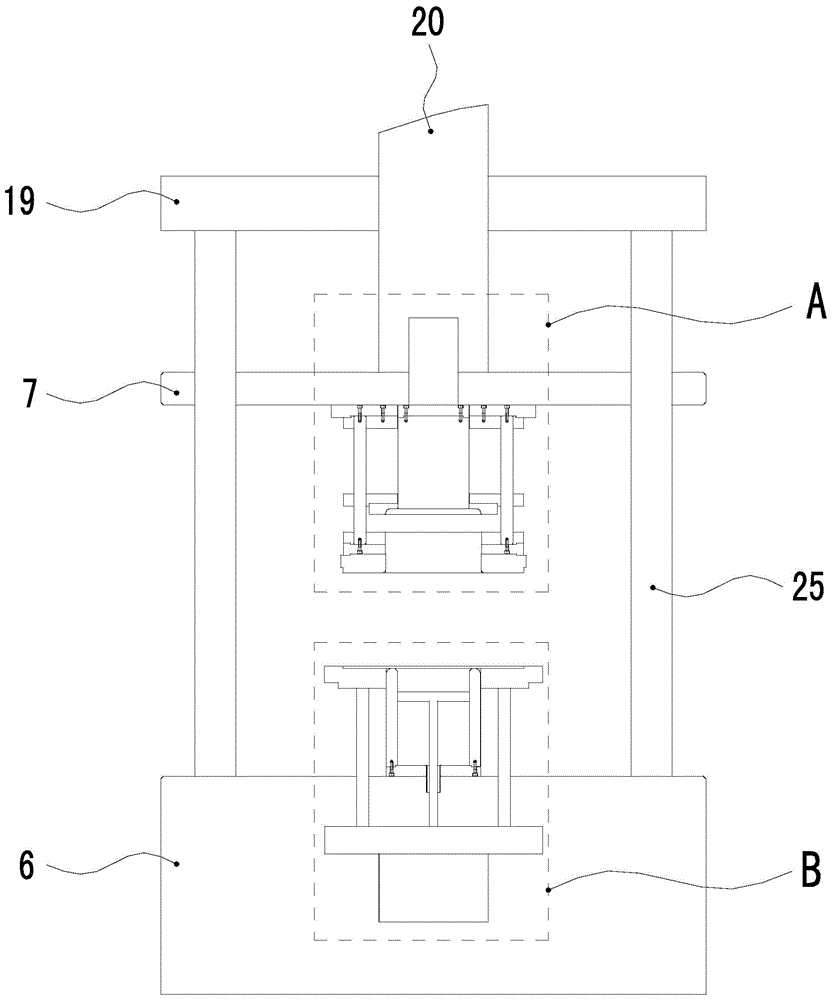

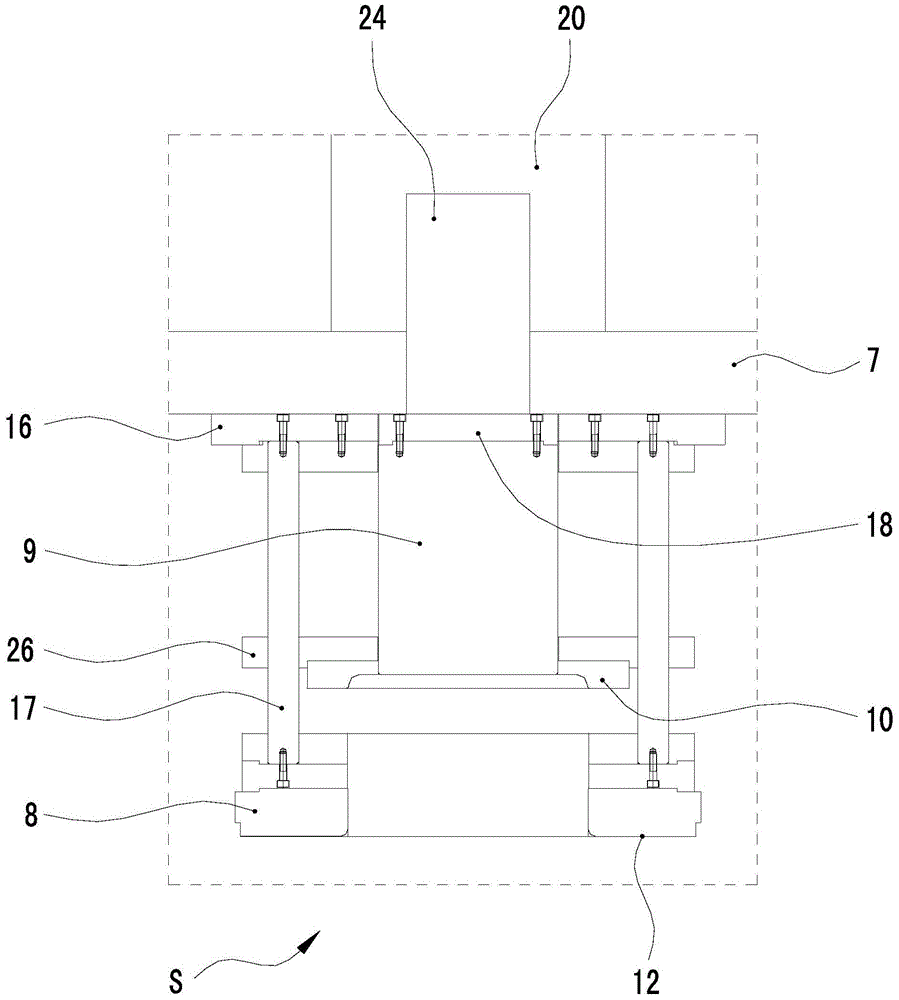

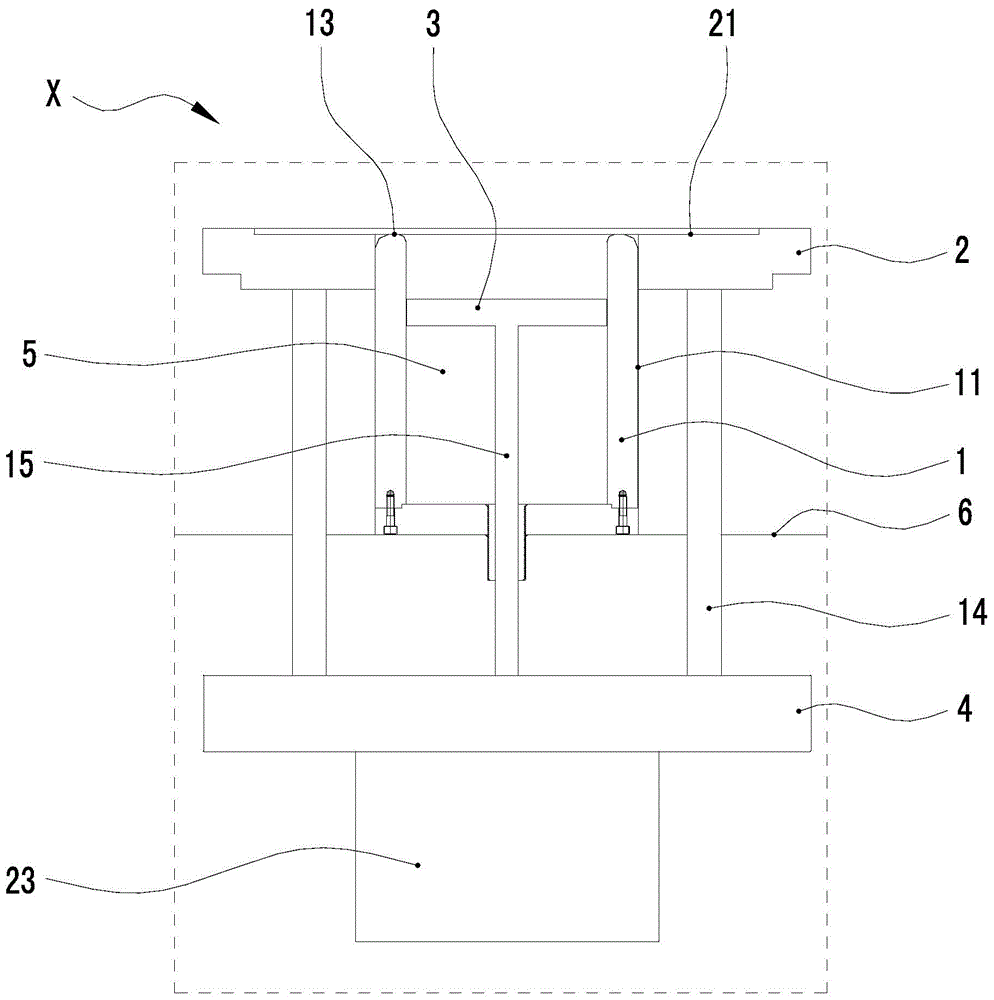

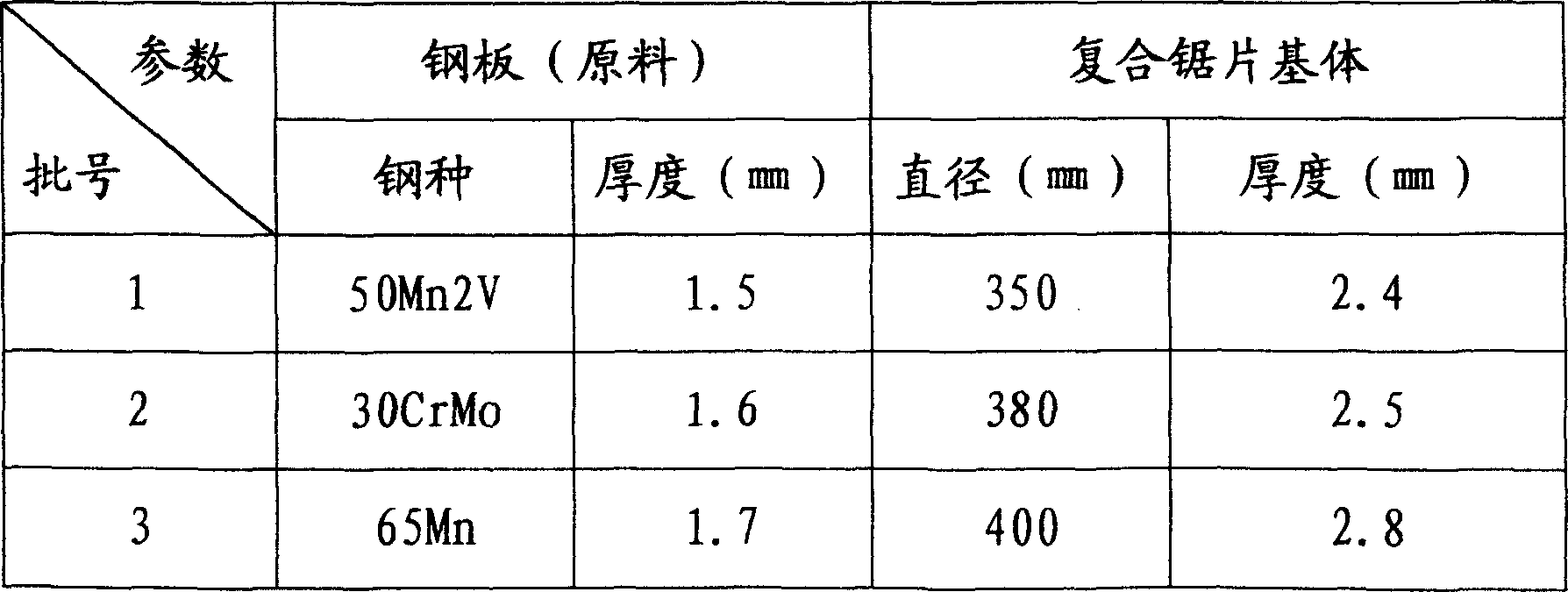

Method for producing composite diamond saw blade substrate

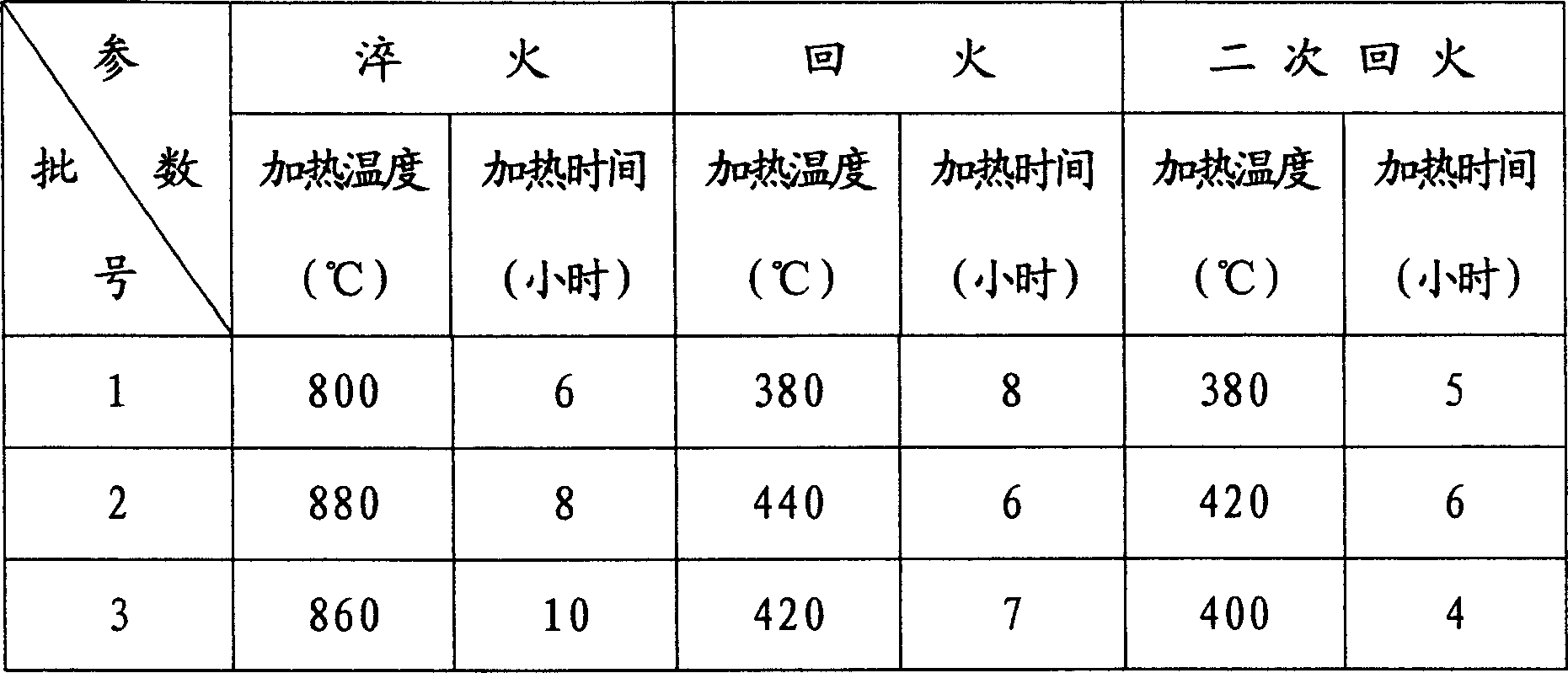

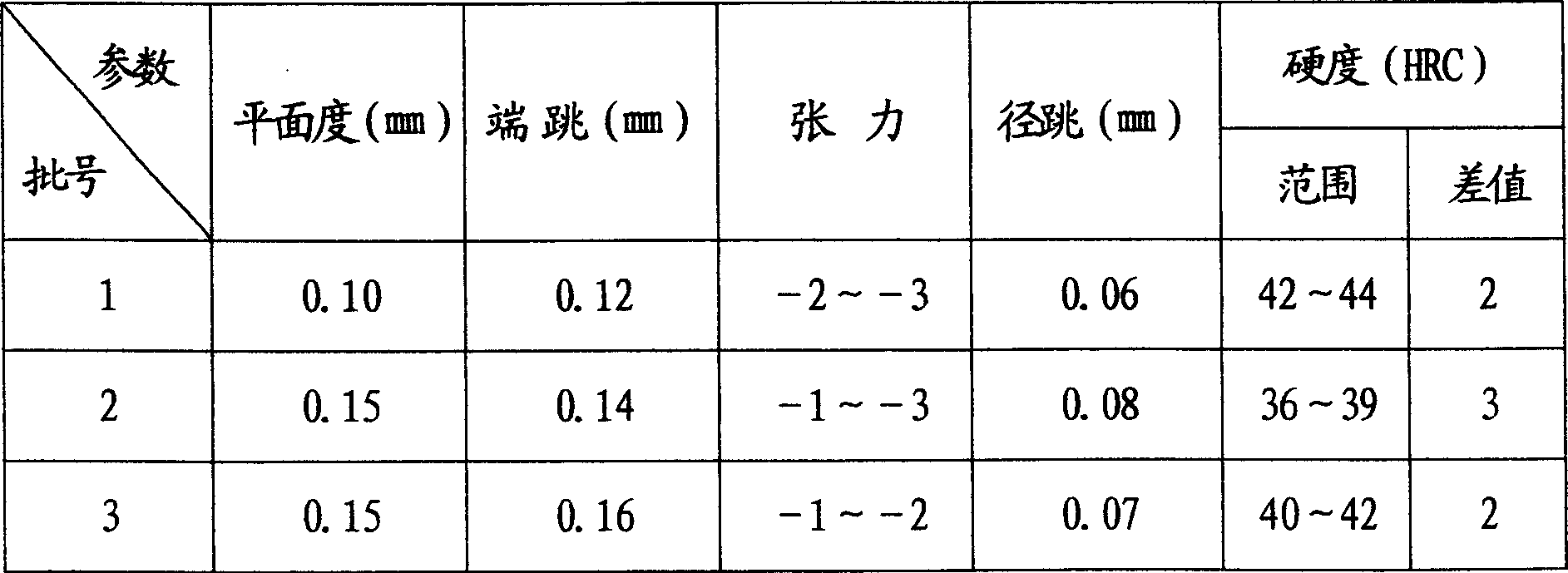

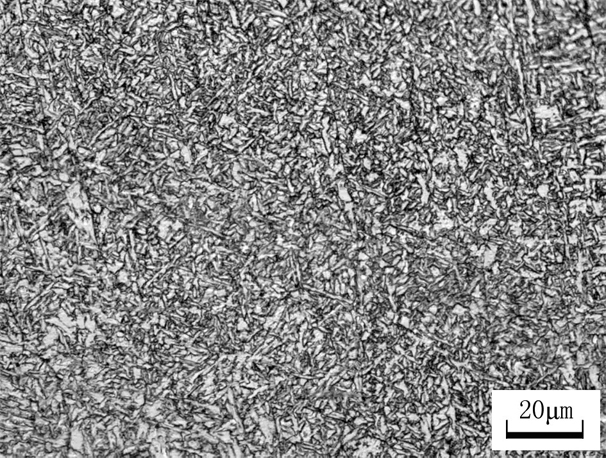

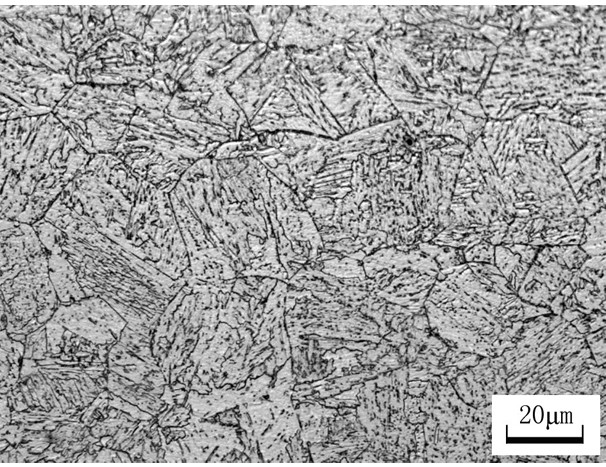

ActiveCN1820883AFlatness controlUniform internal stressMetal sawing tool makingOther manufacturing equipments/toolsComposite substrateHardness

The present invention belongs to the field of cutting tool, and relates to cutting tool for stone material, cement, glass and ceramic product. The production process of composite diamond saw blade substrate includes the technological steps of: preparing two single saw blade substrates, combined dot welding, quenching and tempering, finish machining, secondary tempering and finishing grinding to form the composite diamond saw blade substrate product. The present invention has the advantages of homogeneous hardness, high production efficiency and less crack forming possibility of the composite substrate.

Owner:HEIXUANFENG SAW IND

Easy-to-weld ultra-high strength steel with cold crack sensitivity coefficient less than or equal to 0.25 and production method

The invention relates to easy-to-weld ultrahigh-strength steel with cold crack sensitivity coefficient less than or equal to 0.25. The easy-to-weld ultrahigh-strength steel comprises the following components in percentage by weight: 0.07-0.10% of C, 0.15-0.30% of Si, 1.6-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0-0.04% of Nb, 0.09-0.13% of Ti and 0.20%-0.35% of Mo + Cr, wherein each of Mo and Cr is not zero; a production method comprises the steps of desulfurizing molten iron, smelting and casting into a blank; heating the casting blank; rough rolling;finish rolling; cooling, coiling and tempering. On the premise of ensuring that the yield strength of a steel plate is not less than 822MPa, the tensile strength is not less than 860MPa, the elongation A50 is not less than 18%, the low-temperature toughness at -20 DEG C is not less than 78J, and the transverse and longitudinal cold bending properties can meet the requirements that D = a and is qualified at 180 degrees, crystalline grains are refined through the TMCP + ultra-fast cooling + tempering process, the structure is uniform, the welding performance is excellent, and the cost performance is high; preheating-free welding can be achieved, internal stress is uniform, and strength and toughness are excellent.

Owner:武汉钢铁有限公司

Method for producing hard wood composite floor

InactiveCN1565818AReduce moisture contentUniform strength and densityWood working apparatusWood layered productsParquetinaHeat press

The invention discloses a method for producing wood composite floor which includes the following steps: prepressing the base material for not less than 20 seconds at pressure above 8MPa and temperature above 100 degree Centigrade; cooling the base material, sanding the base material according to the required thickness with grinding belt whose mesh is above 100m, then choosing one side of the base material as decorative surface, and sanding the decorative surface with grinding belt whose mesh is above 200m to obtain a base material with a thickness tolerance of + / -0.3mm and an angularity of less than 2%; combining the base material, the faced layer, the balance layer into a blank, heat pressing for not less than 20 seconds at the temperature above 150 degree Centigrade and pressure above 5Mpa; then cooling the treated base material for 8 hours or longer, cutting and machining into the finished product in the mortising machine.

Owner:段素英

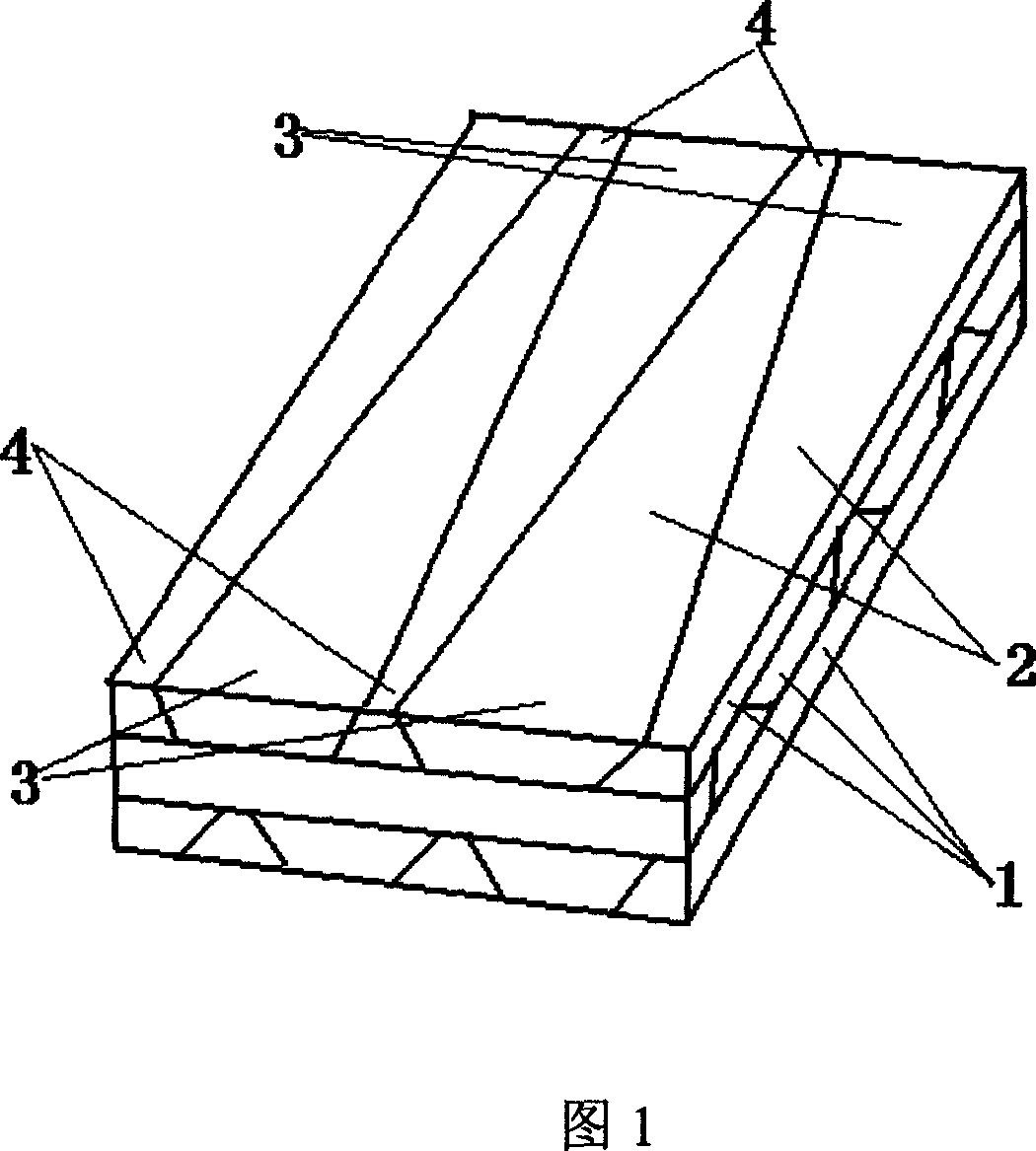

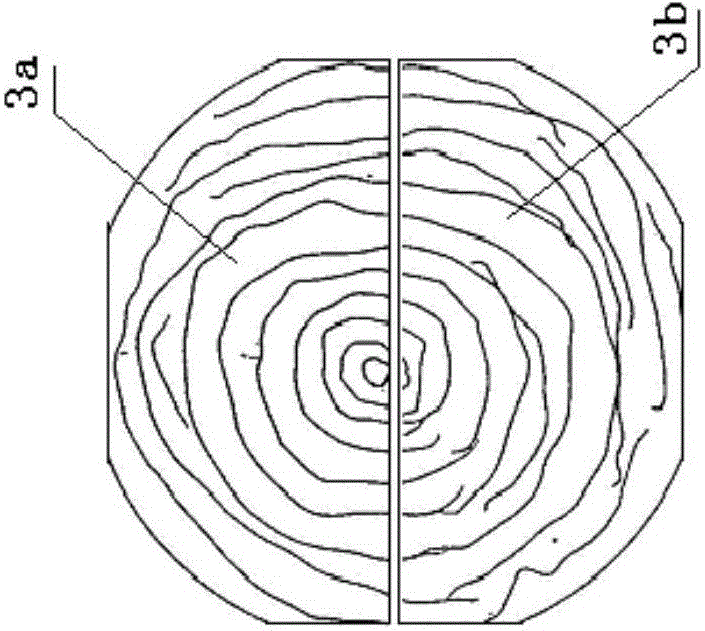

Lumber and the processing method

InactiveCN101041243AUniform deformation and internal stressIncrease profitWood veneer joiningWood layered productsSolid woodEngineering

The invention discloses a solid wood. The figure of flat plane direction of splicing plate (2) is trapezoid. The height direction of said trapezoid is the longitudinal direction of wood fiber. Two ends of splicing plate (2) are the big end (3) and the small end (4) of splicing plate respectively according to the long bottom margin and the short bottom margin of trapezoid. Big ends (3) and small ends (4) of adjacent splicing plates (2) are arranged in cross with each other. The invention makes wood with difference in different position be distributed reasonably so as to make inner stress and deformation of product uniform. The invention makes full use of the natural figure of original material produce product so as to improve the using rate of wood. It makes full use of the natural figure of original material splice product to decrease the processing volume and improve the producing efficiency.

Owner:冯士祥

Toughened ceramic for insulator and preparation method of toughened ceramic

The invention discloses toughened ceramic for an insulator and a preparation method of the toughened ceramic. The toughened ceramic is prepared from, by weight, 2-3 parts of aluminum borate whiskers, 70-80 parts of silicon carbide micro powder with the proper size, 20-30 parts of aluminum nitride micro powder with the proper size, 1-1.5 parts of calcium fluoride powder, 10-15 parts of carbon powder, 10-15 parts of molybdenum silicide, 6-8 parts of ethyl orthosilicate, 3-5 parts of absolute ethyl alcohol, 3-5 parts of purified water and 1.5-2.5 parts of thermoplastic phenolic resin. By means of the steps of raw material preparation, insulator pre-preparation, insulator sintering and completing, the high-tenacity insulation ceramic with the volume resistivity larger than or equal to 2*1,013 omega-cm, the dielectric strength larger than or equal to 750 kV / cm, the thermal conductivity larger than or equal to 25 W / m.K, the bending strength larger than or equal to 400 Mpa, the Young modulus larger than or equal to 320 Gpa and the breaking tenacity larger than or equal to 25 Mpa is formed. The toughened ceramic is good in economical efficiency, resistant to high temperature oxidation and high in breaking tenacity, and the functions of main materials complement one another.

Owner:宁波高智科技咨询服务有限公司

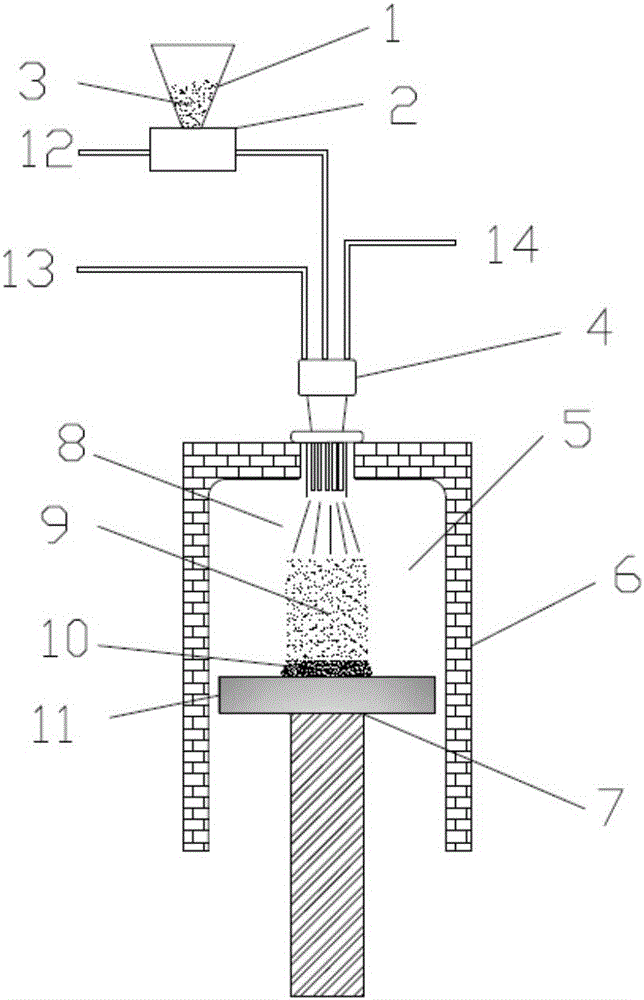

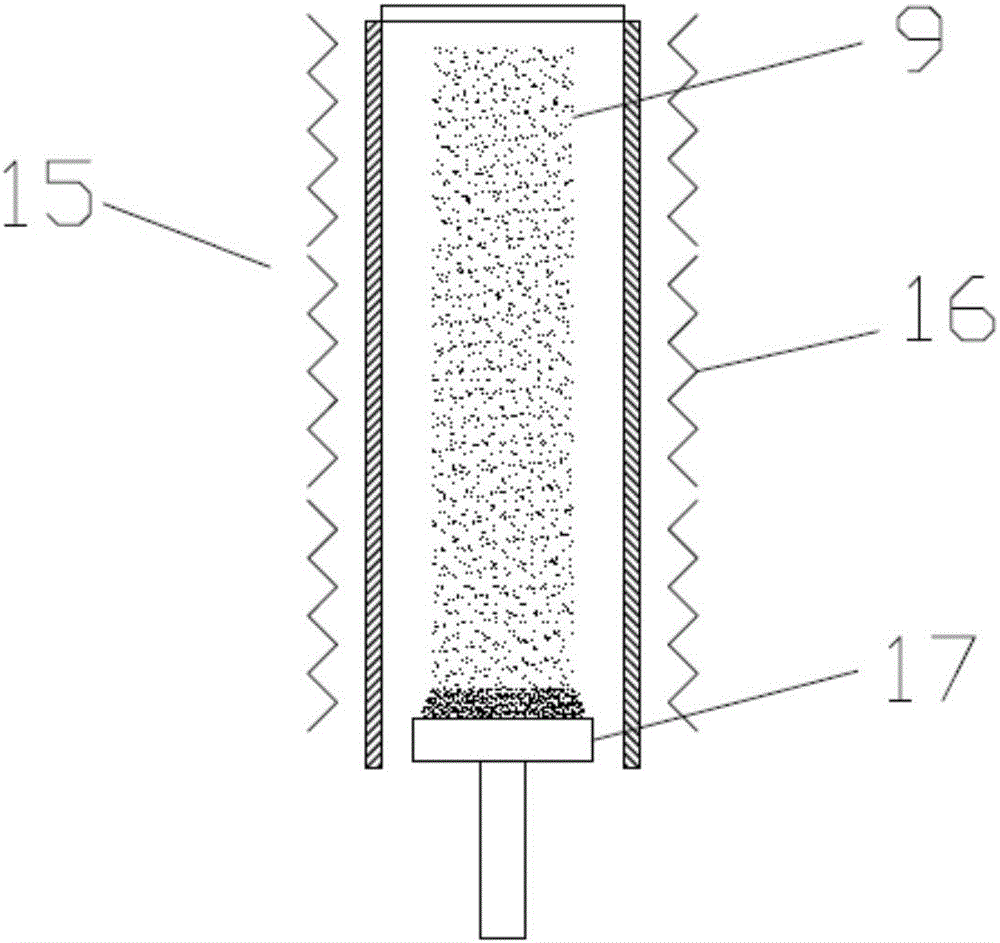

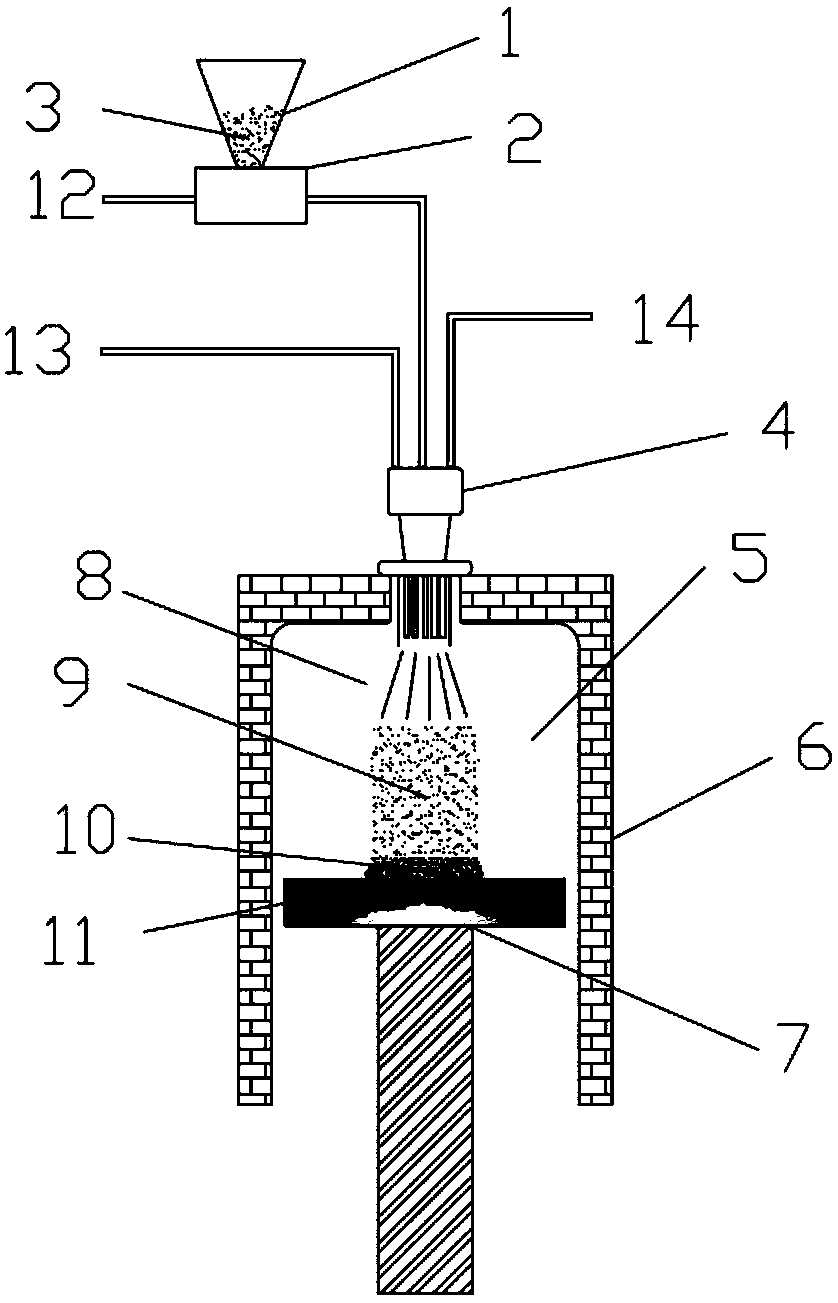

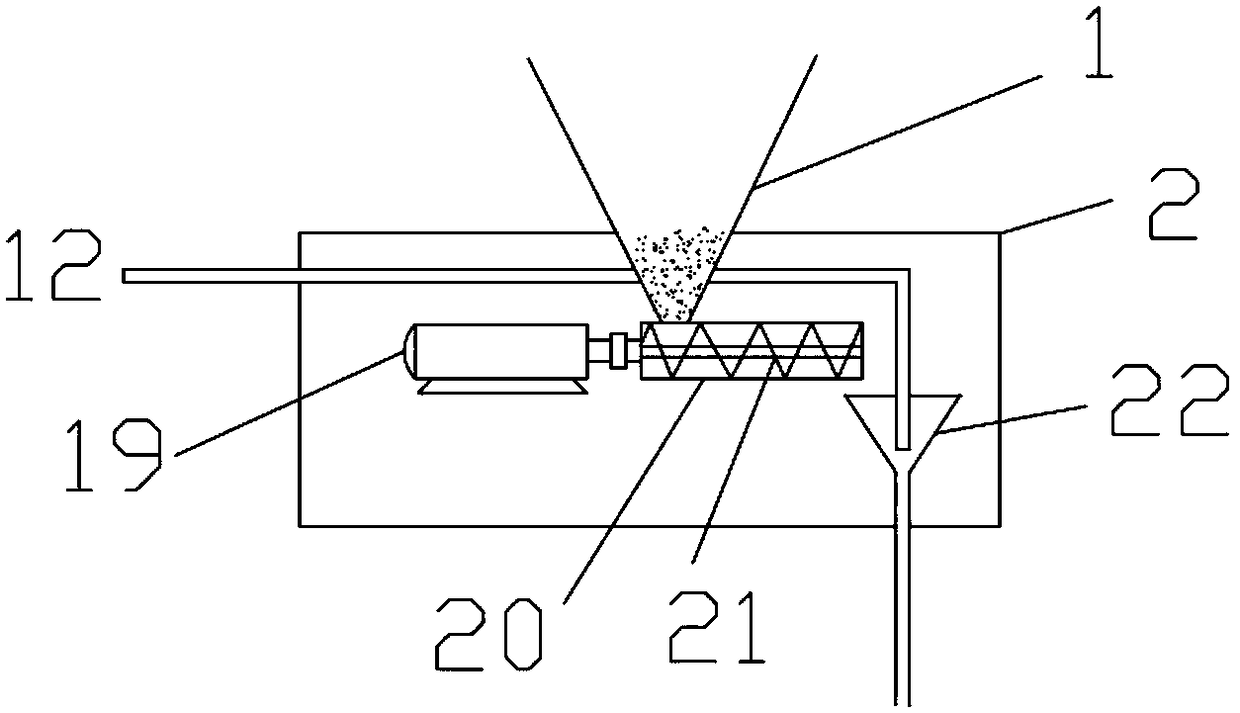

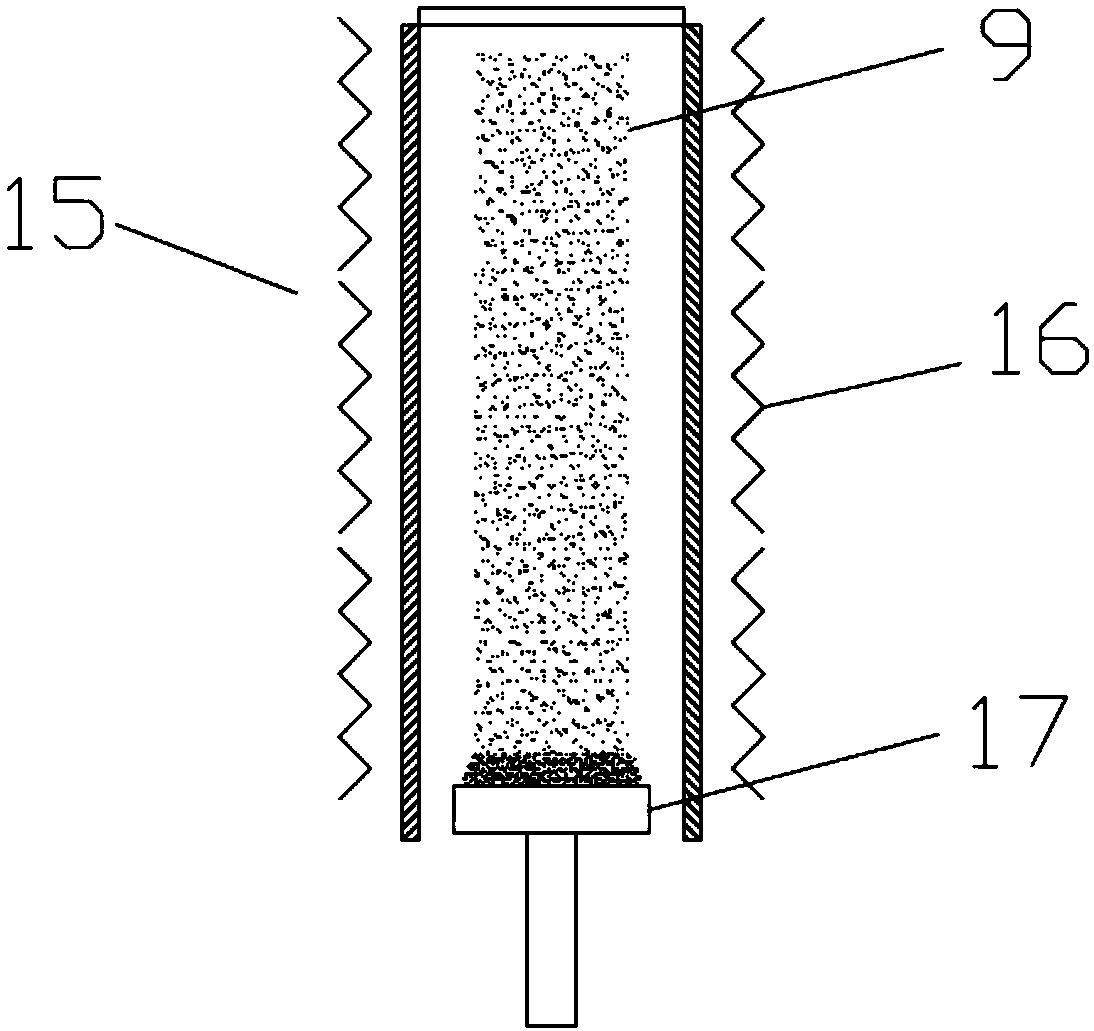

Preparation method of quartz glass

The invention discloses a preparation method of quartz glass. The method comprises the steps of: (a) heating quartz particles to partial melting to form a porous quartz body; (b) subjecting the porous quartz body obtained in step (a) to dehydration treatment so as to obtain a dehydrated porous quartz body; and (c) heating and sintering the porous quartz body obtained in step (b) to form the quartz glass. The invention relates to the technical field of preparation of a quartz glass material from quartz sand or quartz powder through oxyhydrogen flame, as a breakthrough, quartz sand at a semi-molten state is sprayed to the porous quartz body, and the porous quartz body is dehydrated, the hydroxy content is greatly reduced to less than 15ppm, or even below 5ppm, thus improving the purity of the prepared quartz glass material without significant increase of the preparation cost by a simple preparation process and preparing the high purity quartz glass.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Plate material, solid wood composite floor base material and column material made from branch materials and round rod materials, and manufacturing method

The invention provides a plate material, a solid wood composite floor base material and a column material made from branch materials and round rod materials, and a manufacturing method. A core material is formed by splicing half-square round battens; each half-square round batten is a square round batten material obtained by cutting the front, back, left and right surfaces of the a round bar material into bastard faces and forming a circular arc between the two adjacent bastard faces; the square round batten material is sawed into two symmetrical halves by through a center axial line and a bastard face center line to become two half-square round battens with the same cross sections; a part of a plurality of square round batten materials and / or half-square round battens and / or half-square round battens is combined according to requirements; the adjacent bastard faces are bonded to form the required column material, plate material or solid wood composite floor base material. Through the ingenious design and the simple process, the branch materials and the rod materials are made into various materials, so that the wood utilization rate is greatly improved; the precious wood resources are saved; the importing rare hardwood is reduced; the plate material cost is reduced. The purpose is wide; the solid-wood composite floor base material and various plate materials can be manufactured; partition walls, furniture, floor slabs, upright posts and cross beams can be made.

Owner:WUHAN WANGRENZHONG NOVEL SHEET MATERIAL INVESTMENT MANAGEMENT CO LTD

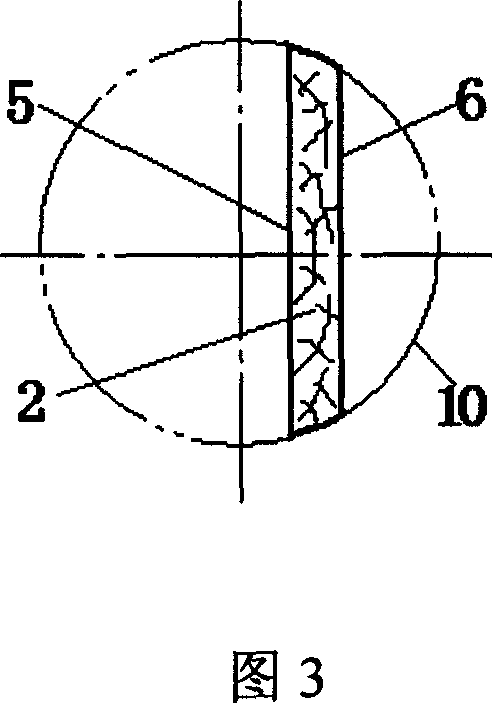

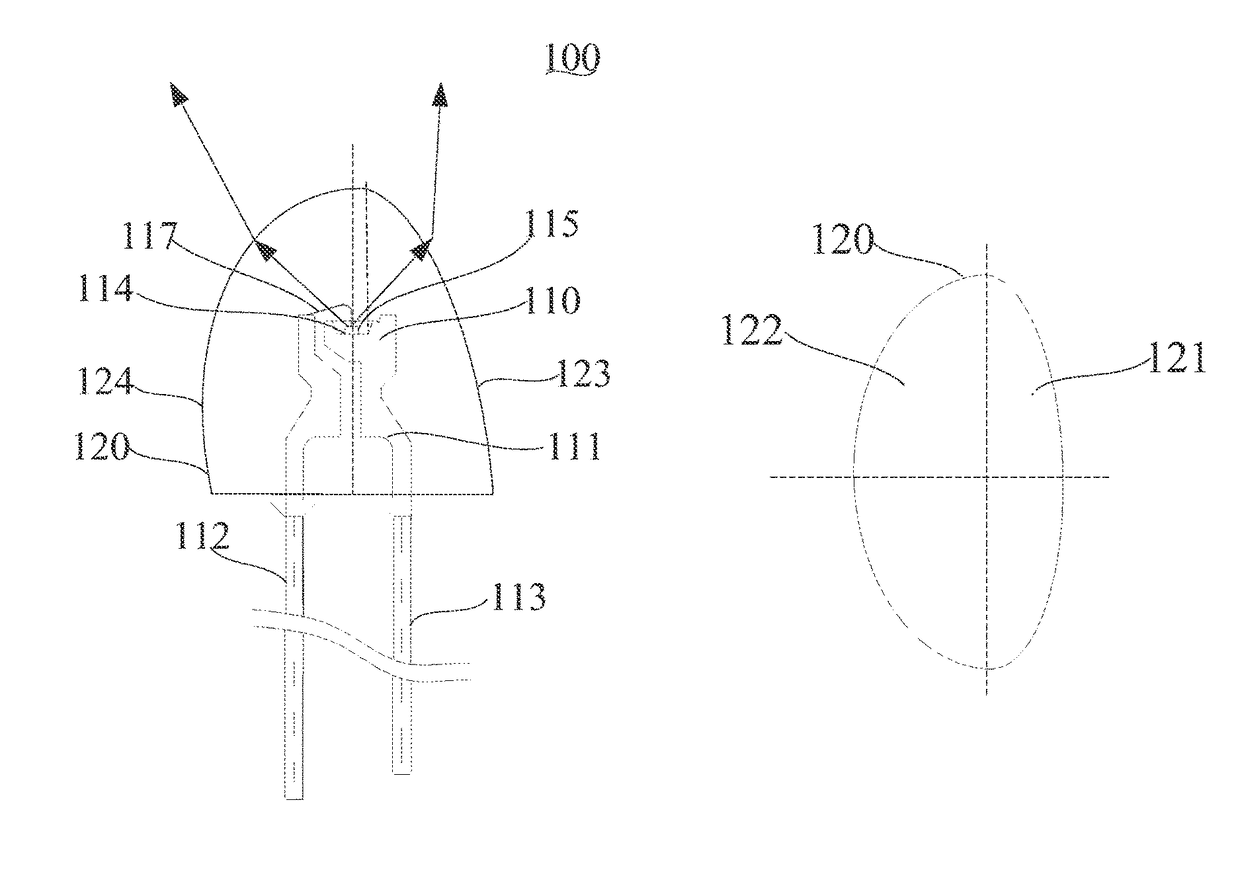

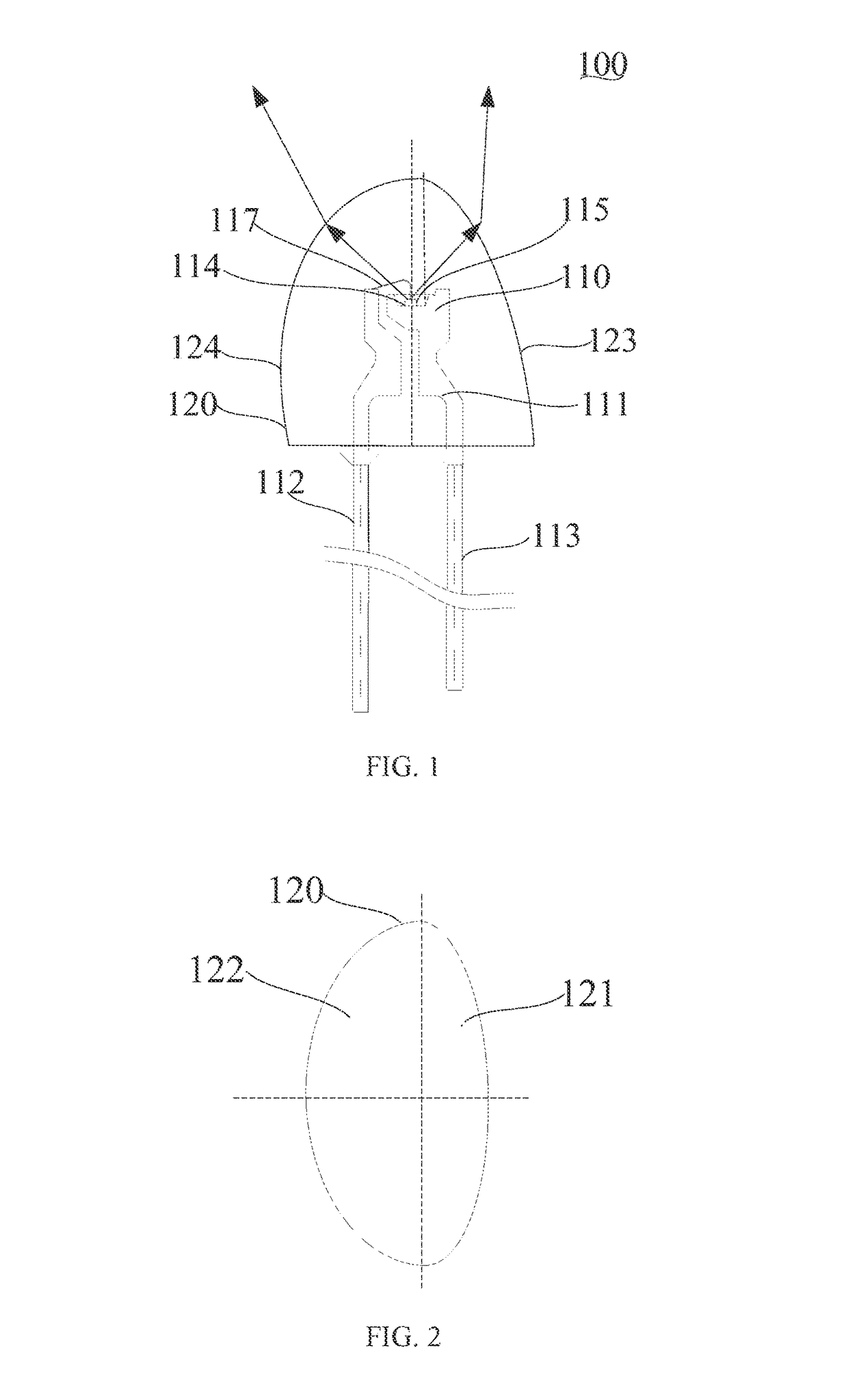

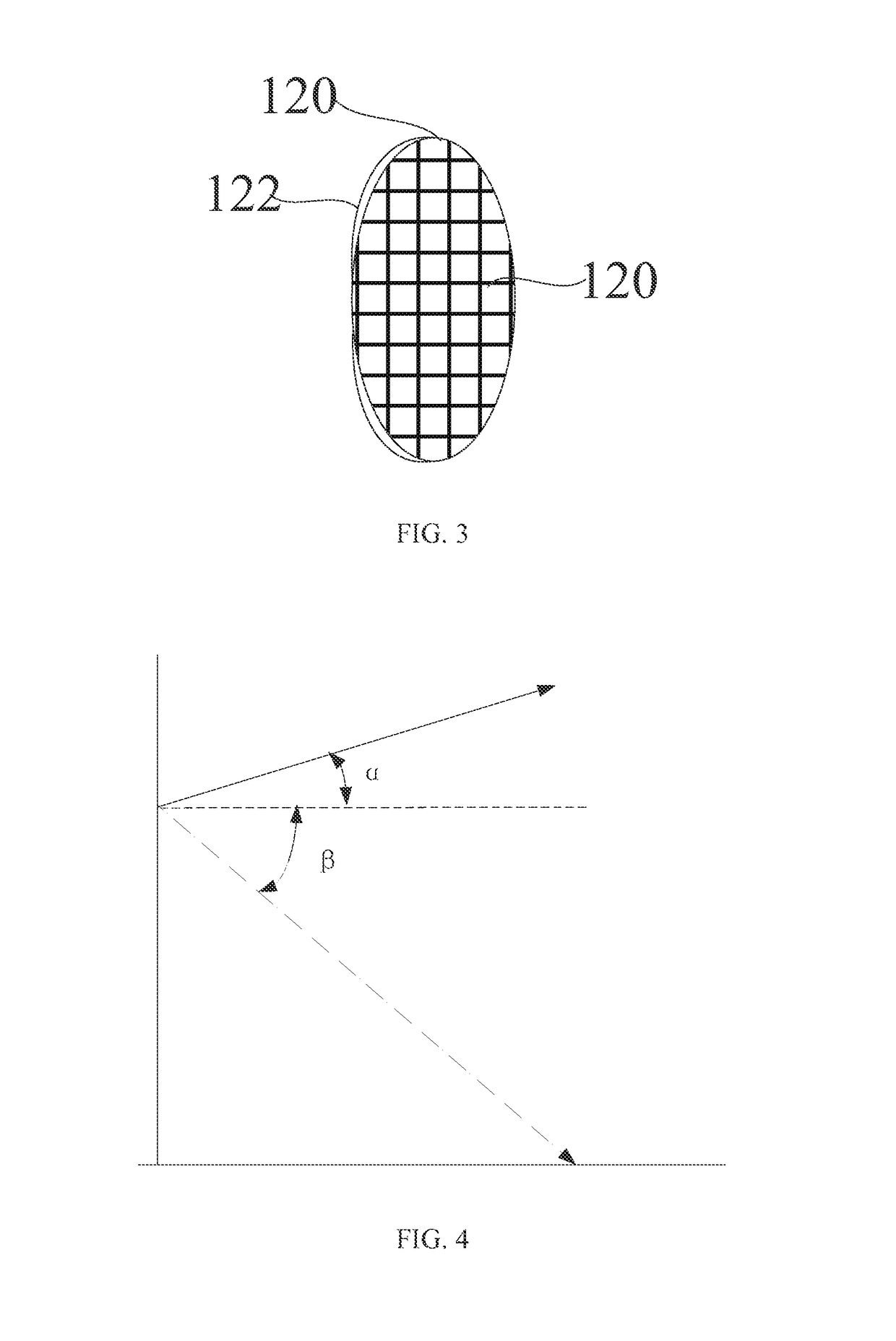

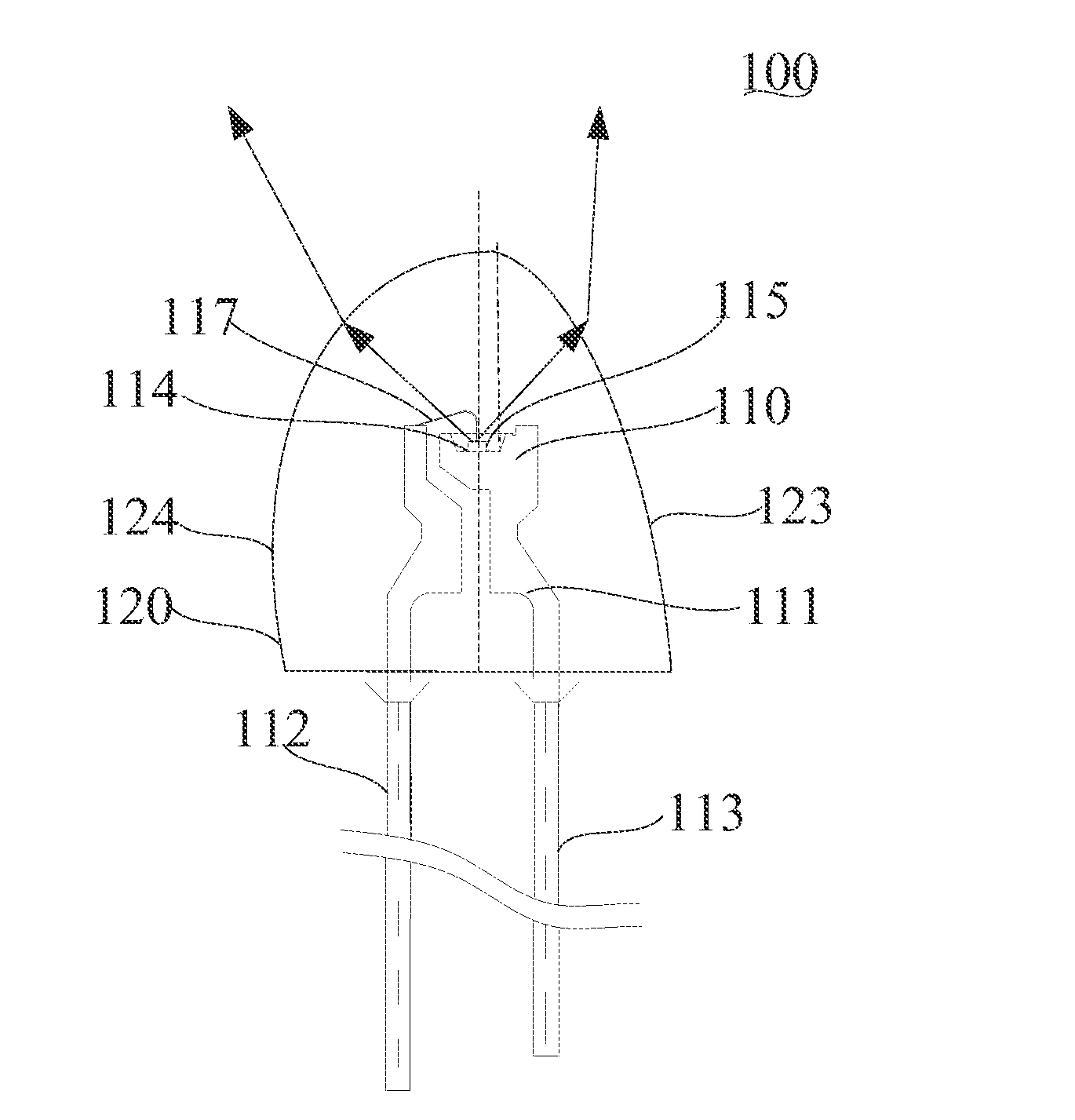

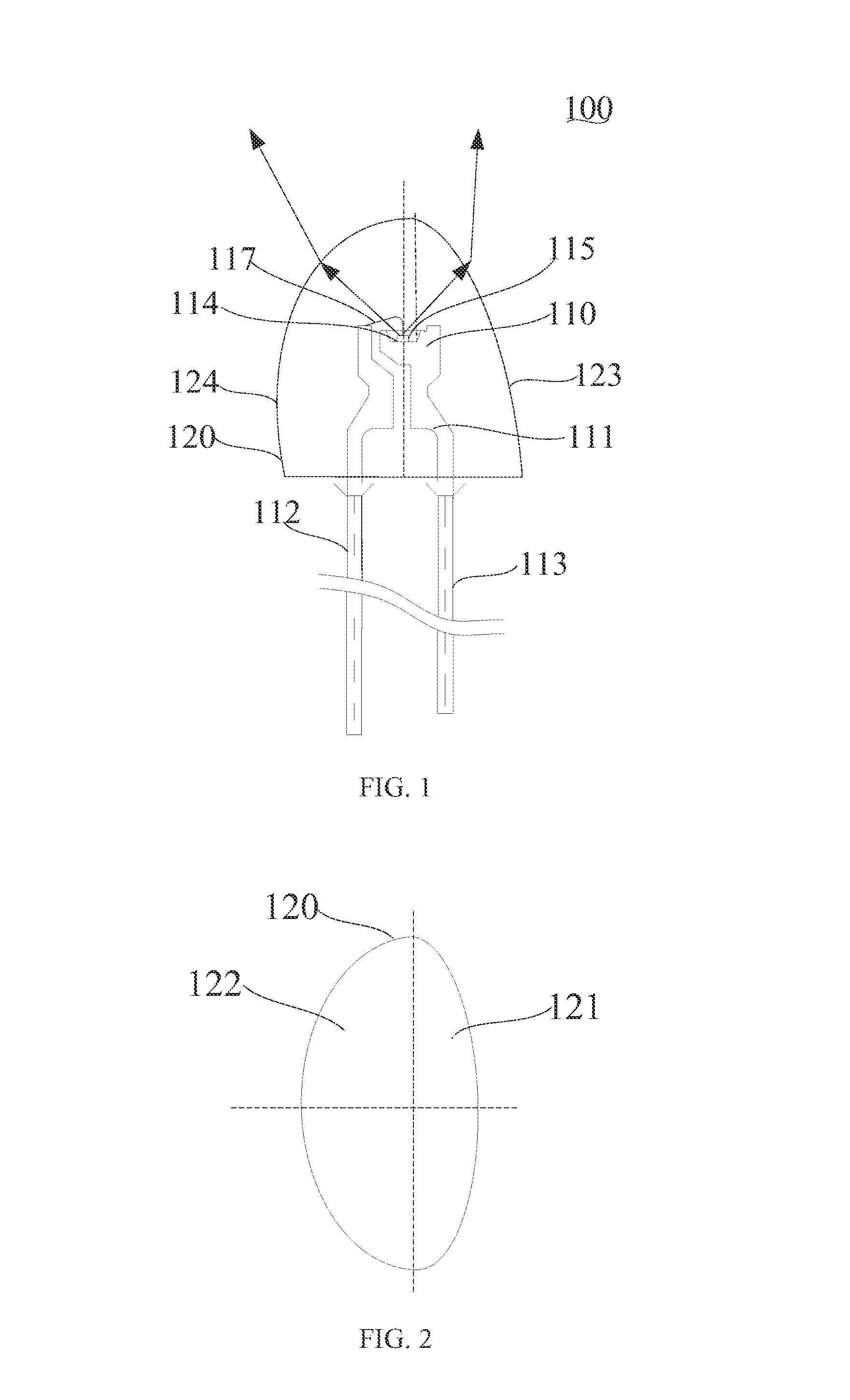

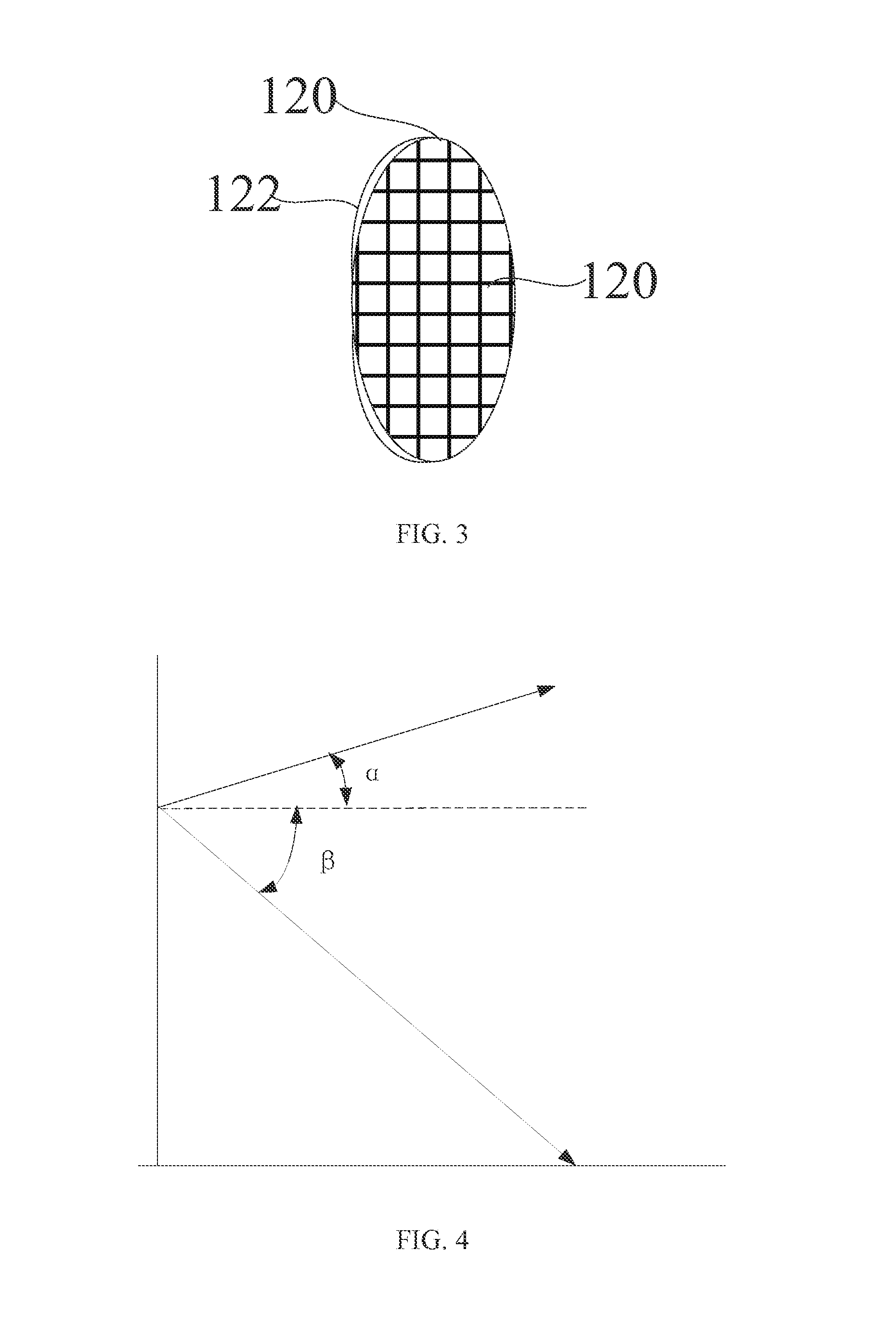

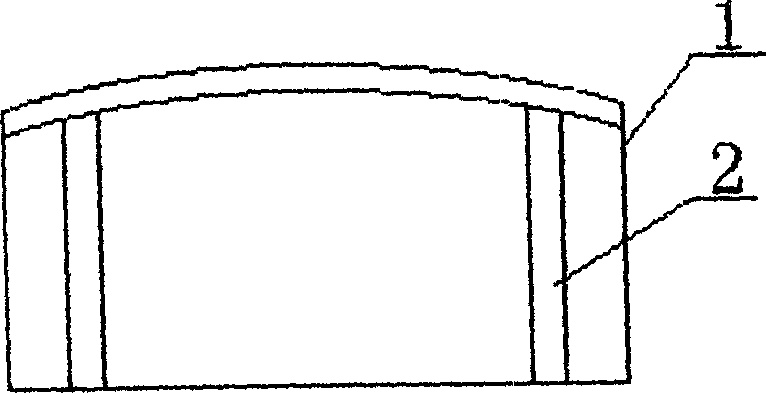

LED and LED packaging method thereof

An LED is provided, the LED comprising a lighting assembly and a light bead. The light head encases the lighting assembly. A cross-section of an upper portion of the light bead is an asymmetric shape with respect to the projection of a normal of the lighting assembly on the cross-section of the upper portion of the light bead, while a cross-section at the lower portion of the light bead perpendicular to the axis is a symmetric shape with respect to the projection of the normal of the lighting assembly on the cross-section at the lower portion of the light bead. The lighting assembly is located at a symcenter of the lower portion of the light bead. The aforementioned LED can increase its visible range, and can ensure an even distribution of the internal stress surrounding the lighting assembly. An LED packaging method is also provided.

Owner:LEDMAN OPTOELECTRONICS CO LTD

Toughened glass insulator and fabrication method thereof

The invention discloses a toughened glass insulator and a fabrication method thereof. The insulator at least can resist lightning steep slope peak 6,000kV / s and can stand repeated circulation impact of -50 to 50 DEG C in a standard load condition, a standard load can be still supported after self explosion at 0 DEG C, the surface pressure stress is not lower than 150Mpa, the impact strength of an U-shaped gap is not lower than 20J / cm<2>, and the light transmittance is not lower than 98%. On the basis that lead glass belonging to toughened glass, lanthanum oxide and bismuth oxide which are used for improving chemical stability and light transmittance of glass are added, zirconium oxide and titanium oxide which are used for improving acid and alkali resistance, light transmittance and radiation protection capability of the glass are also added, and the toughened glass insulator is finally fabricated through tempering under the protection of nitrogen. The toughened glass insulator has the advantages of good electrical property, high automatic fracture toughness, high light transmittance, good integrated mechanical property, long service lifetime and good economy.

Owner:河南新弘电力科技有限公司

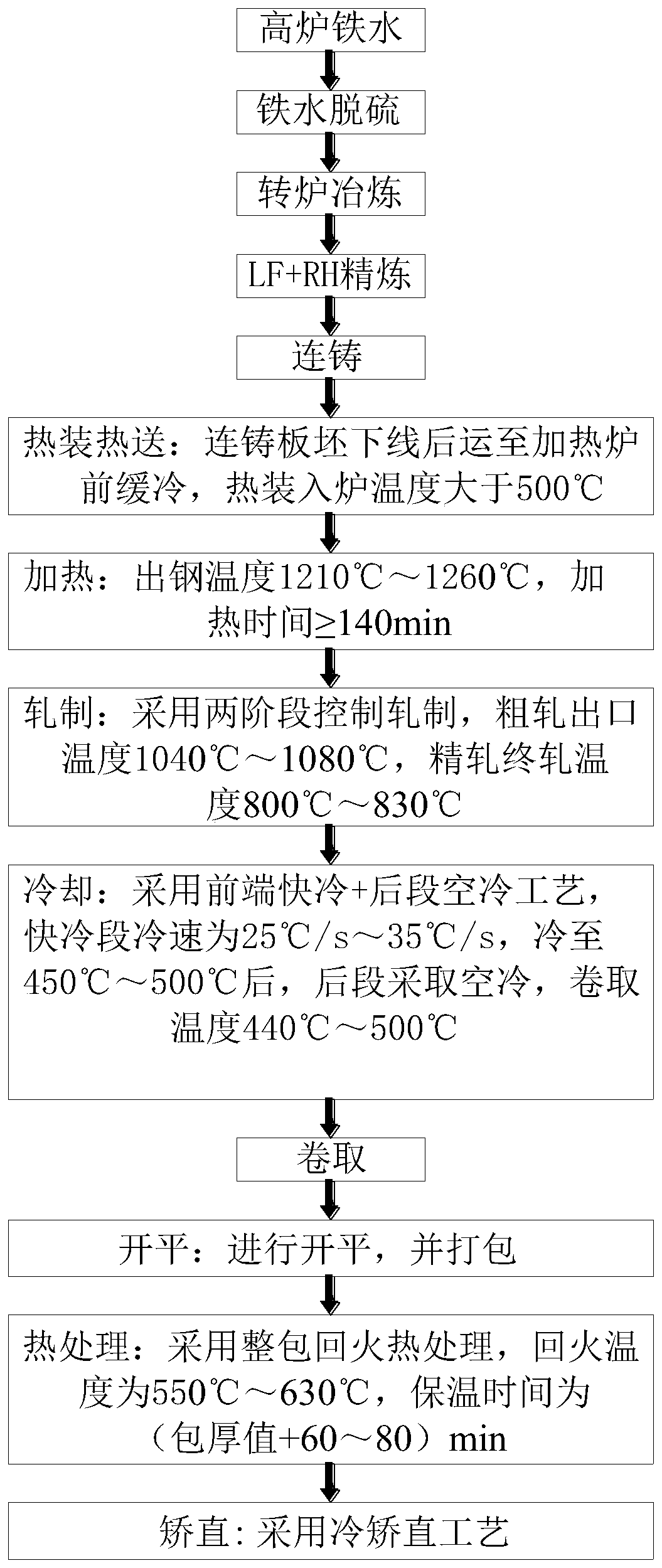

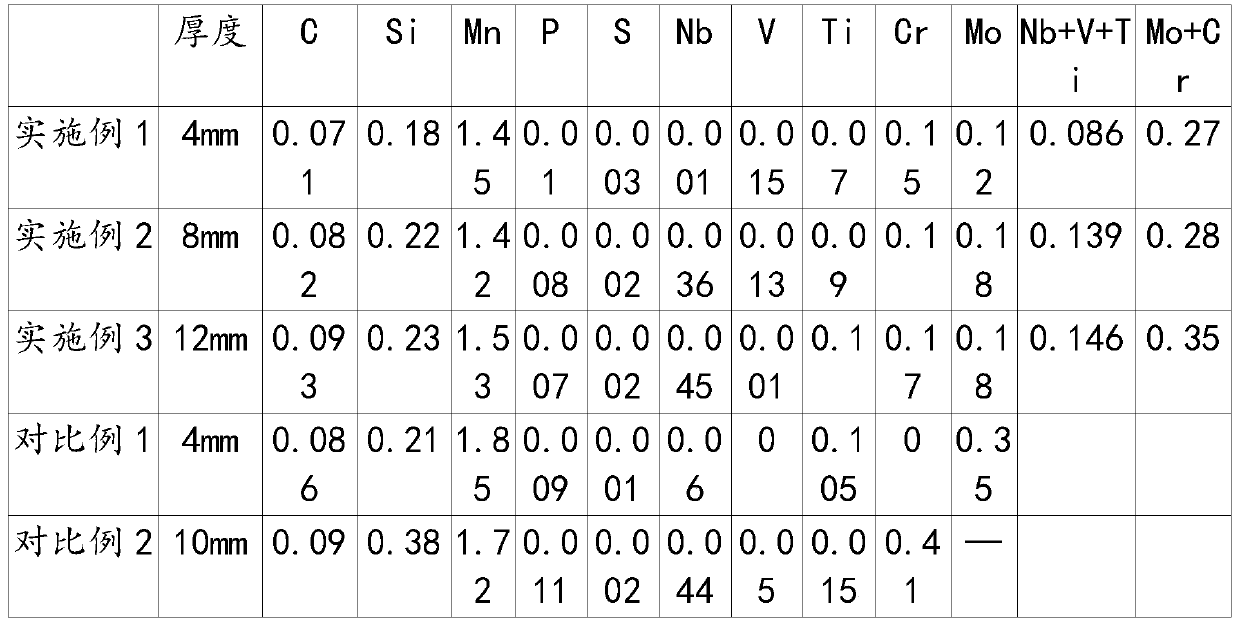

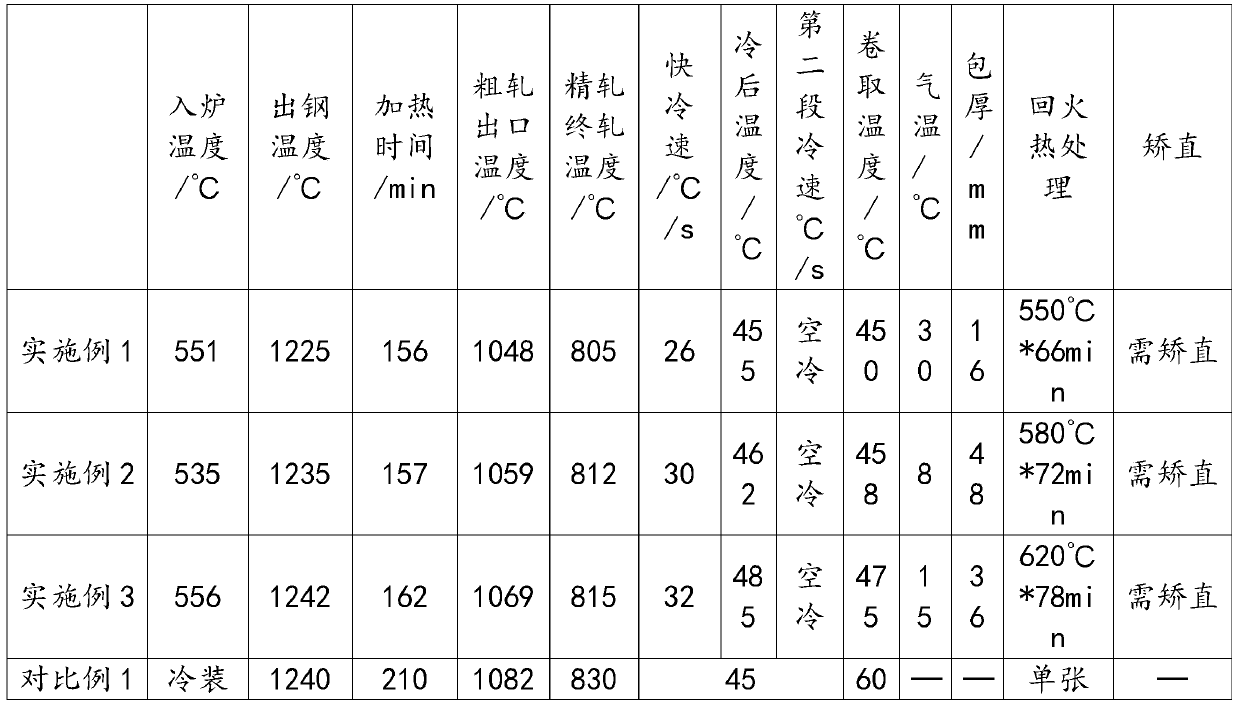

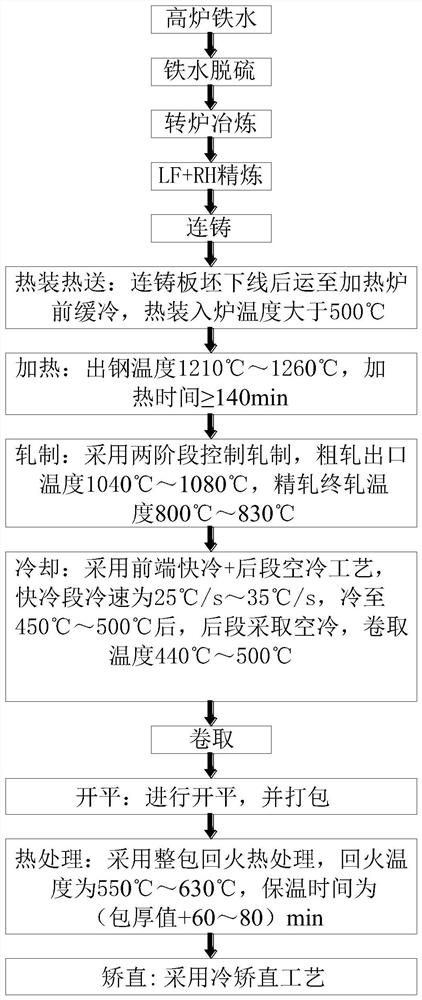

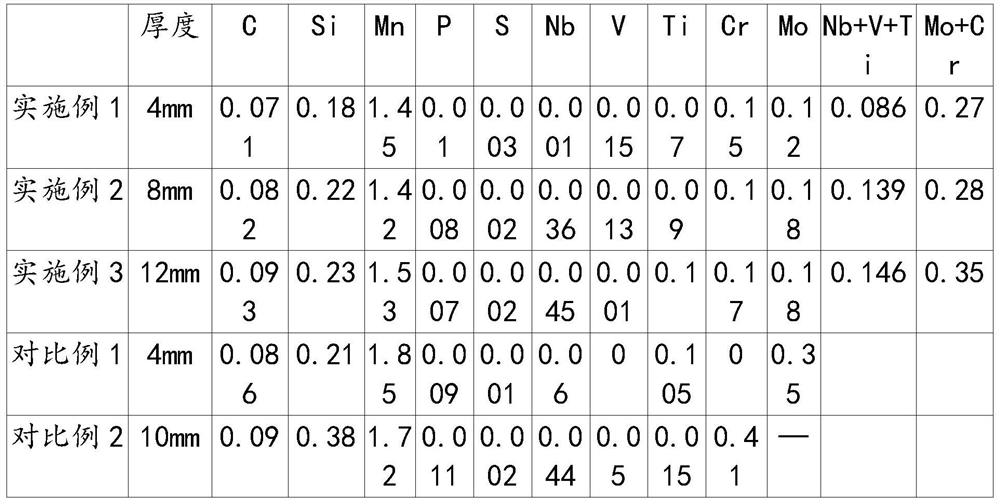

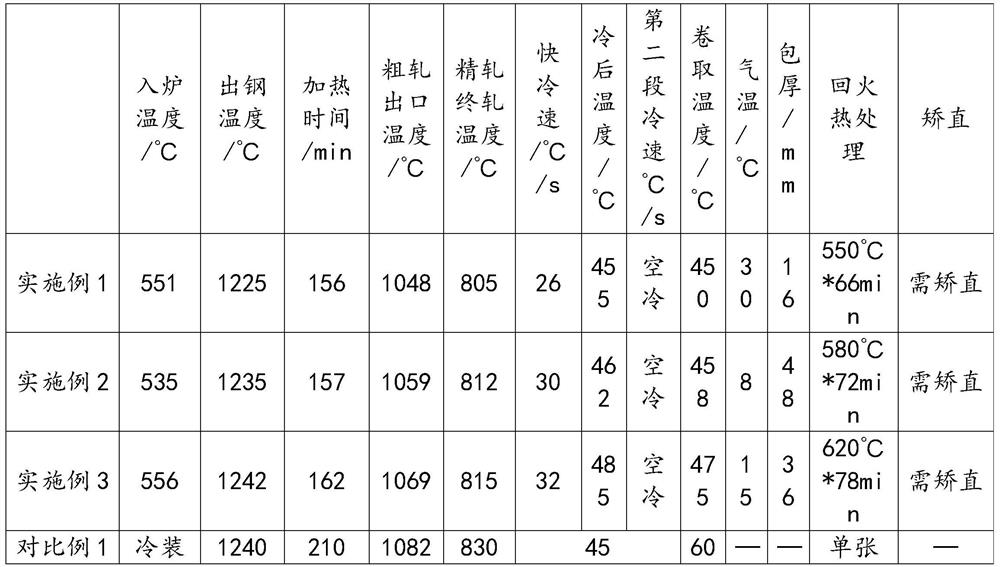

Thin size high-strength steel for engineering machinery and strip shape control method

ActiveCN110106322AGood value for moneyImprove mechanical propertiesFurnace typesHeat treatment furnacesContinuous castingBlast furnace

The invention relates to thin size high-strength steel for engineering machinery. The steel is prepared from the following components in percentage by mass: 0.07%-0.10% of C, 0.15%-0.30% of Si, 1.2%-1.6% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0%-0.08% of Nb, 0%-0.07% of V, 0.06%-0.13% of Ti, 0.1%-0.2% of Cr, 0.1%-0.2% of Mo, 0.08%-0.15% of Nb+V+Ti, 0.25%-0.35%of Mo+Cr, and the balance Fe and impurities. The the strip shape control method is characterized in comprising blast furnace molten iron, molten iron desulfurization, converter smelting, LF+RH refining, continuous casting, hot charging and hot conveying, heating, rolling, cooling, coiling, flattening, tempering heat treatment and straightening process. According to the steel, the yield strength is greater than 690 MPa, the tensile strength is greater than 785 MPa, and the impact work at minus 20 DEG C is greater than 100 J.

Owner:武汉钢铁有限公司

Ceramic insulator with built-in tough frame and manufacturing method thereof

InactiveCN106278340AGood thermal conductivityEvenly heatedFibre chemical featuresTetraethyl orthosilicateDielectric strength

The invention discloses a ceramic insulator with a built-in tough frame and a manufacturing method thereof. The ceramic insulator comprises the following raw materials in parts by weight: 50-60 parts of silicon carbide powder, 10-15 parts of carbon powder, 10-15 parts of silicon dioxide, 6-8 parts of tetraethyl orthosilicate, 3-5 parts of anhydrous ethanol, 3-5 parts of pure water and 1.5-2.5 parts of thermoplastic phenolic resin. A central radial basket-shaped fiber touch frame woven from graphitized carbon fiber is implanted at the center of the ceramic insulator. The ceramic insulator disclosed by the invention has a volume resistivity of not less than 5 *10<12>.cm and a dielectric strength of not less than 650 kv / cm, a thermal conductivity of not less than 45 omega / m .K, a bending strength of not less than 550Mpa, a Young's modulus of not less than 400Gpa, and a fracture toughness of not less than 30Mpa. The ceramic insulator disclosed by the invention has the advantages of good internal thermal conductivity, good frame structure support, and good impact resistance and high temperature oxidation resistance.

Owner:宁波高智科技咨询服务有限公司

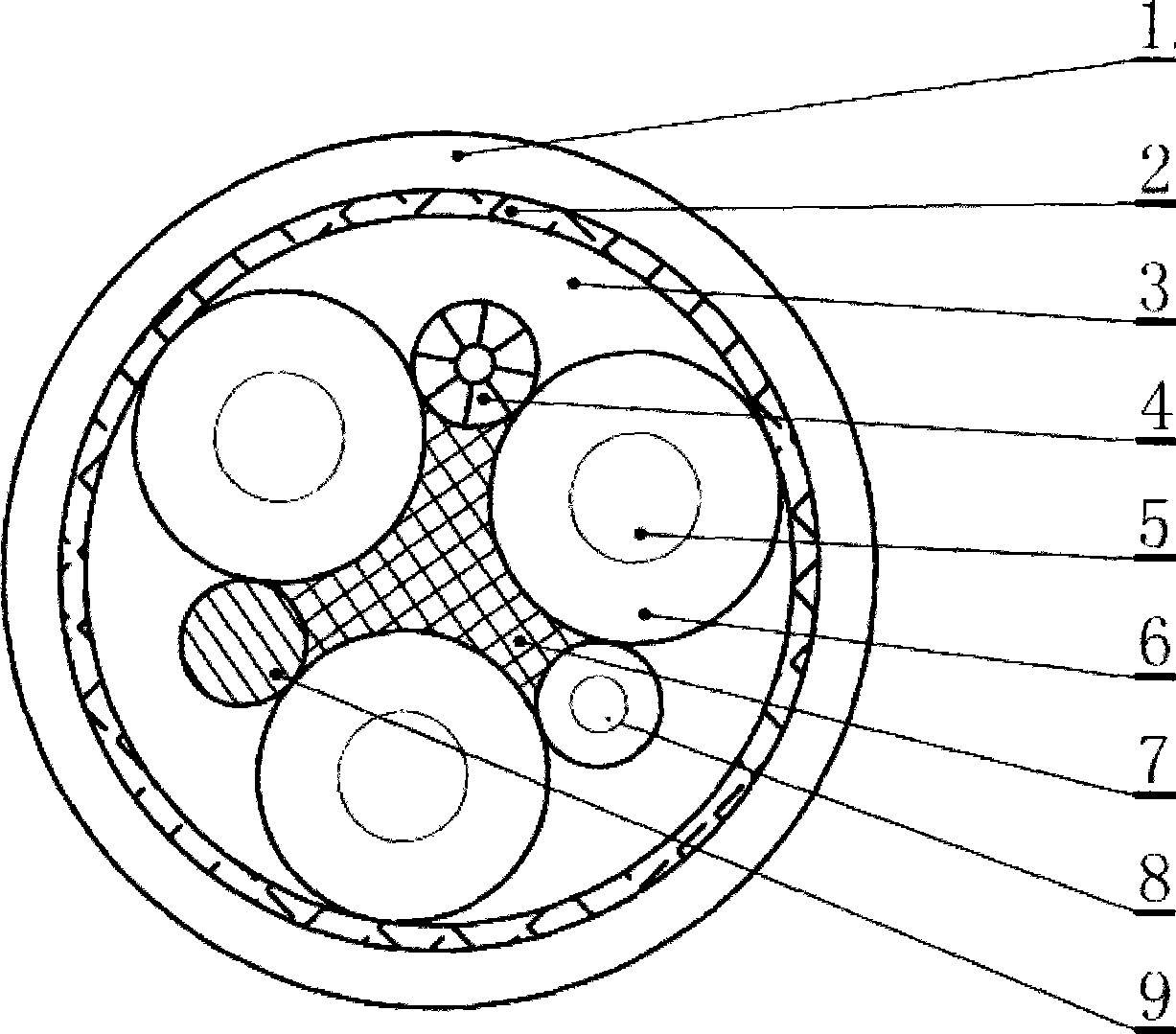

Electro-optic compound port machine pony roll high-voltage cable and production method thereof

InactiveCN101546629ASolving Electrical Induction ProblemsRealize optical/electrical functionRubber insulatorsInsulated cablesWaddingEngineering

The invention relates to an electro-optic compound port machine pony roll high-voltage cable, which consists of three main high-voltage wire cores, an optical cable, an earthing core, a wadding core, a saddle-shaped skeleton strip, reinforcing layers and an outer sheath. The main high-voltage wire cores, the optical cable, the earthing core and the wadding core are positioned on the saddle-shaped skeleton strip; the optical cable, the earthing core and the wadding core are respectively positioned between two adjacent main high-voltage wire cores of three main high-voltage wire cores; and the reinforcing layer are covered outside the main high-voltage wire cores, the optical cable, the earthing core and the wadding core. A liner layer is filled in the interstice in the reinforcement layer, the outer sheath is arranged outside the reinforcing layer; in addition, the invention also relates to a method for producing the cable. The cable of the invention has the characteristics of no electric induction, less space occupation and long service life.

Owner:SHANGHAI NANYANG ELECTRICAL APPLIANCE

LED and LED packaging method thereof

ActiveUS20160126425A1Increase visible rangeImprove visibilitySolid-state devicesSemiconductor/solid-state device manufacturingLed packagingEngineering

An LED is provided, the LED comprising a lighting assembly and a light bead. The light bead encases the lighting assembly. A cross-section of an upper portion of the light bead is an asymmetric shape with respect to the projection of a normal of the lighting assembly on the cross-section of the upper portion of the light bead, while a cross-section at the lower portion of the light bead perpendicular to the axis is a symmetric shape with respect to the projection of the normal of the lighting assembly on the cross-section at the lower portion of the light bead. The lighting assembly is located at a symcenter of the lower portion of the light bead. The aforementioned LED can increase its visible range, and can ensure an even distribution of the internal stress surrounding the lighting assembly. An LED packaging method is also provided.

Owner:LEDMAN OPTOELECTRONICS

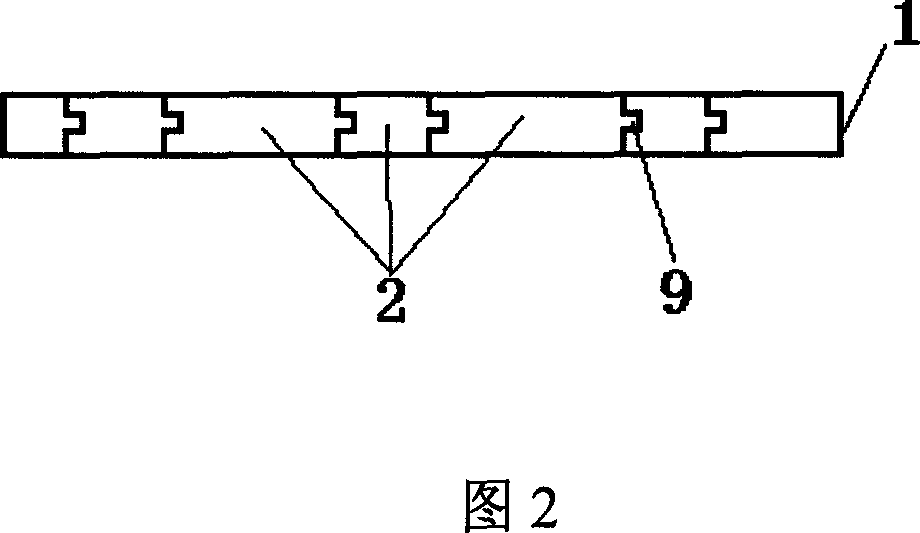

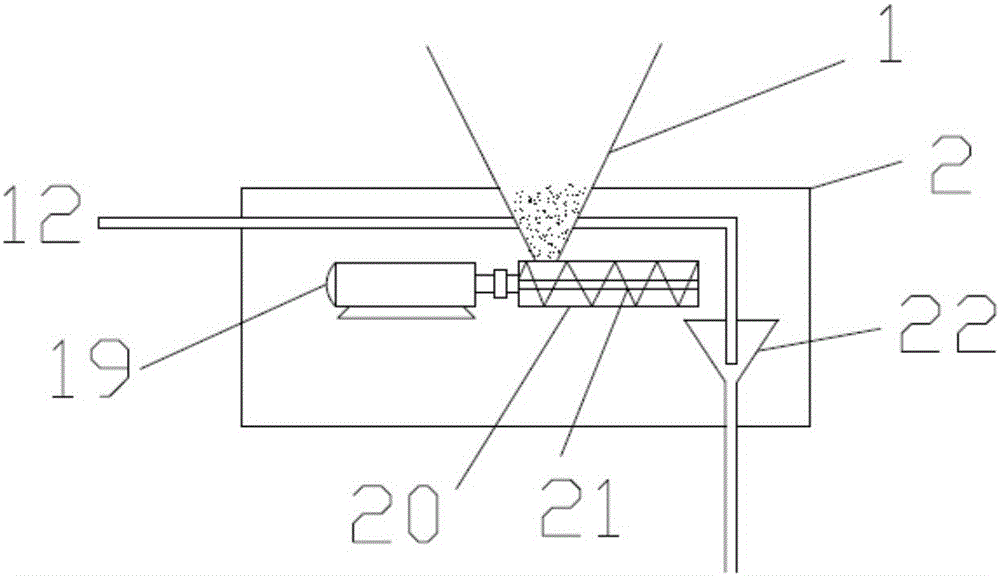

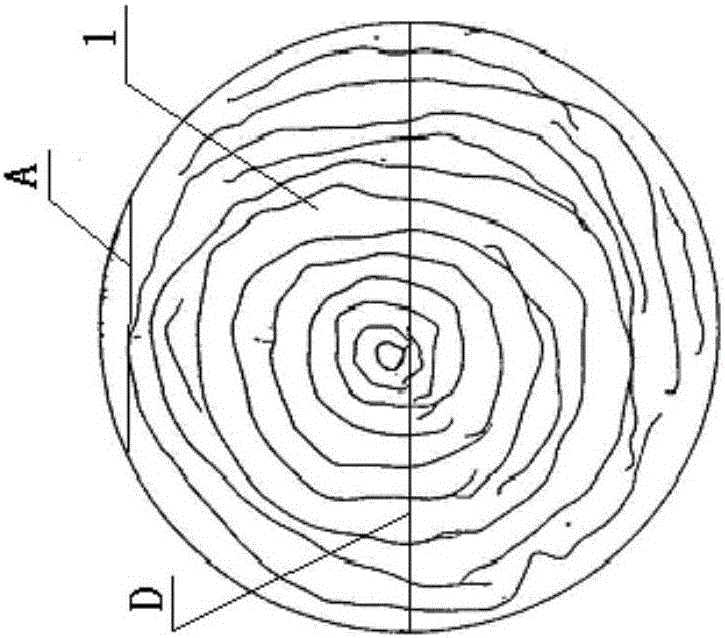

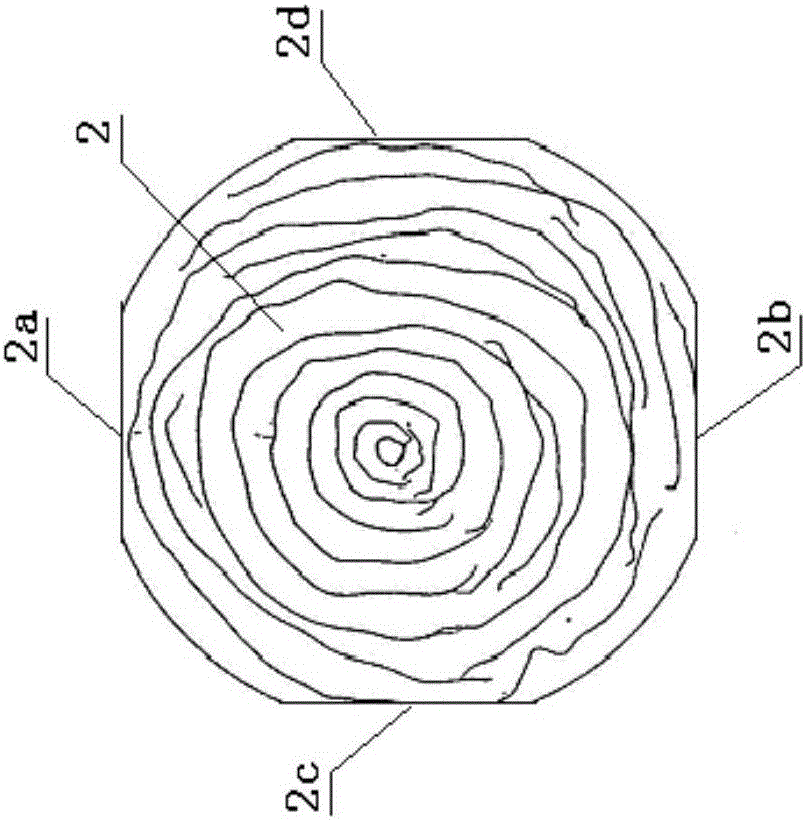

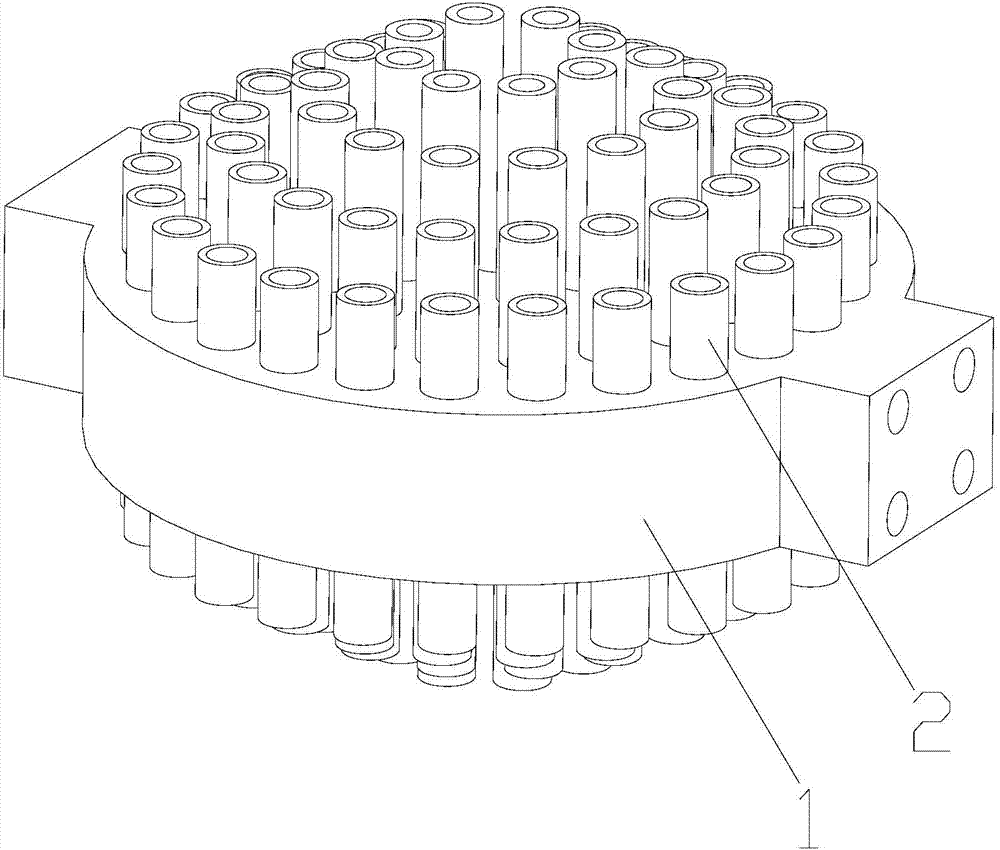

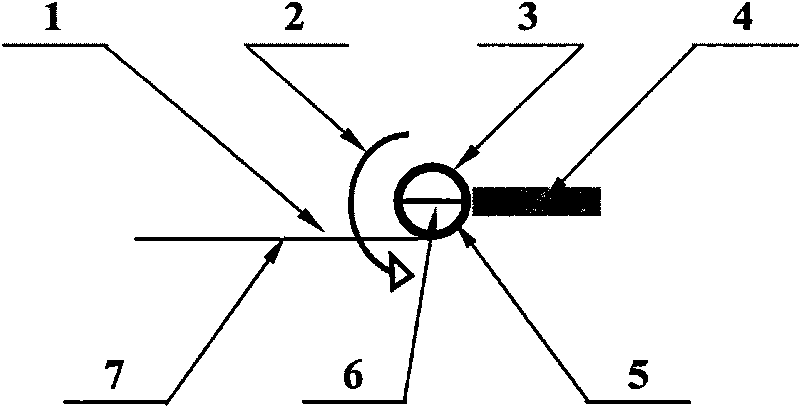

Wiring harness cabling device

ActiveCN104733135AUniform internal stressQuality improvementFibre mechanical structuresCable/conductor manufactureEngineeringInternal stress

The invention discloses a wiring harness cabling device. The wiring harness cabling device comprises a wire board and multiple through holes penetrating through the wire board, and the axes of the through holes are parallel; multiple through hole layers in concentric circles are formed in the end face of the wire board by the through holes, and the through holes are formed in the edges of the concentric circles at equal intervals, and the distances between every two adjacent through holes formed between the two corresponding adjacent through hole layers respectively are the same. According to the wiring harness cabling device, internal stress of multiple wiring harnesses in a cable can be uniformized, and core wires in the wiring harnesses are prevented from breaking, so that the quality of the cable is improved.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

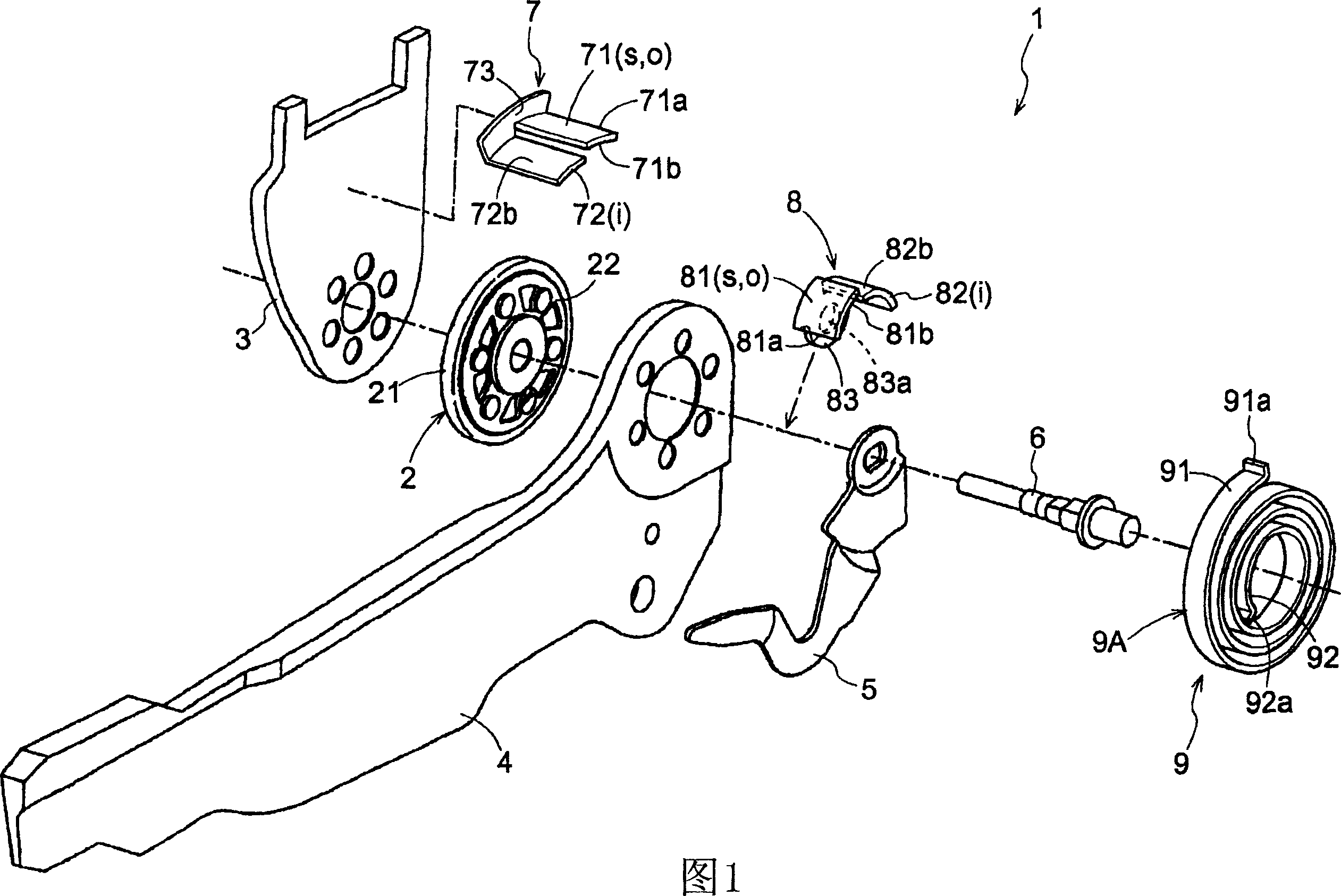

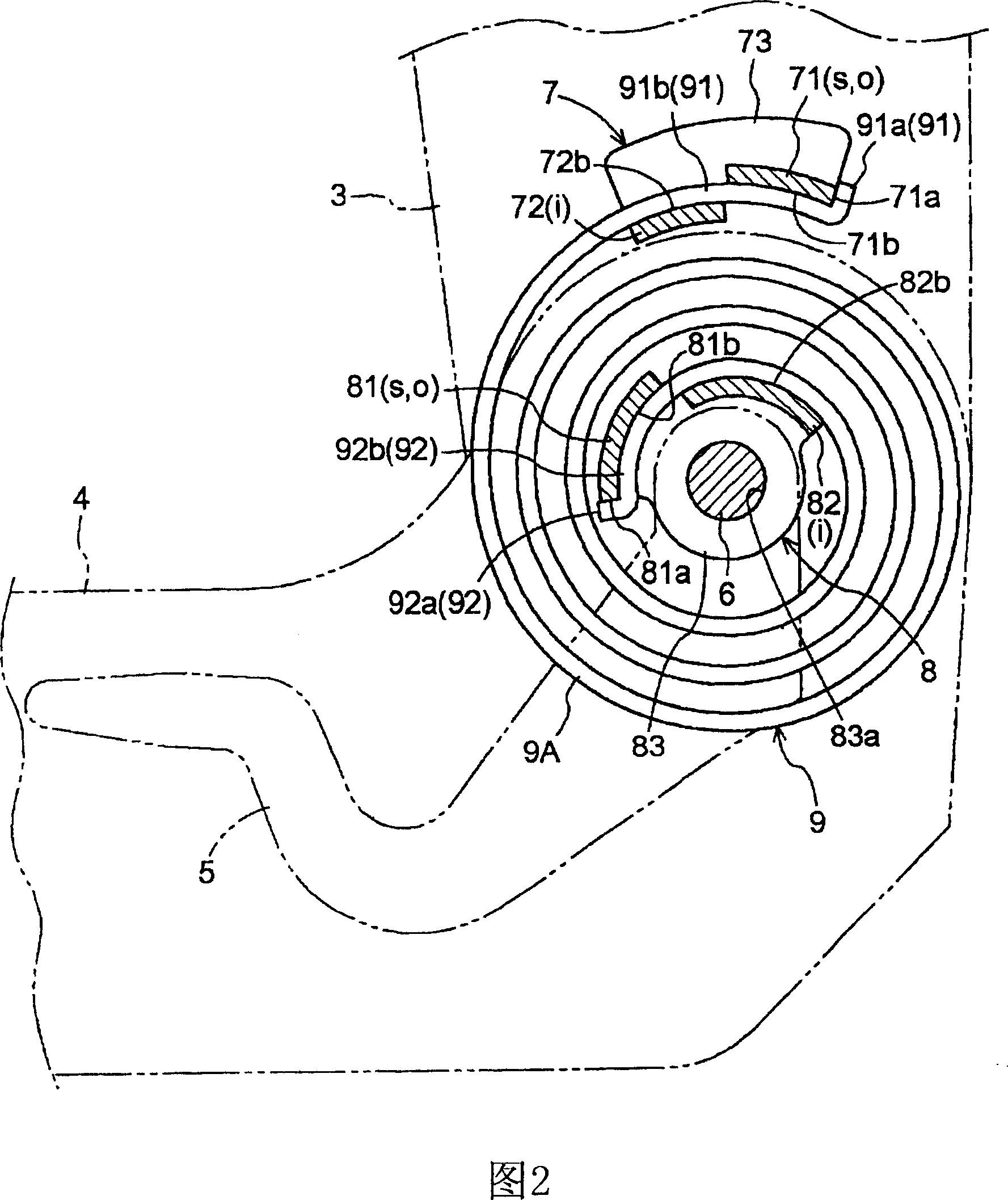

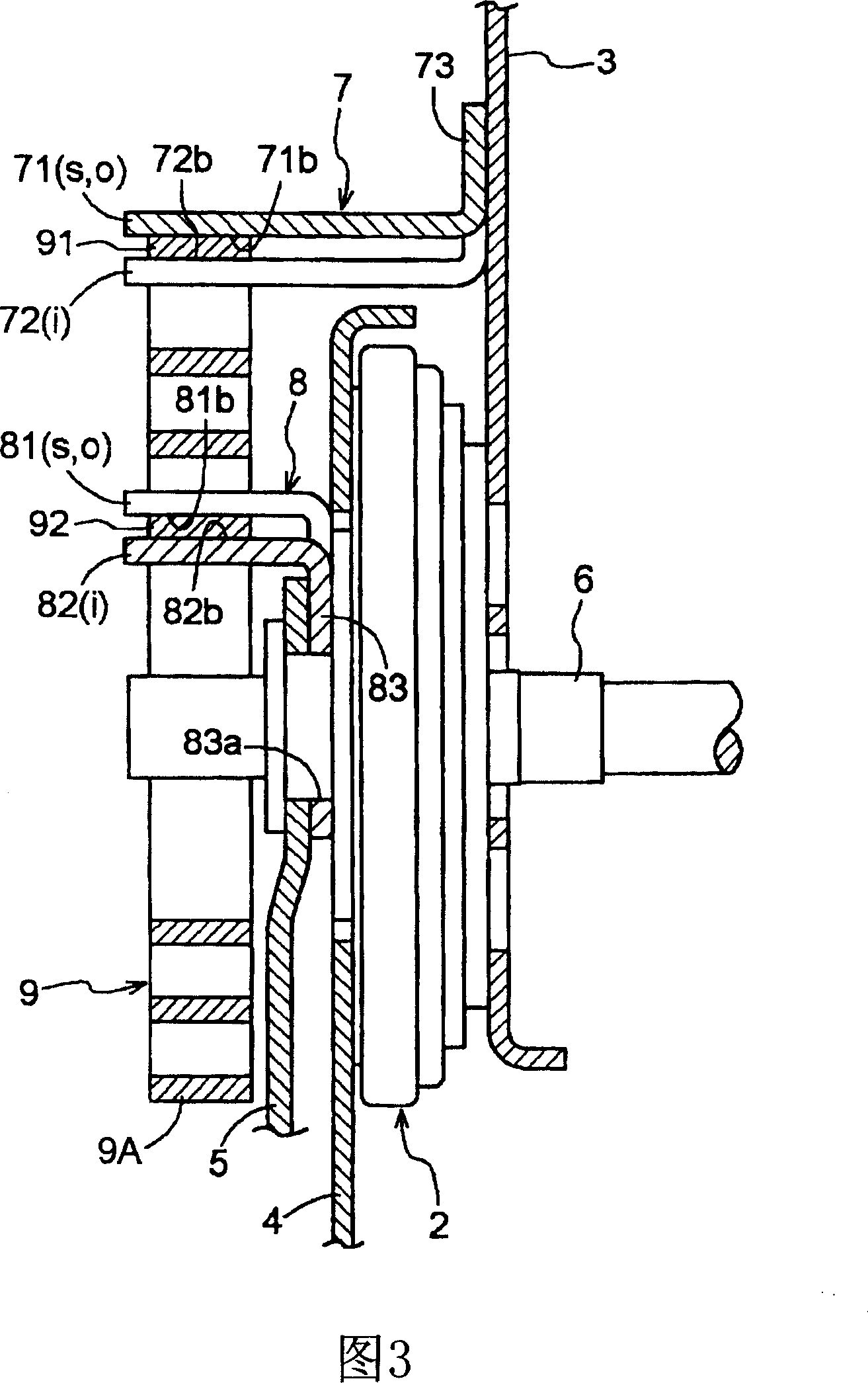

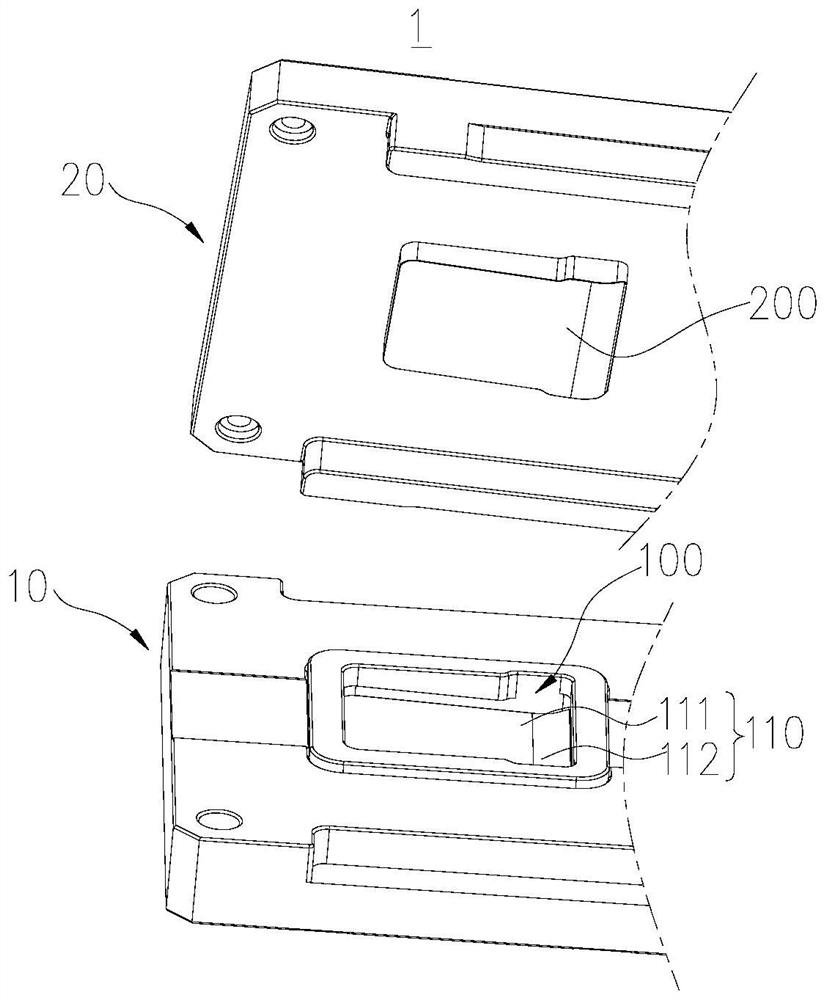

Seat reclining device

Owner:AISIN SEIKI KK

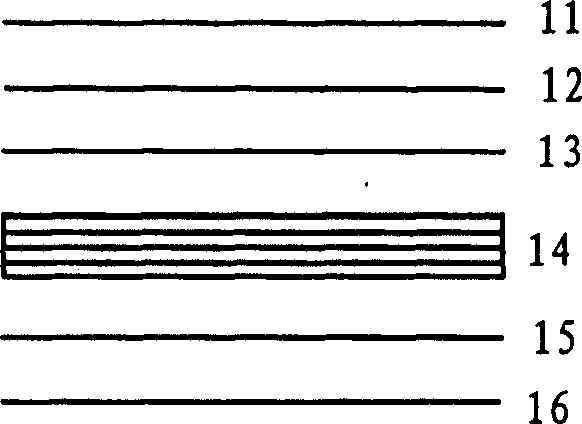

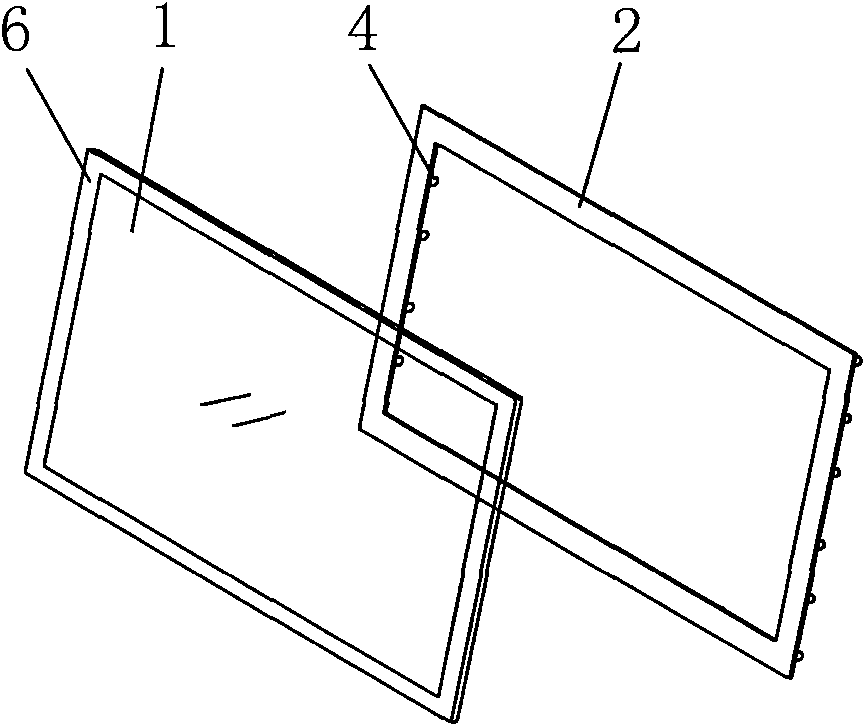

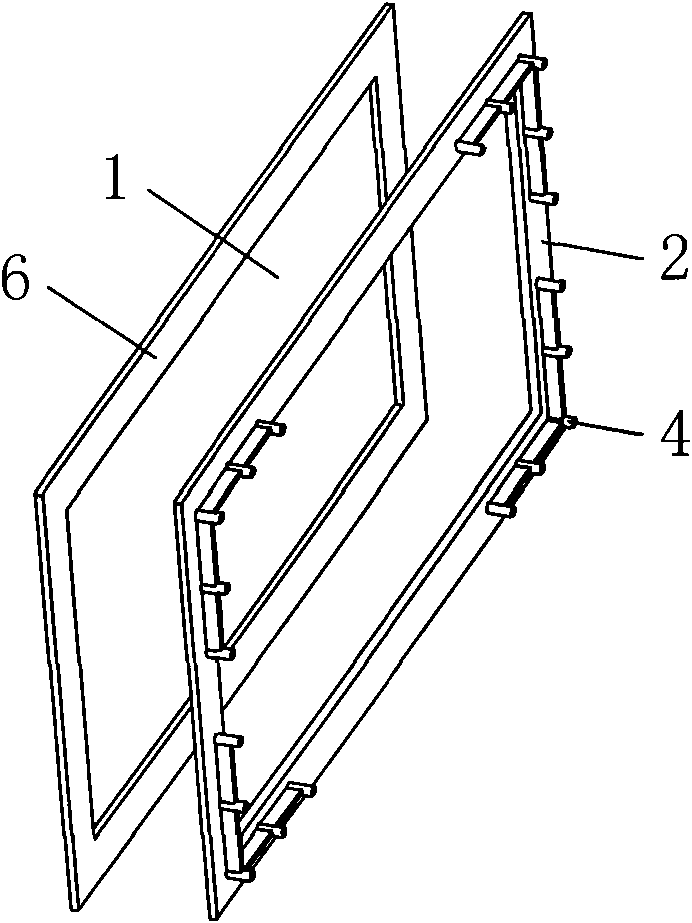

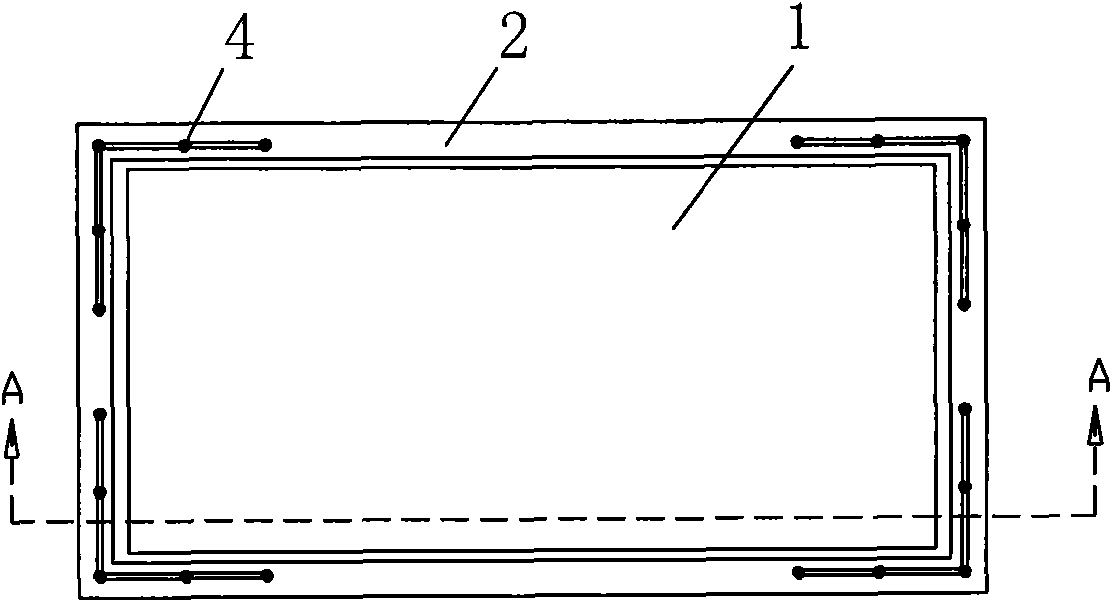

Display front housing and manufacturing method thereof

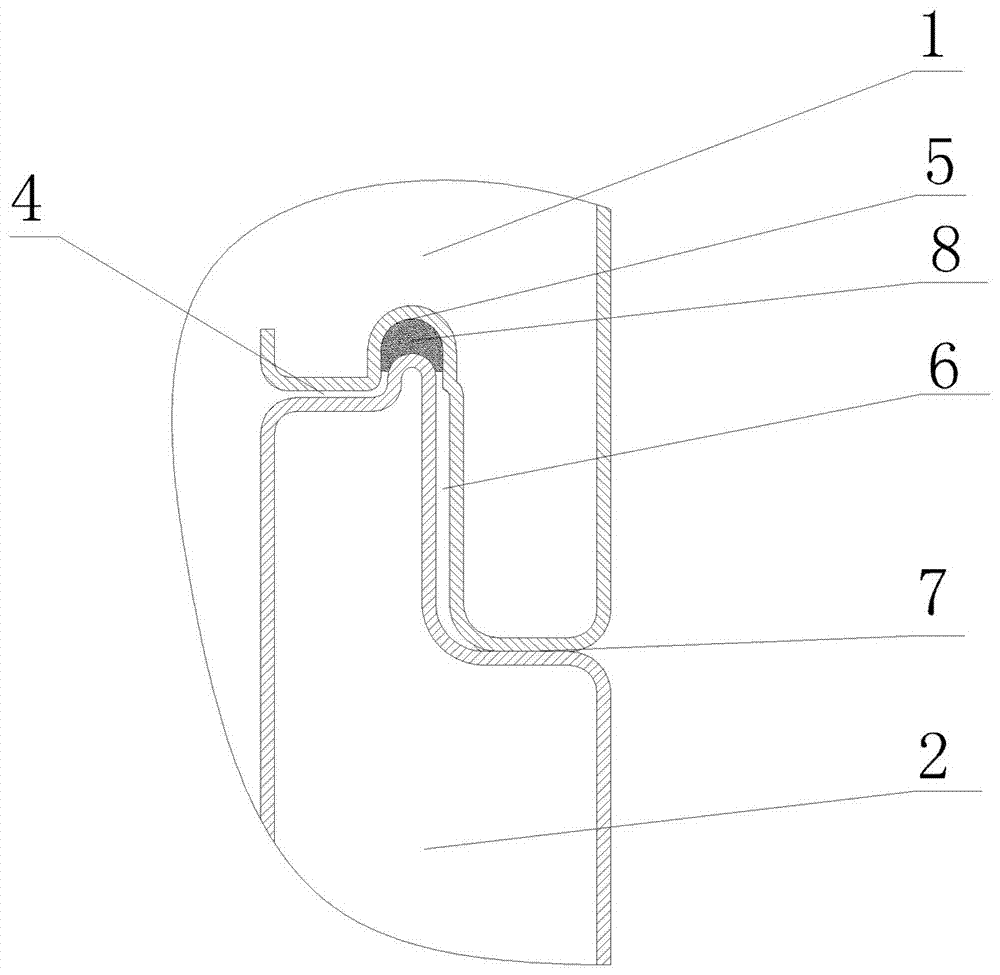

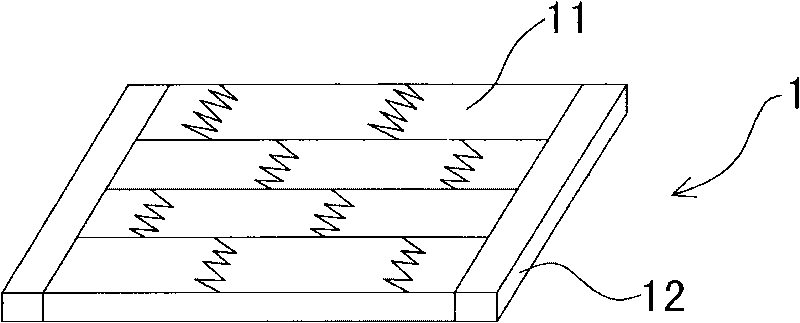

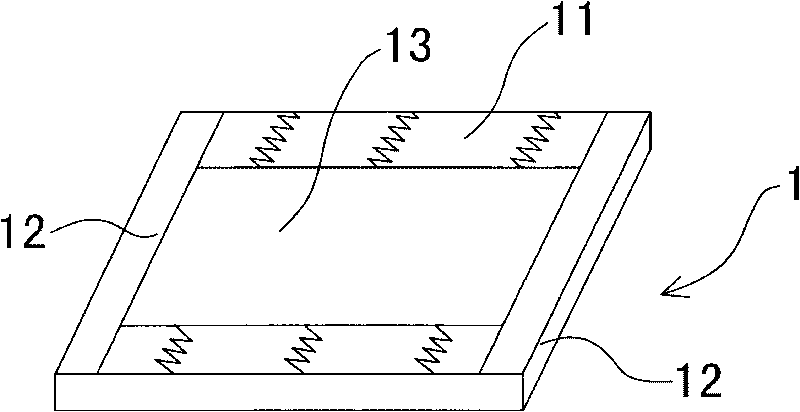

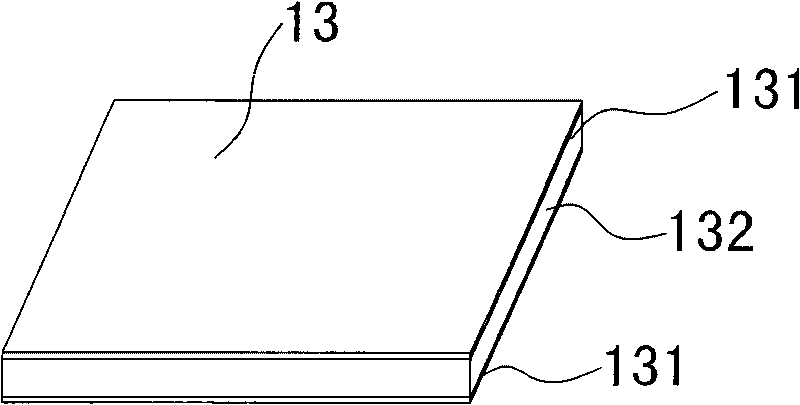

ActiveCN101894500AOrderly rowsUniform internal stressIdentification meansElectrical apparatus casings/cabinets/drawersLED displayDisplay device

The invention discloses a display front housing. The display front housing comprises a transparent panel (1), a decorative layer (6) arranged around one side of the panel, and a face frame (2), wherein the face frame (2) is connected with the panel (1) into a whole by injection molding, and the decorative layer (6) is positioned between the joint face between the panel and the face frame. The invention also discloses a manufacturing method of the display front housing. The display front housing has the advantages of high light transmission of the panel, safe and reliable connection between the panel and the face frame, certain three-dimensional (3D) effect of the decorative layer seen out of the transparent panel, low cost, simple process, short manufacturing cycle, high yield and reliable quality and leads an inevitable development trend of the modern LED displays.

Owner:DONGGUAN HAOSHUN PRECISION TECH CO LTD

Method for the Manufacture of an Aluminium Alloy Plate Product Having Low Levels of Residual Stress

ActiveUS20120042995A1Decrease in levelReduction in thickness directionMetal rolling arrangementsStress relievingHeat treated

This relates to a method of the manufacture of a thick gauge aluminum alloy plate having reduced level of residual stress. The method includes (a) providing a solution heat-treated and quenched aluminum alloy plate having a thickness of at least 80 mm, (b) stress-relieving the plate by cold rolling the plate to achieve a reduction in the thickness direction of the plate product in a range of at most 8%.

Owner:NOVELIS KOBLENZ GMBH

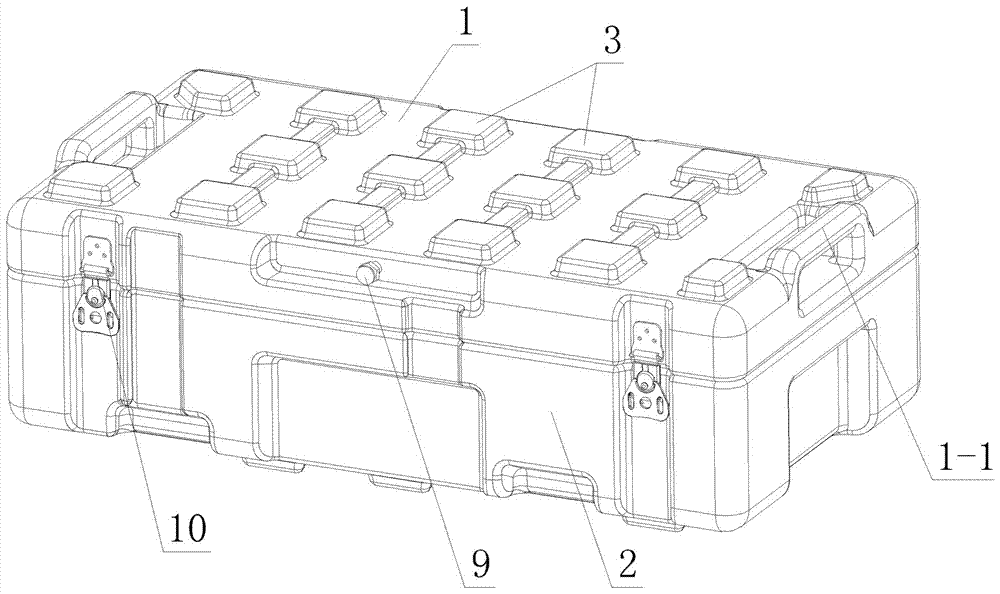

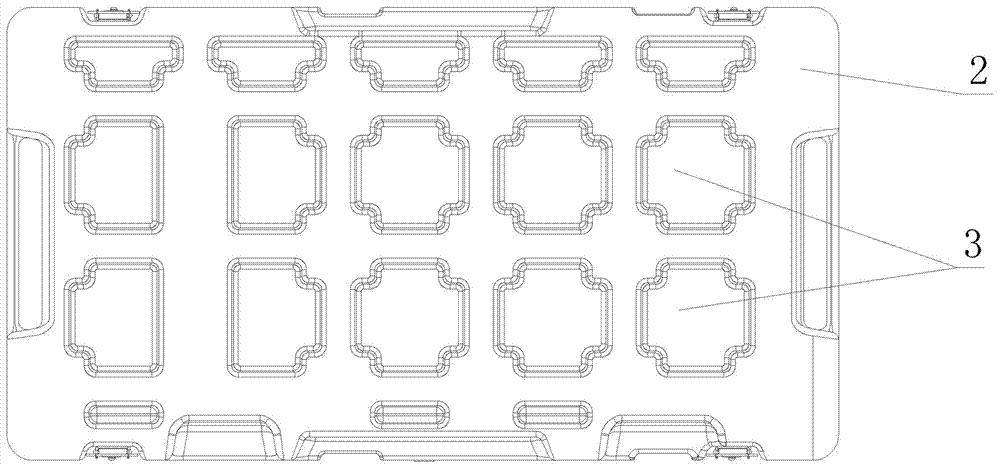

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

Solid wood composite floor board baseplate and manufacturing method thereof

InactiveCN101748880AUniform internal stressReduce distortionWood working apparatusFlooringParquetinaSolid wood

Owner:曹绪勇

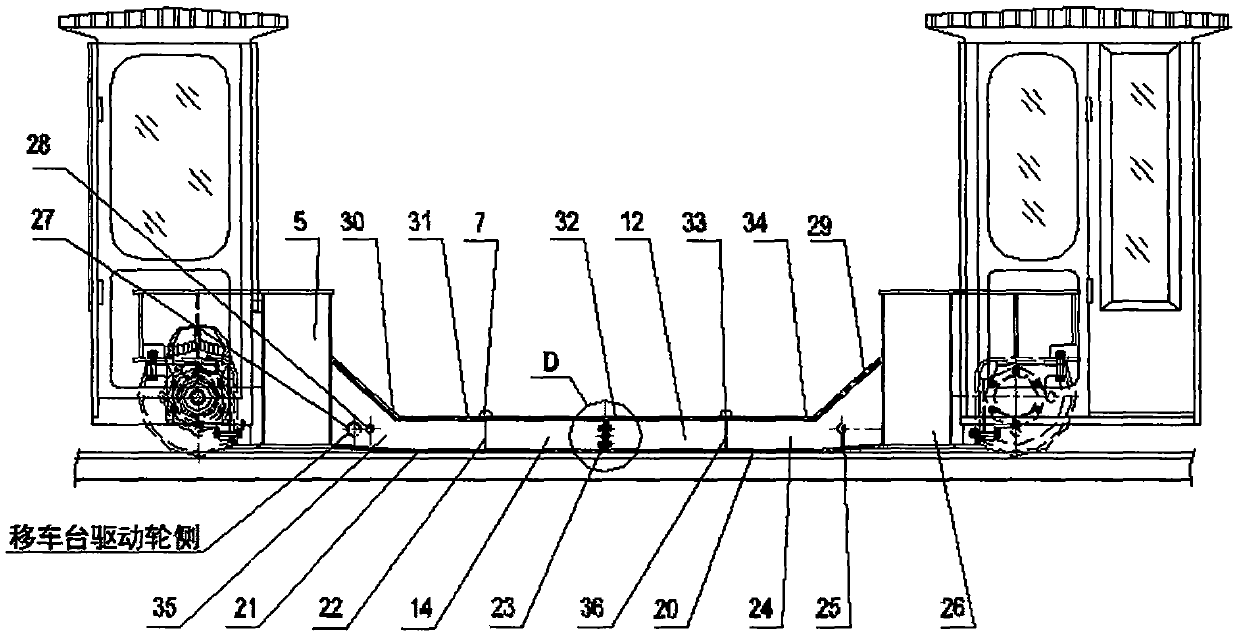

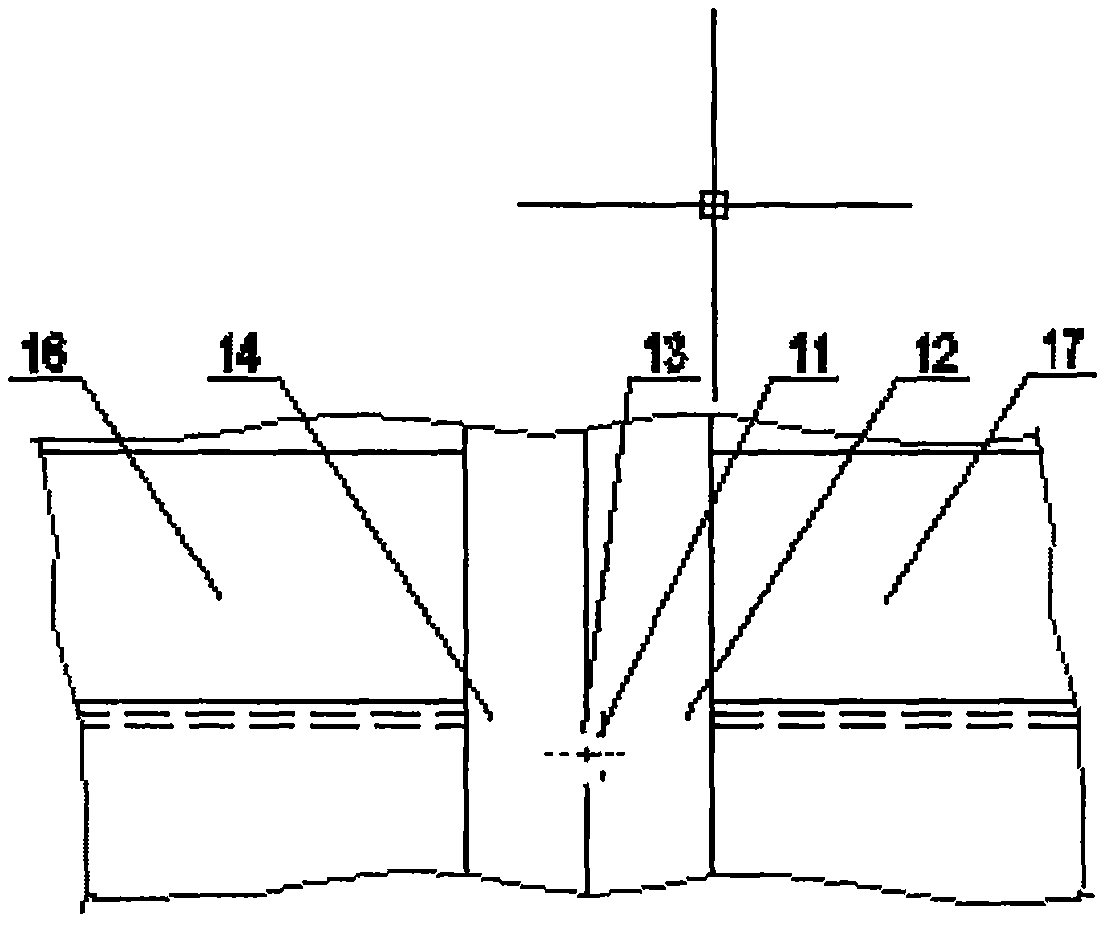

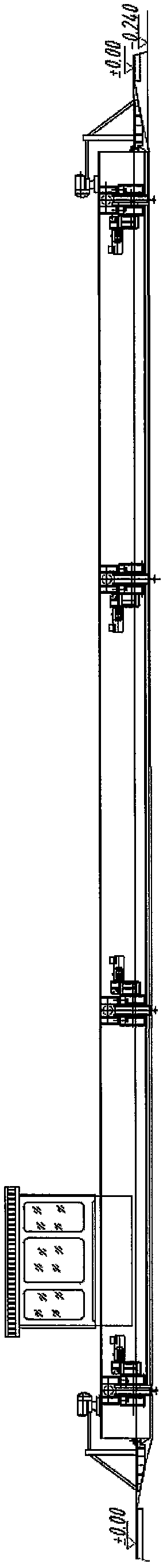

Integral locomotive moving platform

The invention relates to a special maintenance device for realizing locomotive shunting operation at a railway locomotive maintenance field and the special maintenance device allows railway locomotives to complete parallel shunting operation. A locomotive moving platform is a large and medium device in the rail transit industry and has a large size. According to a traditional manufacturing method,parts can only be produced in factories and transported to the field to be assembled and welded for forming, so the mutual parallelism and perpendicularity of wheelsets of a walking part of the locomotive moving platform can not be ensured resulting in rail gnawing, deviation and other situations during the operation process of the locomotive moving platform and an influence on the safe and reliable operation of the locomotive moving platform. An integral locomotive moving platform of the invention adopts the integral manufacturing in a manufacturing plant to ensure the parallelism, perpendicularity and stable operation of the wheelsets during the operation process of the integral locomotive moving platform assembled on site and the avoidance of hunting, rail gnawing and other situations,and can achieve the reliable bidirectional connection of rails of the integral locomotive moving platform. By virtue of the integral manufacturing, disassembled transportation, fixing pins for fixingpositions, bolts for jointing and assembling and welding for forming, the integral locomotive moving platform reduce the on-site workload, shorten the assembling time and improve the installation efficiency. The integral locomotive moving platform has a neat and delight exterior, and the wiring is safe and reliable.

Owner:CHINA RAILWAY HUATIE ENG DESIGN GRP CO LTD

Production method of novel environment-friendly wood-plastic floor

InactiveCN107099161AFlat surfaceEasy to clean and maintainCoatingsPolyvinyl alcoholThermal insulation

The invention relates to a production method of a novel environment-friendly wood-plastic floor. The production method includes the steps of firstly, adding amino resin, polyvinyl alcohol, ethanol and a thermal stabilizer into a high-speed mixing machine, performing thermal-insulation mixing for a certain period of time, naturally cooling, adding a lubricating agent, adding the materials into a ball milling machine, and performing ball milling to obtain coating liquid; secondly, premixing a PVC plastic raw material, plasticizer, an acrylate impact modifier and straw powder to obtain a first mixture; thirdly, mixing the first mixture with modified bamboo powder, calcium carbonate, a titanate coupling agent and an anti-aging agent to obtain a second mixture; fourthly, using a double-screw extruder and a molding die to perform high-temperature extrusion molding on the second mixture, using the molding die for molding, and performing water cooling, traction and cutting to obtain a base plate; fifthly, coating the surface of the base plate with the coating liquid obtained in the first step to obtain the novel environment-friendly wood-plastic floor. The novel environment-friendly wood-plastic floor is high in wear resistance and corrosion resistance.

Owner:合肥易美特建材有限公司

Process for forming lining plastic core pipe of round thin-film capacitor by heat sealing

ActiveCN101707138AImprove quality reliabilityImprove long-term reliabilityThin/thick film capacitorStacked capacitorsHot meltThick wall

The invention discloses a process for forming a lining plastic core pipe of a round thin-film capacitor by heat sealing. In the process, in the initial stage of the coiling process of the capacitor, an inner packaging thin-film coiled on a coiling block is heated to be melted and bonded layer by layer to form a hollow plastic pipe, namely the lining plastic core pipe, with a 0.2 to 1.20 millimeter thick wall, the size of the hollow plastic pipe varies with the coiling block synchronously without being limited by the size of the capacitor, the lining plastic core pipe is formed after an inner package heating device is removed, and a follow-up coiling process is completely consistent with the conventional production process. The process has the advantages that: the inner circle looseness problem of thin-film capacitors without lining core pipes is solved; the capacitor has reliable quality and long service life; the product size is small; the consistency is high; the production efficiency is high; the production period is short; the product cost is low; and the implementation is simple and convenient and the promotion is easy.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

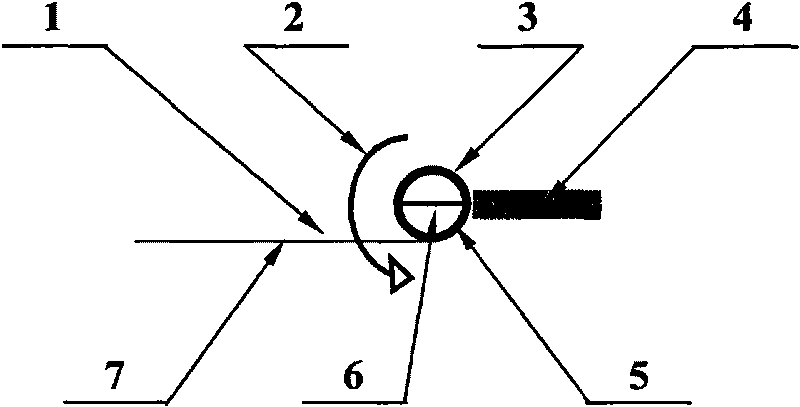

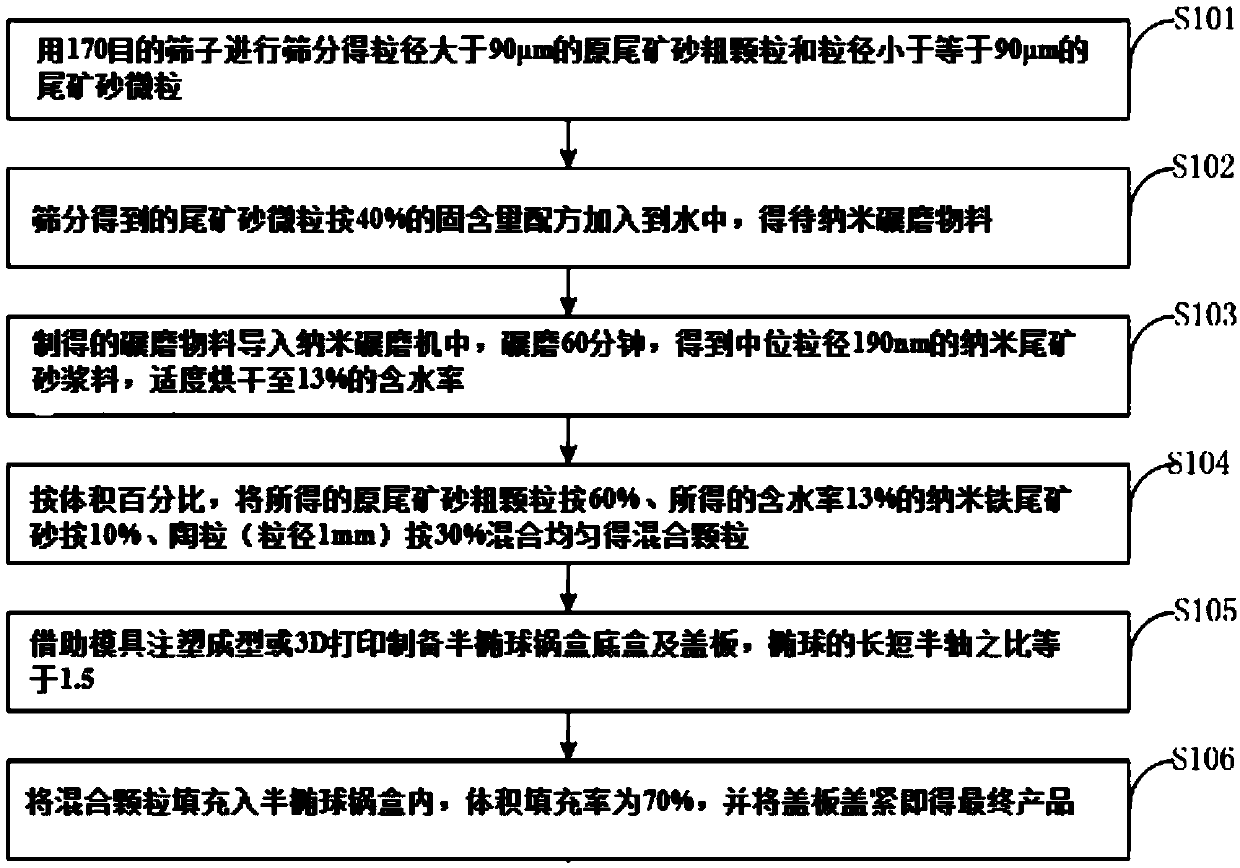

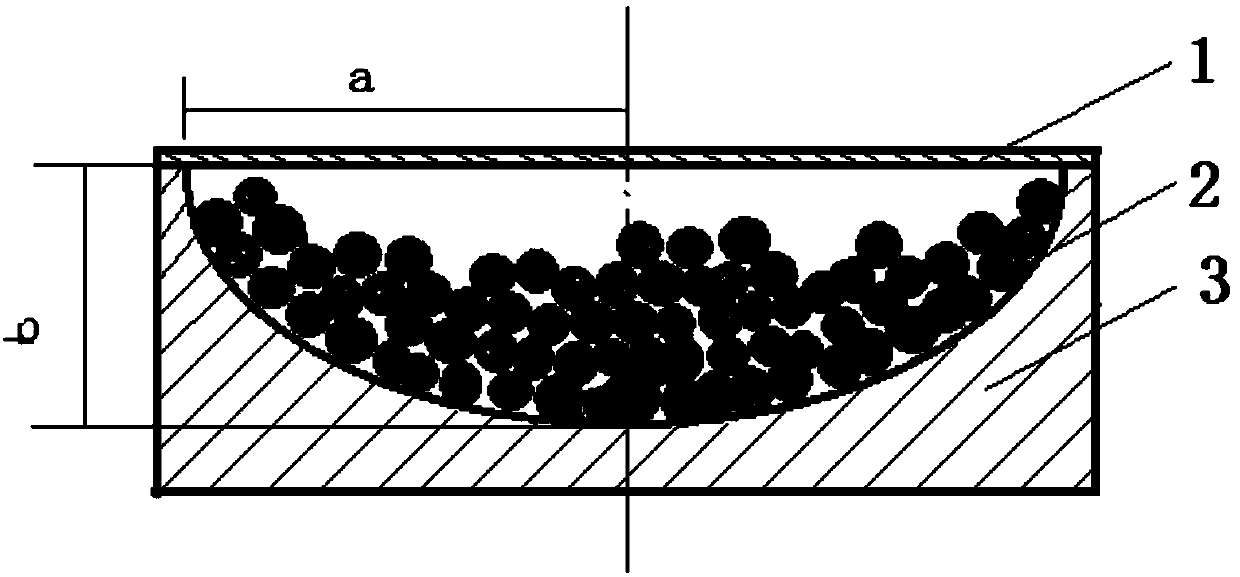

Semi-ellipsoidal pot box vibration absorber filled with iron tailing sand and ceramsite mixed particles and preparation method of semi-ellipsoidal pot box vibration absorber

ActiveCN109538675ASolve the problem that friction and collision energy consumption is not enoughIncrease damping energy consumptionOther chemical processesFriction dampersNoise controlExpanded clay aggregate

The invention belongs to the technical field of environmental vibration and noise control, and discloses a preparation method of a semi-ellipsoidal pot box vibration absorber filled with iron tailingsand and ceramsite mixed particles. The vibration absorber is a pot box with an inner cavity with a box cover in a semi-ellipsoid shape, the semi-ellipsoidal pot box is loosely filled with mixed particles with the volume ratio of 70%, and the mixed particles are composed of the following components of, 60% of original tailing sand particles, 30% of ceramsite and 10% of nano iron tailing sand. According to the method, the semi-ellipsoidal pot box structure capable of effectively dissipating external vibration energy during horizontal vibrating in each direction and the particle proportion in the pot box can be obtained; the novel concept that the waste iron tailing sand is used as the main energy consumption particles of the vibration absorber is achieved; and a new recycling way of the waste iron tailing sand is obtained, the pollution of the iron tailing sand to the environment can be reduced, and the damage of the vibration and the noise to the environment can be reduced. In conclusion, the comprehensive performance of all aspects of the semi-ellipsoidal pot box vibration absorber filled with the iron tailing sand and the ceramsite mixed particles is excellent, and the absorber has a good application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

Dual aluminum film composite embossing flame retardant curtain fabric and manufacturing method thereof

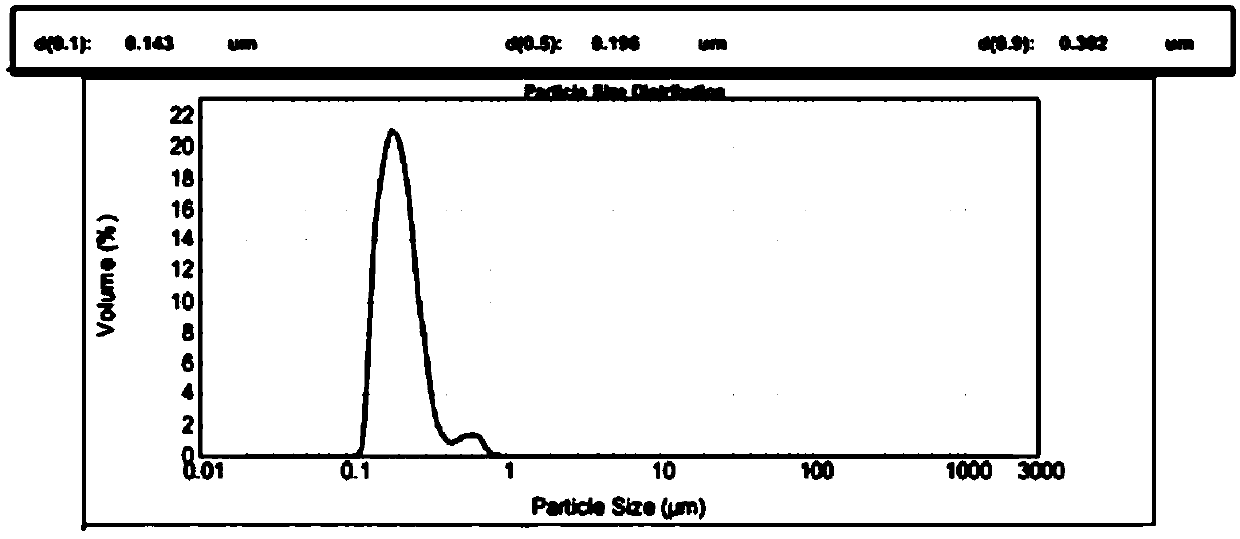

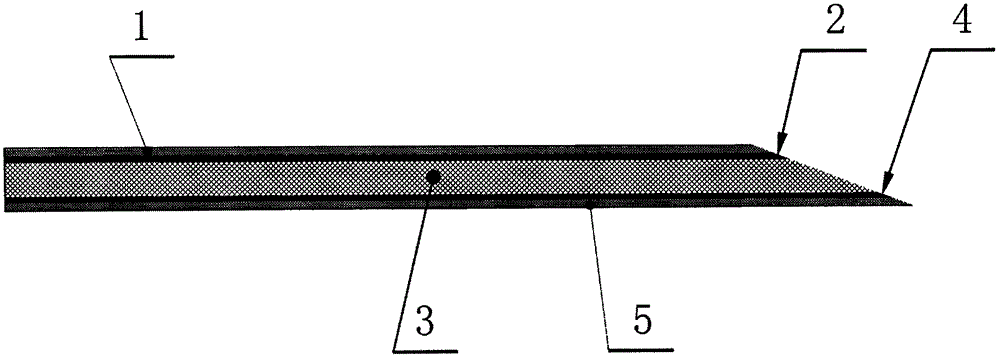

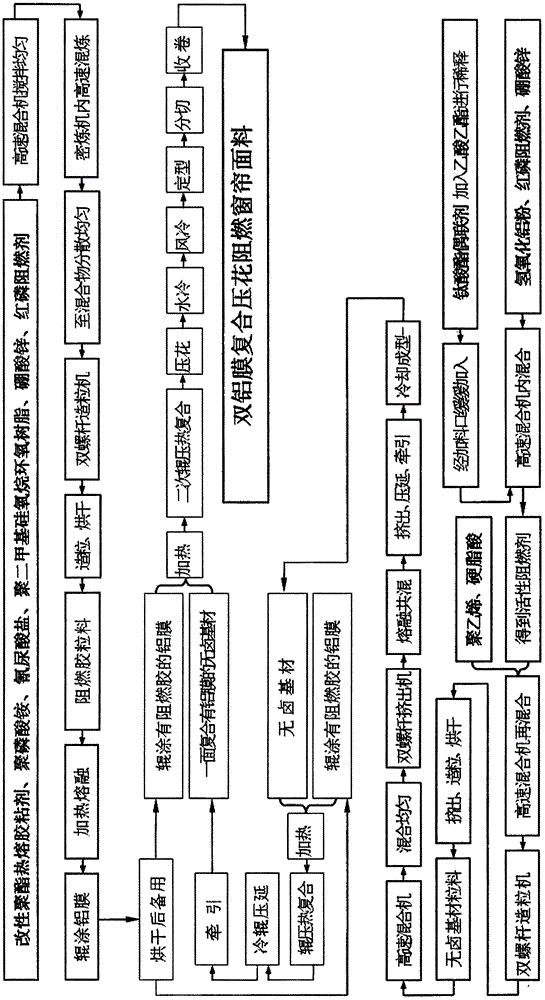

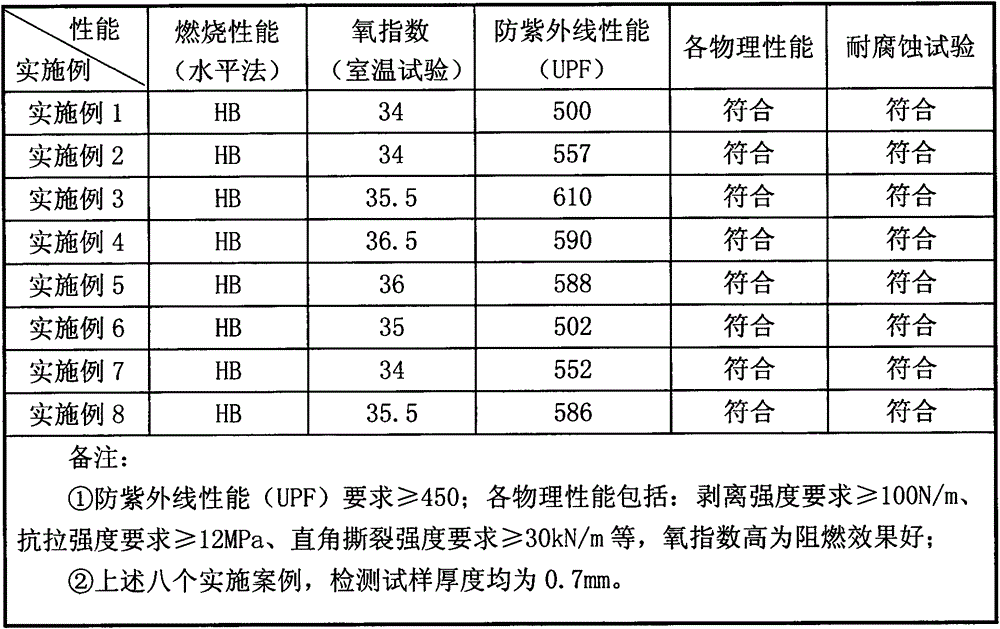

ActiveCN104905664AImprove tensile propertiesHigh tear strengthLamination ancillary operationsSynthetic resin layered productsMaterials preparationRemote control

The invention discloses a dual aluminum film composite embossing flame retardant curtain fabric and a manufacturing method thereof, wherein the curtain fabric is made by compositing an aluminum film, flame retardant glue, halogen-free basic material, the flame retardant glue and the aluminum film; through the halogen-free basic material preparation and the flame retardant glue granule material preparation, the aluminum film upper roller is coated with the flame retardant glue; and then the dual aluminum film composite embossing flame retardant curtain fabric is obtained by roller press and heat composition twice. The curtain fabric has the advantages that the flame retardant performance and the smoke suppression performance are highly efficient; the performances of extension resistance, tearing resistance, peel strength, ultraviolet light resistance, aging resistance and corrosion resistance are excellent; the inner and outer layers are all identical aluminum film materials; the inner stress is uniform and even, thus the inner and the outer faces of the curtain fabric is extremely even ans smooth; at the same time, during the preparation process, the inner layer aluminum film can be embossed to be various colorful patterns and the stripes are clean and fashion; if the curtain fabric is put indoor and matched with modern remote control extension, a decorative scene is extremely beautiful; the preparation method is simple, thus the curtain fabric is suitable for industrialization scale production.

Owner:JINHUA SHAIKANG PLASTIC IND TECH

A kind of preparation method of quartz glass

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

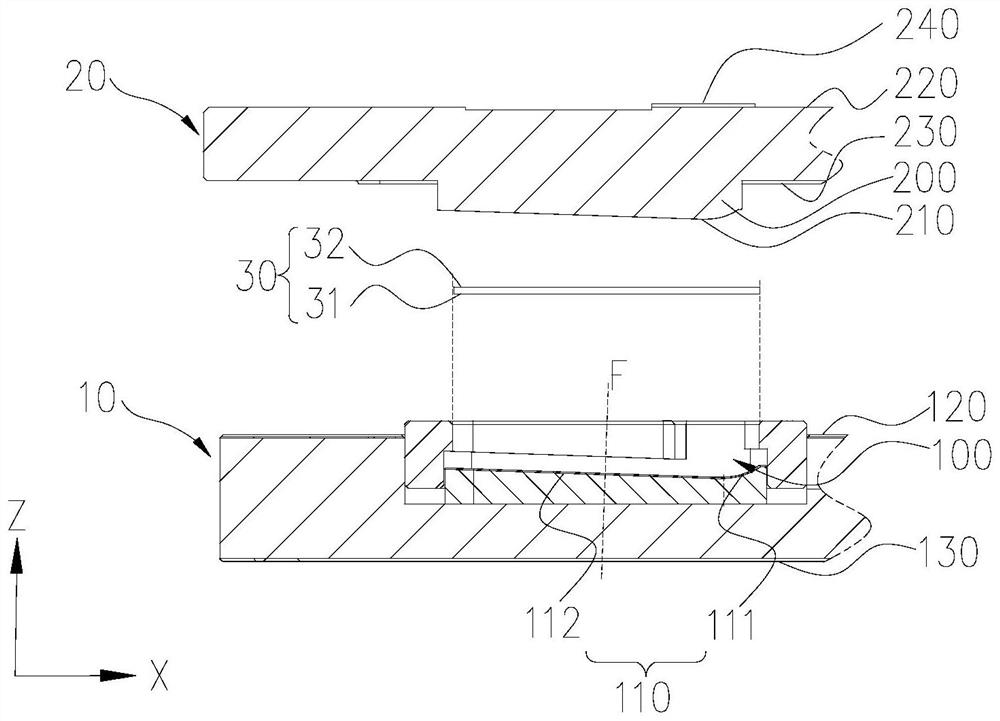

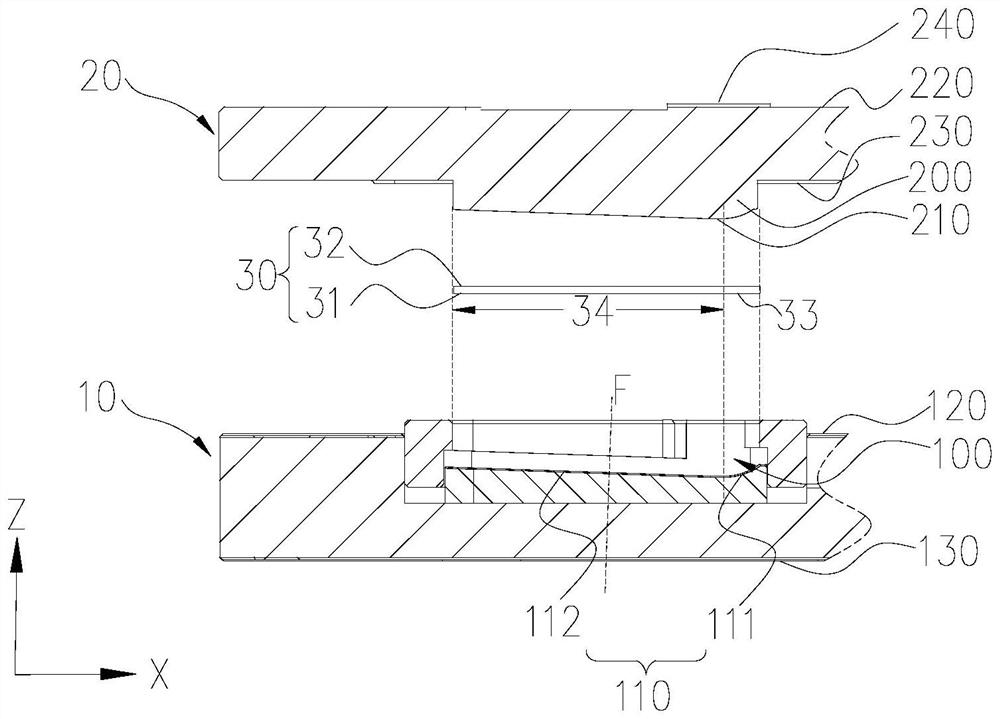

Hot bending die and hot bending equipment

PendingCN113716846AUniform internal stressImprove molding yieldGlass reforming apparatusStructural engineeringMechanical engineering

The invention provides a hot bending die and hot bending equipment, wherein the hot bending die is used for hot bending to-be-processed glass, and the hot bending die comprises a first die and a second die; the first die is provided with at least one cavity, a cavity bent surface is arranged in the cavity, and the cavity bent surface comprises a first plane and a first curved surface which are connected; the normal direction of the first plane intersects with the thickness direction of the first die, the second die and the first die are oppositely arranged, at least one protruding block is arranged on the side, facing the first die, of the second die, and the protruding block is provided with a protruding block bent face; and the protruding block bent surface and the cavity bent surface are respectively pressed on two opposite sides of to-be-processed glass during hot bending and guide the to-be-processed glass to be bent. According to the hot bending die provided by the invention, the internal stress of the whole to-be-processed glass is relatively uniform, so that the phenomenon that the to-be-processed glass deviates due to non-uniform stress is avoided, and the forming quality of the processed to-be-processed glass with the bent surface is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Hard alloy drill plate and drill bit

The present invention relates to hard alloy brazing plate and bore bit. The brazing plate has a brazing plate body and locating fins in the same height on two sides of the body to ensure the brazing plate body fixed in the center of the slot for homogeneous brazing seam, high brazing seam strength, the homogeneous elimination of the high temperature stress of the hard alloy brazing plate during the brazing, stable performance, homogeneous strength and no cracking. Or, the brazing plate has symmetrical inward notches on two sides to raise the raise the radial shock resistance and wear resistance of the brazing plate and ensure the homogeneous radial wear. The bore bit with the hard alloy brazing plate embedded in the fixing slot has high product quality, and long service life of driving length up to 800-900.

Owner:姚勋

A high-strength steel for thin-gauge construction machinery and its shape control method

ActiveCN110106322BImprove mechanical propertiesMeet the requirements of the construction machinery industryFurnace typesHeat treatment furnacesUltimate tensile strengthMaterials science

The invention relates to a high-strength steel for thin-gauge engineering machinery. The composition mass percentage is: C: 0.07%-0.10%, Si: 0.15%-0.30%, Mn: 1.2%-1.6%, P≤0.012%, S≤0.003 %, Nb: 0%~0.08%, V: 0%~0.07%, Ti: 0.06%~0.13%, Cr: 0.1%~0.2%, Mo: 0.1%~0.2%, Nb+V+Ti: 0.08% ~0.15%, Mo+Cr: 0.25%~0.35%, the rest is Fe and impurities. Adopt blast furnace hot metal, hot metal desulfurization, converter smelting, LF+RH refining, continuous casting, hot charging and hot delivery, heating, rolling, cooling, coiling, leveling, tempering heat treatment, and straightening process routes. The yield strength is greater than 690MPa, the tensile strength is greater than 785MPa, and the impact energy at -20°C is greater than 100J.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com