Large-central-angle magnetic shoe forming upper die and large-central-angle magnetic shoe forming method

A technology of central angle and magnetic tile, which is applied to the upper mold of large central angle magnetic tile forming and the field of large central angle magnetic tile forming, which can solve problems such as inching, reducing green density, and tape position offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

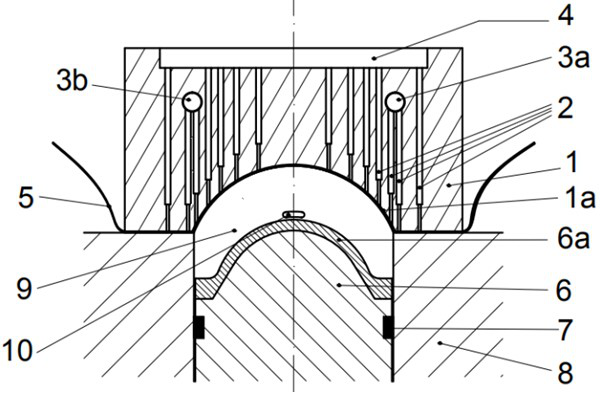

[0028] Referring to the accompanying drawings, the embodiment of the large central angle magnetic tile molding upper mold of the present invention includes a rectangular molding upper mold body 1, the lower end surface of the molding upper mold body 1 is provided with a concave arc surface 1a, and the top of the molding upper mold body 1 is provided with a concave curved surface 1a. There is a main water storage cavity 4, and the inside of the upper molding die body 1 is located below the main water storage cavity 4 with a left branch water storage cavity 3a and a right branch water storage cavity 3b, and the left and right branch water storage cavities are respectively located in the arc shape. Above the arc left and right ends of the surface 1a, the main water storage chamber 4, the left branch water storage chamber 3a, and the right branch wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com