Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve molding yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

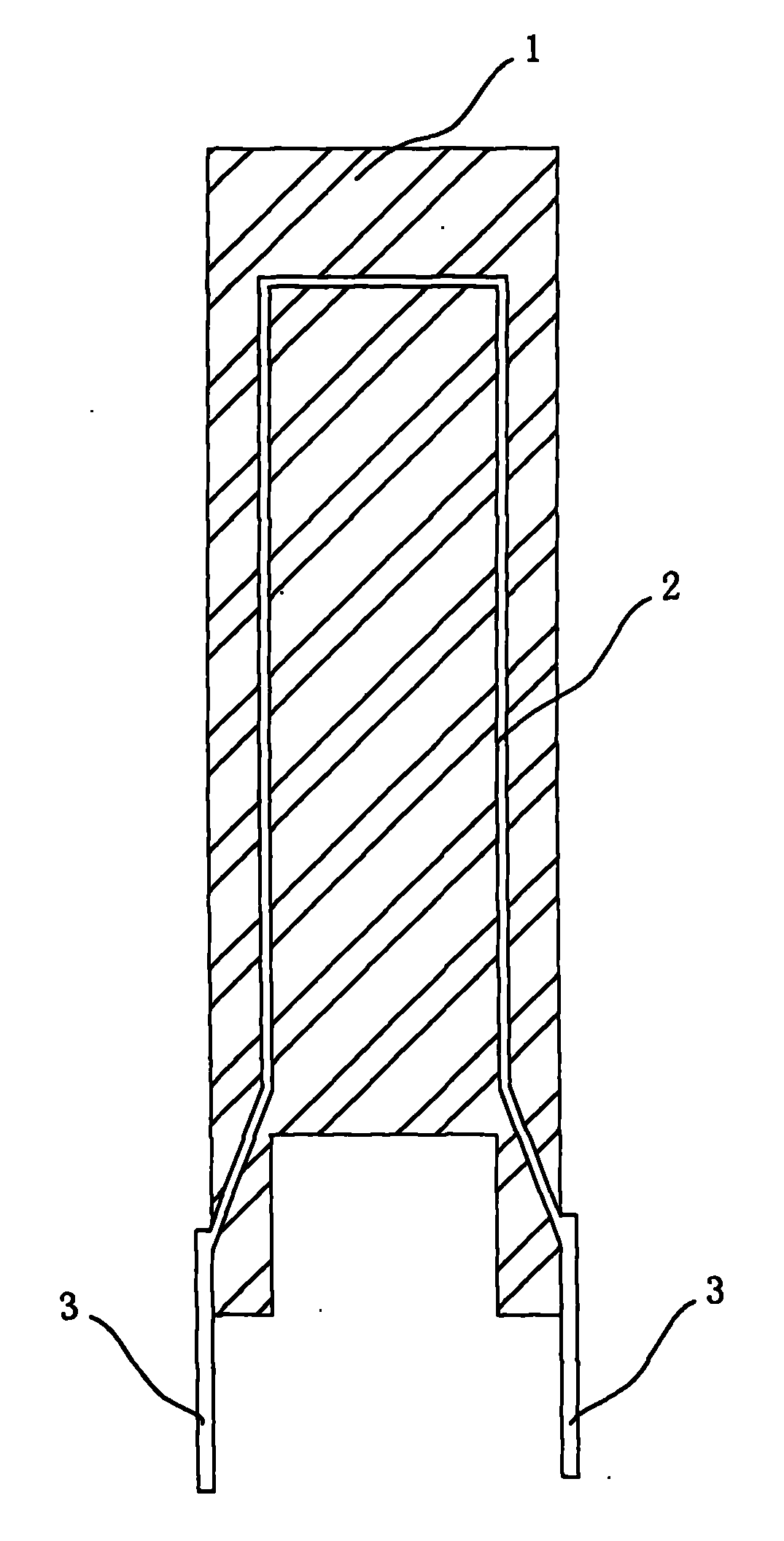

Production process for preparing silica ceramic crucible by use of pressure grouting method

InactiveCN102528899AAccelerate the injection molding speedImprove work efficiencyCeramic shaping apparatusSmall footprintPolycrystalline silicon

The invention relates to a production process for preparing a silica ceramic crucible by use of a pressure grouting method and belongs to the technical field of high-grade refractory materials in a polycrystalline silicon industry. The pressure grouting comprises steps of preparation of pouring slurry, die assembling, molding by pouring slurry and demolding for fetching a green body, i.e., (1) ball-milling fused silica grain composition into slurry; and (2) fixing a resin die and assembling the die, grouting, pressurizing quartz slurry with the initial pressure being 0.1-0.2Mpa, enhancing the pressure to 0.3-1.5Mpa after a die cavity is filled with quartz slurry, keeping the pressure for about 5 minutes to filter water in the silica slurry by virtue of a micro-reticular resin mold to form a square crucible green body, and during demolding of the green body, and applying pressure of 0.2-0.3Mpa to the surface of the green body through the back layer of the micro-reticular resin mold by utilizing compression air. The green body of the silica ceramic crucible, prepared by the process, has high intensity, does not have residual air holes and is easy to demold, the product is good in thermal shock resistance and high in temperature resistance, and can meet the process requirements of polycrystalline silicon production; and the process has the advantages of high biscuit drying speed, small occupied area for production, shortened manufacturing period, low cost, and suitability for scale production.

Owner:咸阳陶瓷研究设计院有限公司

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

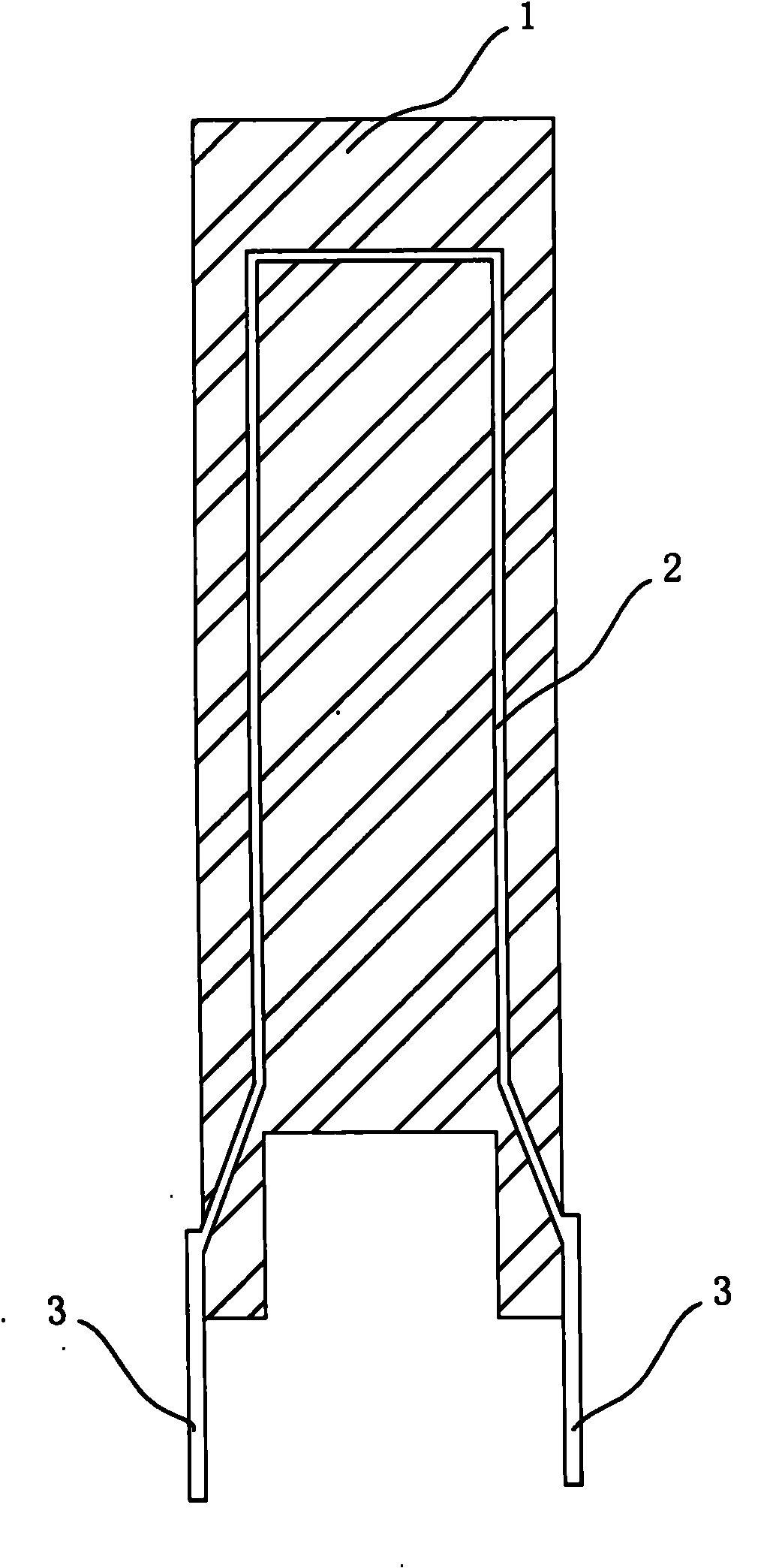

Method for manufacturing silicon nitride heating body

ActiveCN102170716AHigh thermal conductivityReduced insulation performanceHeating element materialsSlurryBoron nitride

The invention relates to a method for manufacturing a silicon nitride heating body, which comprises the following steps of: charging silicon nitride powder and a small amount of high-temperature liquid phase combustion assisting agent into anhydrous ethanol for mixing; after mixing for 10-72 hours, spraying and granulating to obtain a prescription material; then embedding a metal heating wire into the prescription material and drily pressing for moulding; further pressing for moulding by the cold isostatic pressure of 180-220MPa and keeping for 3-12 minutes to obtain a biscuit; then uniformlycoating a boron nitride isolating layer on the surface of the biscuit, drying; carrying out hot press sintering at the sintering pressure of 20-30MPa, the sintering temperature of 1,600-1,900 DEG C and the temperature keeping time of 0.5-4 hours to obtain a blank; and finally, charging the blank into a vacuum atmosphere furnace, keeping the constant temperature of 1,300-1,600 DEG C for 10-24 hours and then naturally cooling to room temperature. The born nitride isolating layer is thick slurry which is formed by mixing boron nitride powder with the silicon nitride powder and blending the mixture with the anhydrous ethanol.

Owner:JIANGSU JINSHENG CERAMIC TECH

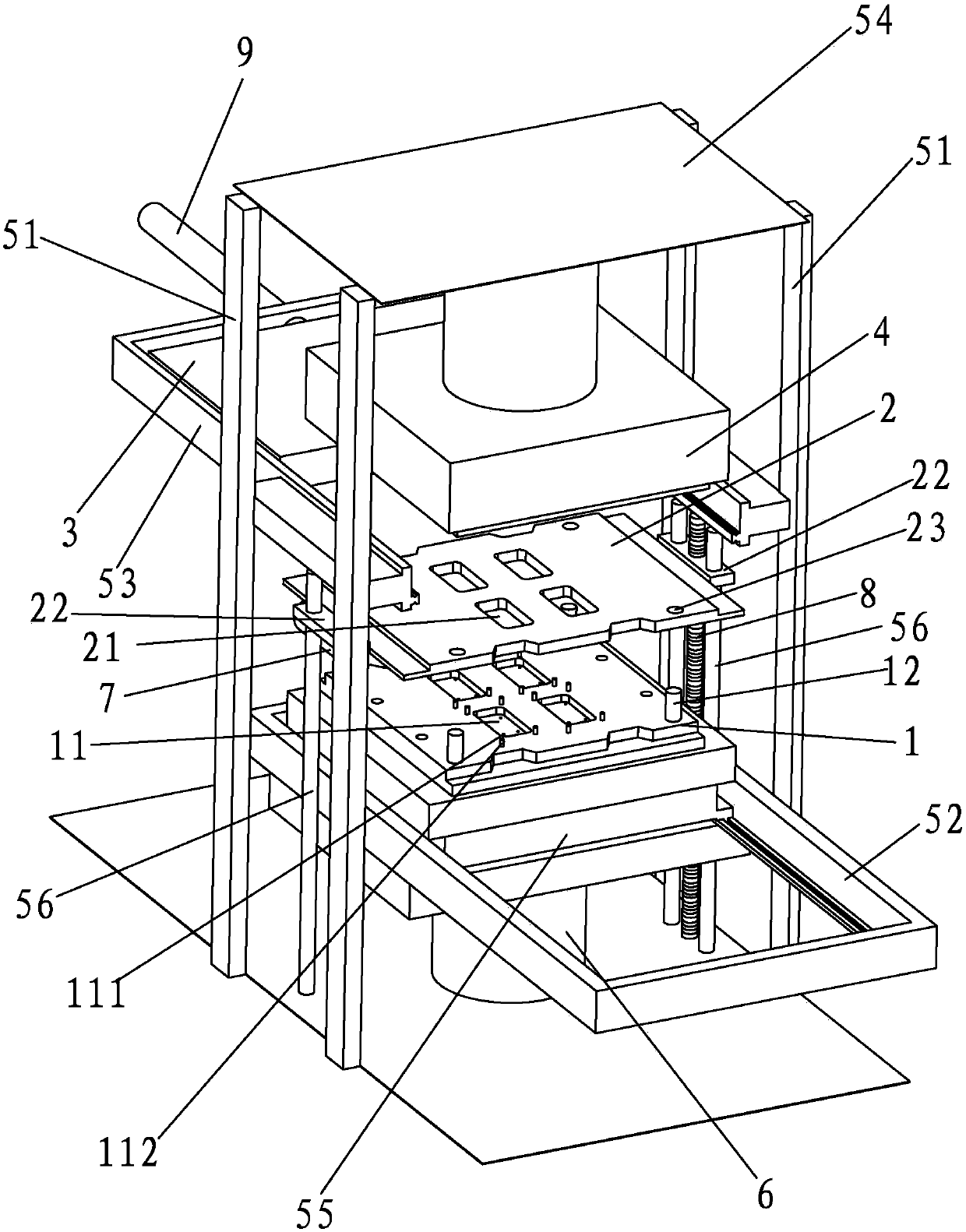

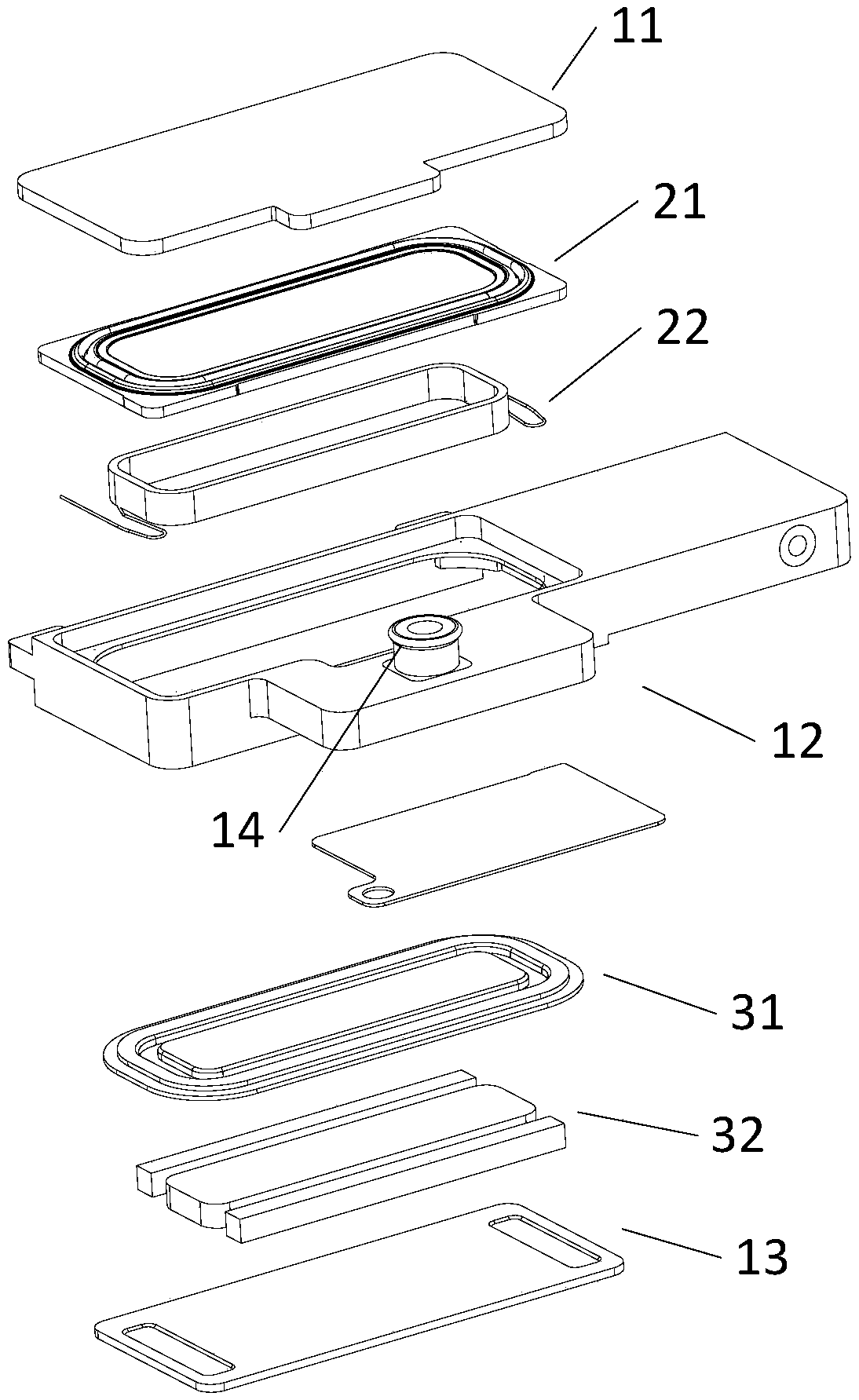

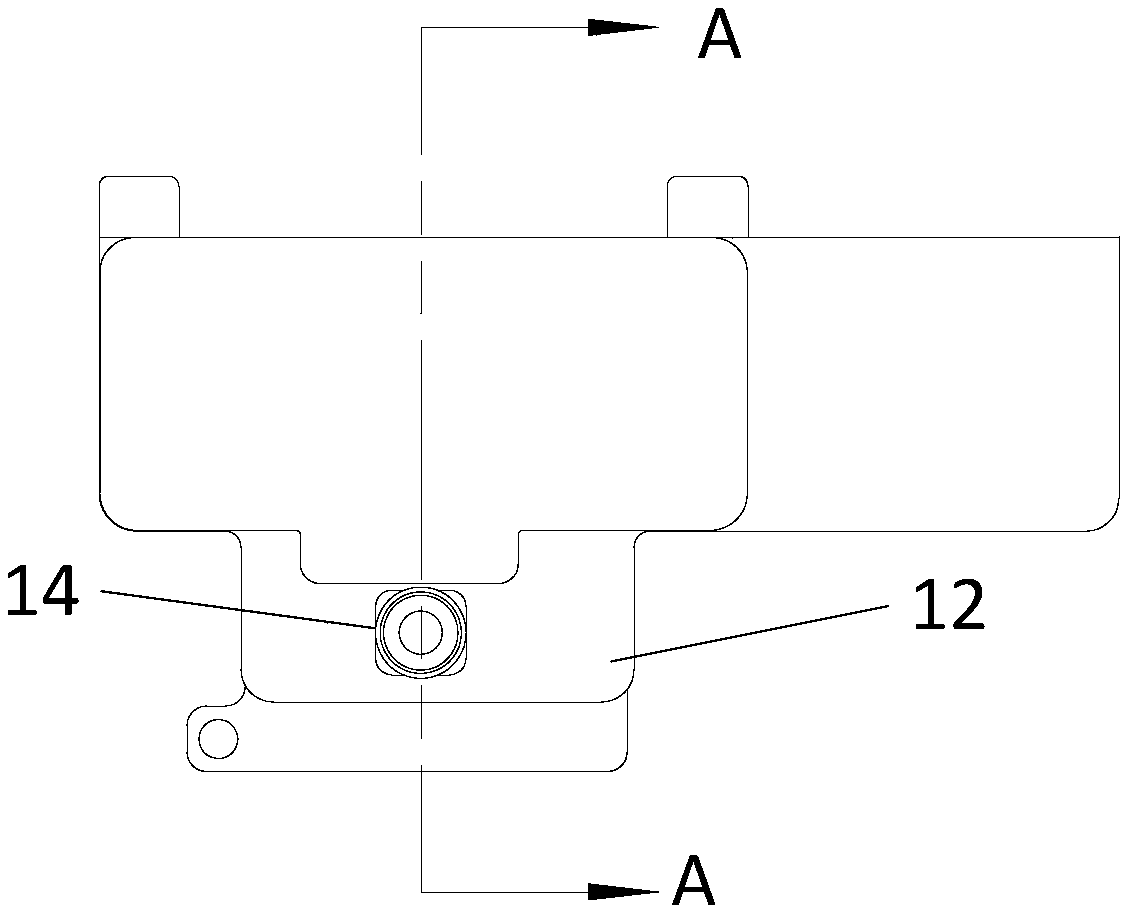

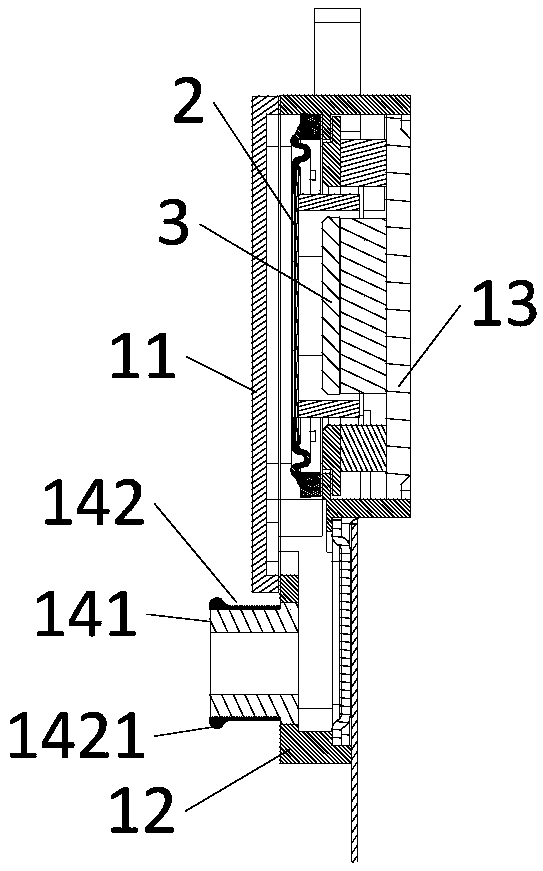

Production process and molding equipment for 3D (three-dimensional) battery cover

PendingCN107819089AImprove surface glossHigh molding yieldSynthetic resin layered productsLaminationSurface finishingHardness

The invention discloses a production process for a 3D (three-dimensional) battery cover. The production process is realized by the following steps: compounding a PMMA (Polymethyl Methacrylate) film with a PC (Polycarbonate) thin film to form a compound board; sequentially arranging a LOGO pattern printing layer, a UV(ultraviolet) transfer printing texture pattern layer, an optical film layer and abase color ink layer on the bottom surface of the PC thin film from top to bottom to form a to-be-molded sheet; putting the to-be-molded sheet on molding equipment for molding at high pressure to obtain a molded semi-finished product; carrying out shower coating of UV hardening liquid on the top of the surface of the molded semi-finished product by using a pressure gun; enabling the surface of the molded semi-finished product to be coated with the UV hardening liquid fully, and then drying to form a surface treatment part; cutting on the surface treatment part by reverse placement by using aCNC (Computer Numerical Control) cutter to form a finished product of the 3D battery cover. Compared with the prior art, the 3D battery cover has the advantages that the battery cover also has good toughness and higher hardness on the premise of reaching excellent strength as well as high rate of the molded finished product and highlight effect of the surface. The invention also discloses moldingequipment for the 3D battery cover.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

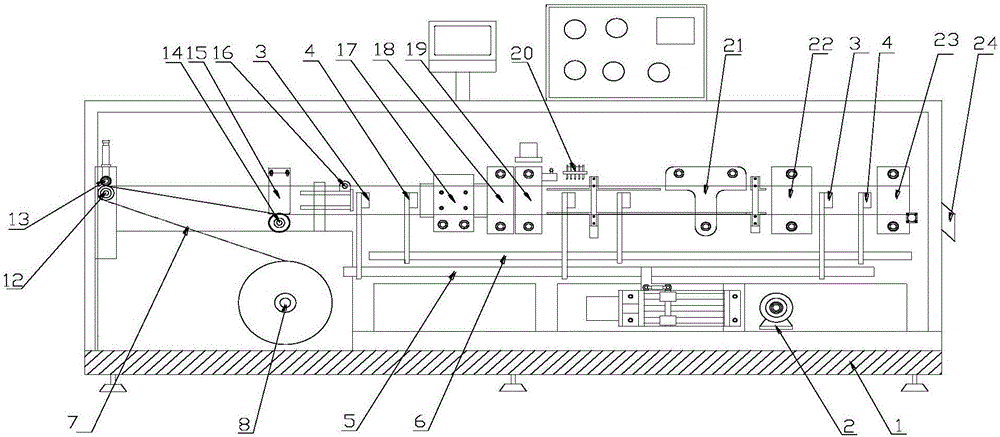

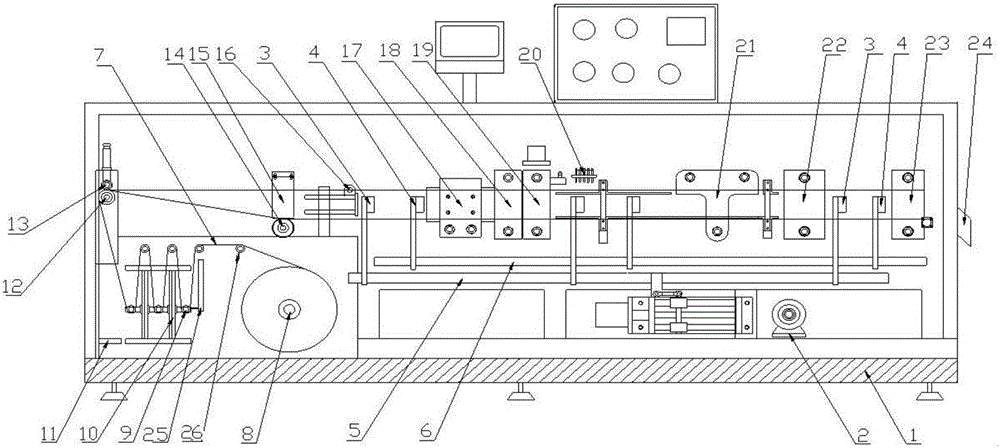

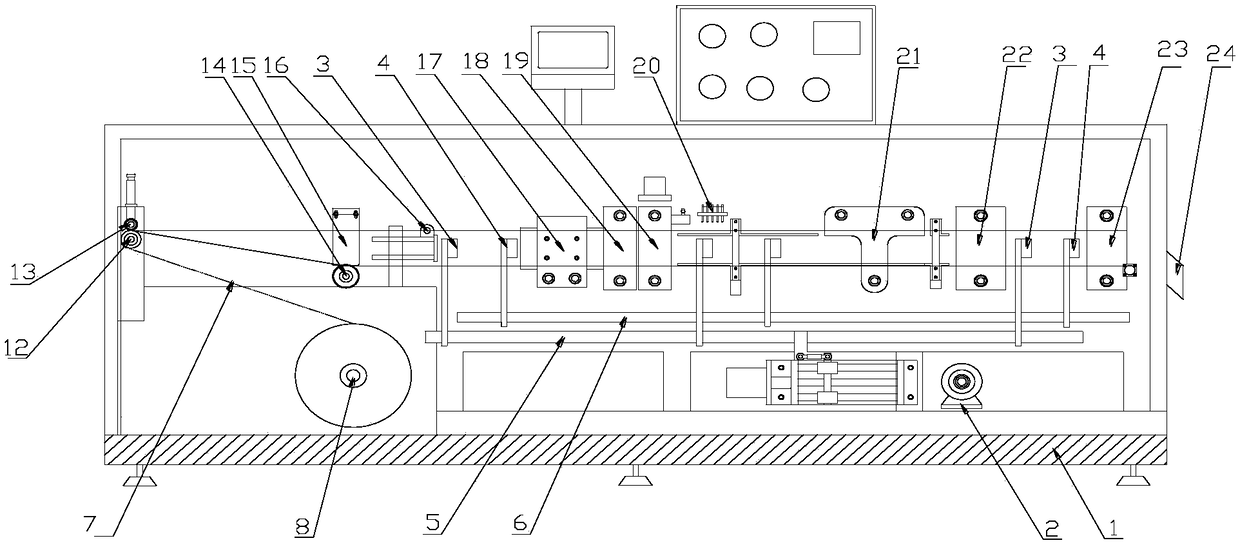

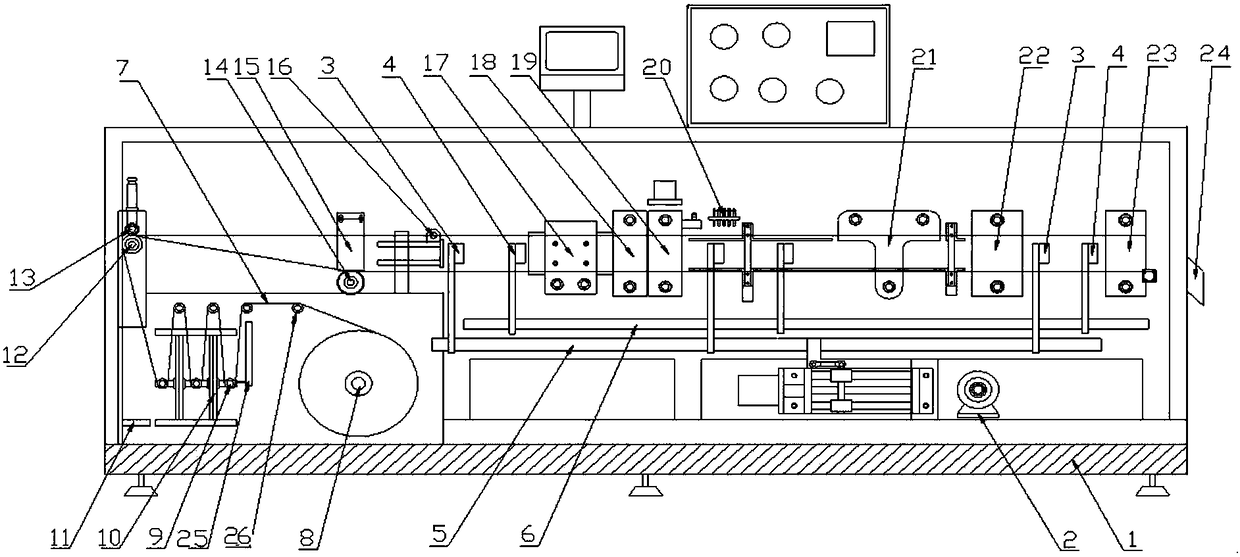

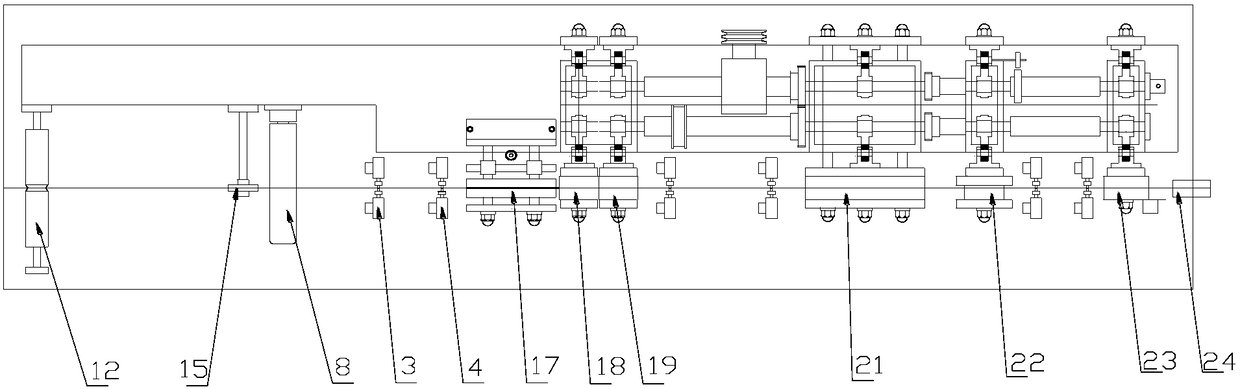

Plastic bottle automatic forming liquid filling machine

ActiveCN105799139AAvoid influenceReduce deformationBottle-handling machinesHollow articlesState of artEngineering

The invention discloses a plastic bottle automatic forming liquid filling machine. The liquid filling machine is sequentially provided with a plastic sheet film conveying unit and a forming unit (19); the plastic sheet film conveying unit comprises a feeding roller (8) and a plastic sheet film dividing assembly; the feeding roller (8) is used for conveying a rolled plastic sheet film (7); the plastic sheet film dividing assembly is used for dividing the conveyed-out plastic sheet film (7) into two parts in the motion direction of the plastic sheet film (7), and the two divided parts are subject to forming treatment through the forming unit; and compared with the prior art, the whole plastic bottle automatic forming liquid filling machine avoids the influence of the high-temperature on filled liquid, the technology efficiency is higher, the yield is higher, leftover materials generated through the technology are fewer, and the production cost is greatly reduced.

Owner:瑞安市高波机械有限公司

Preparation method for silicon nitride heating body

ActiveCN103096528AMaterial stress reliefPromote crystallizationHeating element materialsSilica fumeSilicon nitride

The invention relates to a preparation method for a silicon nitride heating body. The preparation method comprises that silicon nitride powder and small amount of high-temperature liquid-phase sintering aid are arranged into absolute ethyl alcohol to be mixed, the mixture is made into a formula material through spraying granulation 10-72 hours after mixing; a metal heating wire is embedded into the formula material, the formula material is formed by drying and pressing; then the formula material is further formed by pressing through isostatic cool pressing of 180-220Mpa, pressure is maintained for 3-10 minutes, and the material is formed into a biscuit; then a boron nitride isolation layer is evenly coated on the surface of the biscuit, the biscuit is dried; the biscuit is sintered through hot pressing, sintering pressure is 20-30MPa, sintering temperature is from 1600-1900 DEG C, heat insulation time is 0.5-4 hours, and a blank is formed; and finally, the blank is arranged into a vacuum atmosphere furnace, constant temperature of 1300-1600 DEG C is kept for 10-24 hours, and then the blank is naturally cooled to room temperature. The boron nitride isolation layer is thick slurry formed by mixing the absolute ethyl alcohol with a mixture prepared by mixing the boron nitride powder and silicon nitride powder.

Owner:JIANGSU JINSHENG CERAMIC TECH

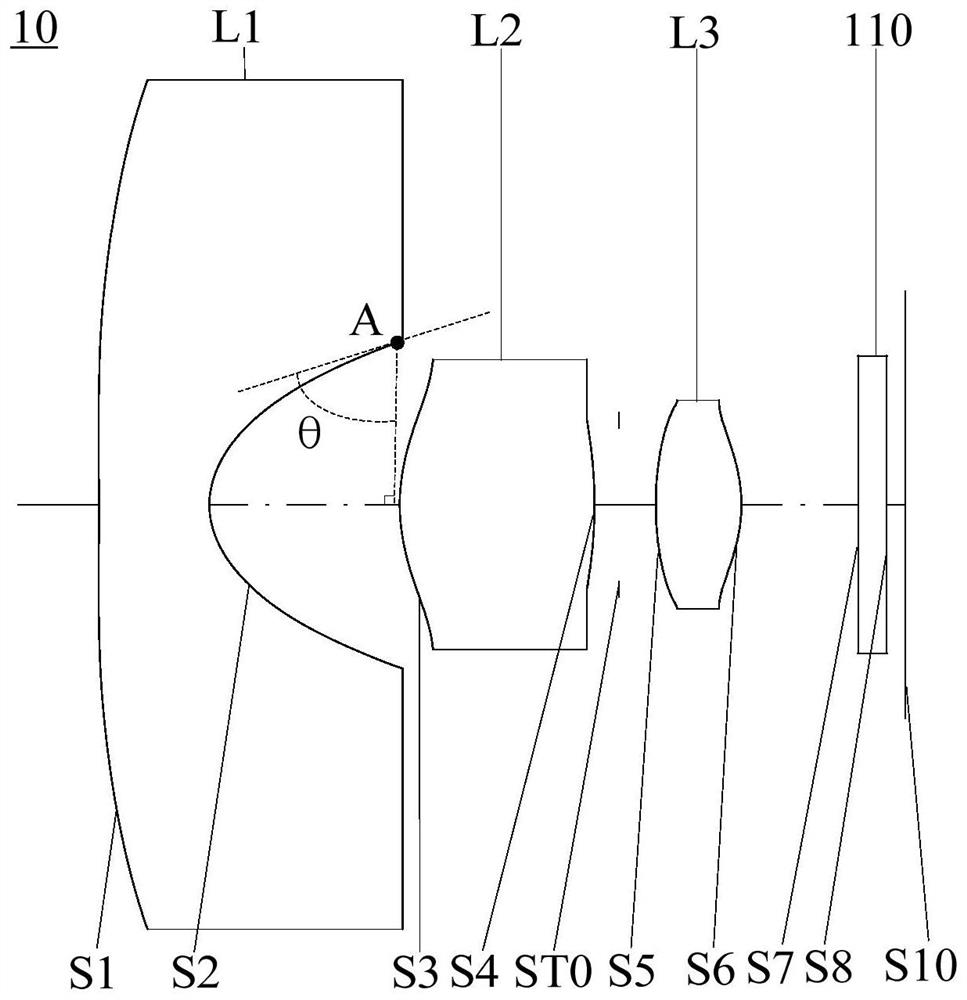

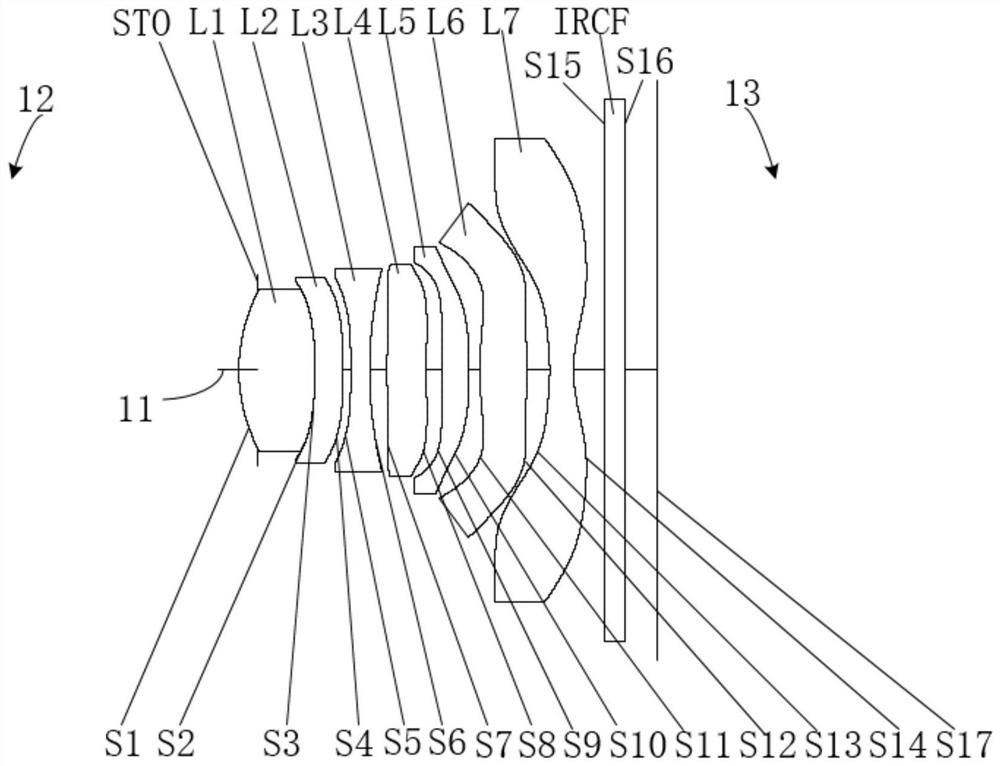

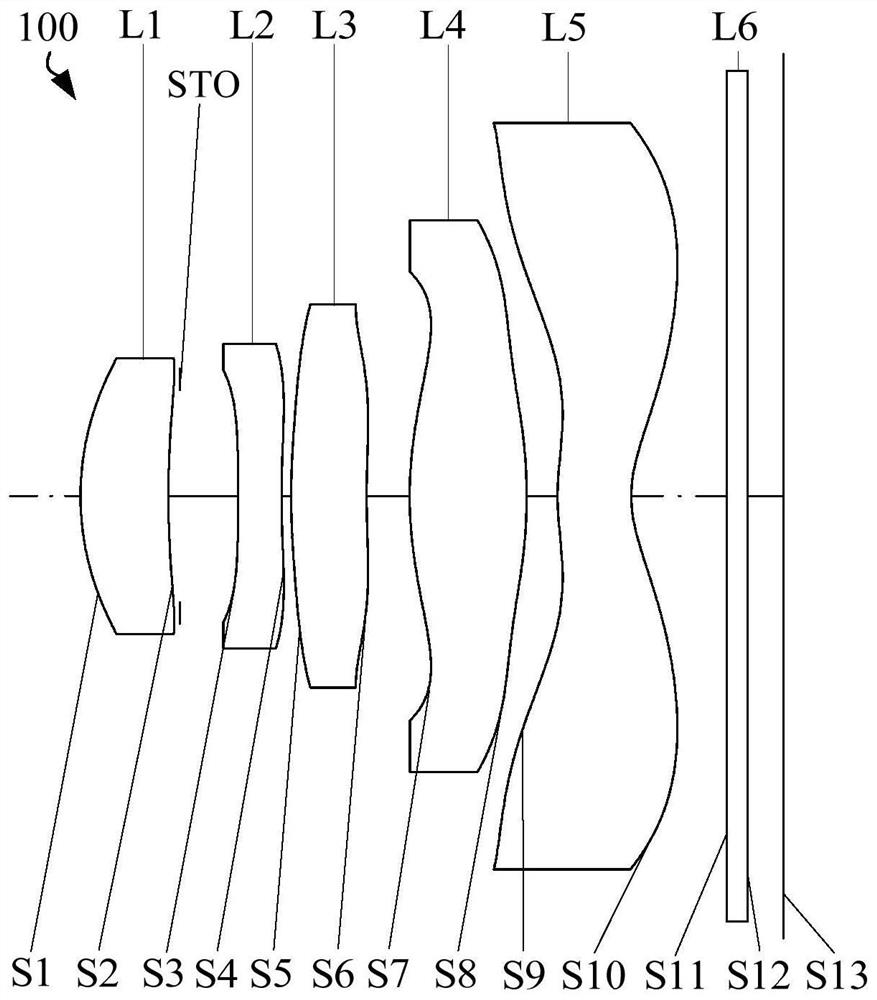

Image capturing lens, recognition module and electronic device

The invention relates to an image capturing lens comprising, in order from an object side to an image side: a first lens element with negative refractive power; a second lens element with positive refractive power; a third lens element with positive refractive power; the image capturing lens satisfies the following relational expressions: SD11 / sin (ANG12) is greater than 2.50 mm and less than 5.20mm, wherein SD11 is the height of the maximum effective diameter of the object side surface of the first lens relative to the optical axis, and ANG12 is the included angle between the tangent line ofthe curved surface of the image side surface of the first lens at the maximum effective diameter and the vertical line of the optical axis. When the relationship is satisfied, the effective semi-aperture of the object side surface of the first lens can be reasonably controlled to effectively enlarge the field angle of the image capturing lens; and meanwhile, the included angle between the curvedtangent line and the tangent point vertical line of the image side surface of the first lens at the maximum effective diameter can be controlled, so that the surface type of the image side surface ofthe first lens is not bent excessively, the forming yield of the first lens is improved, and the manufacturing difficulty and cost are reduced.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

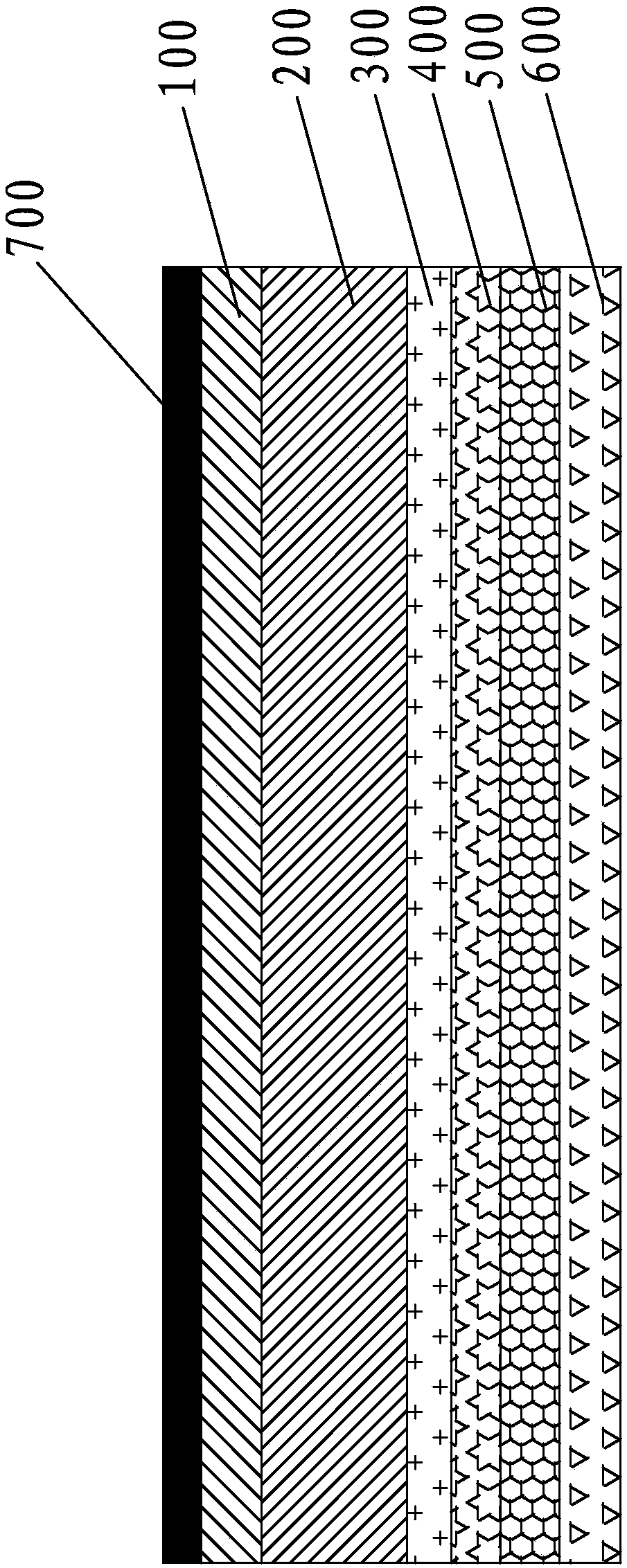

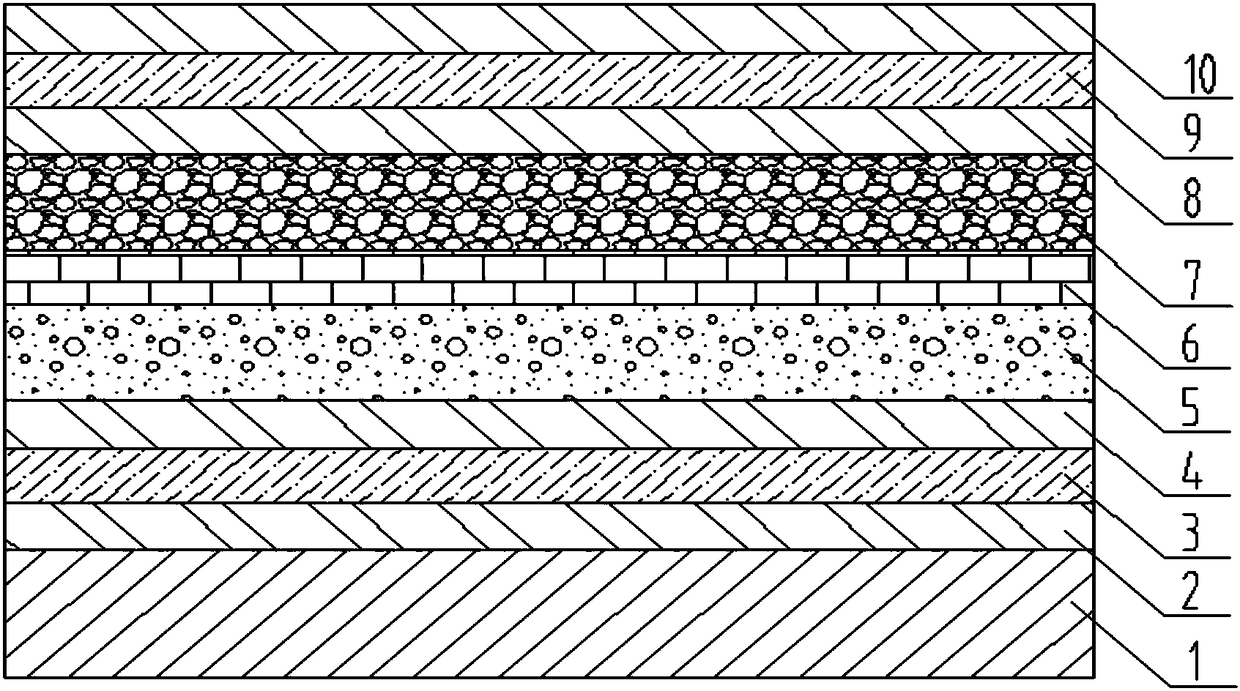

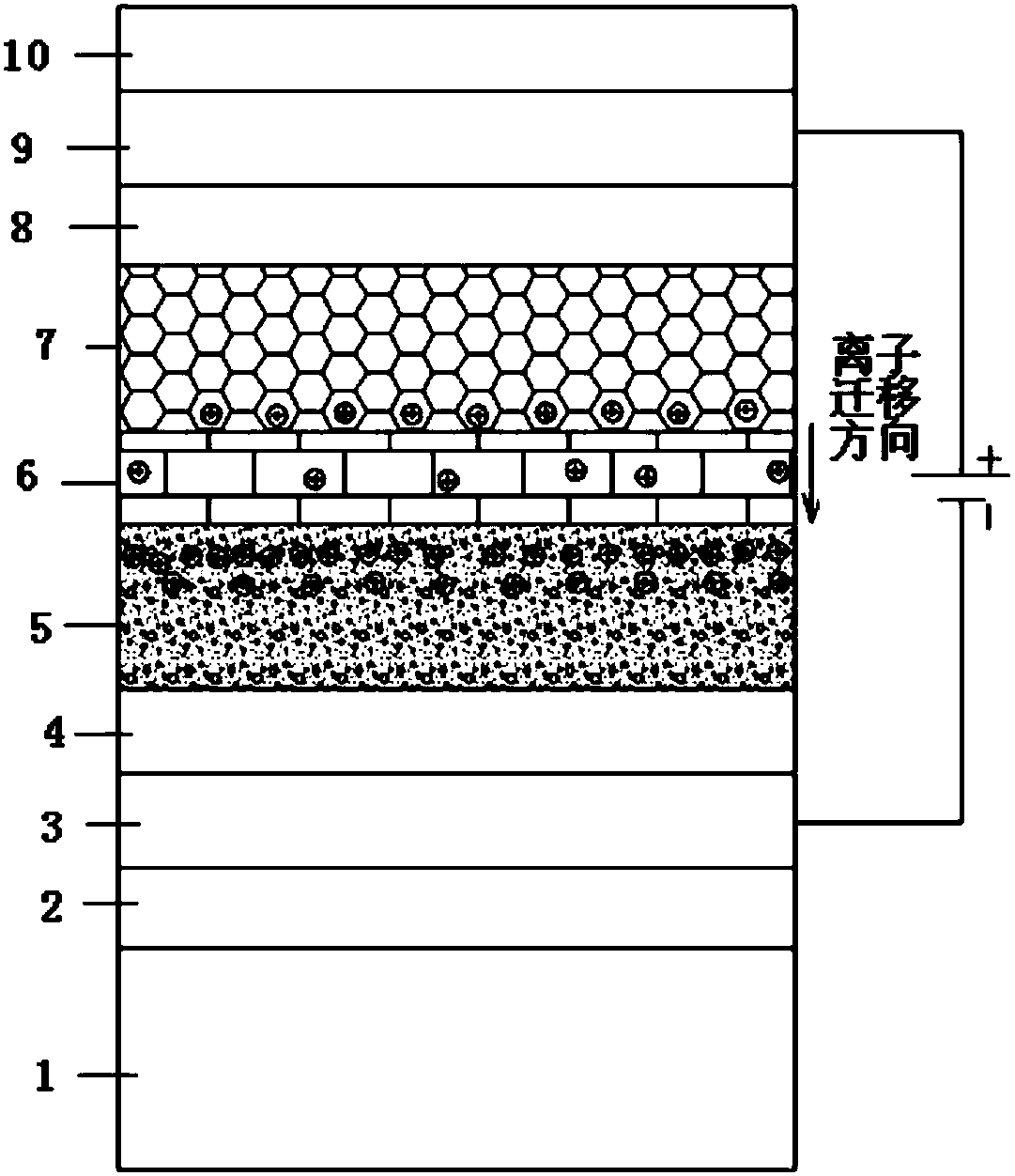

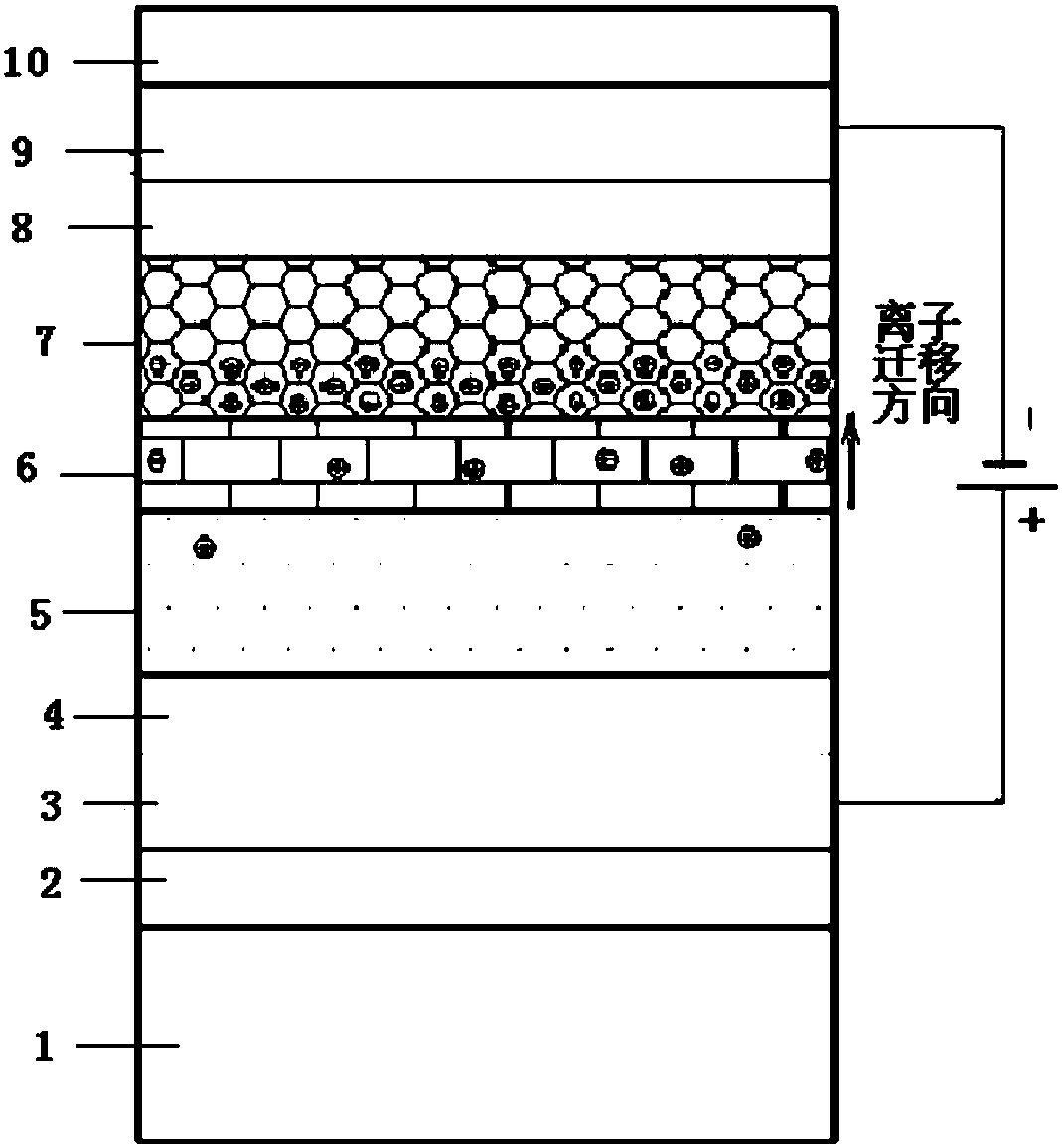

High-reliability inorganic all-solid-state electrochromic film device and preparing method thereof

InactiveCN108279541AExtend your lifeImprove performanceCoatingsNon-linear opticsAll solid stateElectrical conductor

The invention provides a high-reliability inorganic all-solid-state electrochromic film device and a preparing method thereof. The device comprises a substrate, and a first protection layer, a first transparent conductor layer, a second protection layer, an inorganic discoloring layer, an inorganic ionic conduction layer, an inorganic ion storage layer, a third protection layer, a third transparent conductor layer and a fourth protection layer which are arranged on the substrate in sequence. The film combination is of an all-solid-state structure, all film layers are in inorganic solid states,the activity of film materials cannot degrade or reduce over time, or there is no mutual corrosion problem among the materials. In the high-reliability inorganic all-solid-state electrochromic film device, the protection layers arranged mainly to avoid short circuit inside the transparent conductor layers and discoloration and failure. Therefore, the performance of all the film layers is strengthened, the light pass rate can be controlled precisely, the response time is prolonged, the good-product rate of shaped films is increased, the service life of the electrochromic device is prolonged, and the cost is reduced.

Owner:安徽鑫昊等离子显示器件有限公司

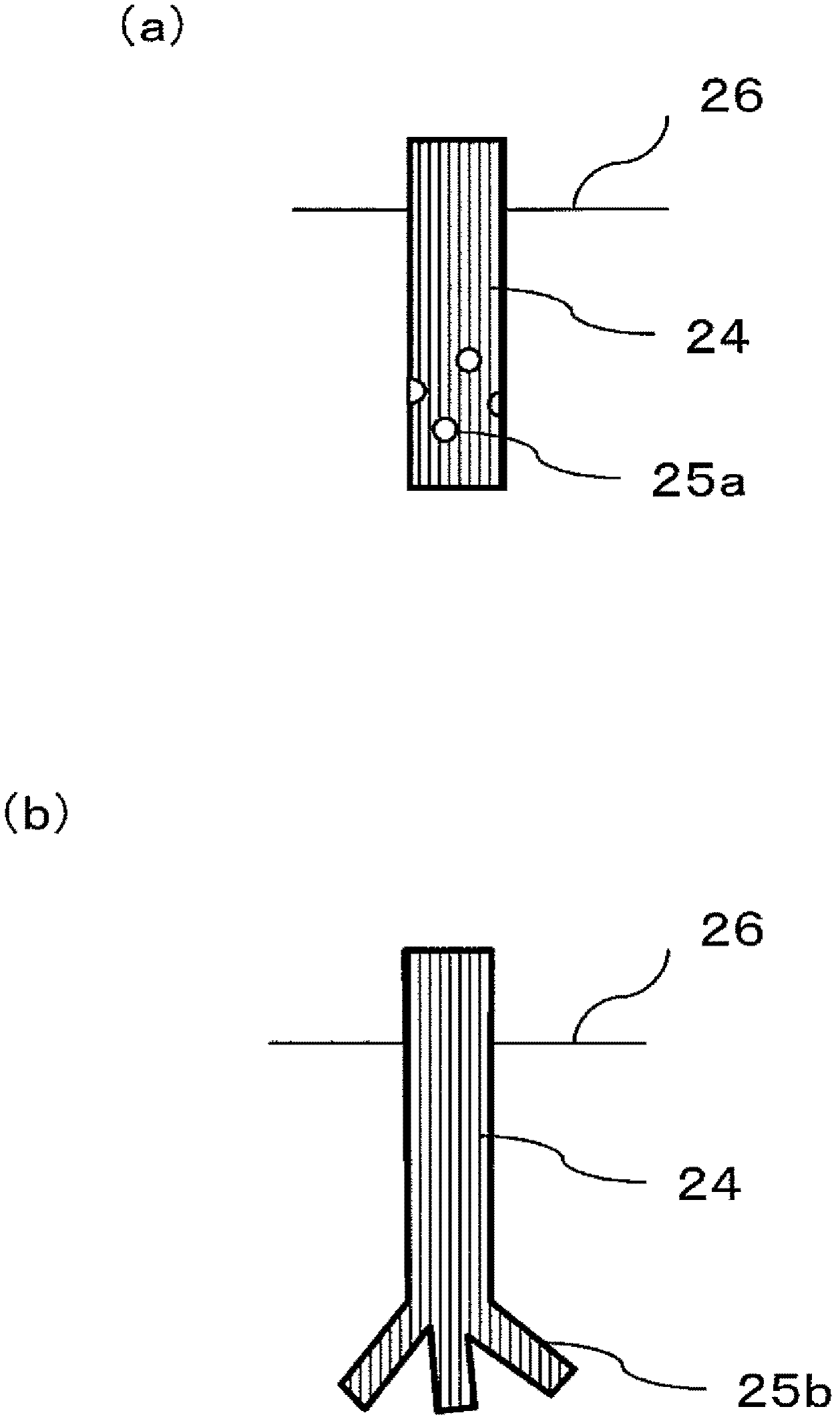

Lubricating oil composition for die forging and die forging device

InactiveCN102510895AImprove the lubrication effectSolution to short lifeForging/hammering/pressing machinesHingesChemical compositionSprayer

Provided is a lubricating oil composition for die forging which has excellent lubricity. Also provided is a die forging device which is suitable also for the lubricating oil composition for die forging. The lubricating oil composition for die forging comprises at least two solid lubricants differing in particle diameter, an extreme-pressure additive, and a base oil as the remainder. The die forging device comprises: a pair of dies, an upper die and a lower die, that is for sandwiching therebetween a material to be forged and forming the material; and a lubricating-oil-composition sprayer for spraying the lubricating oil composition for die forging over the surfaces of the dies. The lubricating-oil-composition sprayer is equipped with an oil supply tank in which the lubricating oil composition for die forging is stored and a supply pipe for sucking up the lubricating oil composition for die forging from the oil supply tank and supplying the composition to a nozzle, the supply pipe having a plurality of suction ports.

Owner:MITSUBISHI HEAVY IND LTD +1

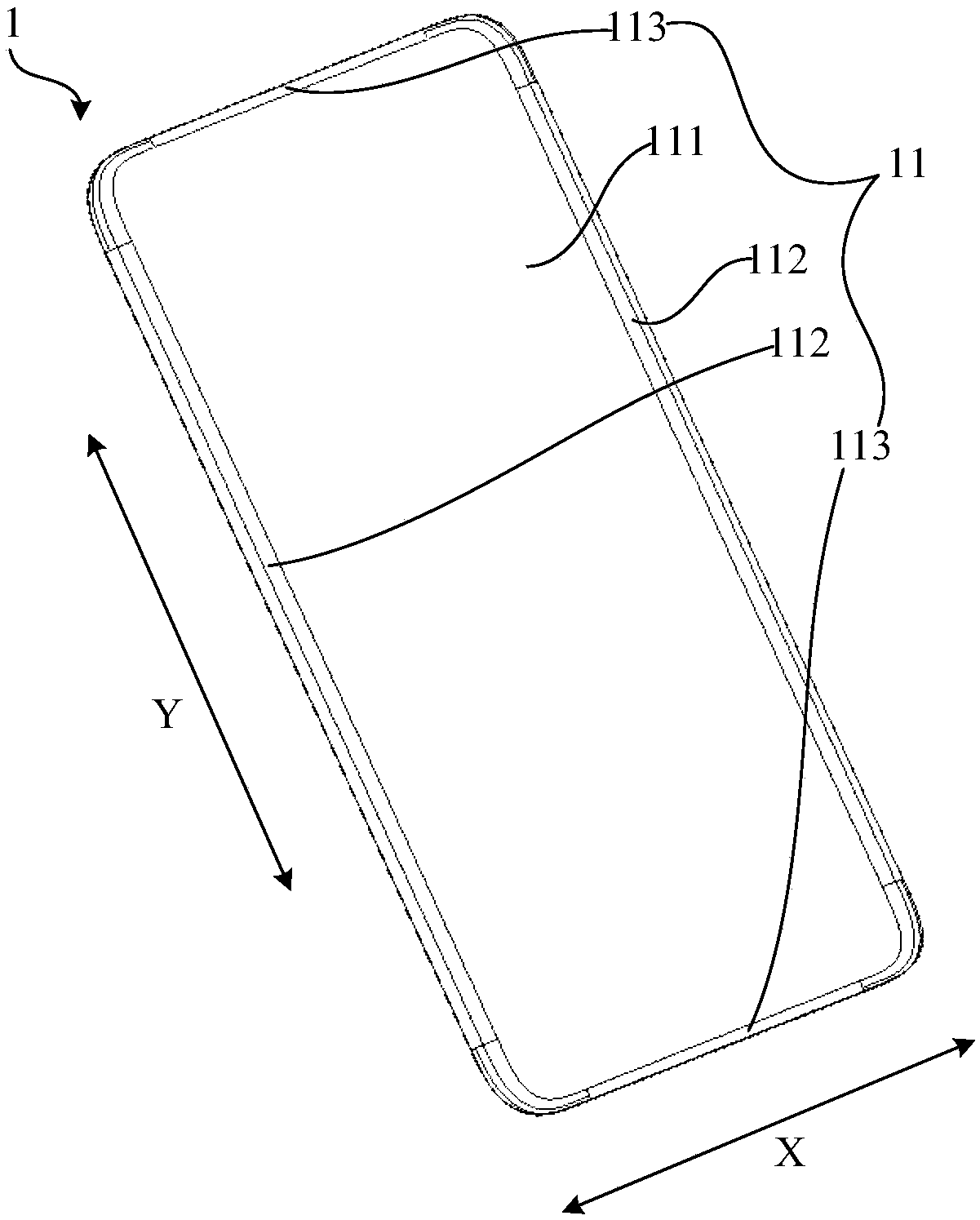

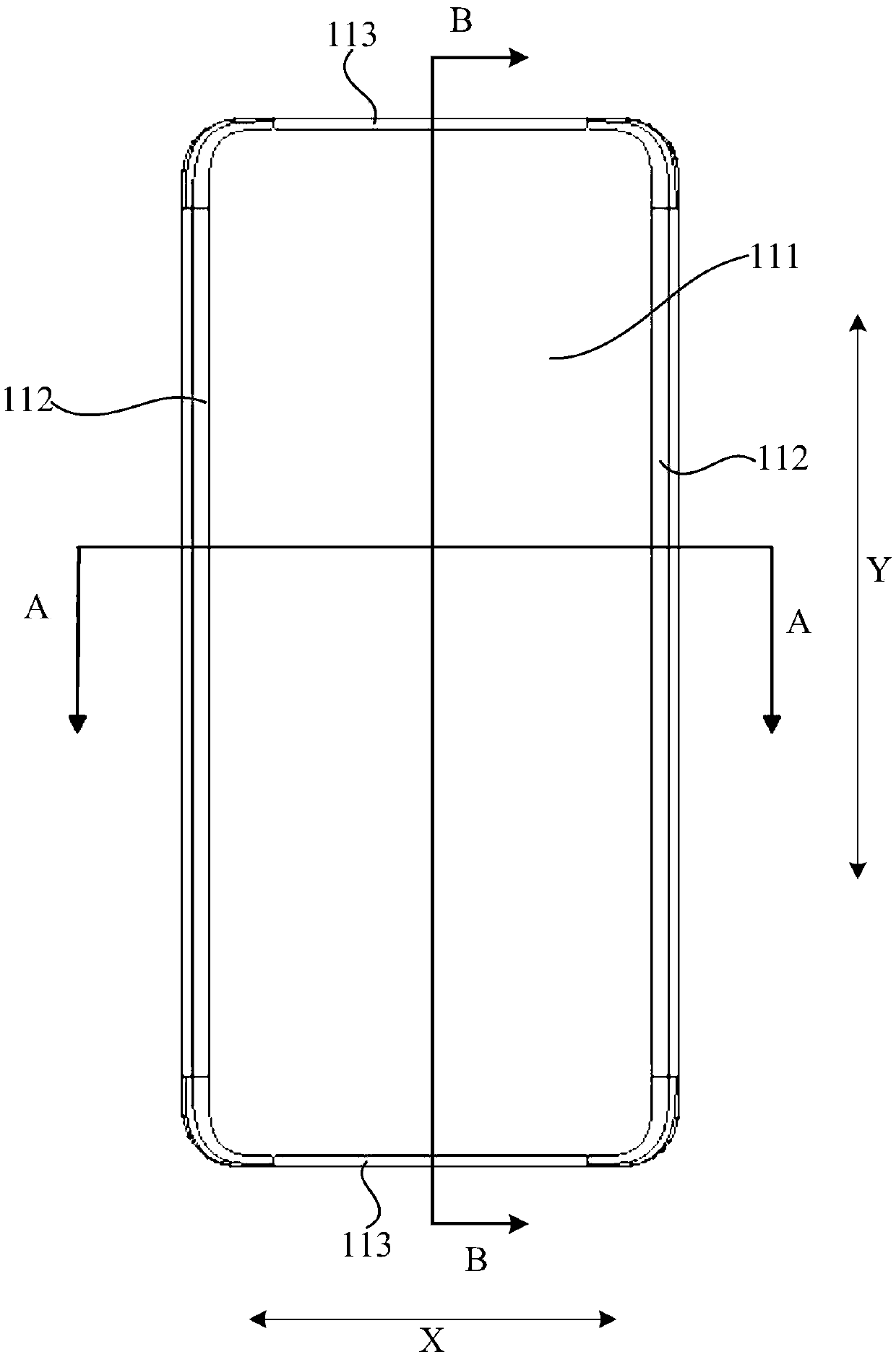

Curved surface cover plate, processing method of curved surface cover plate and terminal

InactiveCN110661906AFeel goodGood lookingTelephone set constructionsEngineeringStructural engineering

The invention discloses a curved surface cover plate, a processing method of the curved surface cover plate and a terminal, and relates to the technical field of terminals. The problems of how to improve the hand feeling and the appearance effect of the curved surface cover plate, reduce the machining difficulty of the curved surface cover plate and improve the attaching yield of the curved surface cover plate and a display screen are solved. The curved surface cover plate comprises a front surface and a back surface, wherein the front surface comprises a first middle region, two first edge regions and two second edge regions; wherein the first edge area and the second edge area are both cambered surfaces, the back surface comprises a second middle area and two third edge areas, the two third edge areas are respectively opposite and parallel to the two first edge areas, the second middle area is parallel to the first middle area, and the second middle area is opposite to the first middle area and the two second edge areas. The curved surface cover plate is used in the terminal to cover a screen or a battery.

Owner:HONOR DEVICE CO LTD

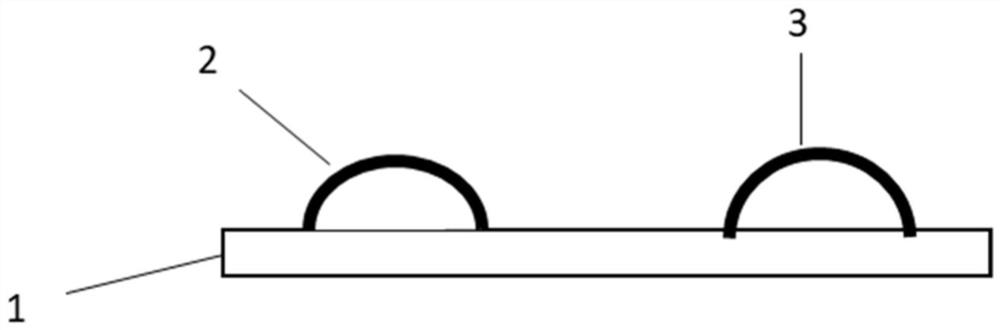

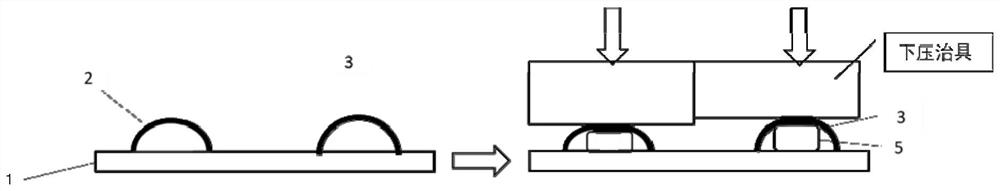

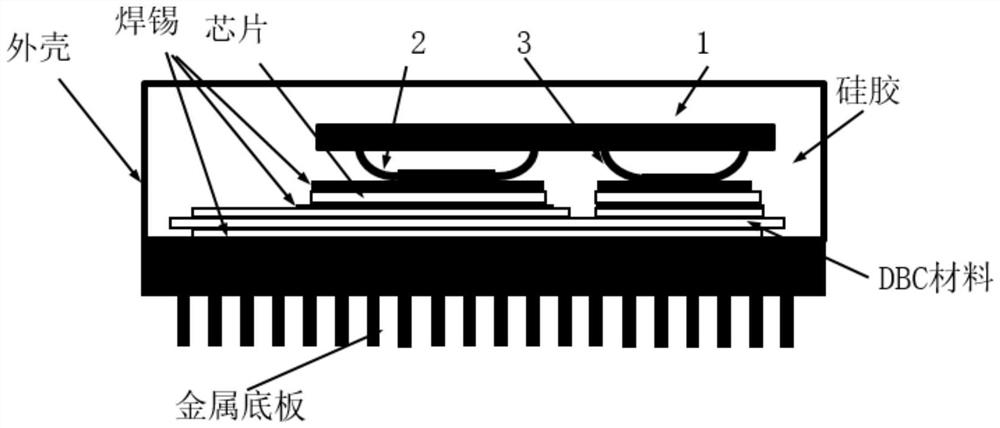

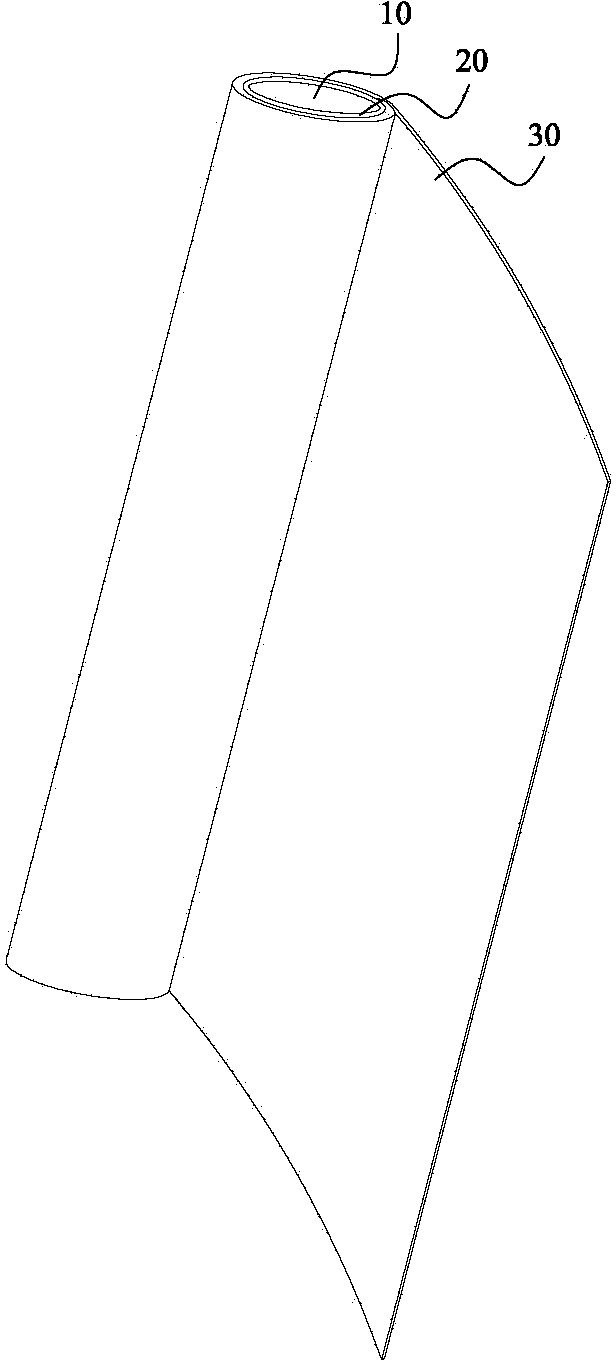

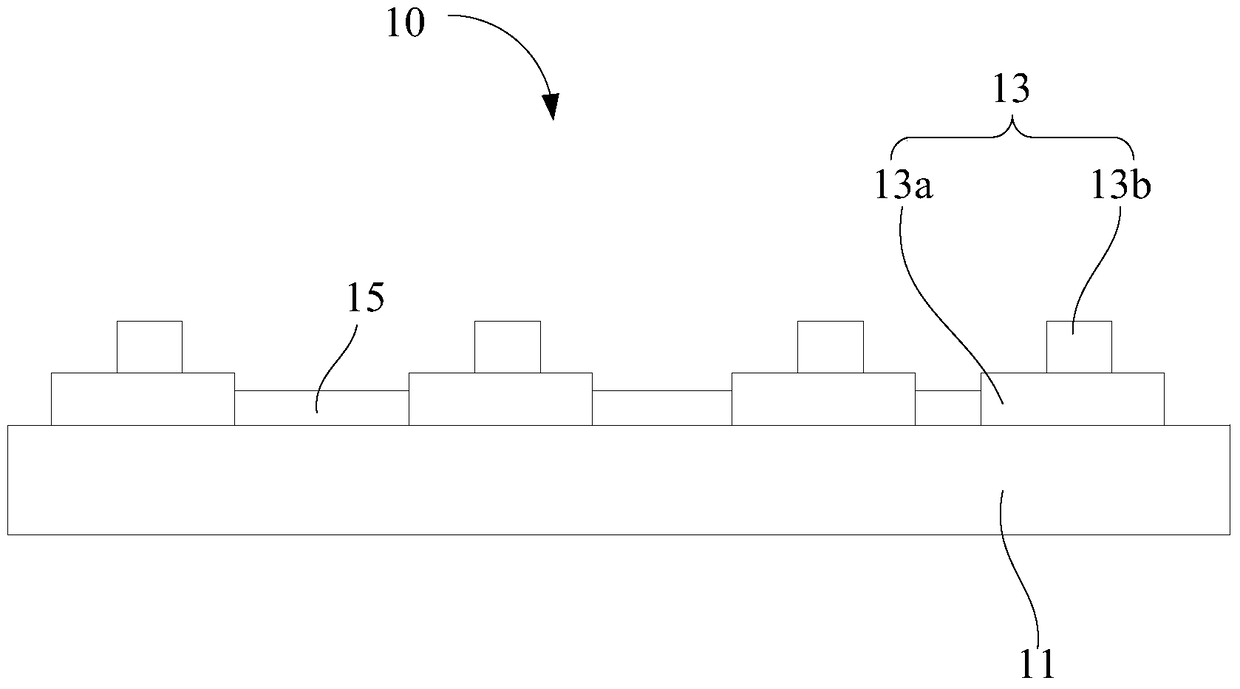

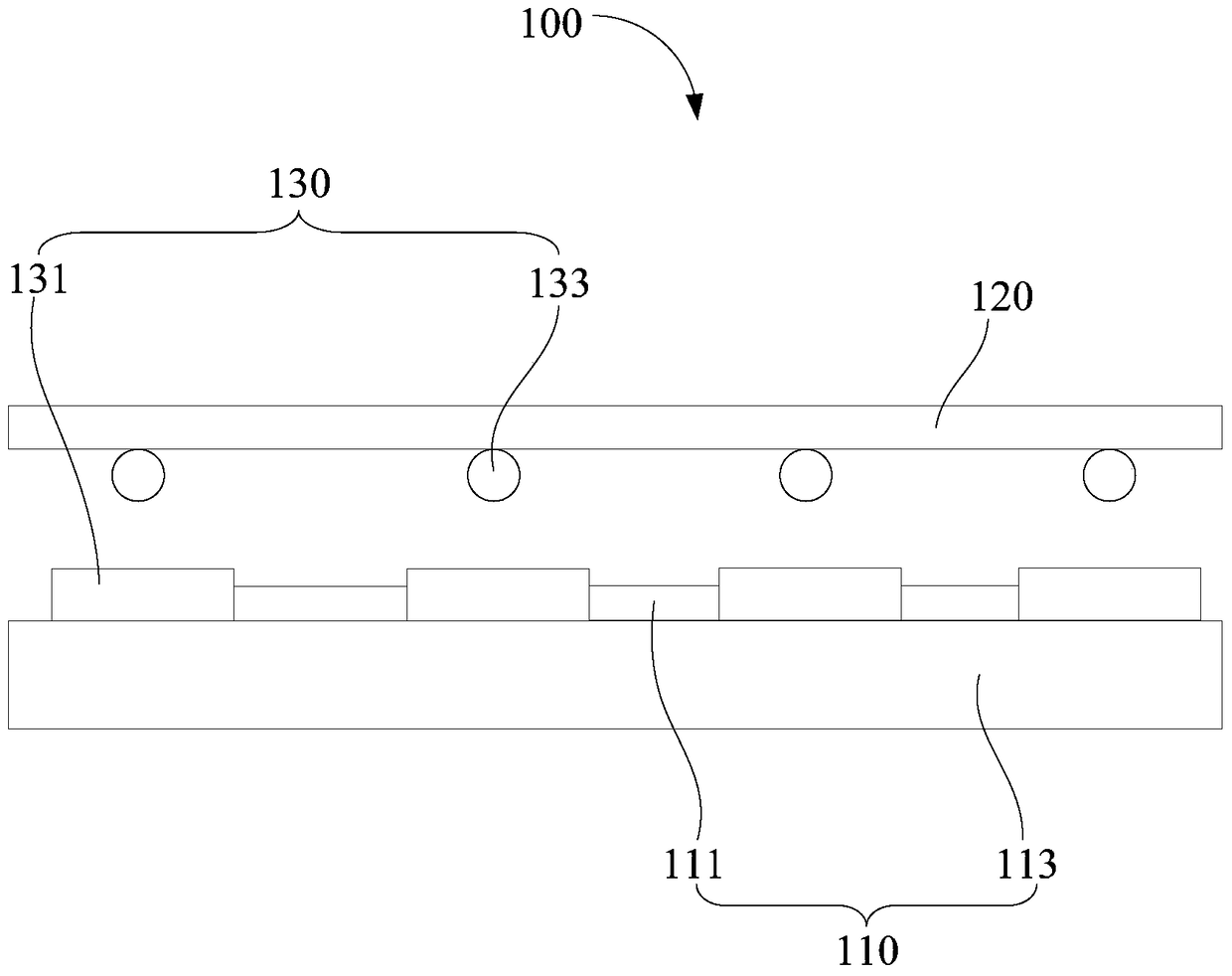

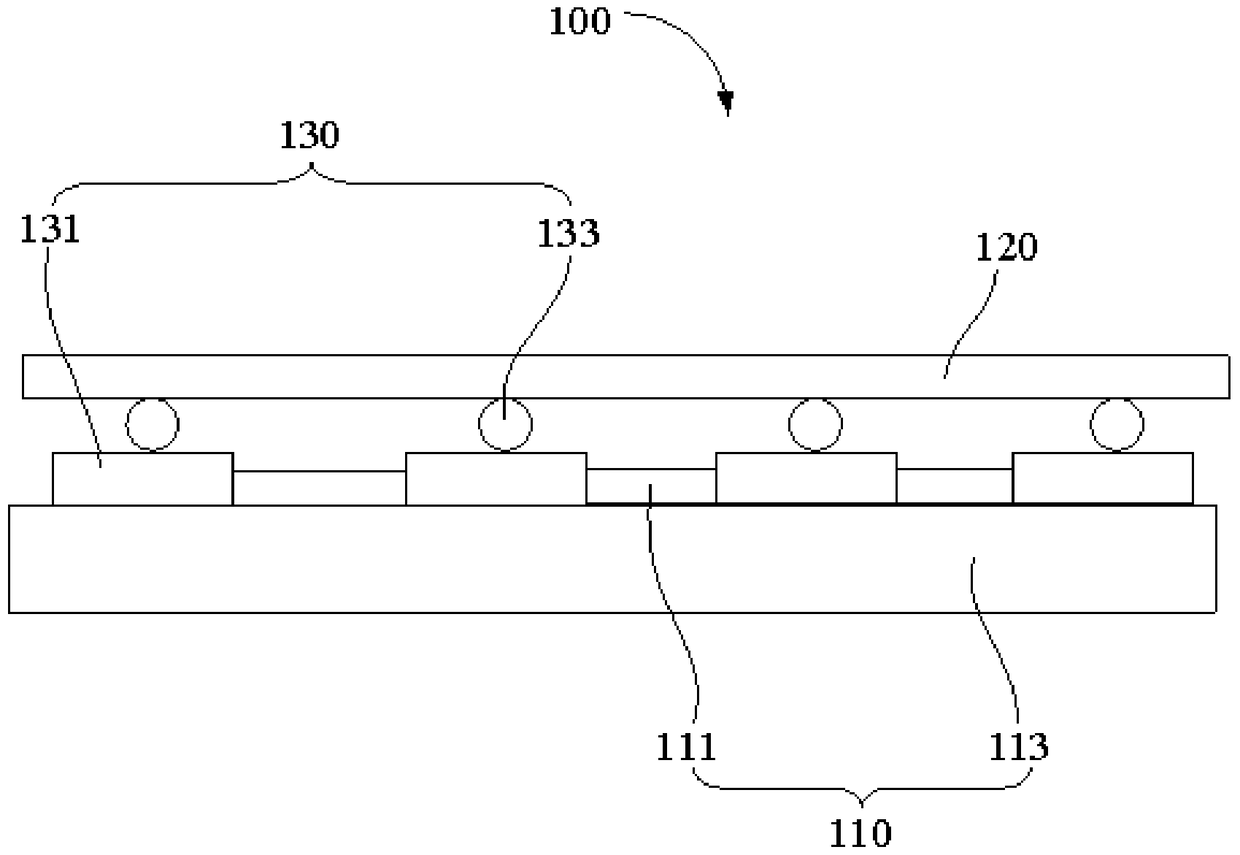

Power module internal connection copper sheet, preparation method thereof, and power semiconductor module

PendingCN113658934AReduce weightReduce mechanical fracturingSemiconductor/solid-state device detailsSolid-state devicesMetallurgySemiconductor

The invention provides a power module internal connection copper sheet and a preparation method thereof. The power module internal connection copper sheet comprises a copper plate, a first copper strip and a second copper strip, the first copper strip and the second copper strip are arranged on the copper plate at an interval, the first copper strip and the second copper strip are arc-shaped, the two ends of the first copper strip are both connected to the copper plate, and the two ends of the second copper strip are both connected to the copper plate. The secondary forming difficulty of the copper plate in the module is reduced, and batch production capacity is achieved.

Owner:WUXI LEAPERS SEMICON CO LTD

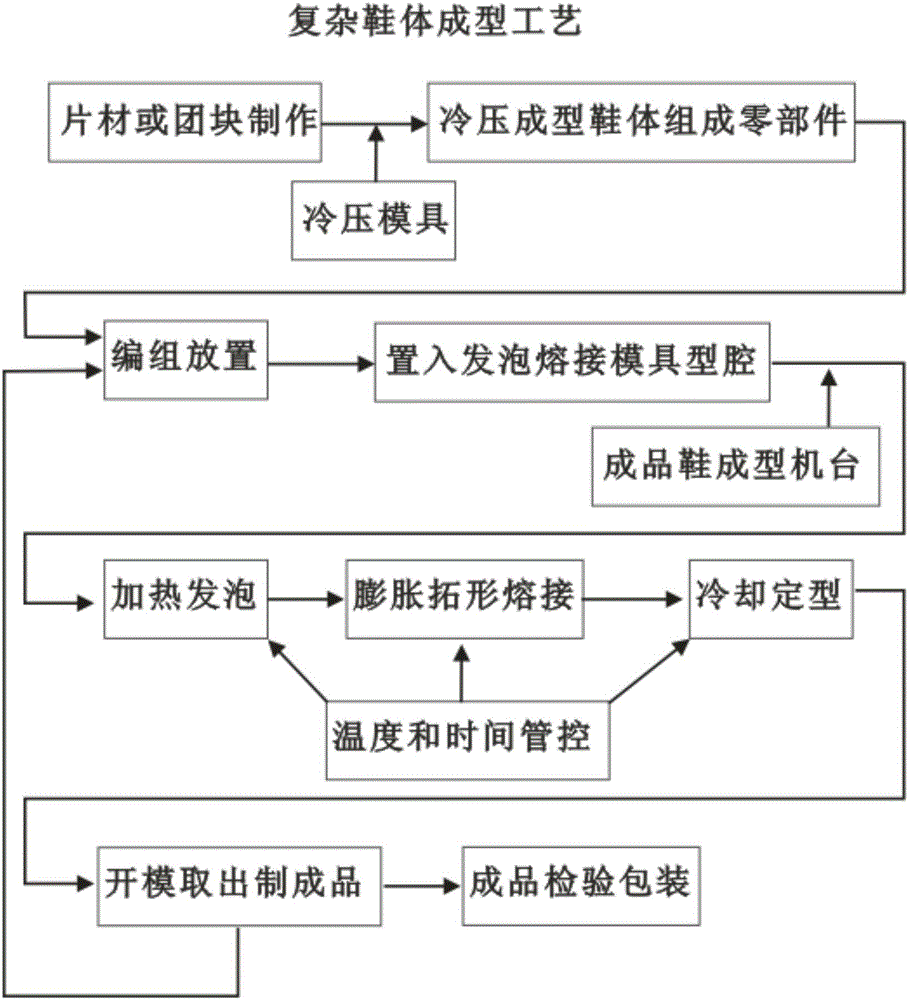

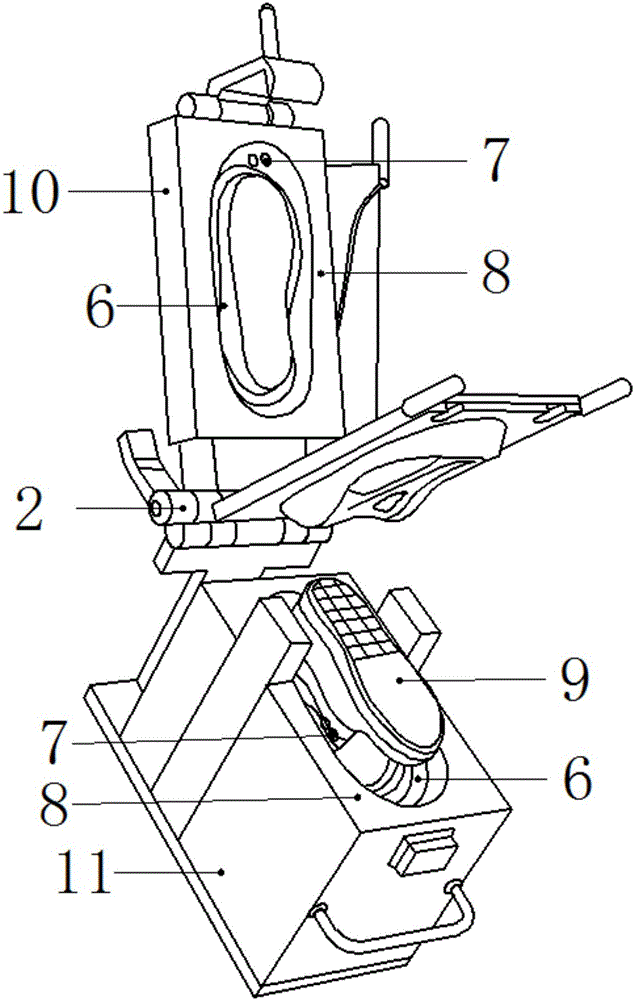

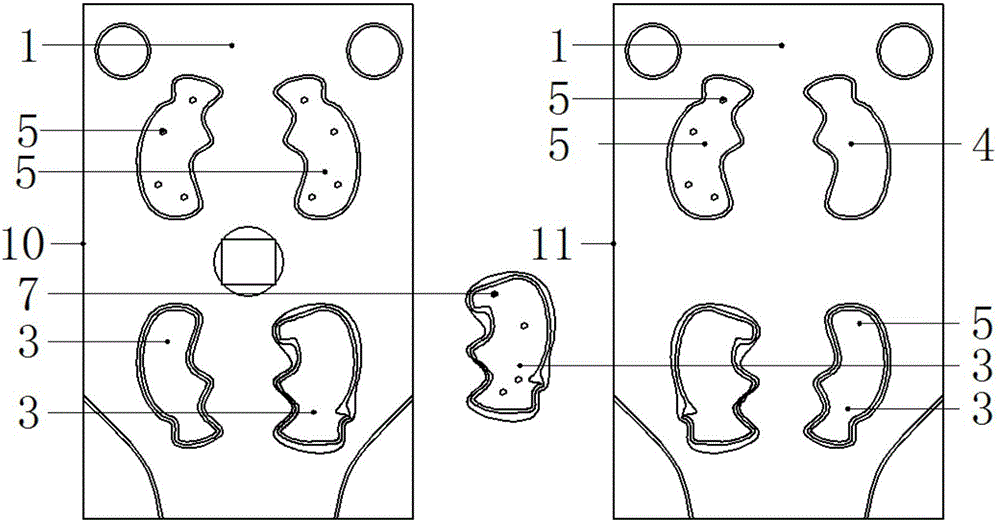

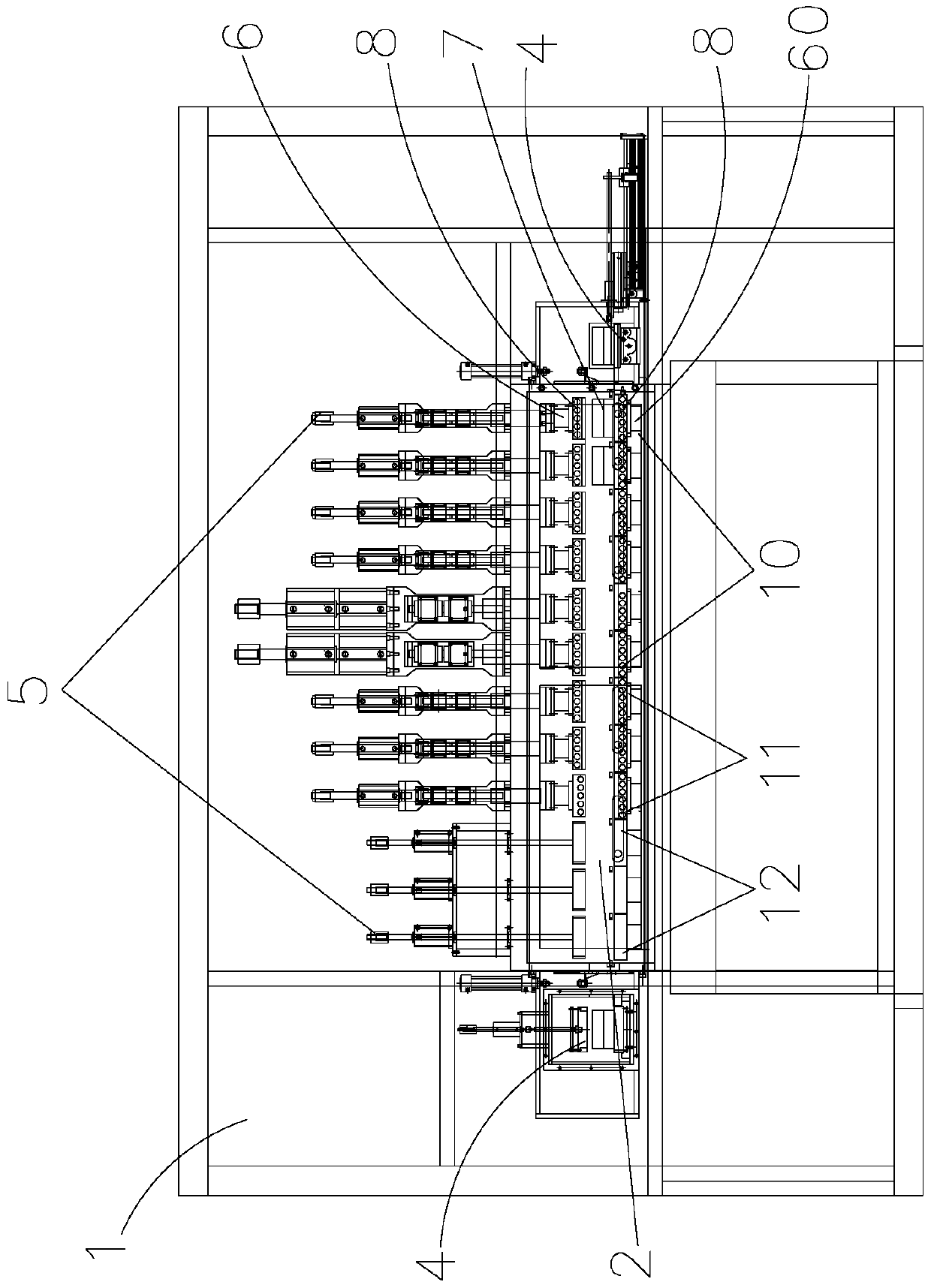

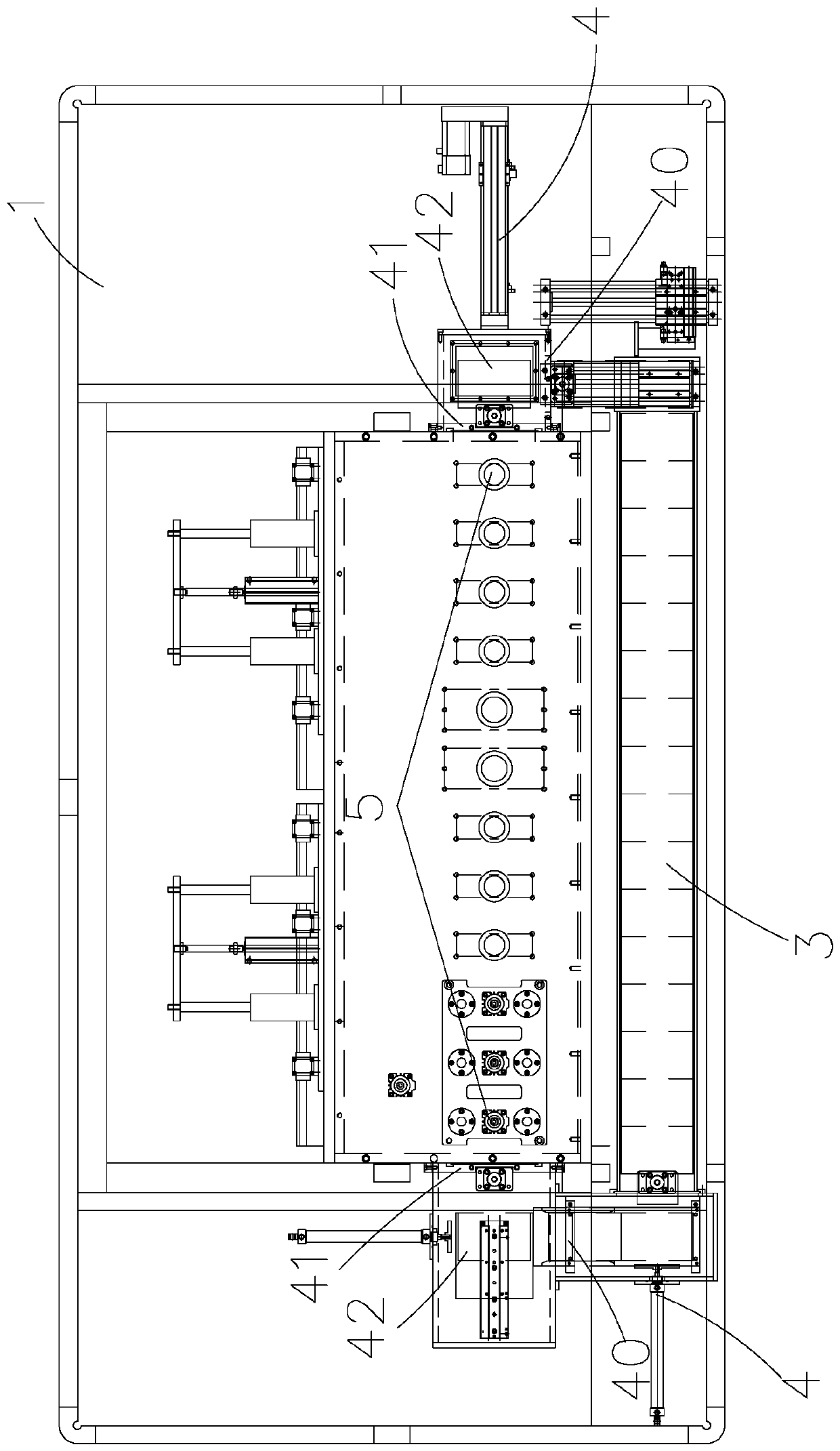

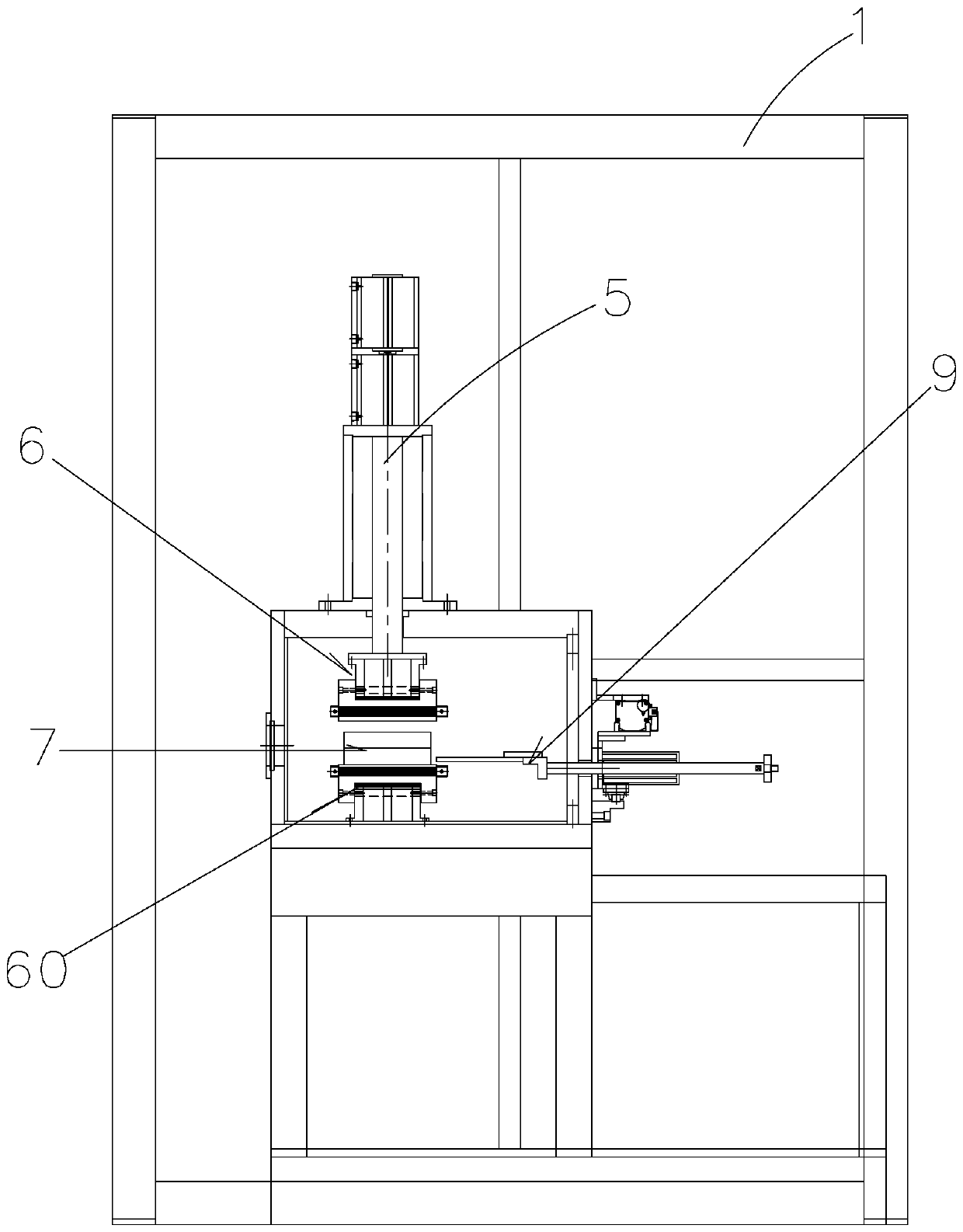

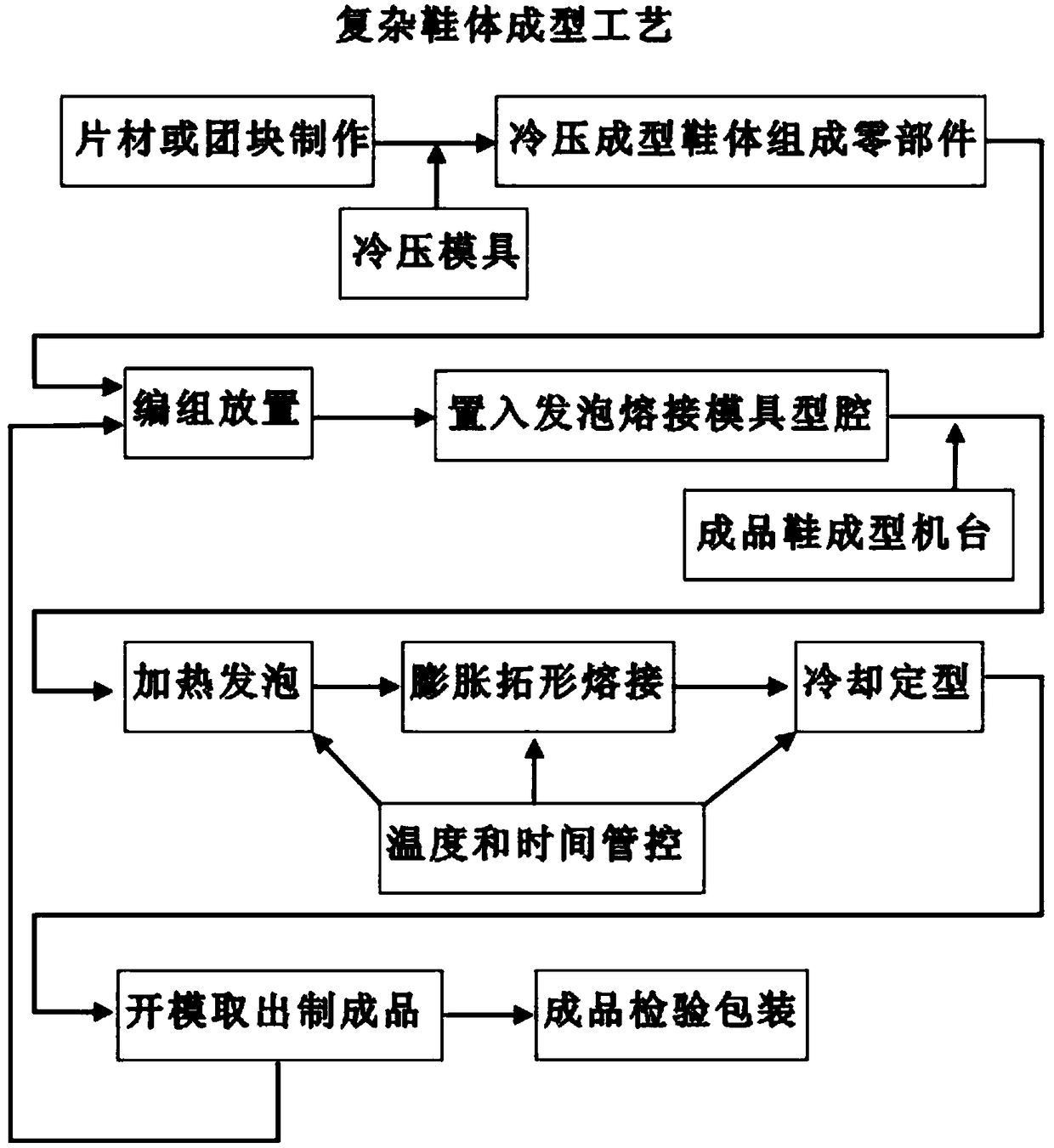

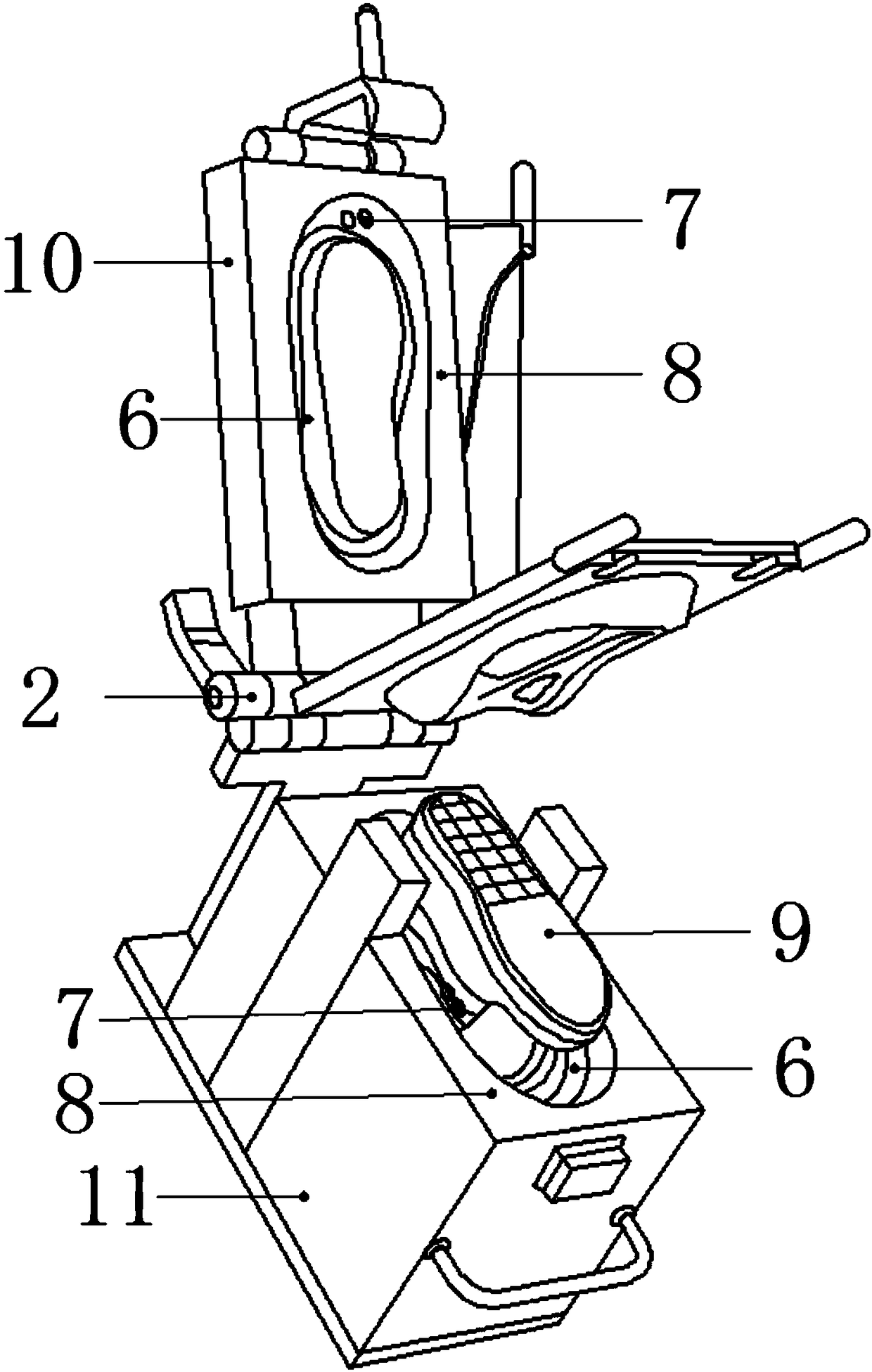

Foaming, welding, forming and manufacturing process of complex shoe body

ActiveCN106346812AReduce labor intensityShorten molding cycleDomestic footwearEngineeringUltimate tensile strength

The invention discloses a foaming, welding, forming and manufacturing process of a complex shoe body. A target formed complex shoe body has a plurality of complex raised grains or holes or color blocks, and forming process materials of the target formed complex shoe body include a shoe material which contains an unexcited foamer, a cold pressing mold, a foaming and welding mold and a finished shoe forming cabinet; during production and manufacturing, the shoe material which contains the unexcited foamer is prepared into sheets or agglomerates and then is divided into parts and components of the shoe body through cold pressing by the cold pressing mold, the parts and the components of the shoe body are put in the foaming and welding mold and are heated by the finished shoe forming cabinet so as to foam, forming and weld the parts and the components, and the complex shoe body is formed by a plurality of simple spare parts. According to the foaming, welding, forming and manufacturing process, the structure of the mold can be greatly simplified, the labor intensity of operators is reduced, the production speed and the one-time rate of good products are increased, the defects of difficulty in manufacturing the mold of the complex shoe body, long forming and manufacturing cycle, high defect rate and the like are overcome, the maintenance and service are facilitated, the structure is reliable, the cost is low, and multiple purposes are achieved once.

Owner:蔡元耀

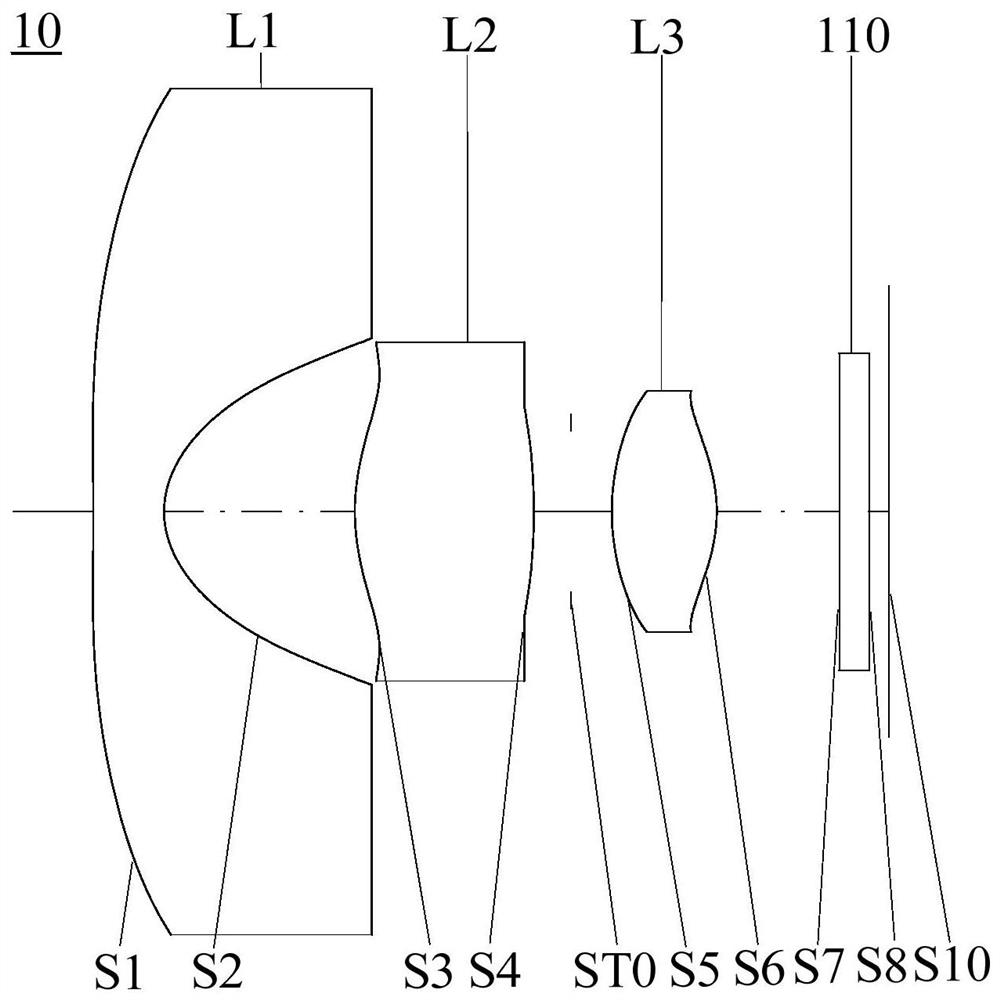

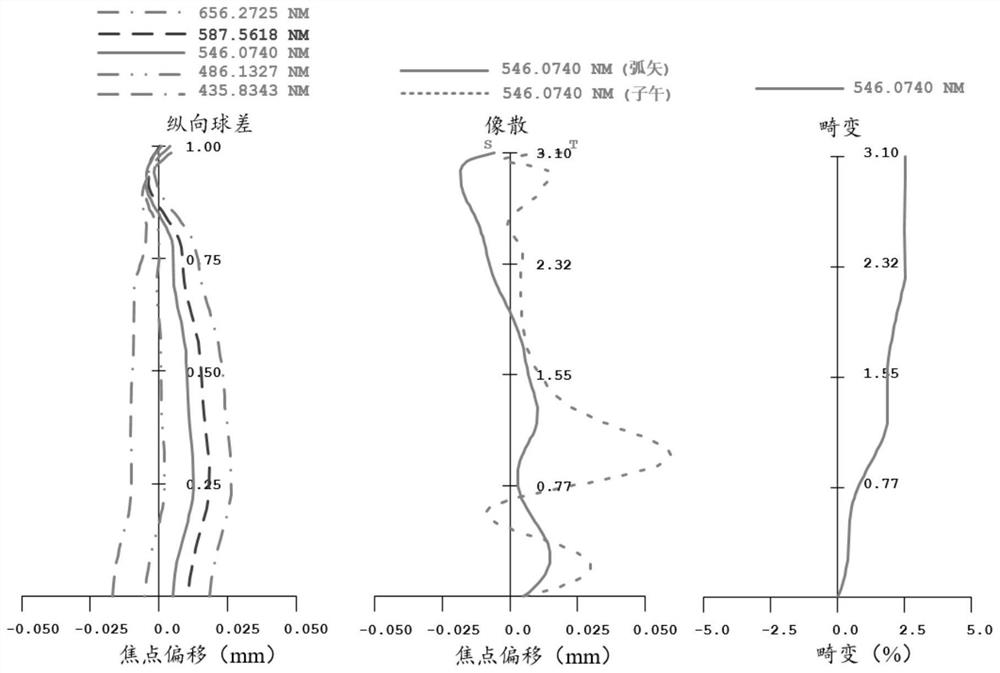

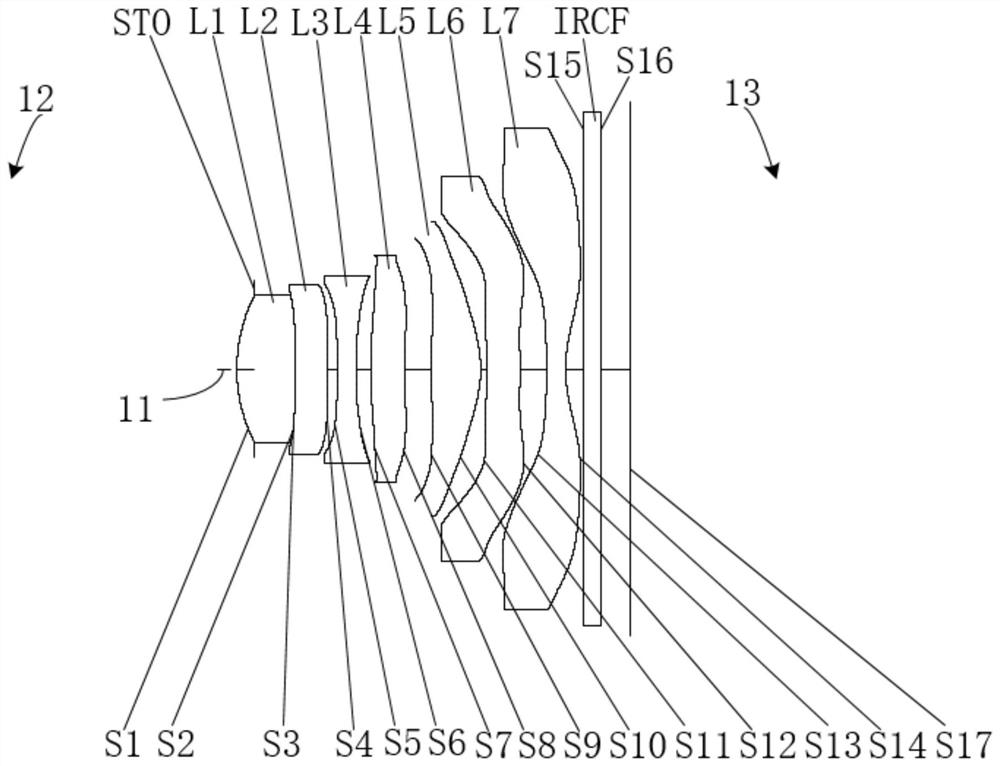

Optical system, camera module and terminal equipment

PendingCN112505882AWith miniaturizationImprove molding yieldOptical elementsNegative refractionOphthalmology

The embodiment of the invention discloses an optical system, a camera module and terminal equipment. The optical system comprises a first lens and a fifth lens which have positive refraction power, asecond lens and a seventh lens which have negative refraction power, and a third lens, a fourth lens and a sixth lens which have refraction power. The object side face of the first lens is convex at aparaxial region, the image side face of the fourth lens is concave at a paraxial region, the object side surface and the image side surface of the fifth lens are convex at a paraxial region, the image side surface of the sixth lens is convex at a paraxial region, and the image side surface of the seventh lens is concave at a paraxial region. The image side surface of the first lens and the objectside surface of the second lens are glued. By reasonably configuring the refractive power and the surface type of the first lens to the seventh lens in the optical system and limiting the first lensand the second lens to be glued, the optical system can achieve the characteristics of miniaturization and small head, and the forming yield of the lens is improved.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

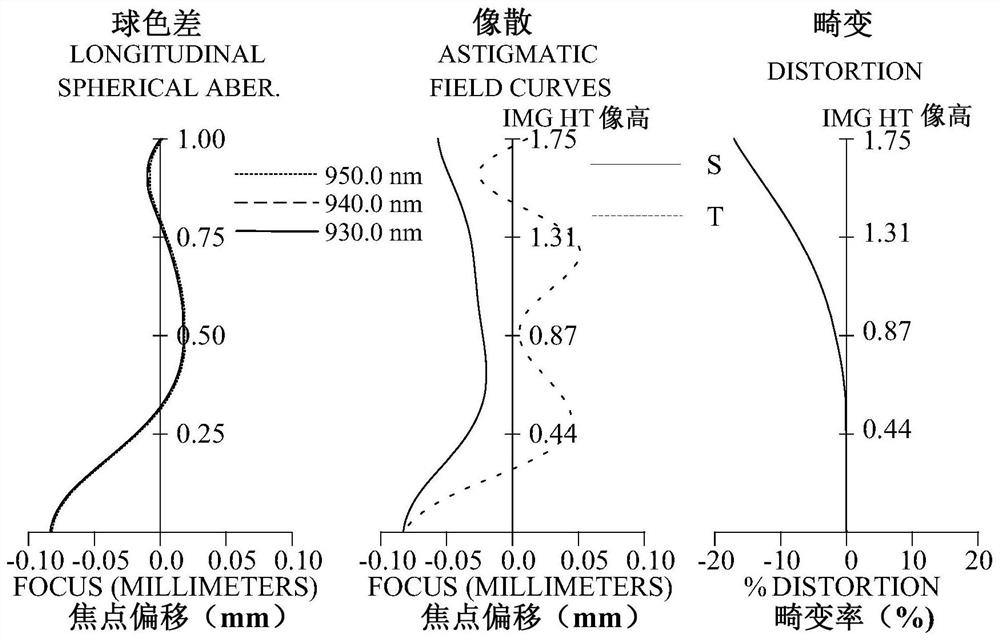

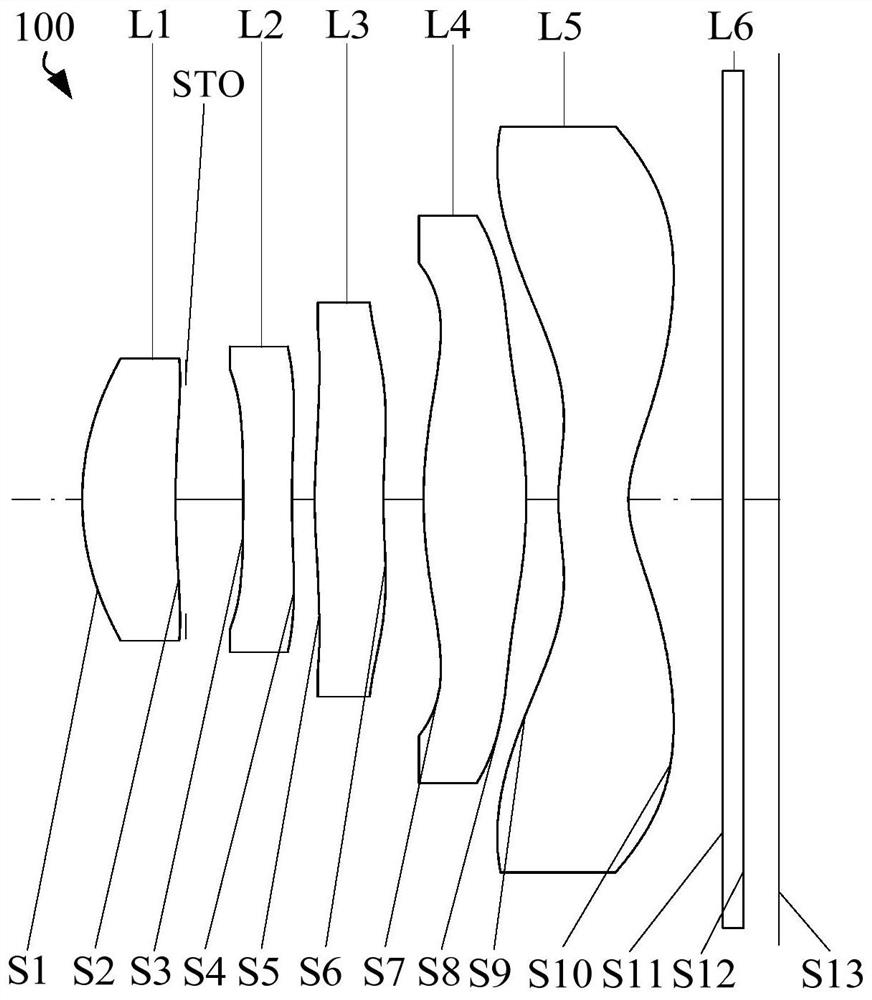

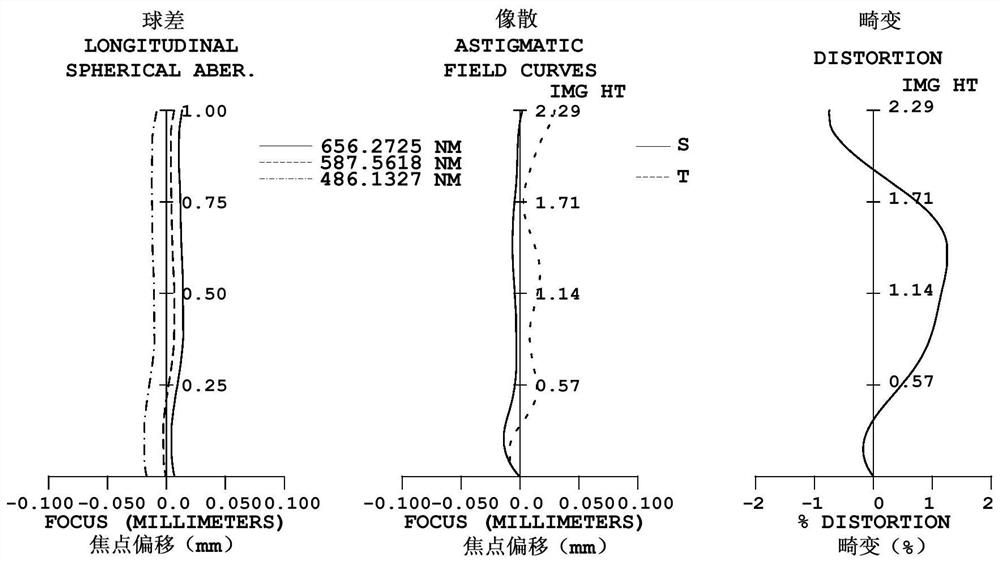

Optical system, image capturing module and electronic device

PendingCN111736307AReduce Tolerance SensitivityImprove molding yieldOptical elementsElectric devicesConditional expression

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes, in order from an object side to an image side: a first lens with positive refractive power; a second lens with negative refractive power; a third lens with refractive power; a fourth lens with positive refractive power, wherein both the object-side surface and the image-sidesurface are aspheric, and at least one of the object-side surface and the image-side surface has an inflection point; and a fifth lens with negative refractive power. The optical system satisfies thefollowing conditional expressions: 0.5 <= ET8 / CT8 <= 1.2, wherein RT8 is the edge thickness of an air lens composed of the image-side surface of the fourth lens and the object-side surface of the fifth lens, and CT8 is the distance between the image-side surface of the fourth lens and the object-side surface of the fifth lens on the optical axis. According to the optical system, the fourth lens and the fifth lens are not easy to collide with each other in the assembling process, and the assembling yield of the optical system is improved.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

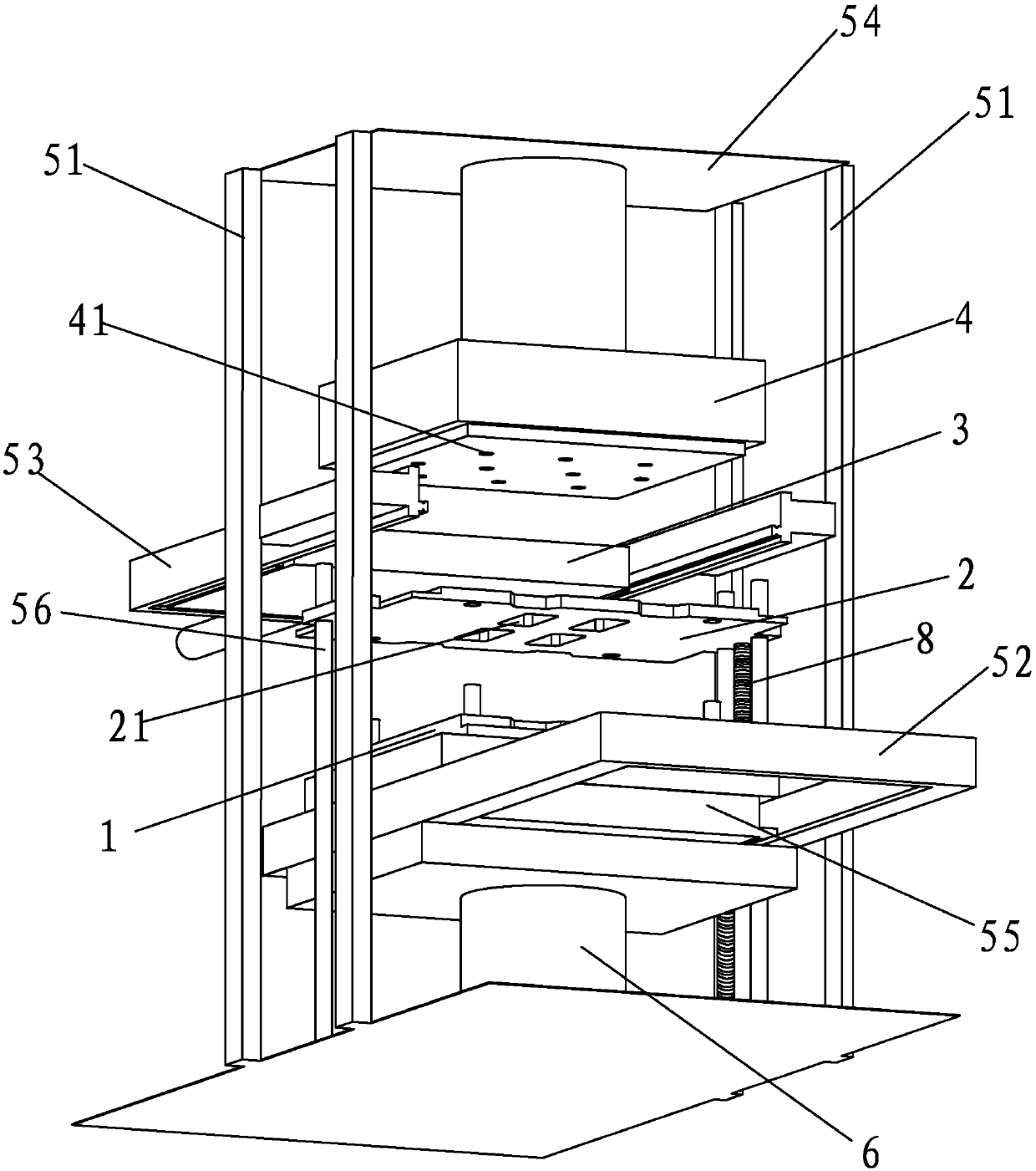

Hot bending die and hot bending equipment

PendingCN113716846AUniform internal stressImprove molding yieldGlass reforming apparatusStructural engineeringMechanical engineering

The invention provides a hot bending die and hot bending equipment, wherein the hot bending die is used for hot bending to-be-processed glass, and the hot bending die comprises a first die and a second die; the first die is provided with at least one cavity, a cavity bent surface is arranged in the cavity, and the cavity bent surface comprises a first plane and a first curved surface which are connected; the normal direction of the first plane intersects with the thickness direction of the first die, the second die and the first die are oppositely arranged, at least one protruding block is arranged on the side, facing the first die, of the second die, and the protruding block is provided with a protruding block bent face; and the protruding block bent surface and the cavity bent surface are respectively pressed on two opposite sides of to-be-processed glass during hot bending and guide the to-be-processed glass to be bent. According to the hot bending die provided by the invention, the internal stress of the whole to-be-processed glass is relatively uniform, so that the phenomenon that the to-be-processed glass deviates due to non-uniform stress is avoided, and the forming quality of the processed to-be-processed glass with the bent surface is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

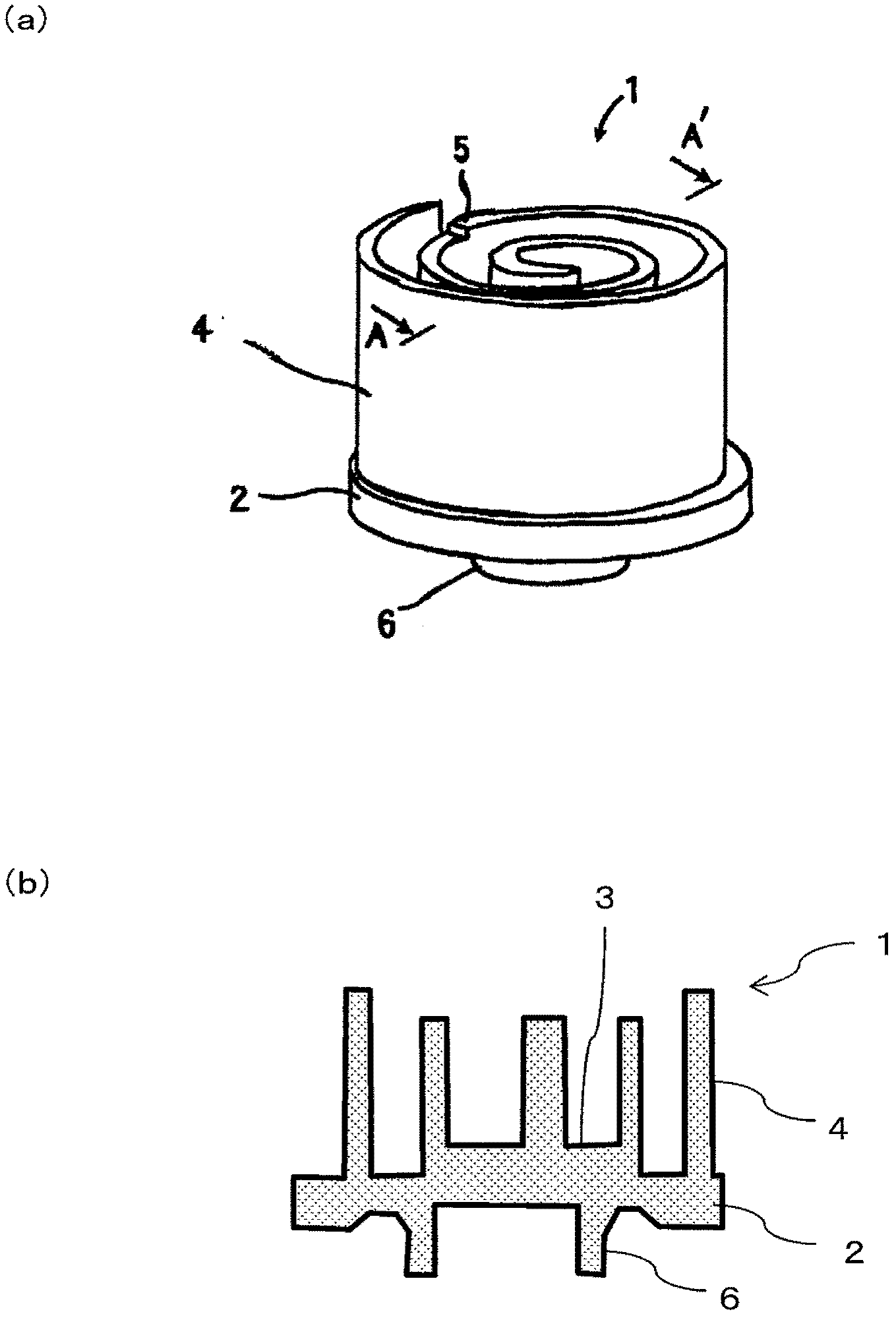

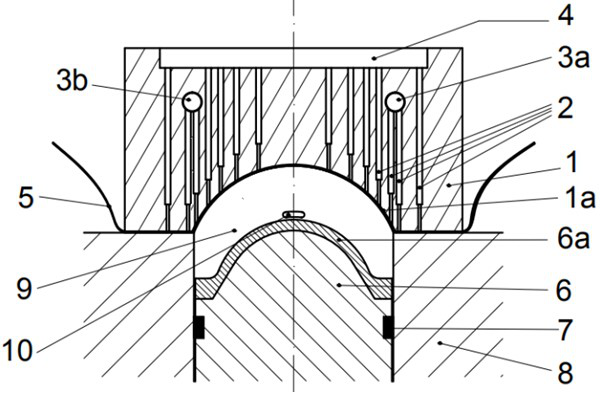

Heating field device of molding three-dimensional continuous glass molding device

PendingCN110451785AGuaranteed accuracyReduce internal stressGlass reforming apparatusGraphiteInternal stress

The invention provides a heating field device of a molding three-dimensional continuous glass molding device. The heating field device consists of a graphite heating block and a base which are integrally molded by a material with good heat conductivity, wherein the heating block has a proper number of groove holes which are tightly combined with heating elements to form a heating field; a bearingplate made of a porous ceramic material is arranged between the heating block and the base; the heating block is fixed on the base through a detachable element; and the base is fixed in a preset position of a molding device through a detachable element. As the heating field has good heat conductivity and temperature uniformity, a molded three-dimensional glass product is small in internal stress and high in molding pass percent, and the precision of sizes of products can be ensured.

Owner:秦文隆

A manufacturing process of complex shoe body foam welding

ActiveCN106346812BReduce labor intensityShorten molding cycleDomestic footwearEngineeringUltimate tensile strength

Owner:蔡元耀

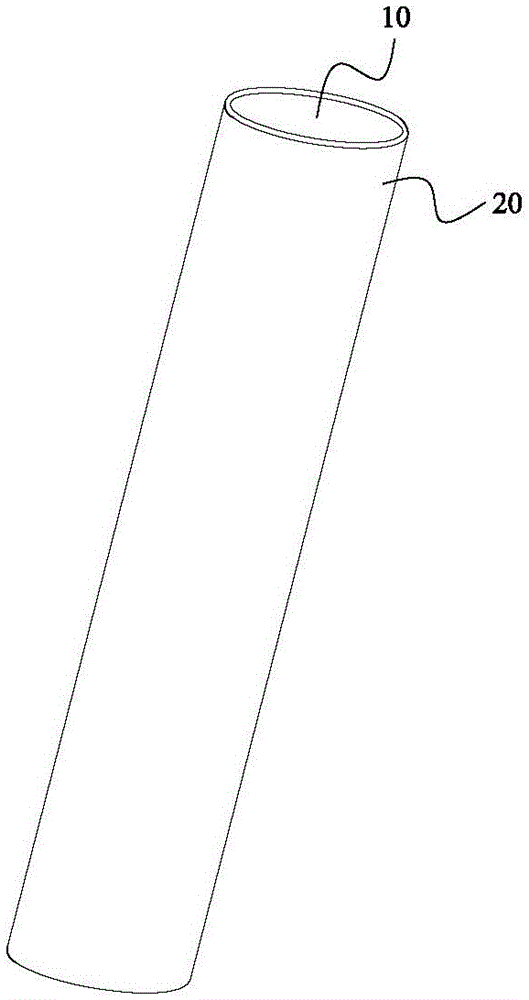

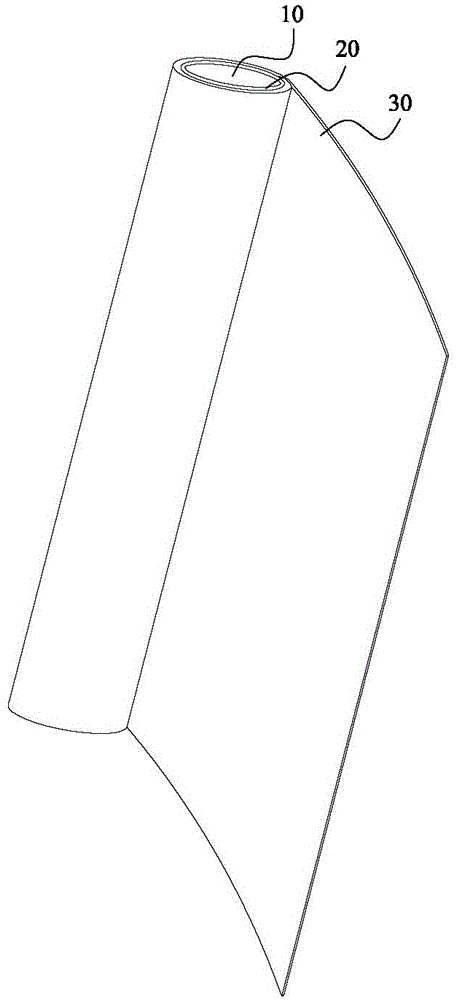

Manufacturing method for fiber tubes

A disclosed manufacturing method for fiber tubes comprises the following steps: (1) prefabricating bulk foam powder; (2) coating with a plastic interlayer; (3) reeling fiber cloth; (4) curing molding; and (5) taking out the finished product from a forming die. According to the manufacturing method, a foam powder is used for preparation of the bulk foam powder with a shape identical to the tube shape according to the shape of the tubes; then the plastic interlayer is covered, the fiber cloth is reeled, and curing molding is performed, thus a conventional mode that a fiber tube is filled with foam particles is replaced, so that the bulk foam powder is heated uniformly and expands, and thus an inner pressure is formed from the interior and the fiber cloth is expanded and clings to the inner wall of the die for molding, so that the manufacturing method helps to put an end to sand inclusion caused by the easily overflowed foam powder and molding defects comprising fake connection and the like caused by hollow foam powder, and effectively improve molding yield rate; and the manufacturing method is simple to operate and has substantially improved working efficiency.

Owner:徐建升

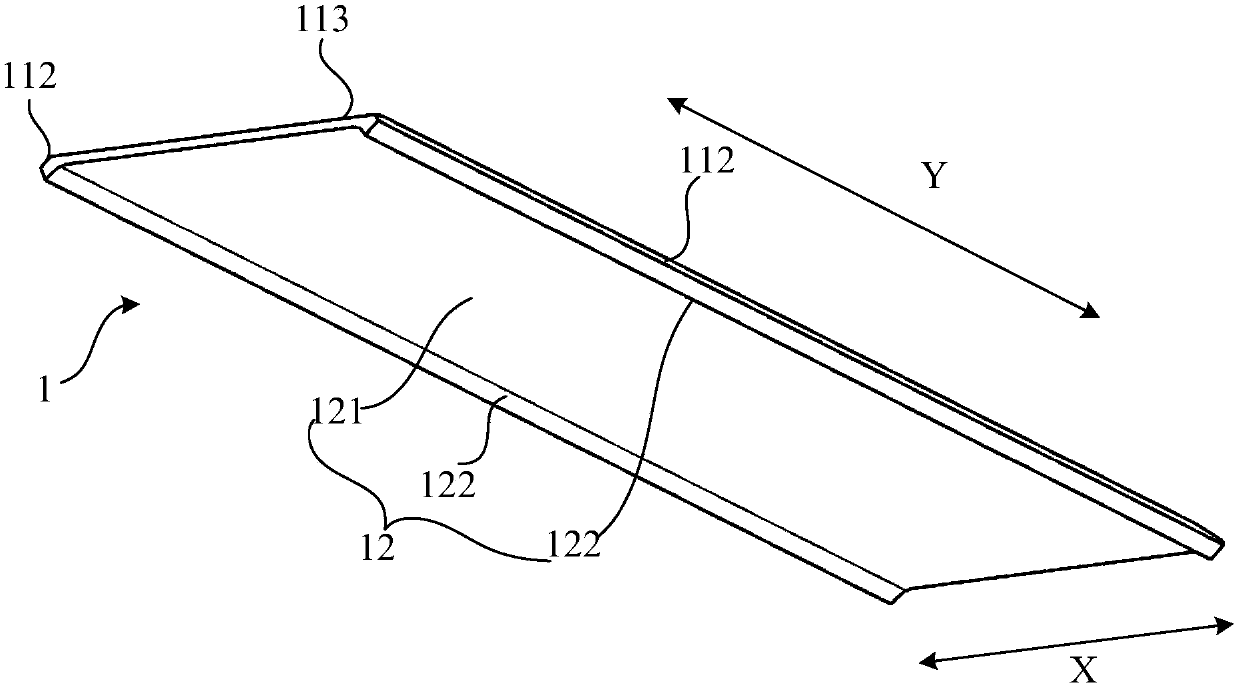

Thermal forming mold and thermal forming method of glass cover plate

PendingCN113336426AControllable shapeSimple processGlass reforming apparatusGlass productionGlass coverThermoforming

The invention discloses a thermal forming mold and method for a glass cover plate. The thermal forming mold comprises a lower mold, a heating mechanism and an upper mold, a first extrusion part and a second extrusion part of the upper mold are arranged to correspondingly act on the middle part and the edge part of to-be-processed glass respectively, extrusion shaping of the to-be-processed glass is completed regionally, so that the glass cover plate with the 3D structure is formed at a time, and the process is simple. The second extrusion part can also push the edge part of the to-be-processed glass into the forming groove from the periphery, so that all parts of the to-be-processed glass can be utilized. In the extrusion process, the wall face of the forming groove, the surface of the first extrusion part and the surface of the second extrusion part act on the surface of the to-be-machined glass in multiple directions, so that all the surfaces of the to-be-machined glass are limited, the shape of the machined glass cover plate is easier to control, product specifications are unified conveniently, and the forming yield is increased.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Speaker housing and forming method thereof

InactiveCN109327774AImprove acoustic performanceIncrease productivityElectrical transducersLoudspeakersEngineeringSilica gel

The invention discloses a speaker housing and a forming method thereof, and relates to the technical field of electroacoustic products. The speaker housing comprises a housing body and a connecting member, wherein the housing body is provided with an accommodating cavity; a sound hole for sound emission is formed in the housing body; the connecting member is fixedly coupled to the sound hole; theconnecting member comprises a body portion; a sound passageway communicating the sound hole with an external environment is formed in the body portion; the body portion comprises a protrusion portionprotruding from the surface of the housing body; the connecting member further comprises a silica gel sleeve formed on the outer wall of the protrusion portion in a manner of surrounding one circle ofthe body portion; and the silica gel sleeve and the body portion are of an integrated structure formed by an injection molding mode. According to the speaker housing provided by the invention, the connecting member of the integrated structure is formed by injection molding at first, and then the connecting member is fixedly coupled to the speaker housing, so that the forming yield of the silica gel sleeve on the housing can be significantly improved.

Owner:GOERTEK INC

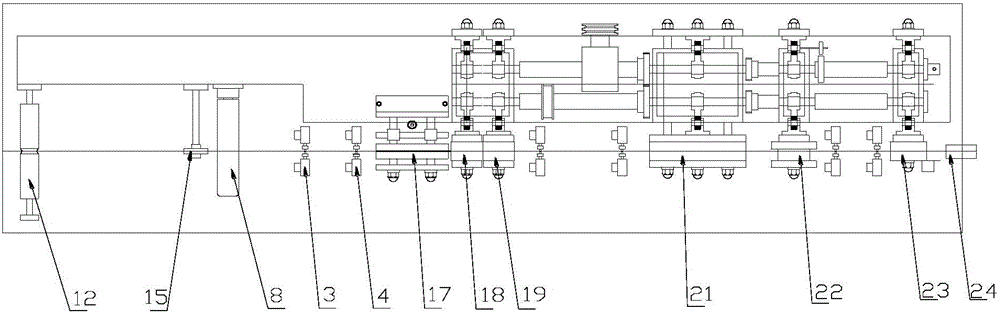

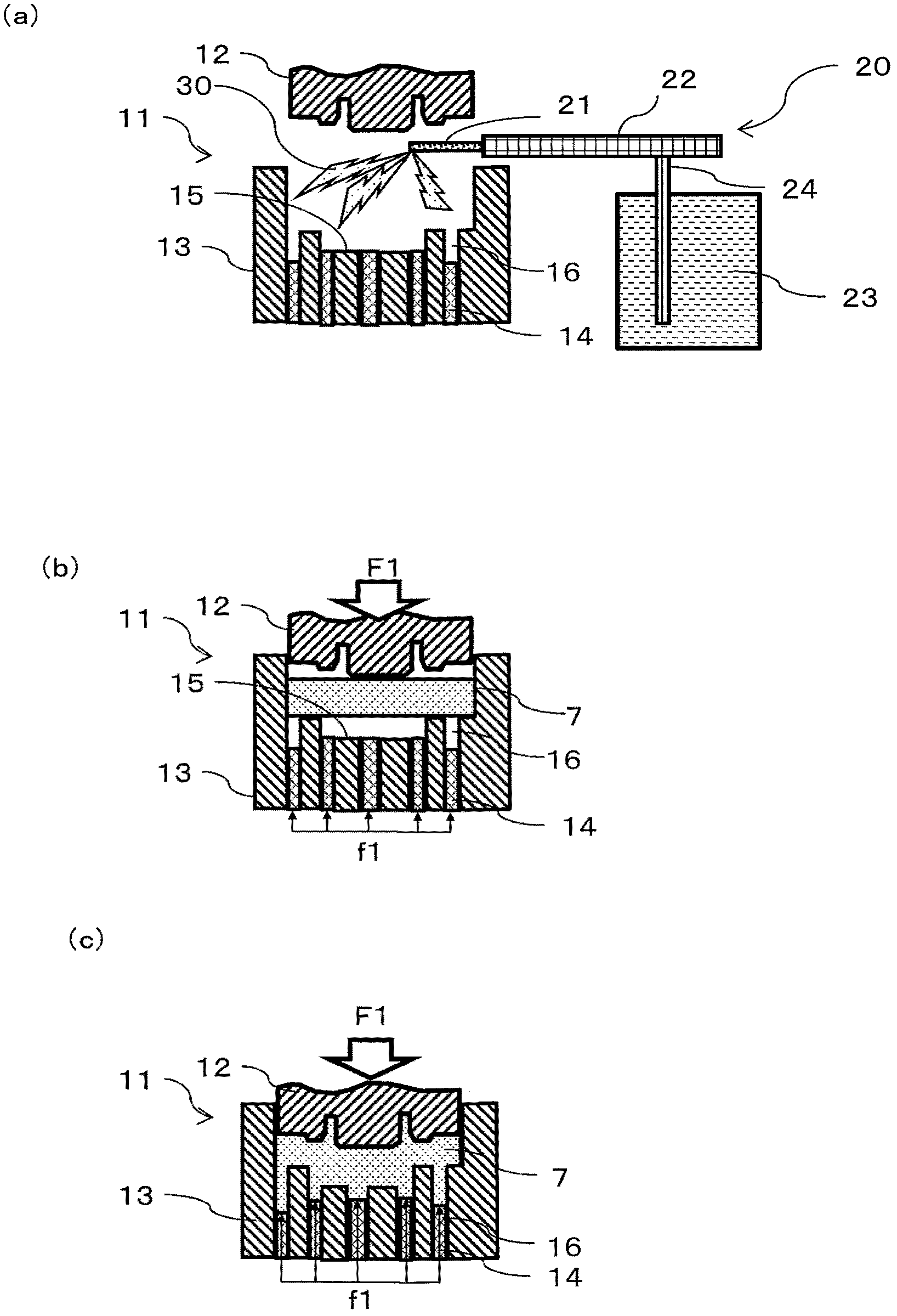

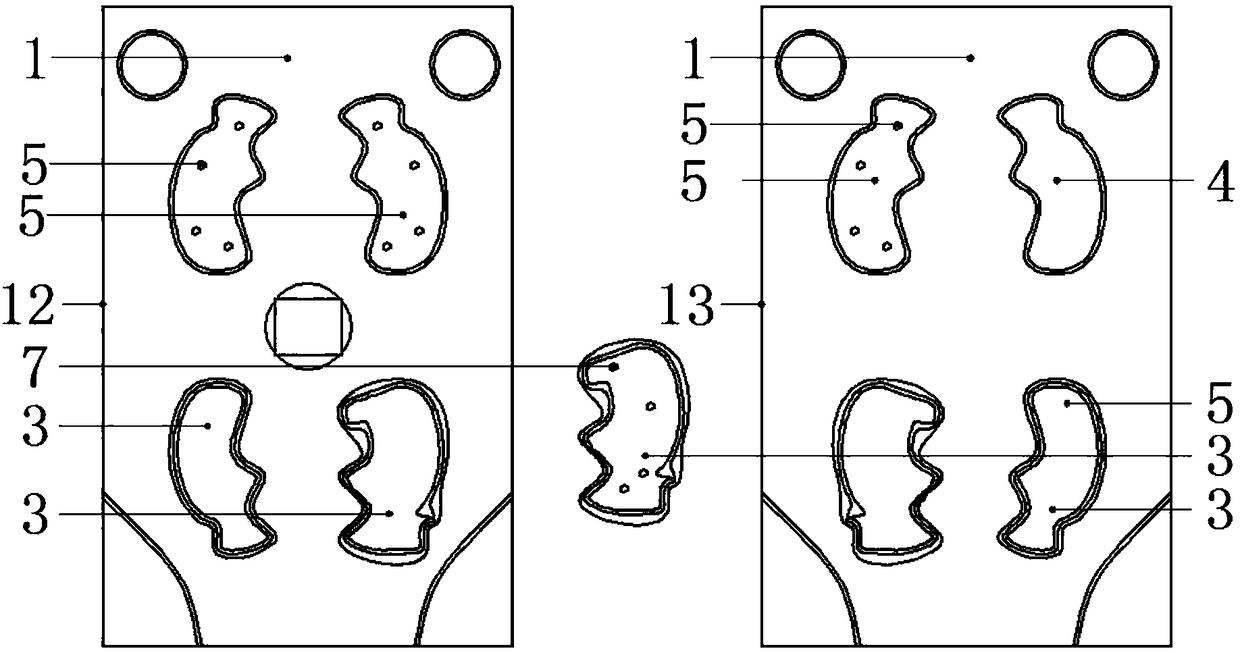

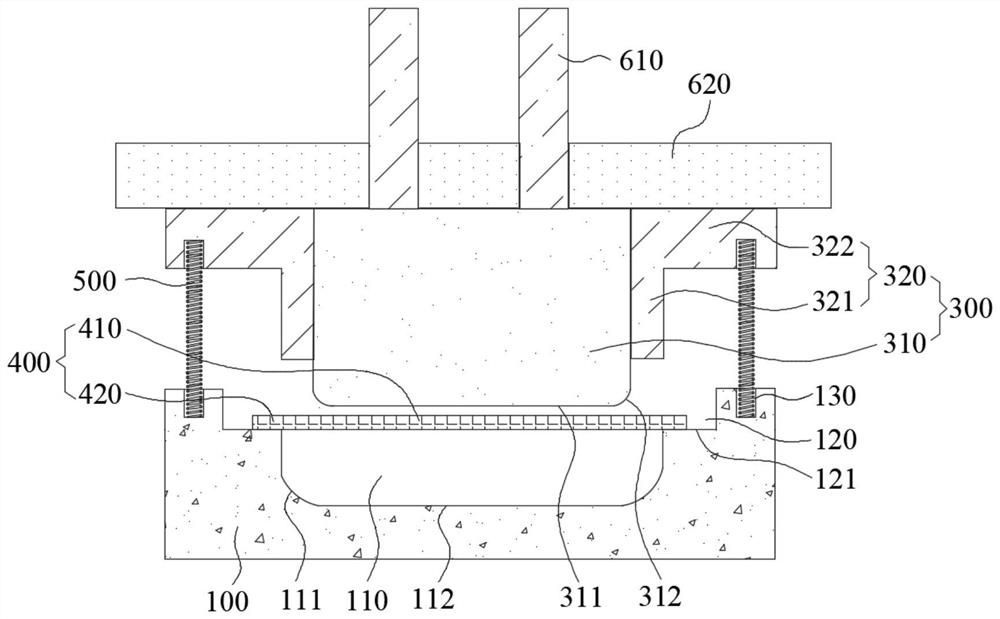

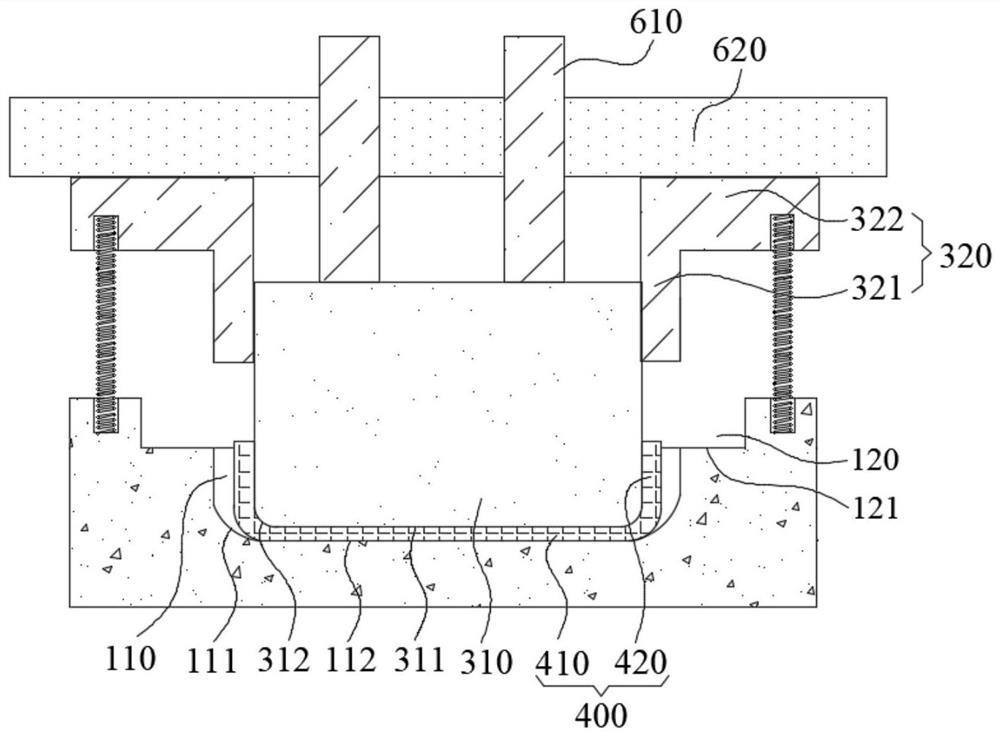

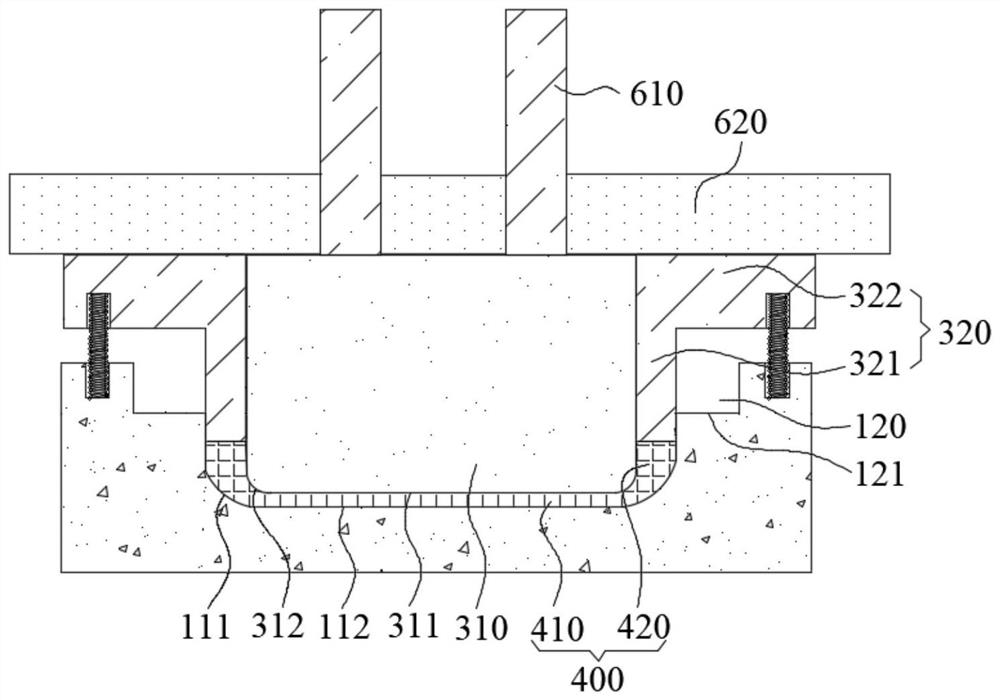

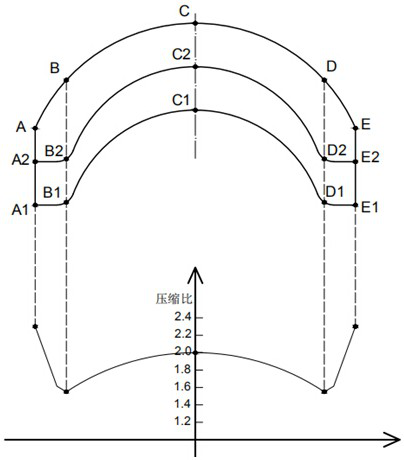

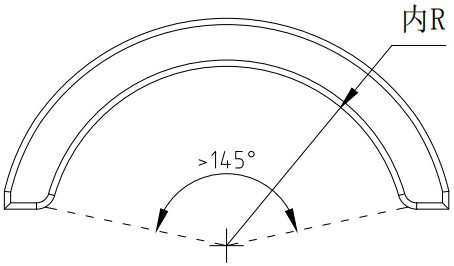

Large-central-angle magnetic shoe forming upper die and large-central-angle magnetic shoe forming method

PendingCN113334531AImprove molding yieldControllable densitySlip casting mouldsPhysicsMechanical engineering

The invention discloses a large-central-angle magnetic shoe forming upper die and a large-central-angle magnetic shoe forming method. The large-central-angle magnetic shoe forming upper die comprises a forming upper die body, the lower end face of the forming upper die body is provided with an inwards-concave arc-shaped face, the top of the forming upper die body is provided with a main water storage cavity, and the main water storage cavity is externally connected with a vacuum negative pressure pipeline; a left branch water storage cavity and a right branch water storage cavity are formed in the positions, located below the main water storage cavity, of the upper die body, the left branch water storage cavity and the right branch water storage cavity are not directly communicated with the main water storage cavity, and the main water storage cavity, the left branch water storage cavity and the right branch water storage cavity communicate with the lower end face of the upper die body 1 through a plurality of vertical small drainage holes, the left branch water storage cavity and the right branch water storage cavity are located above an arc left tail end and the arc right tail end of the arc face respectively. The large-central-angle magnetic shoe forming upper die and the large-central-angle magnetic shoe forming method further comprises the large-central-angle magnetic shoe forming method, the problem that the two sides of the arc of the magnetic shoe forming green body with the inner arc central angle larger than 145 degrees are prone to cracking can be solved, the forming yield of the large-central-angle magnetic shoe is greatly increased, and the method can adapt to the full-automatic magnetic shoe forming process.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

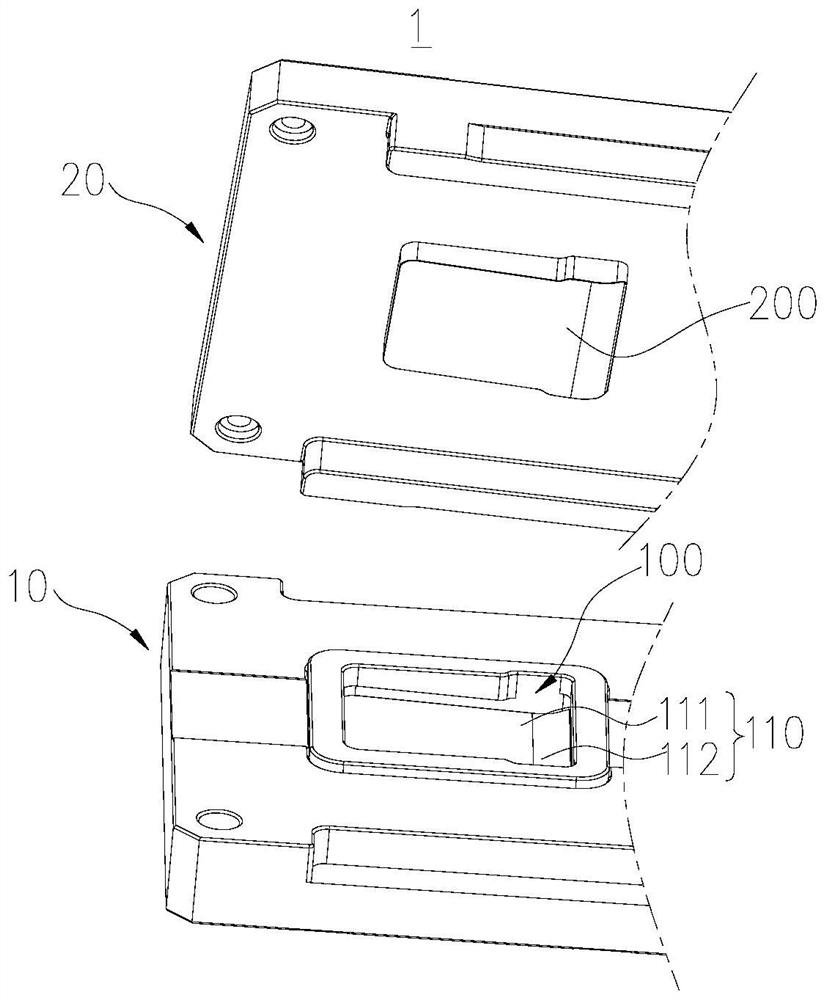

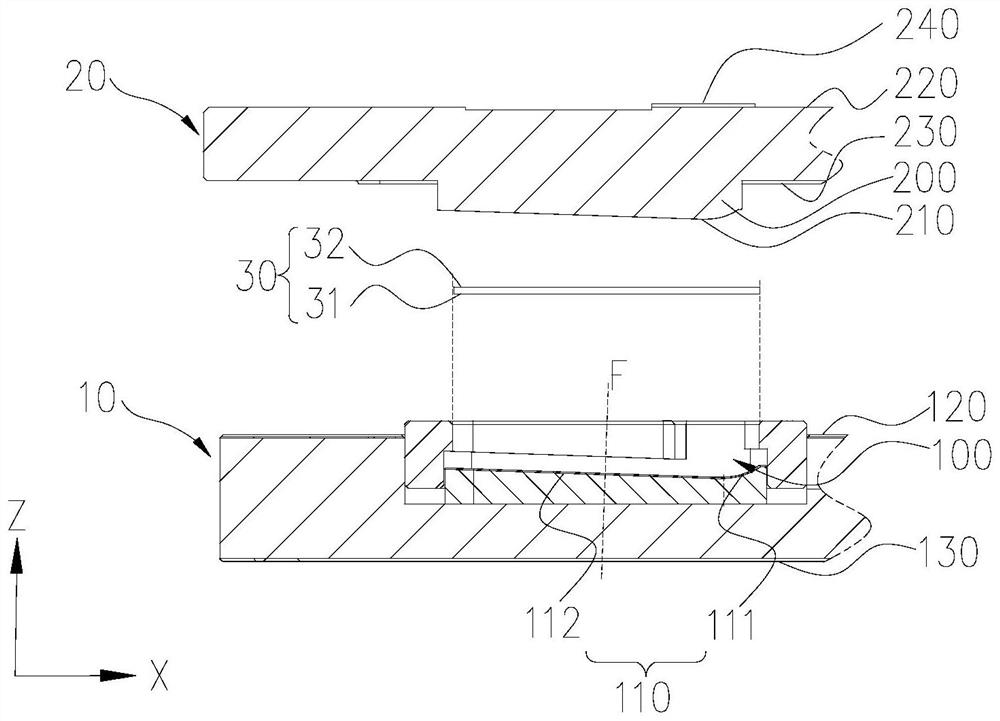

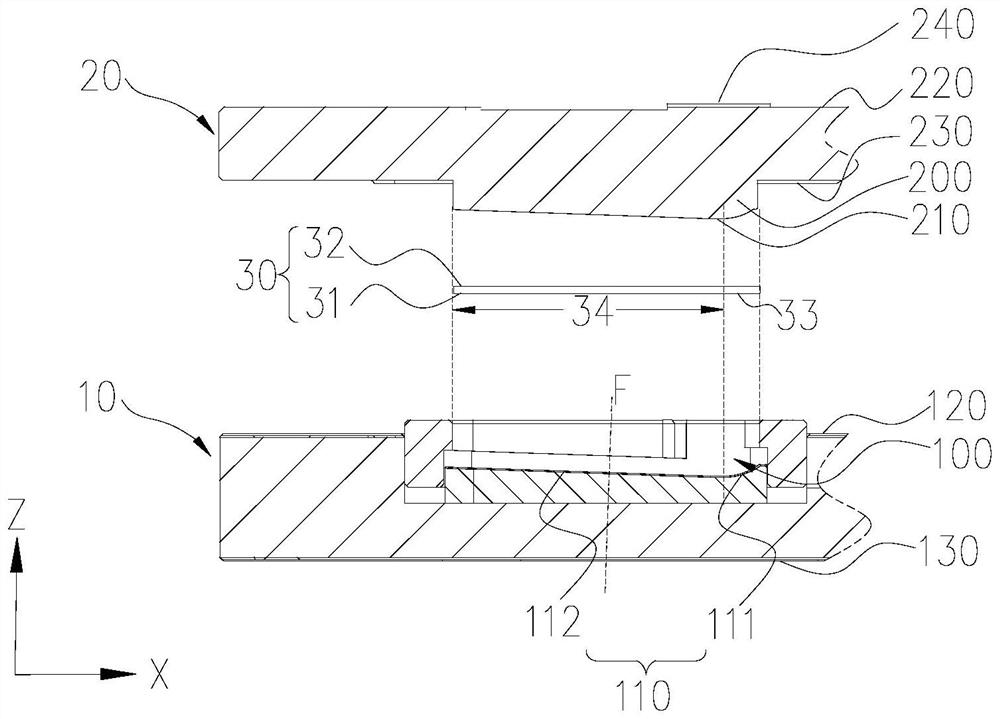

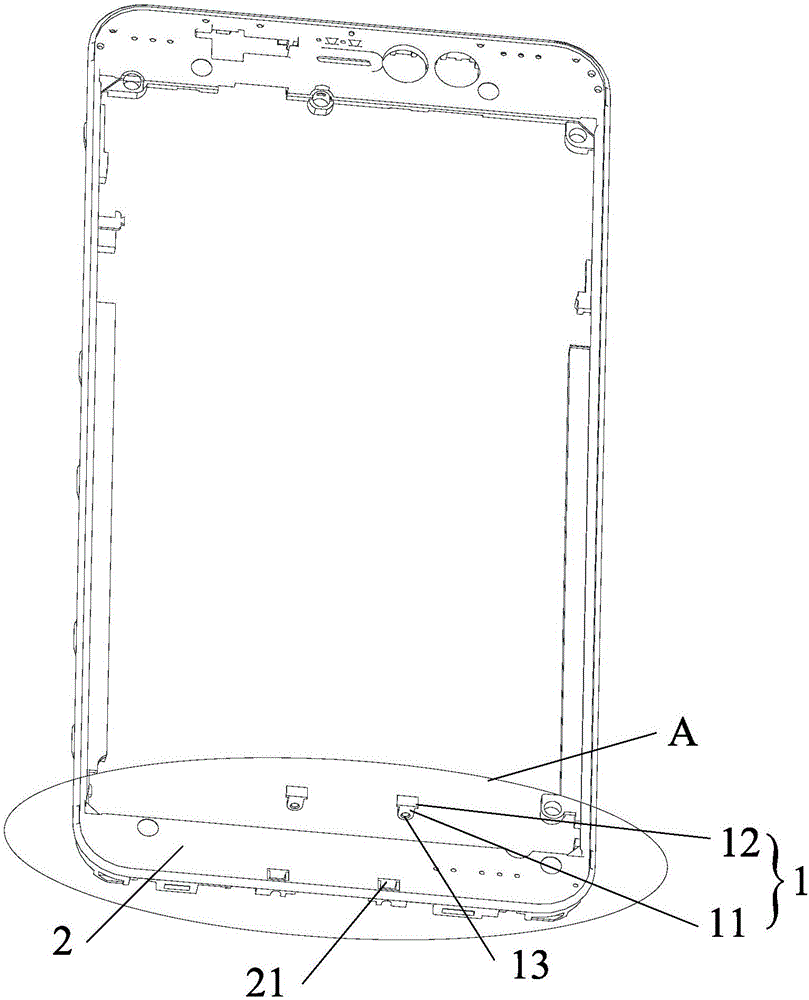

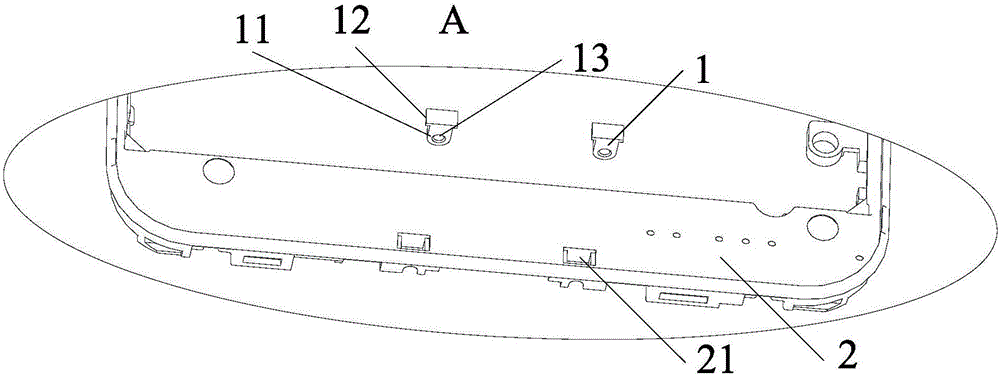

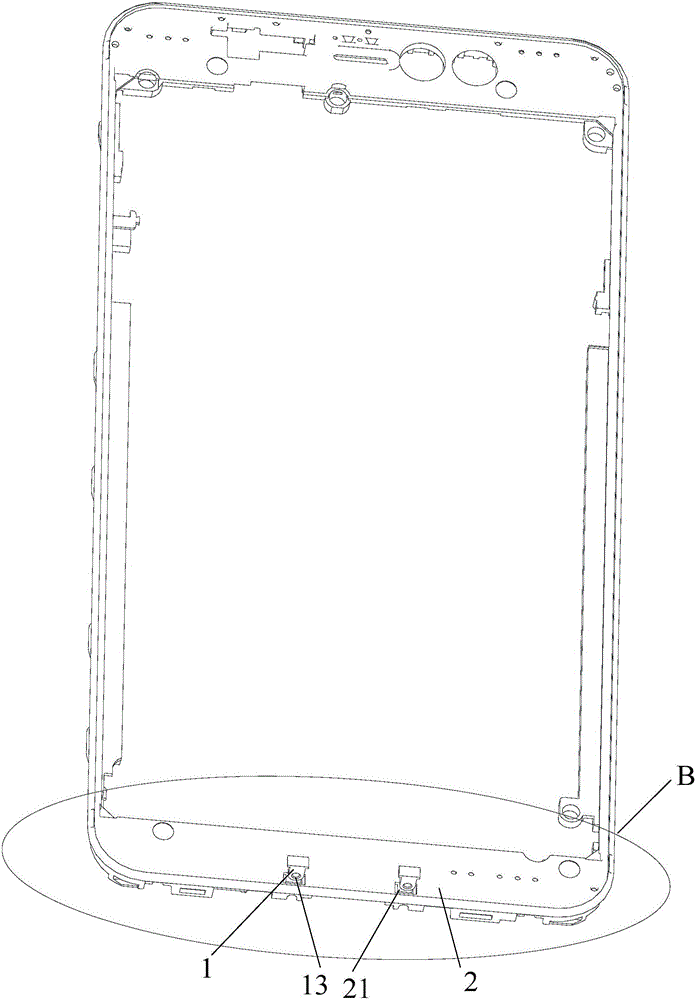

Structure for fixing nuts to surface shell and mobile terminal

ActiveCN106060205AAchieve fixationRestricted movementTelephone set constructionsEngineeringUltimate tensile strength

The invention provides a structure for fixing nuts to a surface shell and a mobile terminal. The structure for fixing the nuts to the surface shell comprises the nuts and the surface shell, wherein the nuts are provided with bodies and limiting parts arranged on the bodies; the bodies are provided with threaded holes; the surface shell is provided with mounting grooves for mounting the nuts; side walls of the mounting grooves are provided with limiting matching parts; the limiting parts are matched with the limiting matching parts in order to limit the movement of the nuts relative to the surface shell. According to the structure for fixing the nuts to the surface shell provided by the invention, the limiting parts on the nuts are matched with the limiting matching parts on the side walls of the mounting grooves after the nuts are mounted in the mounting grooves from open ends of the mounting grooves, so that the movement of the nuts relative to the surface shell can be limited; fixing of the nuts to the surface shell is realized; the requirement on mold accuracy is lowered; and a high molding yield is achieved. Moreover, the nuts can be fixed without any Z-direction structural component, so that the mounting accuracy of the nuts on the surface shell is increased, and the mounting strength is enhanced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Refining process of 5-methoxy-4, 6-dichloropyrimidine

InactiveCN111484456AStability Control RatioImprove molding yieldOrganic chemistryVacuum dryingMethanol

The invention discloses a preparation method of 5-methoxy-4, 5-dimethyl-1, 3-dioxolane. The preparation method comprises the following steps: adding 2 / 3 of methanol into 2-methoxy-malonic acid dicarboxylic acid; dissolving 2-methoxy-malonic acid dicarboxylic acid, adjusting the temperature to -1 DEG C to 0 DEG C, carrying out a reaction for 2-4 h with ammonia gas, filtering, washing with 1 / 3 methanol, and carrying out vacuum drying at 41-45 DEG C to obtain 2-methoxy-malonamide with a yield of 91-93%; heating and stirring sodium ethoxide, 2 / 3 of ethanol and the 2-methoxy-malonamide obtained inthe step 1; during stirring, stirring is conducted for 35-40 min at the temperature of 18-19 DEG C, adding formamide, performing a reflux reaction, adding 1 / 3 of ethyl alcohol for washing after filtering, performing vacuum drying treatment at the temperature of 51-55 DEG C, and obtaining 4, 6-dihydroxy-5-methoxypyrimidine disodium salt, wherein the yield reaches 87-89%. The molding yield of the 5-methoxy-4, 6-dichloropyrimidine preparation is greatly improved.

Owner:CHANGSHU JINSHEN MEDICAL PROD CO LTD

How to make fibrous tubing

InactiveCN103481527BImprove molding yieldImprove work efficiencyTubular articlesInternal pressureFiber

Owner:徐建升

Amoled display device and manufacturing method thereof

ActiveCN105762170BEasy to separate and formReduce manufacturing difficultySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses an AMOLED display device and a manufacture method thereof. The AMOLED display device includes a TFT backboard provided with a plurality of pixel electrodes and a drive transistor; a face board part arranged facing the TFT backboard and provided with a display face and a packaging face arranged opposite to the display face; a pixel definition layer disposed between the TFT backboard and the face board part and including a first pixel definition layer formed on the TFT backboard and a second pixel definition layer formed on the packaging face of the face board part, wherein the second pixel definition layer is connected with the first pixel definition layer fixedly. The AMOLED display device is comparatively simple in manufacture, high in yield rate and low in material cost.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

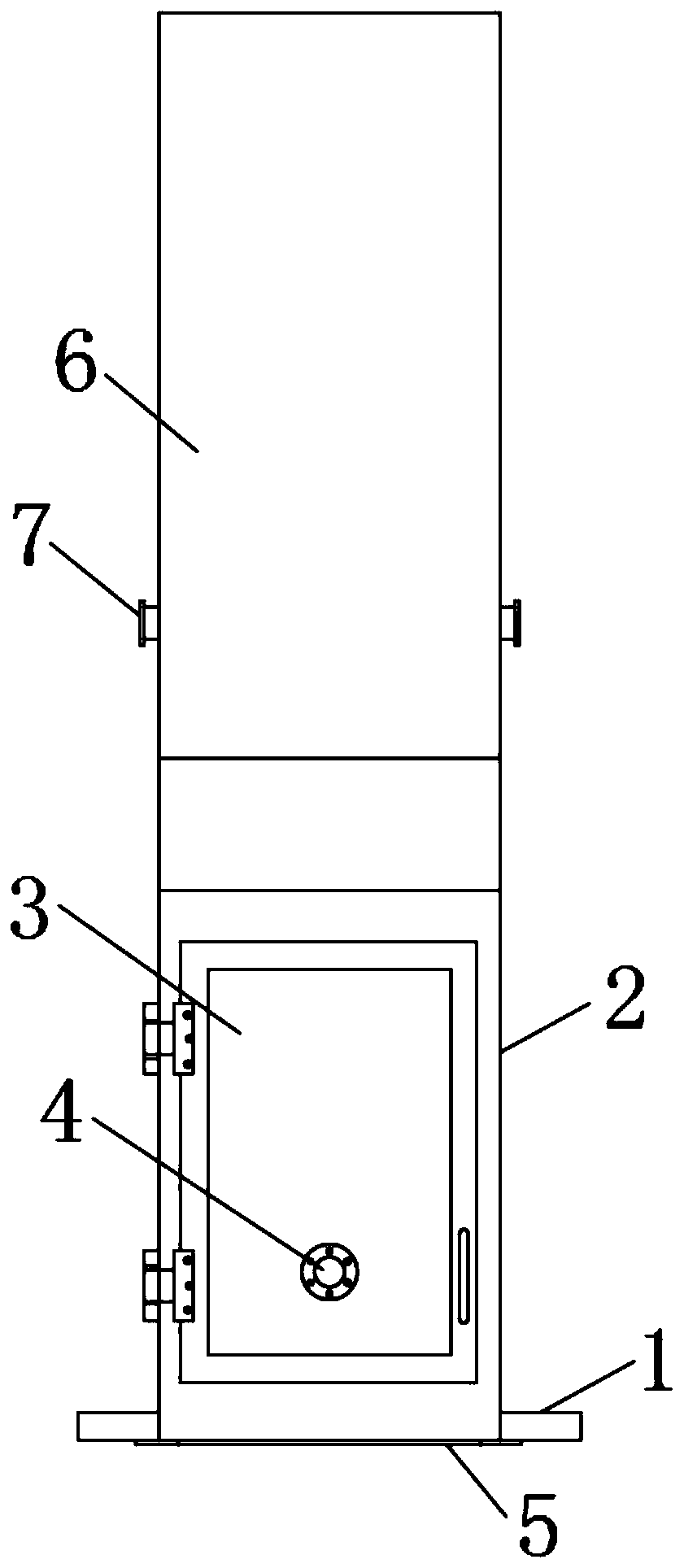

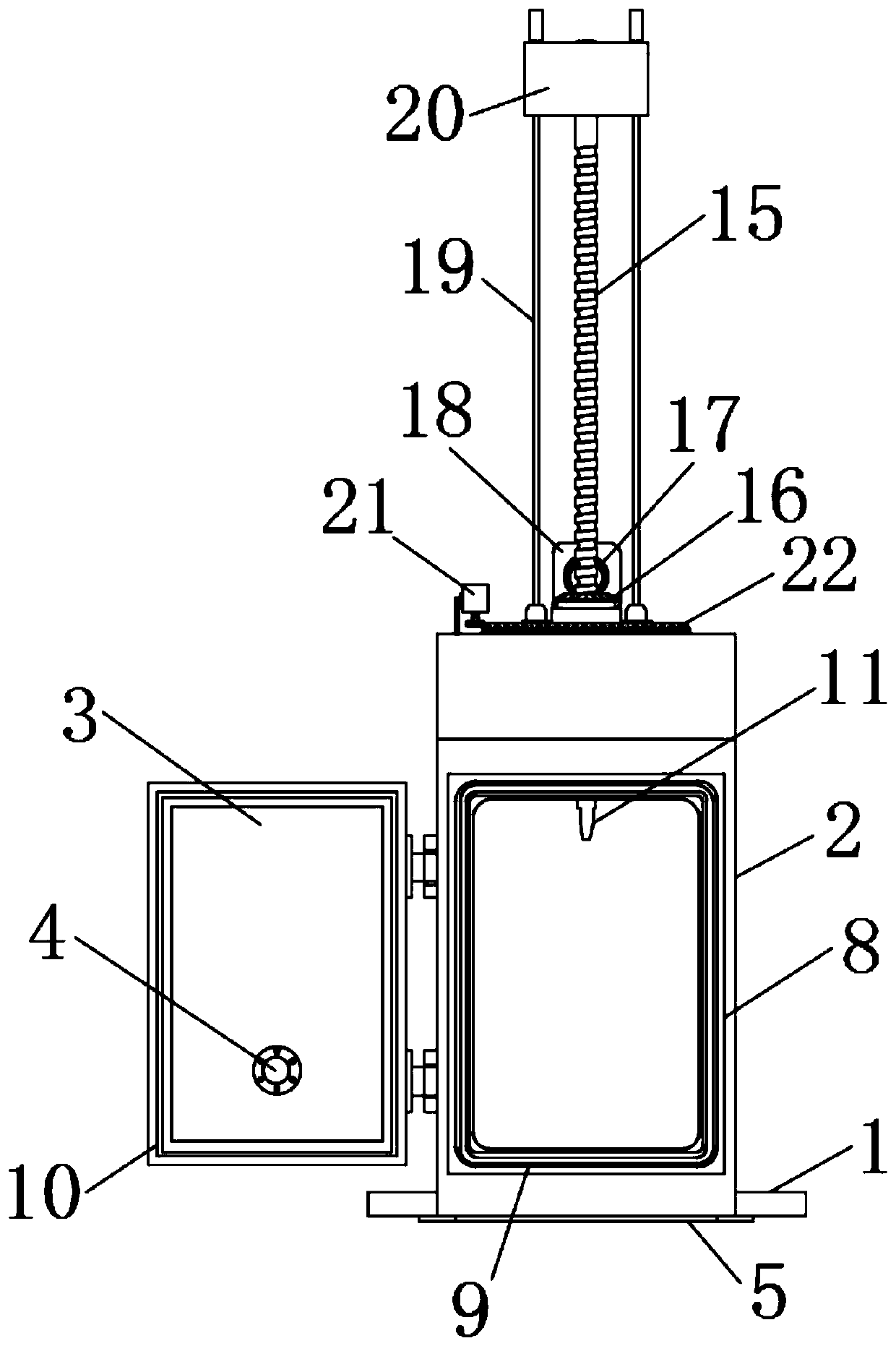

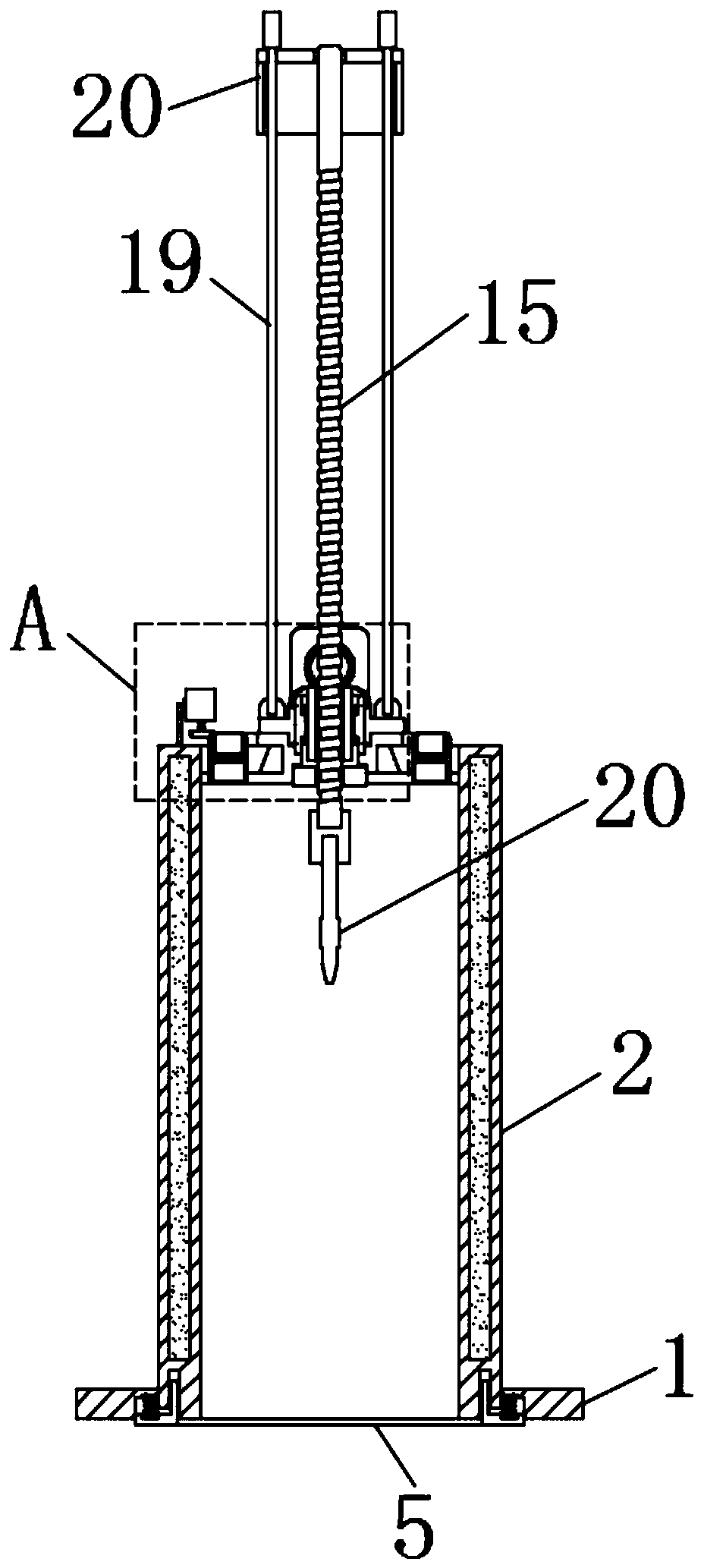

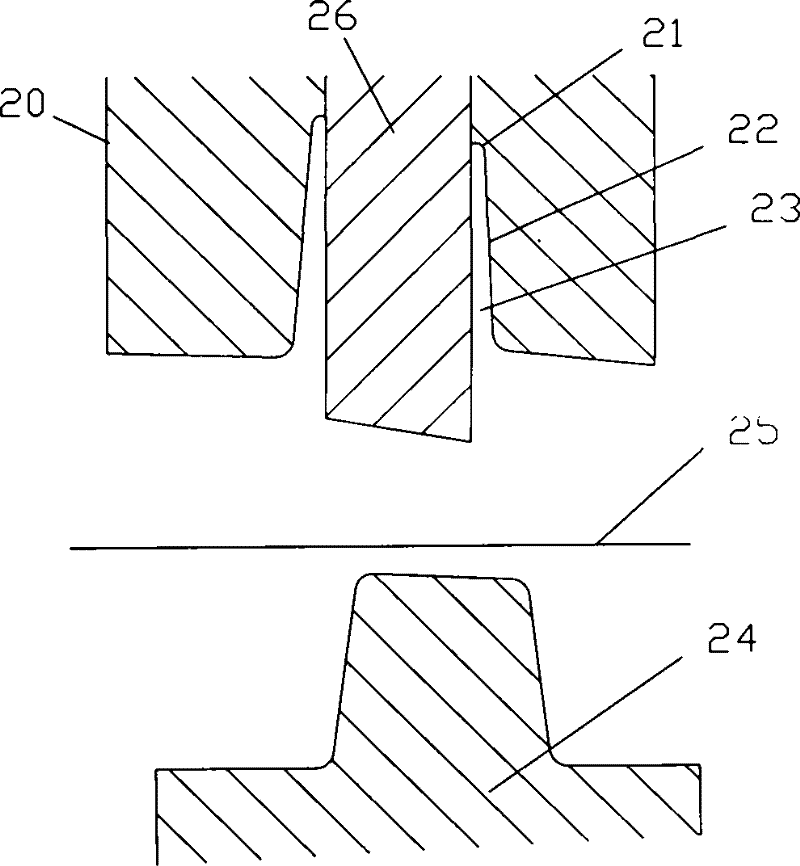

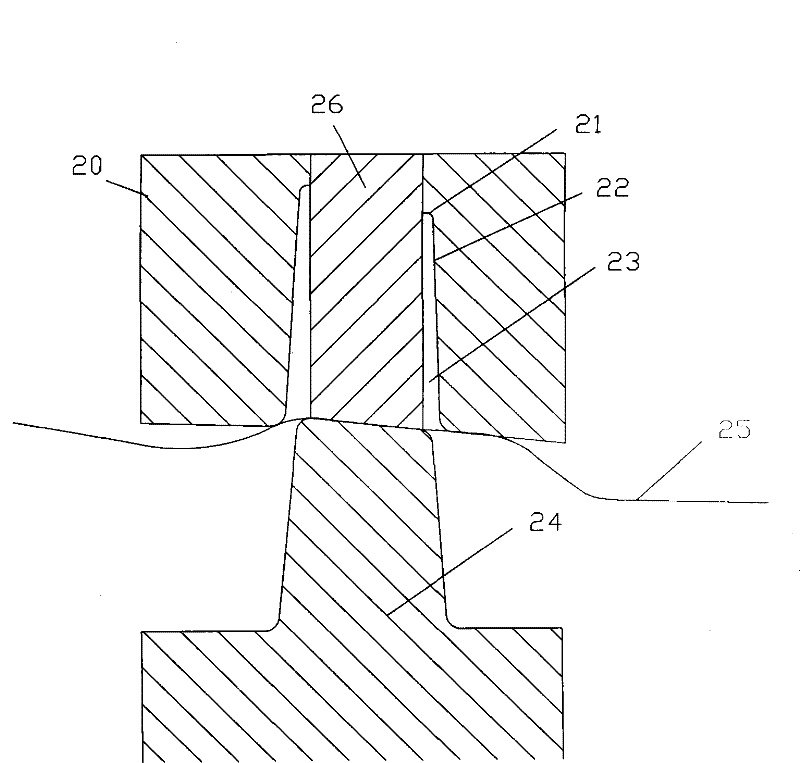

Novel semiconductor crystal bar arrangement forming die

InactiveCN111379030AImprove yieldImprove stabilityAfter-treatment apparatusPolycrystalline material growthPhysicsElectric machinery

The invention discloses a novel semiconductor crystal bar arrangement forming die. The die comprises a base, a mold box, a seed crystal, a first stepping motor and a second stepping motor, the mold box is welded to the upper surface of the base, and a box door is connected to the outer surface of the front end of the mold box through hinges. A protective cover is fixed to the top end of the mold box through screws. Air inlet pipes are fixed to the two sides of the protective cover through screws. A fixed seat is fixed on the upper surface of the mold box through screws; a screw sleeve is arranged on the inner side of the fixed seat in a penetrating manner; the inner side of the screw sleeve is connected with a screw sleeve through a bearing; a screw rod is arranged on the inner side of thescrew sleeve in the penetrating mode, the bottom end of the screw rod is sleeved with a permanent magnet ring, the top end of the screw sleeve is sleeved with a driven bevel gear, the outer surface of the driven bevel gear is meshed with a driving bevel gear, a guide rod is fixed to the upper surface of the fixing base, and the top end of the screw rod is sleeved with an electromagnetic disc. Thearrangement stability is improved, and the crystal bar forming yield is increased.

Owner:朱雪玉

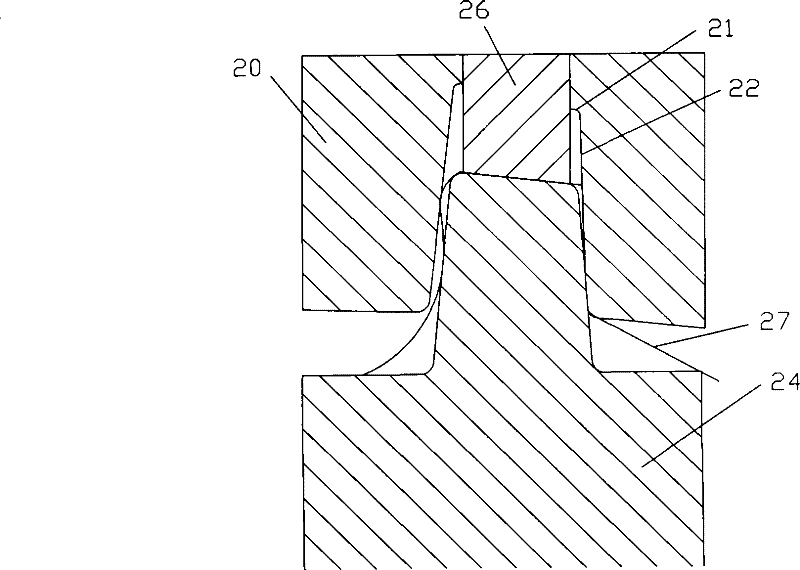

Sheet bending and forming mould and method

The invention relates to sheet bending and forming mould and method. The forming mould comprises a die, a terrace die and an eccentric swage arranged between the die and the terrace die; the shape of the forming face of the terrace die is the shape of a bent finished workpiece; the die comprises a first sub die, a second sub die and a third sub die; the three sub dies are respectively matched with the eccentric swage and the terrace die to carry out three-time mould pressing on a sheet; the first sub die has a die orifice and comprises a first wrap angle part and a transition section transiting to the bottom of the first sub die from the first wrap angle part; the first wrap angle part limits the die orifice and corresponds to the convex corner edge of the finished workpiece in shape; thesecond sub die has an inner side wall corresponding to the side of the finished workpiece; and the third sub die comprises a second wrap angle part corresponding to the convex corner edge of the finished workpiece in shape and an inner side wall extending along the shape of the side of the finished workpiece form the second wrap angle part. The sheet bending and forming mould and the forming method can reduce wrinkling during sheet bending and improve the sheet forming yield.

Owner:BYD CO LTD

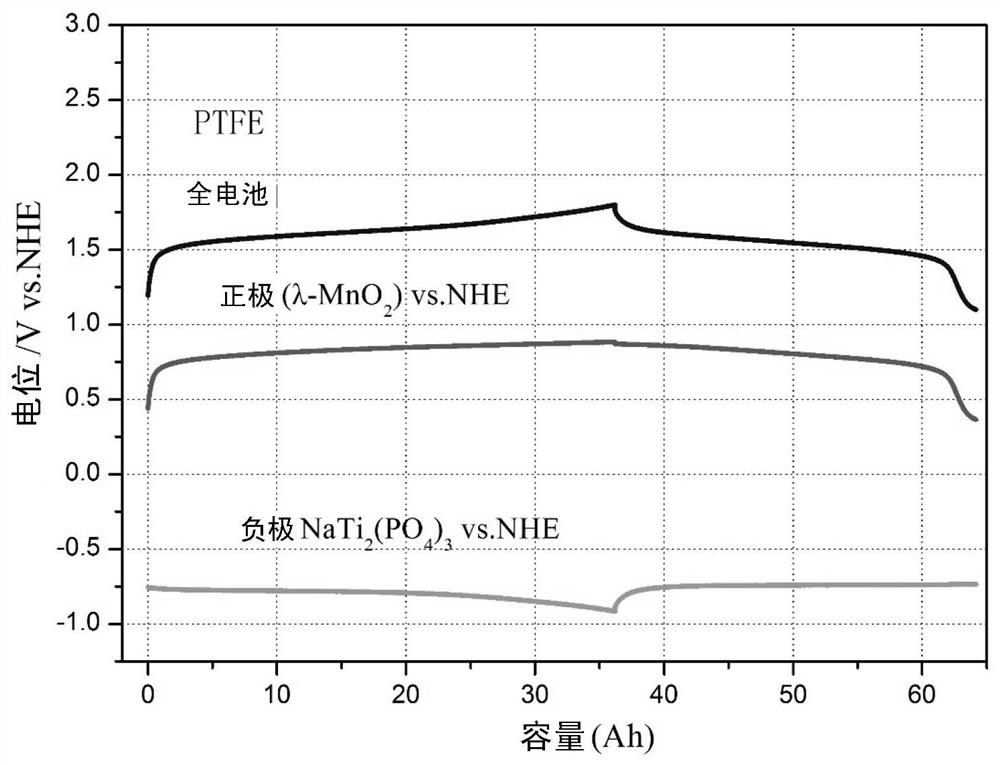

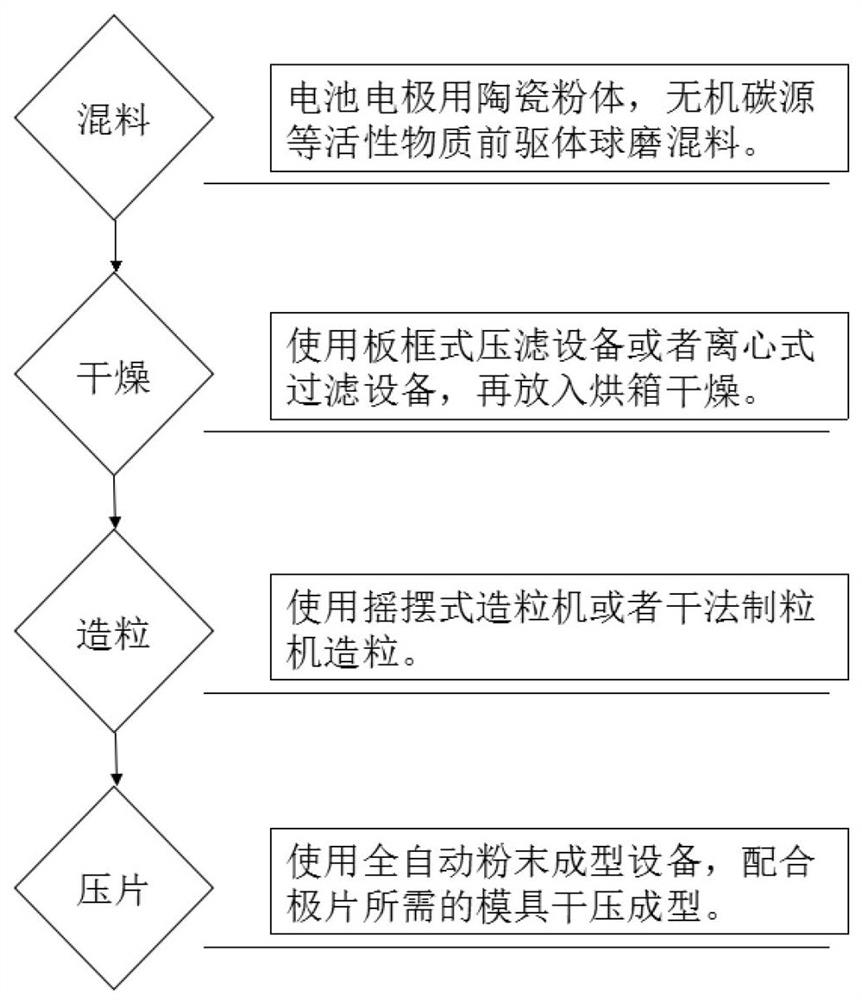

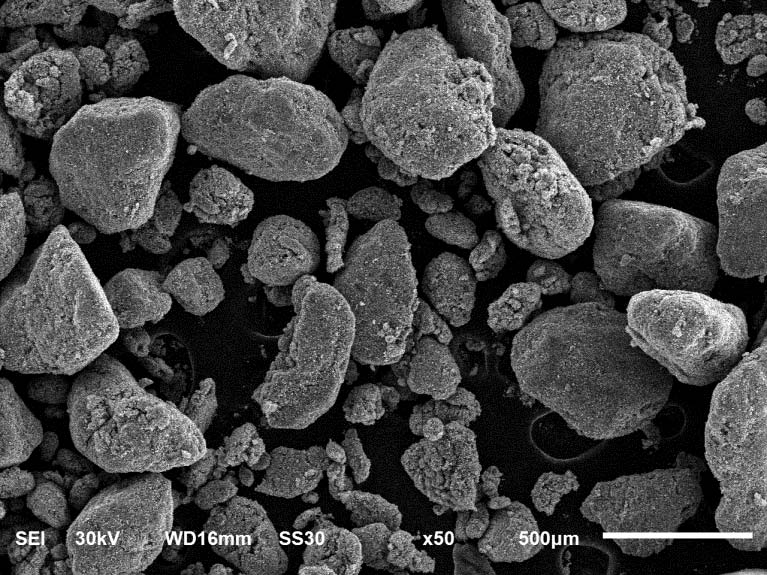

A method for forming pole pieces of aqueous ion batteries based on polytetrafluoroethylene binder

ActiveCN108232195BAchieve carbon coatingImprove conductivitySecondary cellsActive material electrodesPole pieceSlurry

The invention relates to a pole piece forming method of a water-based ion battery based on a polytetrafluoroethylene binder, comprising: step 1) using ceramic powder and an inorganic carbon source conductive agent as raw materials for the electrode of the water-based ion battery, and using water as the Solvent, add polytetrafluoroethylene as a binder, and ball mill to obtain a uniform slurry; step 2) filter the obtained slurry to obtain a filter cake, and further dry the obtained filter cake to obtain a dry powder; step 3) The obtained dry powder is granulated and sieved to obtain a granular powder with uniform particle size; Step 4) The obtained granular powder is prepared in batches for battery pole pieces by dry pressing. The present invention adopts the method of ball milling to make slurry and joint granulation, and the obtained powder is in the form of granules, which greatly improves the fluidity problem of the powder caused by the binder, and makes the forming of the pole piece easy to control, so it is suitable for dry pressing. Produce thick pole pieces.

Owner:BENAN ENERGY

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorous low-carbon aluminum-magnesium non-fired brick for stainless steel ladles and a manufacturing method thereof, comprising high-bauxite of different particle levels, fused magnesia, corundum powder, spinel powder, alumina micropowder, silicon carbide Additives, wetting agents and phenolic resin binders, the mass percentage of each component is: 5-3mm high-bauxite 15-20%, 3-1mm high-bauxite 20-25%, ≤1mm high-bauxite 10-15%, 3-1mm fused magnesia 10-15%, ≤1mm fused magnesia 5-10%, corundum powder 10-15%, spinel powder 15-20%, ≤25μm alumina powder 2- 5%, silicon carbide additive 0.1-2%, wetting agent 0.1-2%, plus binder phenolic resin. Compared with the prior art, the outstanding advantage of the present invention is that it omits the firing process in the conventional method, saves energy, and does not contain phosphorus. Compression molding makes it have a higher density, avoids pollution to the stainless steel molten steel, and also has a higher service life.

Owner:长兴南冶冶金材料有限公司

A plastic bottle automatic forming liquid filling machine

ActiveCN105799139BReduce deformationImprove processing efficiencyBottle-handling machinesHollow articlesPlastic filmMotion direction

The invention discloses a plastic bottle automatic forming liquid filling machine. The liquid filling machine is sequentially provided with a plastic sheet film conveying unit and a forming unit (19); the plastic sheet film conveying unit comprises a feeding roller (8) and a plastic sheet film dividing assembly; the feeding roller (8) is used for conveying a rolled plastic sheet film (7); the plastic sheet film dividing assembly is used for dividing the conveyed-out plastic sheet film (7) into two parts in the motion direction of the plastic sheet film (7), and the two divided parts are subject to forming treatment through the forming unit; and compared with the prior art, the whole plastic bottle automatic forming liquid filling machine avoids the influence of the high-temperature on filled liquid, the technology efficiency is higher, the yield is higher, leftover materials generated through the technology are fewer, and the production cost is greatly reduced.

Owner:瑞安市高波机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com